Leaderboard

Popular Content

Showing content with the highest reputation on 05/03/21 in all areas

-

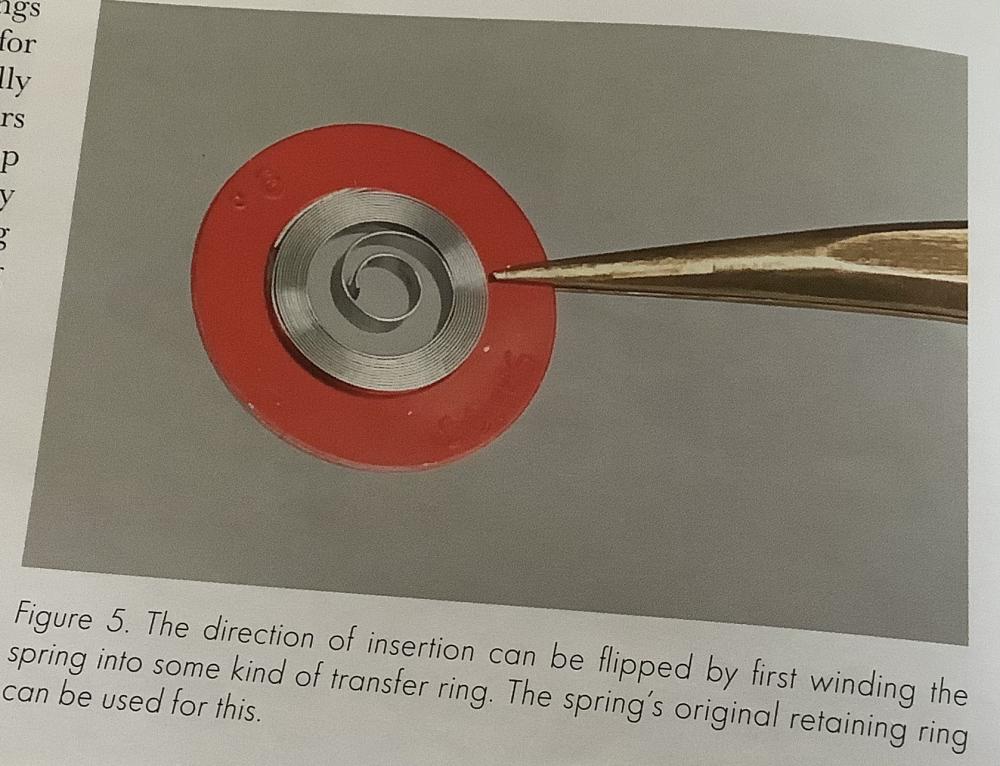

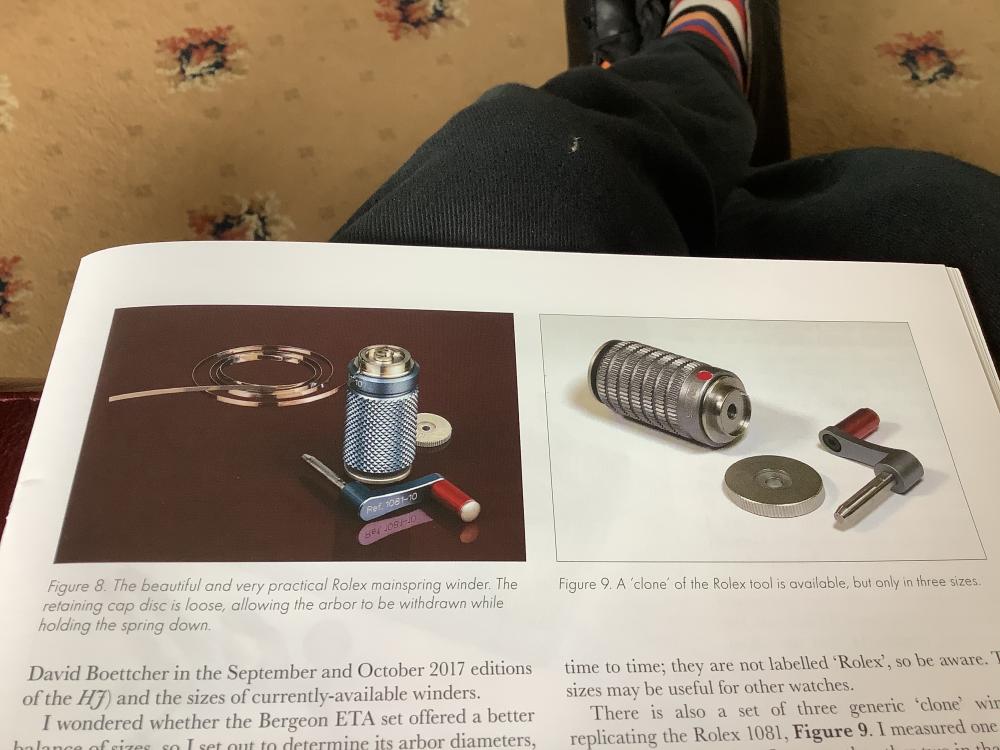

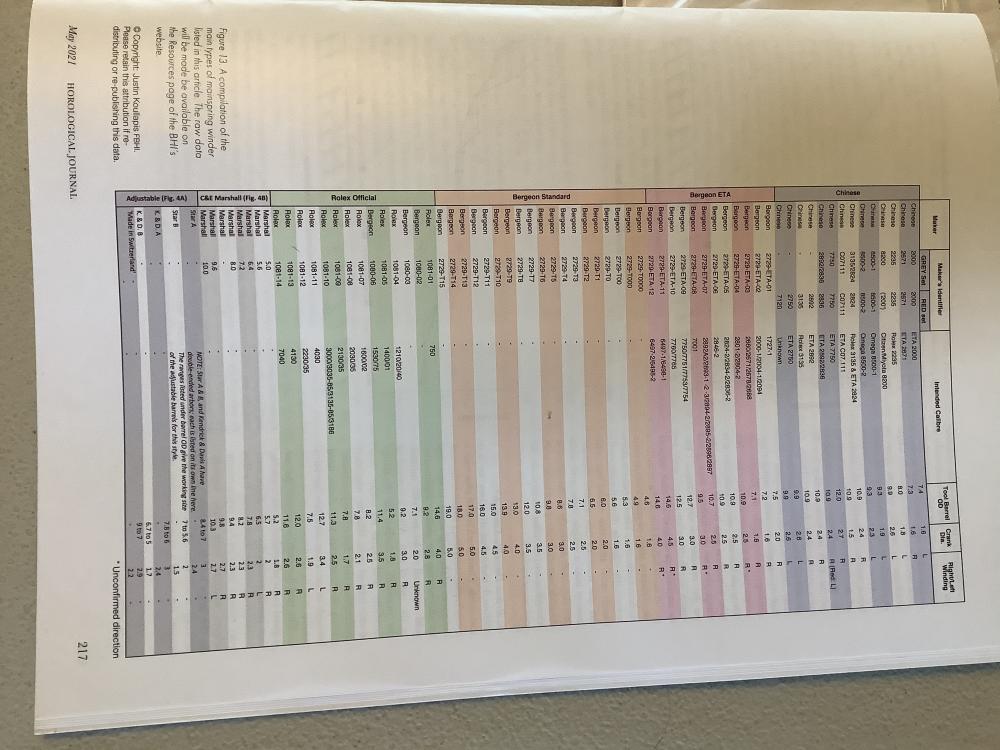

In this months BHI (May 2021) mag there is an excellent article covering watch mainspring winders. The winders reviewed/ tested were Bergeron, Rolex, Chinese, Marshall,Kendrick & Davis (‘K&D’). The conclusions made replicate what I have said many times. One set does not cover all requirements with regard to barrel and arbour sizes. The Bergeron winders are supplied in either caliber specific (ETA) or by barrel size. The problem with this to cover all options 31 barrel bodies and cranks(arbors) have to be purchased. Not only is this above most horologist budgets the arbours are often too fat or too thin. The Chinese winders come in two sets. Red & Grey. The reviewer comes to much the same conclusion as our Marks opinion that the hooks on the arbours are made of Brass so wear could well be an issue. However the Grey version has a slightly better build as the arbours are Brass but are Nickel/ Chrome plated. He therefore lent a Grey set to a pro horologist for a month to see how it performed.Wear was evident with the hooks but not significant so these might still be good for the keen amateur. His most favoured winder is the Rolex manufactured winder supplied to accredited Rolex horologists. The reason given is superb build quality and the barrel covers are loose so when the arbour is removed from the wound spring the cover can still be held in place to stop the spring flying away. However cost is a big problem. I found one on the net with a price tag of $2900. However Cousins supply a clone of the winder, but in only 3 sizes with a cost £300 for the 3 or £109 each. I have attached a chart which shows the barrel and arbour sizes which is real handy to avoid duplicates or to find appropriate arbour to fit the spring being wound. This is just a snapshot of the article and I would have liked to have given more detail but I might well be in breach copyright issues with the BHI.4 points

