Leaderboard

Popular Content

Showing content with the highest reputation on 04/26/21 in all areas

-

This PowerPoint presentation covers the basics in removing an Etachron stud, making your own tools to do so, replacing the Etachron stud to be able to remove the hairspring and balance, as well as removing & replacing Incabloc settings in the mainplate & the balance to be able to replace lyre springs. In slides marked 'Video' in the top left corner, move your cursor to the bottom of the screen and a play sign will appear in the bottom left of the slide 377149799_Lesson15.Incablocsettingsandspringreplacement.pptx3 points

-

If you are a "I have to have a tool for everything", go for it ? Never had one, never needed one, will never need one, neither a spring-winder. 10x trained fingers do make wonders happen ?3 points

-

Another trick is to rotate the arbor against the direction the mainspring is wound. This opens up the hole slightly. But yeah, some go in easy, some take some persuasion. Sometimes I've had to enlarge the hole a little with tweezers, especially when using a new mainspring that might not be an exact replacement.2 points

-

What are you using to hold the arbor? Stainless steel tweezers, brass tweezers, pin vise or pin tongs? Steel tweezers tend to slip more easily, brass is a little better. But the best method my mentor taught me was to use a barrel arbor vise. I don't think it is manufactured anymore. It looks like a pin tongs. So I bought a cheap pin tongs from Cousins and bored out the hole to grip the shoulder of the arbor. It gives a very secure grip on the arbor. A pin vise works too. I'm sure if you look through your inheritance, you might just find a vintage barrel arbor vise. Happy hunting!2 points

-

1 point

-

Folks. I went all the way here and made a video on how to make a jewel setting from scratch. This setting was for an upper plate intermediate (3rd) wheel. The challenge I had was the jewel I used was a 30/180 and should have been a 30/170; so it made making the rim for burnishing a bit tricky. You will see some really close action here as well. Please comment on this full feature film.1 point

-

my understanding is the military radium products are very very bad compared to the civilian. Usually the watchmaking point of view you'll see radium burn on the dial I've never seen it on a crystal. The other place where I see it is the old hand assortments. Hands were mounted on a piece of paper and the radium hands if you move the hand you can see where burn the paper. This even came up the other day somebody asked about it I showed him the hands the radium hands you could see the paper was burned. unfortunately for watch repair, you will see it as I said on dials occasionally the hand assortments if you're still on the paper occasionally. The problem watch repair is things like the hand assortments there's a brand-new hand assortments from whatever it doesn't have a date on it most people wouldn't know the radium unless you knew what to look for. Unless you have a Geiger counter you don't know that that nice assortment a hands that you bought some of them are radium. So unfortunately the radium stuff is still around unless you have a Geiger counter unless it burns the paper a dial or crystal he can't look at him and tell entirely. Then you only see the burn if it stays in one place long enough to burn something.1 point

-

Thanks Jerryvs worked with tweezer I move the spring and the arbor enter then counter clockwise it catch the pin. Thanks the doc it'll me a lot as I forgot to take picture when I disassemble the movement Great tip1 point

-

Needs a little adjusting but a hell of a bargain. This is what I had and it is one of the best machines I have had the privilege of owning https://www.ebay.co.uk/itm/265135129677?hash=item3dbb49044d:g:NwAAAOSwLEBggV3R1 point

-

Hi all, Problem is now solved, and it was pretty simple. I had the reduction wheel installed upside down. Once installed properly the autowind mechanism went back on without a hitch. I realized something was wrong after the watch was back together and it ran out of juice despite the rotor working properly. Lesson learned. Thanks again for all the help.1 point

-

An Eclipse pin vice No. 123 is what I use to grip the arbor, after that whatever the technique you use, you will never lose the arbor again. It makes fitting the arbor into the spring child's-play. Any pin vice the correct size will work, there isn't a need for any specialist tool, trust me, try it and you'll see.1 point

-

1 point

-

Then I suggest the Unimat 3 this is what I have and it will handle anything right up to Longcase clocks including the barrels and center wheel. You can still buy accessories even though most are second hand. Some of the lathes I have seen on ebay even have the milling attachment (you can get that separately if you wish)1 point

-

Hi The clock looks nice, I personally do not strip the wood and re varnish. I got like that in life its part of the character of any clock. clean it and beeswax and elbow grease should do. Spiral gongs differ I have three clocks with them and all sound different. As OH says the type of wood and condition of the case can make a difference. As said try the tricks with the hammer should be leather.1 point

-

The type of case sometimes can cause the strike to sound dull. Any splits in the wood won’t help the tone. Try moving the hammer away from the gong or if the hammer is on a rod move it back a fraction. If the new hammer is hard that can cause problems, if you are able to soften the material it is made out of paint some oil on it to soften it up.1 point

