Leaderboard

Popular Content

Showing content with the highest reputation on 03/16/21 in all areas

-

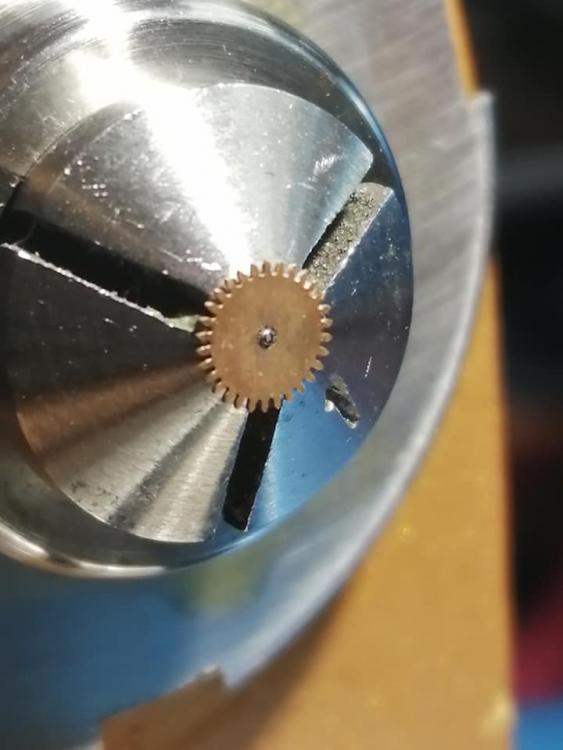

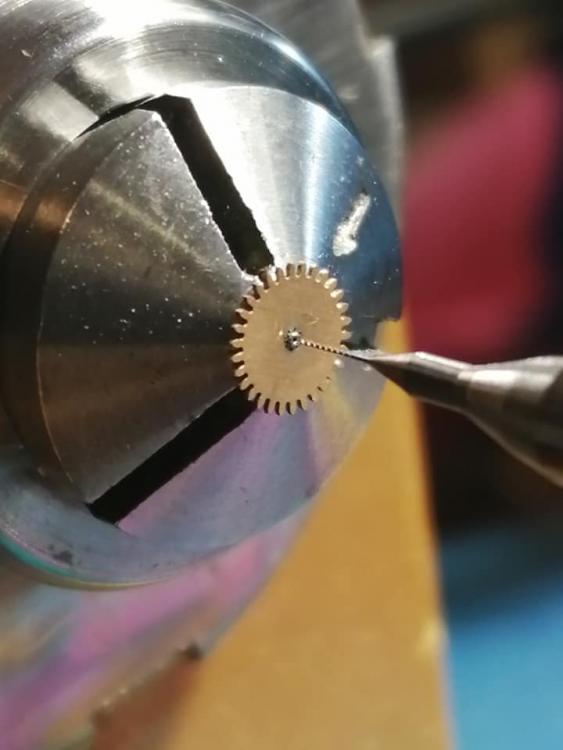

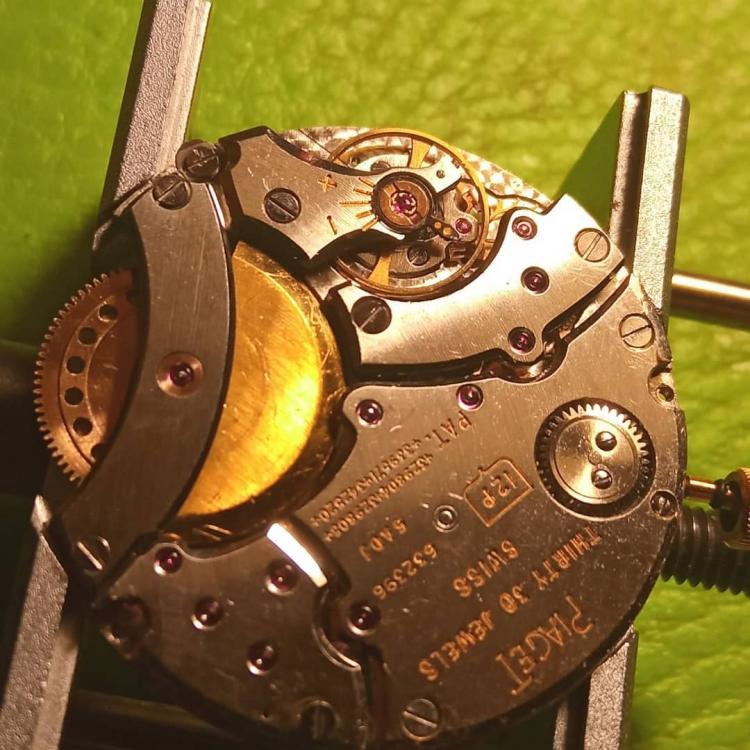

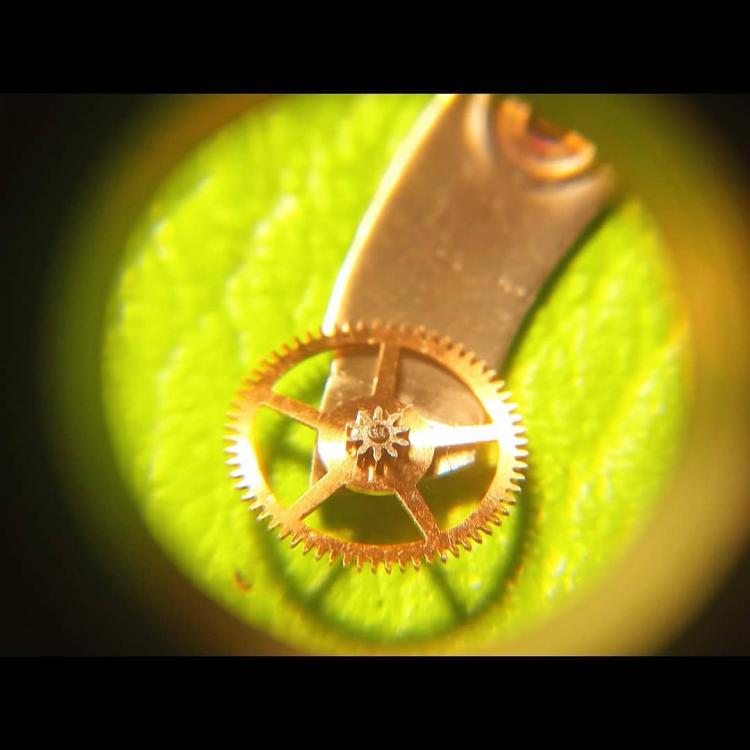

Hello to all, During the latest lockdown, a piaget 12p ultra thin came to my workshop wearing not its original crown, with a broken shaft at oscillating weight and two automatic wheels broken. With a little help from a friend who's a specialist in reconstructing watch parts and tools, i repivoted all the broken wheels and shaft,. Then, i serviced the movement and cleaned up the case in the ultrasonic cleaner. Finally, i went on with the reconstruction of the original golden crown upon customer request. Thanks for taking the time to read it4 points