-

I designed and printed this. It has a bearing embedded in it with a small clearance to create a nice rotation feel. The PLA I used prints beautifully and allows you to sand it a little which creates a tactile smooth finish.3 points

-

the absolute best would be to replace it. Then depending upon how bad it is you just want to burnish the material if you do anything to change the shape that's going to really screw things up. the problem of having too many books is to remember which one I saw something in? The problem may have with burnishing or doing anything is there's a guard pin in the way. So whatever you use if it goes through has to be super thin. Somewhere saw a picture of where they used a mainspring and they must've lightly filed to make it like a burnished or so it is little bit a texture. But then they held it in like a blow so each end is being pulled on and use that the burnished the inside. But anything beyond light burnishing you're going to really have an issue.2 points

-

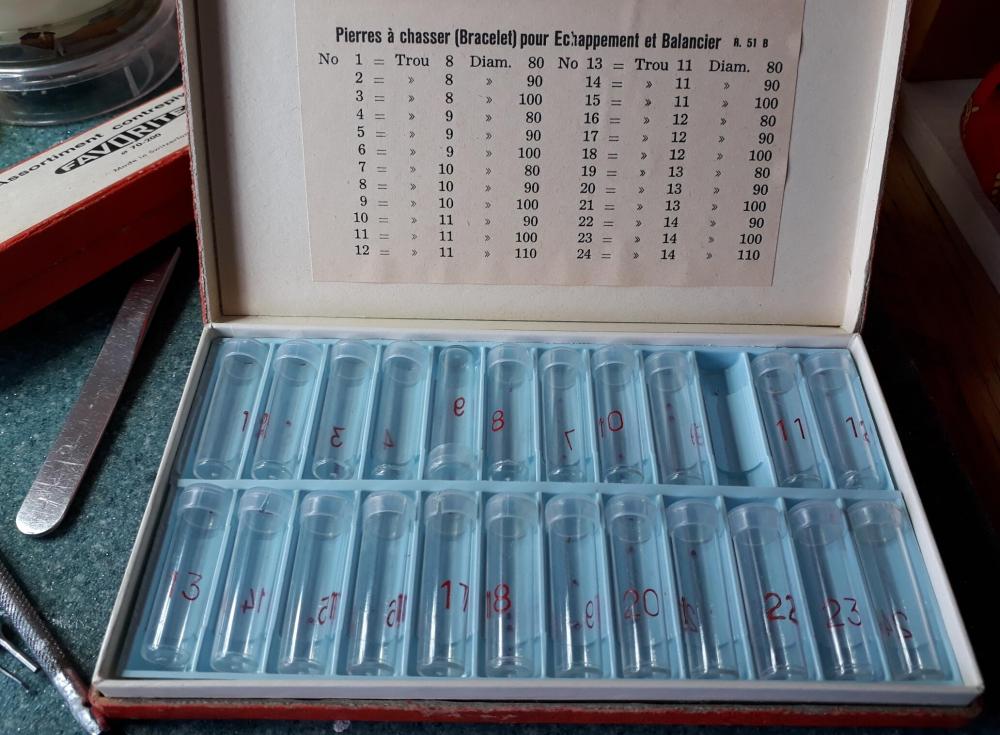

I have been given this watch recently, it's of no value at all really, but I decided that I would get it working again, if I could. Balance staff was in 2 pieces, lower jewel was smashed and the movement was totally gummed up. Good old Ebay got me a staff £8.00 and after a lot of searching through my box of jewels I actually found one that was close, so after opening up the setting with a brooch and pushing the new jewel in place we were a step closer. Unfortunately I'd run out of cleaning fluid, my own fault, so believe it or not I had to get out the Pegwood and clean it the old fashioned, but hand. But at the end of the day my 80 year old watch thing lives again, I actually don't know what it called.2 points