-

You're a brave one. I didn't dare ask OH any more heretical questions lest he excommunicate me. I think it should work but I think a lathe is still needed to cut off the old pinion and shape the arbor to the correct diameter to fit into the quick pivot.1 point

-

Thank you Jon for this lesson, interesting tool that lets us reinstal the setting back to pre-removal depth. Always following and learning your lessons with interest. Joe1 point

-

https://www.cousinsuk.com/product/barrel-arbor-holders?code=B0043E I just discovered that Cousins still sell this tool. It's made by Bergeon.1 point

-

This clock was liberated from the Belsen WW2 prison camp by my father. He was one of the first into Belsen and this clock was in the Commandant's quarters. There is a note somewhere, currently mislaid, from within the clock which contains Commandant Kramer's name. It sat on the mantelpiece at my Father's and worked everyday up until about 2006. I think it is an 8day movement. The movement is signed Kohler and the case has Berchtesgaden and Bergen on it. I cannot find any info at all onthe 'net.1 point

-

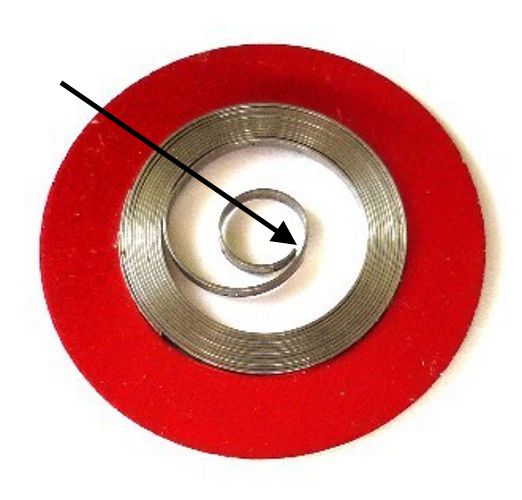

Make sure that the arbor-hook is facing exactly the "opening / gap" in between the end of the spring and first inner-coil of the spring (picture taken of internet just to show, but of course the spring has to be seated in the barrel) While holding / pressing the arbor with brass-tweezers, I usually hold/support the barrel between my thumb, index- & middle finger; gives you far more "wiggling"-flexibility and you don't have to worry about that the arbor "stands-up". With a bit of practice and the arbor pops-in with not too much effort. Suc6 ?1 point

-

It takes time and practice but slight pressure on the Arbour at an angle so the mainspring opens a bit with the angled pressure as you slide it into the hole. It is of course over a hole on the bench block. I should make a video on this technique1 point

-

I was thinking a hollow staking set punch would be nice to hold the barrel arbor in place while I mess with the spring. I've been looking at staking sets recently.1 point

-

one of the problems with watch repair is the failure to grasp that parts are not always interchangeable. Often times watches will be made over a number of years modifications and changes will be made. Then there is a problem of vintage watches? For instance American pocket watches mass-produced we have a parts catalog to prove that the parts can all be changed replaced etc. but can they really? If you look at American pocket watch they serial number the watch and all of the plate components. that's because all the components like bridges are made for each watch which is why they all have serial numbers. Even the gears and miscellaneous parts may be hand fit. Their early videos of the watch factory's mass-producing watches but you'll notice it each of the station's they can still be hand adjusting to get the parts to fit I would find it extremely unlikely that you to get another balance bridge to fit that watch without modification to something. This means you have to fix the bridge you have. So perhaps a picture of what's wrong with the balance bridge jewel and we can give you ideas as to how to fix the problem.1 point

-

Thanks guys, BUT, I got it back in, got one side in, and the other almost all the way in, gave it a little push and. heard a click, and it's all good, lol1 point

-

1 point

-

Hello Micheal1962, I picked this up from a gentleman who sells antique and vintage items out of Tasmania on ebay. I have a few of these ww2 Elgin pocket watches and this one is very interesting as it has the original box and crystal with the radium burn. That shows that it has sat somewhere for years and years in the box. Not very often you come across radium burn. Have a great day Micheal1 point

-

https://orient-watch.com/FromManufacturingSite This site contains a lot of data re Akita, Part of the EPSON group1 point

-

Hi there is a movement on Ebay Akita 9GB00 pretty cheap, might be worth a punt Akita 9GB00 Quartz Watch Movement Machine Watch Machinery Motion _ eBay.html1 point

-

Yes. Very clearly not a Patek Philippe; more Patrick Philip. But at least they put 'JAPAN MOVT' loud and clear on the dial. And you're right that does look like 96800 doesn't it?! But I think you'll find it's 9GB00. So do a search for 'Akita 9GB00' and you should have better luck finding some info / a replacement.1 point

-

Hi Eli, you are right this is a fake, So far as I know "nautilus" the least expensive piece patek phililppe makes costs over 70k. Best wishes Joe1 point

