Leaderboard

Popular Content

Showing content with the highest reputation on 04/16/21 in all areas

-

Not really. If you want to remove the doubt from your mind fit a new mainspring, isn't expensive and doesn't require a winder.3 points

-

Hi there Micheal, by definition a field watch is a simple military watch, originally called “trench watches” they were designed for soldiers to wear in WWII. They were made to do one thing, and one thing very well: tells accurate time. They were made to be dust and waterproof, usually made of stainless steel casing. Hope that helps.3 points

-

Seem to remember that the spring should not be over lubed. i gather there needs to be some friction to stop it overrunning as it ticks over but not too much to make it judder. I have a note from somewhere I can't recall where (possibly from Cal 1022 which apparently may be similar to 550 as scribbled on same piece of paper!!), which states, "Adjust it (the spring) so that it has enough tension that once you lift it. the gear train spins just a little but not too much when the pallet fork is out. You want the centre (second?) wheel to turn about about half a rotation when you do this. You want to get crazy, epilame those two parts (spring and pinion) and a little 9010 will keep you out of prison", Wording in brackets is mine not in the original note !! Hope this helps a little.2 points

-

I had the same dilemma with my cal 565. I ended up putting the tiniest smear of oil (9010) under the spring. I hate those springs - very easy to accidently bend, and then break, trying to get the correct pressure on the pinion. And of course, being Omega, not cheap to replace. Too little pressure and the second hand judders, too much and it kills you amplitude.1 point

-

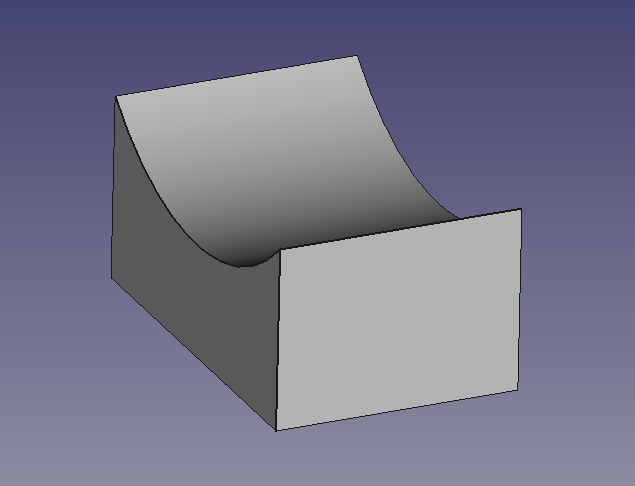

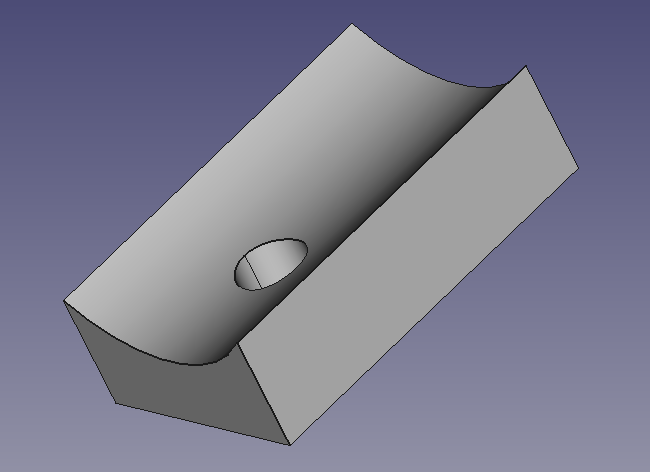

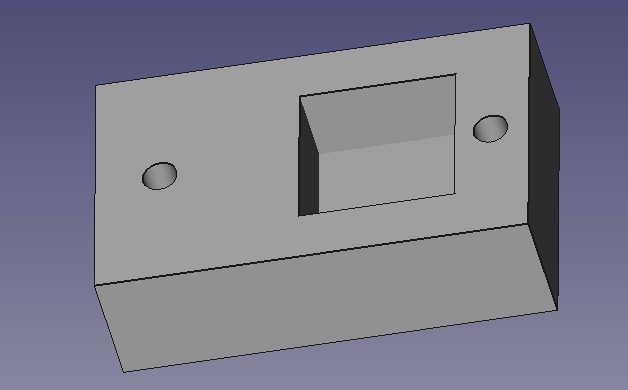

I disassembled the lathe I got from my brother and parted out the Borel base and the motor to another lathe setup. Now I am back to rebuilding with another motor. But...no base!! So I decided to cut a base the same shape as the Borel base and build mounts using printed parts I designed for 3D printing. Here is my progress so far. Consider this a prototype. The woodworking is pretty lame, but once I prove the concept, I will rebuild with a nice piece of wood.1 point