-

3 points

-

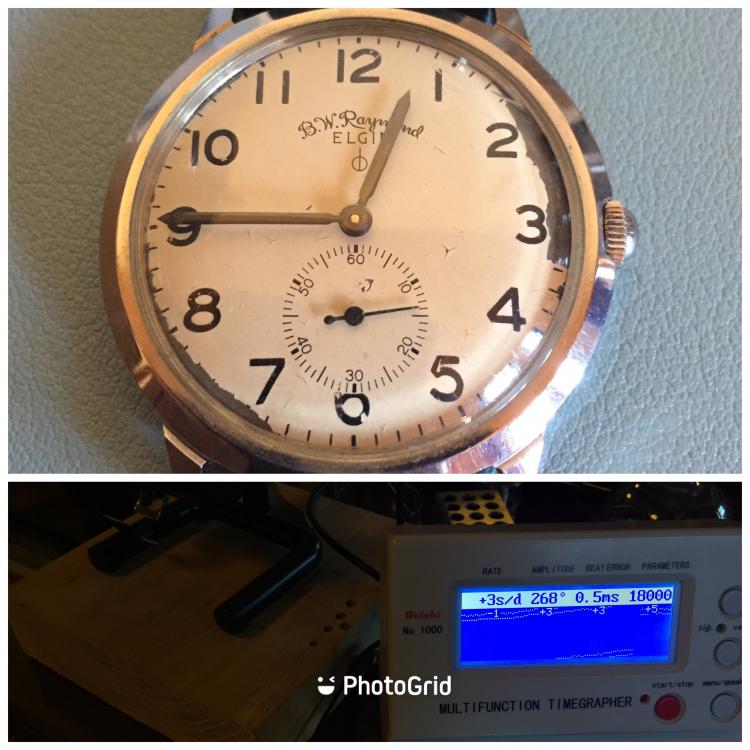

It was productive week with these 3 watches and getting them in working order. The Bancor AS1187/94 was the only one received that was running but needed a new mainspring and cleaning. The Elgin 730A wristwatch stopped and started and the pocket watch had a broken staff. The PW, Elgin grade 96, was a gift for my father. All running well now. Lastly, I made some cosmetic improvements to my staking set last month. The tools inside needed minor refreshing but the box had seen better days. Scraped to bare wood - poplar - stained and finished. before: after:3 points

-

Looks like a Revue 30 ... http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Revue_30 Cousins has a pallet fork listed if you can't track down an alternative source.2 points