-

The safety pin only comes into action when there is a shock, as you pointed out. I think where contact is made on the safety pin during a shock would depend on how the entire balance wheel moved during a shock, although it would be somewhere near the tip of the pin.1 point

-

unfortunately your answered your own question. The slot has to be nice and smooth without notches for the roller jewel to catch in. The size or the width is critical otherwise you'll have to change the roller jewel to match. The angle the horn is critical. I give you were to shorten the ends that would change things. Simplistically everything involved with the escapement is critical that it be right for maximum performance. Sometimes you get by with a little bit so maybe it might be better not to make the fork perfect if you can't get it taken care of just see how it does rather than trying to make it perfect and destroying it perhaps we should probably look up and see how many forks would interchange with this sometimes pallet forks tend to be more generic than the watch itself it's possible that perhaps another Seiko pallet fork would work hopefully1 point

-

There are some mini degussit stones available which might be just what you need.1 point

-

Quite sure these hands are (nickel-)plated. A bit polishing will not remove the plating. You need pure unplated steel (not stainless steel) or iron for blueing. If cheap or not doesn't matter. Frank1 point

-

I don’t think your flame source is hot enough to get the heat through all those shavings. You said the shavings are turning the colors you want though. the spectrum of tempering colors are caused by a heat range and your shavings are getting hot enough but are absorbing too much heat. The shavings are there to help even out the temp and make the hands oxidize in a slower more controllable manner. They aren’t even necessary if you have a thick plate but it look sad if you are using an ashtray. remove half your shavings and try again. if it’s not going passed yellow still, remove another half of the remaining shavings and try again and repeat the process until it works.1 point

-

A hydraulic lifter would certainly work, but lets not miss the point, if tweezers wont lift the hour wheel then something is binding which will eventually affect the amplitude.1 point

-

Oh ok. I was wondering if the bergeon style presto hand removal tool would have worked seeing as there’s a slight edge just below the tube which would allow the jaws of the presto tool to grip.1 point

-

Does he think he is greasing a bloody car engine, talk about over the top if he goes about it like that with all his clock mainsprings he must use pots of the stuff. Disregard what he has done. The bronze line isn’t correct. When the fusse was invented cat gut or a chain would be used, but you cannot use a fusse chain on a fusse that has been made to take a line, the groves are a different cut. Cat gut would have been used as the line. The nearest you can get today is the synthetic gut. He contradicts himself by saying about how you should go about preserving the originality of the clock and he does the complete opposite. I had a preference to use nylon coated wire line, that is what I would use, but I always asked the customer what they wanted. On Vienna regulator clocks you should always use synthetic gut.1 point

-

When cleanliness is paramount, any handling tools (tweezers etc) also need to scrupulously clean to avoid cross contamination.1 point

-

You're showing two different hands there, is the yellow one blue on the bottom? Some stainless steel will get a little yellow but not blue. If the hand is plated then it shouldn't change much or at all. But you say you polished it, so any plating should be gone. As others have said, cleanliness is the most important thing. I frequently blue hands, I've found that clean benzine works best for me but 99% isopropyl alcohol is good too. A final step I do is lay the hand on clean paper, then give it a stroke across with freshly cut pithwood dipped in clean benzine (or alcohol), then puff with a blower to remove any pith bits. The mechanical cleaning as a last step just before blueing really seems to help. The hand goes in a tray with fine brass filings a few mm deep (I make them by filing brass with a 0 or 2 cut file), over the alcohol lamp, then heat up slowly to get the blue as gradually as possible. Several minutes. When I make new filings I will heat them in the tray for quite a while before using them to blue, this is to burn off any residue or contaminants. They tend to smoke a bit when new, and that would mess up the blue.1 point