-

Hi thinking outside the box is some times the answer, as long as the base is stable and vibration friendly should work well. nice job so far, lookforward to the finished article. cheers1 point

-

You might find this of interest re 550 series. Not much on oiling c/sec pinion spring though. Cal History and Info.pdf1 point

-

A sub second pinion on a 552? Forgive me, but I thought this was a centre seconds sweep second movemnt?1 point

-

1 point

-

1 point

-

How did you go about sourcing your balance complete? Now the reason I ask is a lot of times there can be variations. For instance at the second link how many balance completes are there? Looks like there's six separate balance completes usually they're not interchangeable. So if you get a balance complete and it's not the exact one for your watch it will not fit. Then looking at the balance staffs there is even more of those. So do you have the correct balance complete for your watch? If not you're going to have a problem. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&AS_1187 http://cgi.julesborel.com/cgi-bin/matcgi2?ref=AS_1187 There is a couple a separate ways to order mainsprings. You can look up the watch at a variety of sites and see which mainspring you're supposed to have. Like the first link up above Which lists the mainspring then the second link also has the mainspring. If you click on the parts found in the second link you usually get additional information Like the dimension of the spraying and two other numbers which you could use to find the spring plus a list of all the watches that use this mainspring it looks to be very very common. If you go the other route have just measuring the spring you want to be careful do not ground up it needs to physically fit in the barrel and if you make it too big it's not going to fit that's going to be a problem. Especially the first number that is how wide the spring is if it's too wide you're screwed the other numbers you can vary a little bit. MS-711K MAINSPRING 1.60-.10-300 9 GR 4486 http://cgi.julesborel.com/cgi-bin/matcgi2?ref=qWLXEn Using the third number up above you can go the cousins website and find out your mainspring is discontinued as least as far as they're concerned. The first number we would use on the site or got the number but right at this instance they claim their databases down and I can't search except he could search for the parts you just can't see if they actually have it or not. https://www.cousinsuk.com/search?SearchTerm=4486 You will note that the dimensions are all in metric. Then regarding the first number if you change the first two letters into a word like this Mainspring 711K Then go to eBay it's available there. It looks like quite a few of them are available. I don't think I've ever seen anybody not clean their screws? But I can see were somebody nervous about not keeping track of them toward mixing them up maybe that would be why. But as far as I know he always clean the screws at least I do. I tend to think of each watch as unique. So applying things from one discussion to another discussion doesn't always translate. For instance in the watch of the original discussion we have multiple of balance wheels and lots of balance staffs to go with the various wheels. in other words we have lots of variations including conceivably pivot size diameter. So adding a Shim isn't going to help in this particular case providing that is what the problem is. Mainspring - DennisonChart.pdf1 point

-

Your watch uses the most popular Miyota quartz module. The stem release point is the small round point, left to the round setting lever post, which is left of the stem itself, near to the bottom.1 point

-

A few things to take into consideration. Never have a clock near central heating, don’t hang it near draft, it could stop the clock, the pendulums on cuckoo clocks are very light. If your home is prone to dust and it’s a hot environment where you have the doors open each and every day about every 2 to 3 years otherwise 4 to 5. I would check it every year just to make sure it is oiled and not running on dry bearings which as you know will add to wear.1 point

-

As HLPayne said, jewel and caps should be removed, cleaned, pegged and checked under good magnification.1 point

-

How did you check for endshake? its the unforced play on staff "free play" , use an oiler when lifting the balance to check. Any amount of end shake would free the balance to turn, ideally its .02mm . An oscilator with many issues can run, the question is how good does it run. Shimming is not illegal Europe, if it comes down to it , shim.? Regs Joe1 point

-

Hi Ed, I'm new to the hobby and wrestling with the same issue you are having on an AS1187/94. There is a string on the Facebook "Watch Repair Lessons" Group with this discussion linked below. Basically, the movement has had multiple versions of shock resistors over it's life. You probably have the incorrect staff that was installed by a watchmaker of the past. The quick and dirty solution is to add a shim under the balance cock. I was advised to use brass shim stock by one of the group members. I picked up brass shim stock from a hobby shop so I hope it works. The other option is to get the correct balance staff for the shock system on your movement. Mine has the Supershock system which uses a Ronda 305 staff and I found it cross references with other movements on the Ronda Catalogue. BTW, Supershock has capped jewels that require the balance cock to be disassembled to be cleaned. I've added a photo below for your reference. I found this on the Ronda staff catalogue which I'll like below as well. https://www.facebook.com/groups/watchrepairlessons/permalink/807278563210416 Question 2 - This Cas-Ker mainspring catalogue, linked below, has a Dennison to Metric conversion and size list. It has helped my quite a bit. https://www.jewelerssupplies.com/media/pdfs/MainspringsCatalog2018.pdf Ronda Staff Catalogue - (thanks to Vintagewatchparts.net for posting) https://www.vintagewatchparts.net/ronda-balance-staff-catalogue/1 point