-

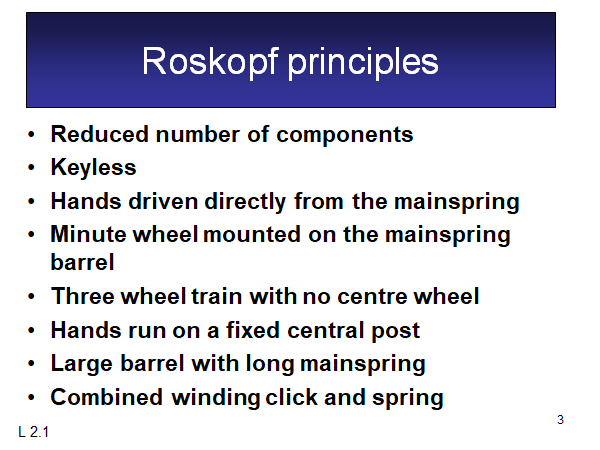

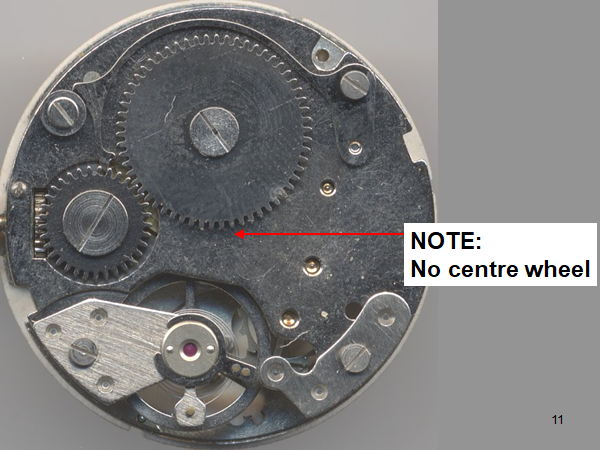

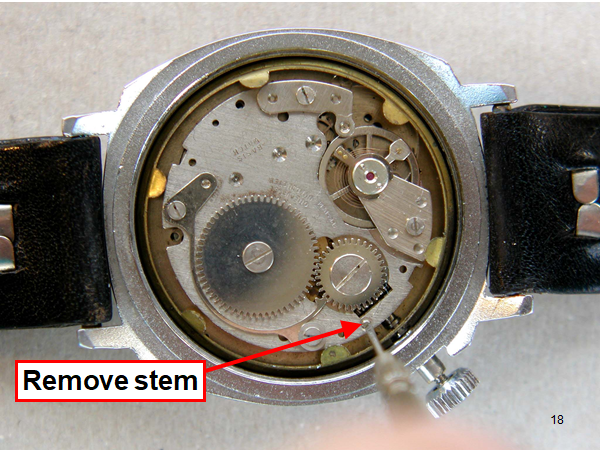

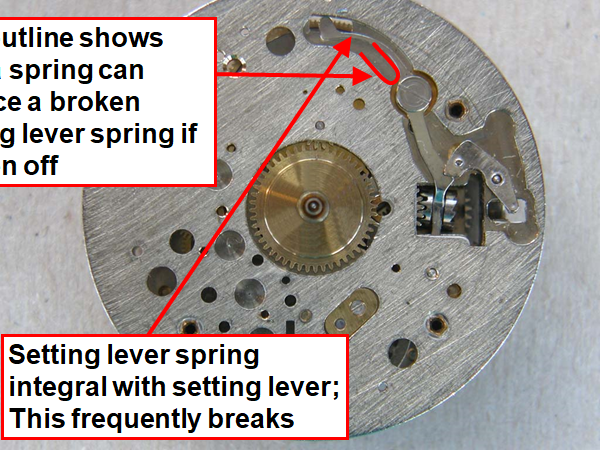

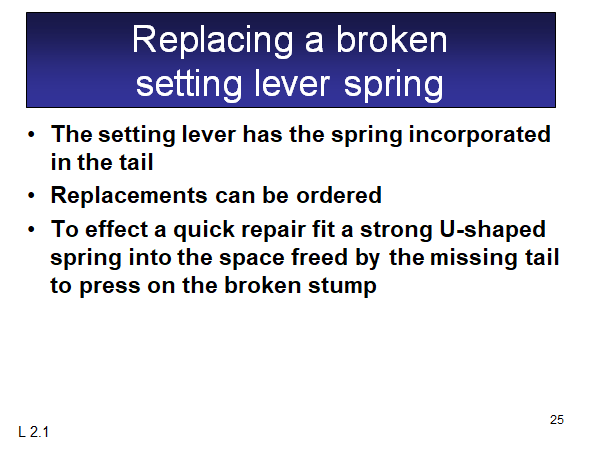