-

Blotching is a sign of grease which clockboy has said. I always preferred an old English penny to brass shavings. It takes a few practises to get it right. When blued quench the hand in oil it gives a nice shine. That is how I would blue clock screws, getting them all the same colour takes practise.1 point

-

Interesting article for those who are confused about watch mainspring winders and which to buy. Thanks clockboy.1 point

-

It can be repaired providing the movement inside is identified. This is required to see if parts are available.1 point

-

Successful Blueing hands requires that they are spotlessly clean and absolutely free of grease. Looking at your results that is the issue.using brass shavings is good and has given me the best results.1 point

-

Seiko does not sell the mainspring alone, only the barrel complete. On the 6R15 the mainspring made of a special steel (SPRON) and even if the barrel complete is found, price may be quite high. On the other hand a generic mainspring likely will not provide the specifications of 50hrs power reserve. That being said I don't know how you have diagnosed that something is wrong with the mainspring, which is not common at all.1 point

-

Hello and welcome to the forum, In the Uk Cousins UK watch parts, A.G Thomas. Gleave and co H.S.Walsh all material houses In the YSA Jules Borel. Esslingers Time savers to name but a few. BTW It is considered polite to give an introduction when joining the forum. cheers.1 point

-

Sounds like you have a loose cannon pinion. When you pull the winding crown out to adjust the time, do you feel the usual amount of resistance or does it feel very loose?1 point

-

Who knew...that this forum was so full of philosophers. I love this place!! Great responses...and inspirational. Thanks for the great responses. Time will tell....1 point

-

IMG_9719.MOV I'm a bit reluctant to share this, because it will probably jinx me again, but i cleaned off that grease i applied to the fork and escape wheel and by golly, it's running again. so it seems like it was operator error ? Thanks for everyone's input on this. Boy, when it works it's fun, but when it doesn't .... I just need to find a bow and clean up the case/crystal and bit. I hope everyone has a great weekend.1 point

-

My personal fascination is more along this bent. I took an online course on special relativity while recovering from an especially bad car wreck a few years back, and gained an entirely new perspective on time. It's a difficult lens to translate, but time pieces are incredible. I've mentioned elsewhere my buddy's work on the new experimental resonator for the atomic clock. It's so accurate, you can measure the difference in elevation within earth's gravity well within a cm... I am also a fan of history, and my first mechanical watch accidentally turned out to be a WWII German issued officer's watch from the eastern front (D# scratched out to remove the Nazi stink), that received a battlefield repair with the pointy end of a bayonet, and ultimately ended up either traded for something out of a POW camp or picked off a corpse as a battlefield trophy. I knew none of this when I bought it on eBay from a seller out of the Ukraine for $35, having only recently discovered the existence of hand wound watches, and some of it is educated and evidenced conjecture that can never be certain, but imagine the awe every time I wear it (which I almost never do because I'm afraid I might damage it). I'm an outlier though. I only know of one or two other watch enthusiasts that are my age, and they're both of the fashion variety. One guy thinks a little outside the box, but definitely no watchmaker. Aside from the watchmaker back in Texas that fixed up the WWII watch mentioned above, I've never knowingly met another in real life.1 point

-

My interest in watches was sparked when I bought a birth year (and month) watch off ebay only to find it didn't work. I rang a few watch repairers and they quoted me about £300. No way was I spending £300, the robbing ********. So, one year later and £4,000 worth of tools I finally fixed my watch. Who's laughing now eh?1 point

-

Whatever the reason, I am happy to see the renewed interest in mechanical timepieces, in hopes that I will have more to work on, and more to save from the scrap heap. So, I'm hoping this trend will continue for a little while longer. I can be a hopeless romantic about mechanical watches. It's fascinating how they needed no battery to fuel them back in the day; just a few second's input of the energy produced by thumb and finger, stored in the spring, could power them for many hours. I always thought that was quite a return. And they seem, in essence, like little "tape measures for the intangible". They move through time with us, marking our place along the way, and showing us how far we've come, and how much time is left. They've shown us upcoming appointments, the approach of the end of our work shift, helped nurses count pulses, timed races, and some of them in their demise have recorded the sinking of ships. These little mechanisms have been so dear to our hearts for so long that it makes me glad that so many among the younger generations have seen enough merit in them to spur a new measure of popularity.1 point