-

Had a good look round found the instruction book, attached just in case you dont have it. All references are that it is not changable, just check the bezel does not screw off before doing anthing else. V851-E.pdf1 point

-

I see two things wrong with this. The first he has removed far to much brass in order to fit that ridiculous bush. You are supposed to remove as little as possible of the original. Second it is not in keeping with the clock, it sticks out like a sore thumb, again you repair as near to the original as possible. I watched a few of his videos and I'm not impressed at all. If I had my way 99% of videos I watch on Youtube about clock repairing I would remove. They give skilled repairers or restorers a bad name. Any new clock repairers on this forum. Do not follow what this idiot is showing you and avoid his videos.1 point

-

We can't possibly remember all details of the auto module geometry, so if you will please show a picture with auto-device removed. to show; - The ratchet wheel - The jewel to ratchet wheel reduction wheel. The lower jewel to reduction wheel ( if there is one) and has moved can bind the reduction wheel. Wrong screw on ratchet wheel can also cause a bind. Check posting pins and if module plate is bent .... See if shimming between the module plate and the bridge it mounts on releases the auto- device to wind. Keep us posted please. Regs1 point

-

Many thanks to all of you for the informed discussion! It's not everywhere you can get people to take such a trivial point of interest so seriously! I love this forum! By the way, I can also vouch for the difference between a smack and a static load. I have some experience in crash-testing, and the peak forces involved are enormous. The only reason you and the car are not crushed completely flat is that the forces only apply for a few milliseconds. If you're lucky, the transfer of energy to your organs is relatively low, and they just wobble around a bit inside you. I've always used the fingernails-on-the-teeth method illustrated above up to now, but maybe I'll get the hammer out next time.1 point

-

I dont know what information you are looking for but your clock is by Christian Kohler GmbH they manufactured clock cases from 1913, they did not produce their own movements, and bought and cased these from other makers and signed them under their own name the movement in your clock is by a company called Friedrich Mauthe there may or may not be a Mauthe trademark stamped on the clock this would be a eagle with the letter F M S in a circle your clock would be pre war and date to the 1930's.1 point

-

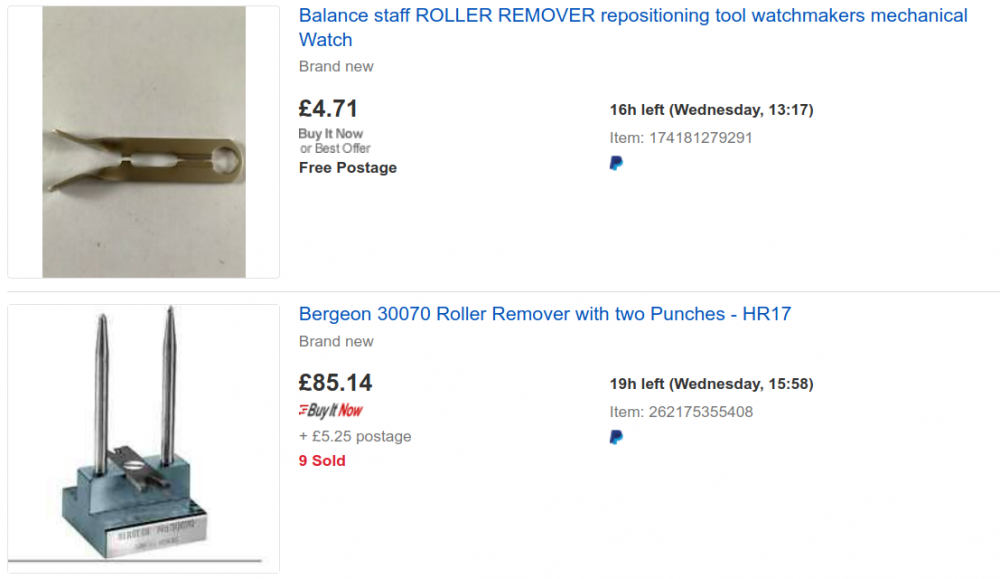

I guess that it could be made to work, with the careful application of a small file, but I like my tools to work, out of the box as it were. I have bought a few cheap tools over the years, but my oft broken personal rule is.. Am I likely to use the tool often? If so, buy a good one. If not, buy a cheap one, but expect to have to buy a good one if it turns out to be junk, or if it turns out that I need to use it often. You can see why it is often tempting to go for the cheaper option, but I know which of the two of these is more likely to work, and to last a lifetime. Sometimes you are pleasantly surprised by something you assumed would be rubbish, which turns out to be good. The Lidl and Aldi own brand stuff is often surprisingly good quality German manufactured, for example (though they also do some compete rubbish), whereas the more mainstream supermarkets and DIY stores often punt nothing but cheaply made stuff. I also find that quality used tools are often a much better bet than cheap new ones.1 point