-

Seiko 'magic lever' style winding. Very similar movement to Seiko 7625 in many ways. Movement is Orient 48748 for reference.1 point

-

Hello, just a quick update on my progress cleaning the mainspring winders. I don't have any chemicals so i just dipped the heads into vinegar for 15 minutes and used a very small brush to clean the loose stuff off on the front and behind the disc. I then dipped the heads in lighter fluid because i thought that would get rid of the water from the vinegar. i then dried it with a hair dryer and finally lightly coated it with some clock oil i have. it actually works nicely now. I did one and now have 5 to go. thanks for the ideas. Arron.1 point

-

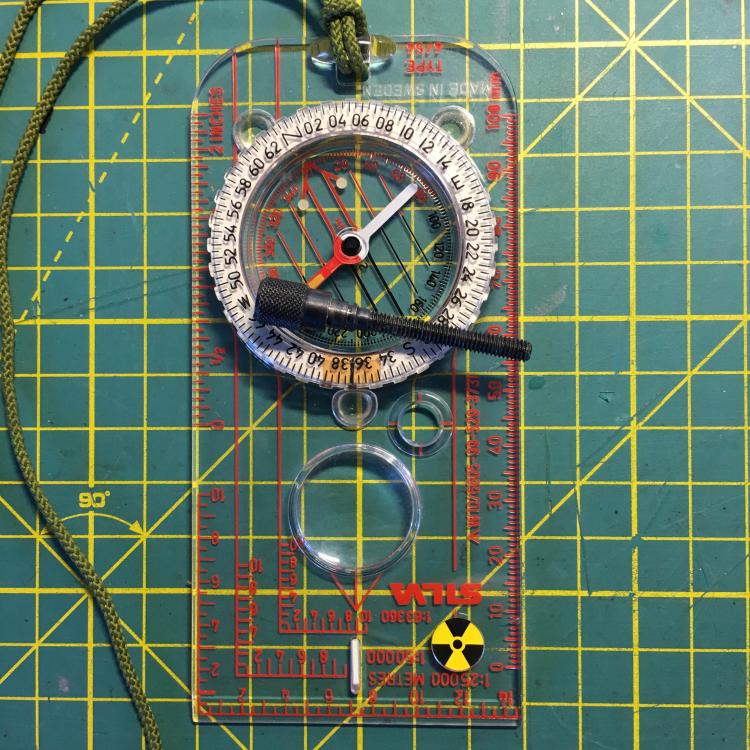

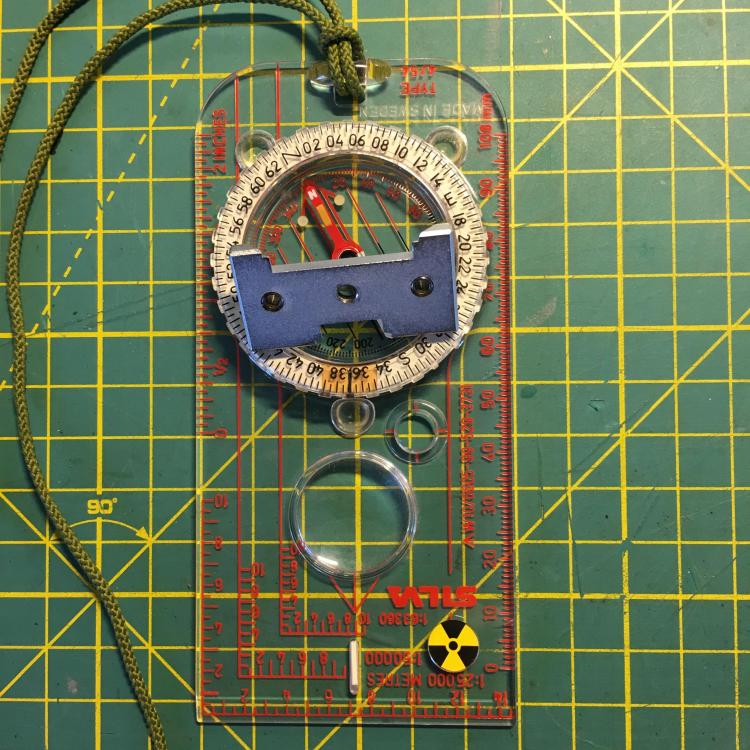

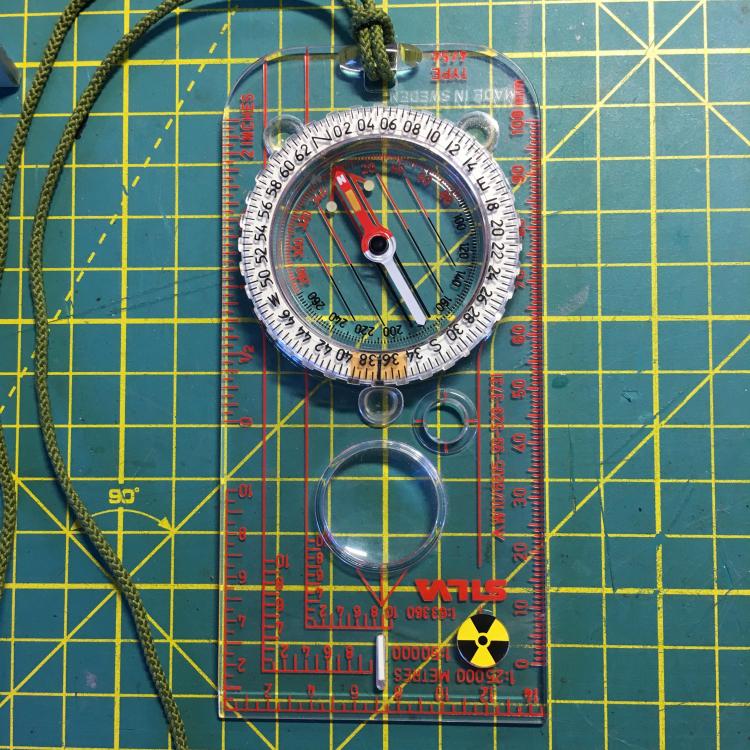

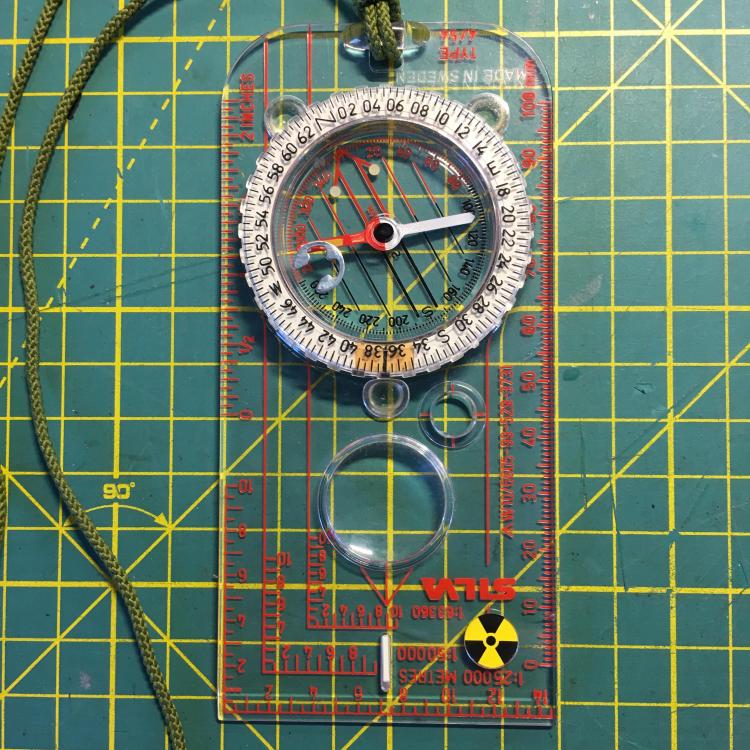

Dear all; Working on a chronograph, after assembling the demagnetized motion-parts, the motion work ran all over the place. Next to a few other suspicions, the possibility that something had gone wrong during the demagnetization of the parts was one of them. Started checking the movement with a compass, but actually found that my metal Bergeon N˚4040 movement holder was magnetized. Even though the holders' side-plates and guides are made out Stainless Steel, the adjustment screw and circlip aren't. To find out exactly what was magnetized, I disassembled the holder and put each part on the compass. First picture the compass in "neutral"; Checking the both side-plates, the small part at first; Some slight residual magnetism in the side-plate with the guide-rails; However, very strong residual magnetism in the screw and circlip. So much so that I could move the compass needle in any desired direction; To be honest, I never checked & suspected my movement holder for magnetism. When demagnetizing watch-parts, I always do keep all other metal objects well away from the demagnetizer. I have used the movement holder already for quite some years, so how and when it became magnetized is unknown to me. That it can become (strongly) magnetized is a new lesson to me. Be aware ?1 point

-

1 point

-

0 points