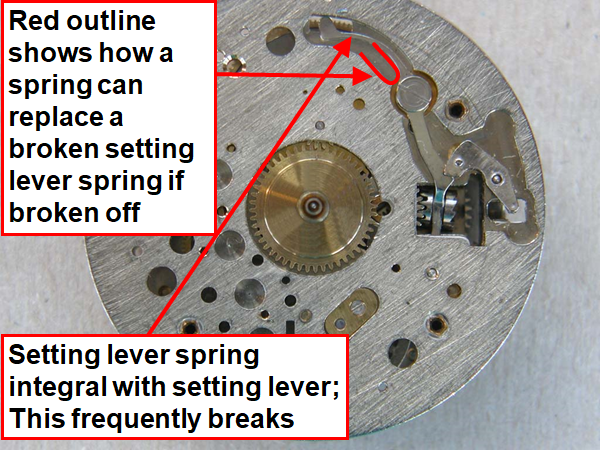

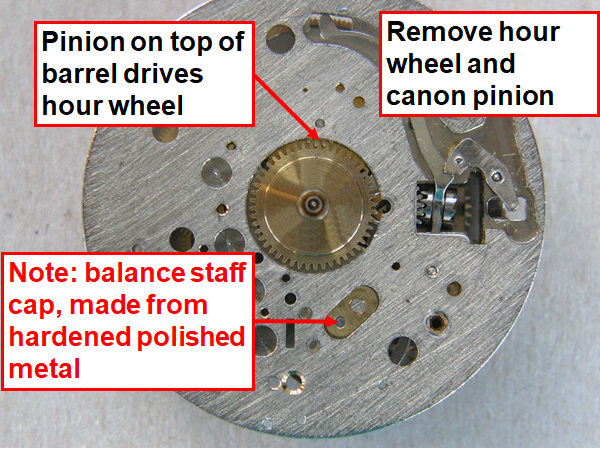

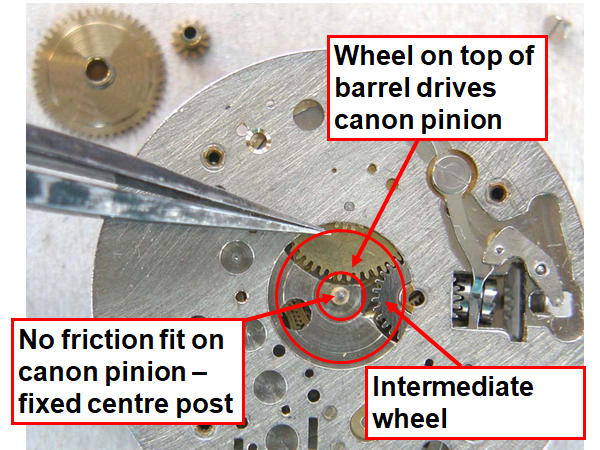

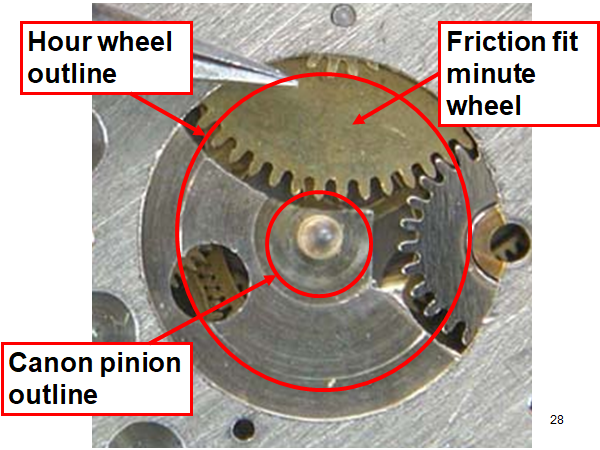

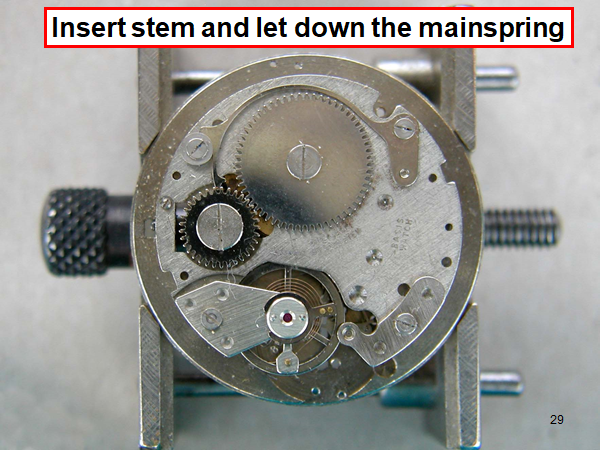

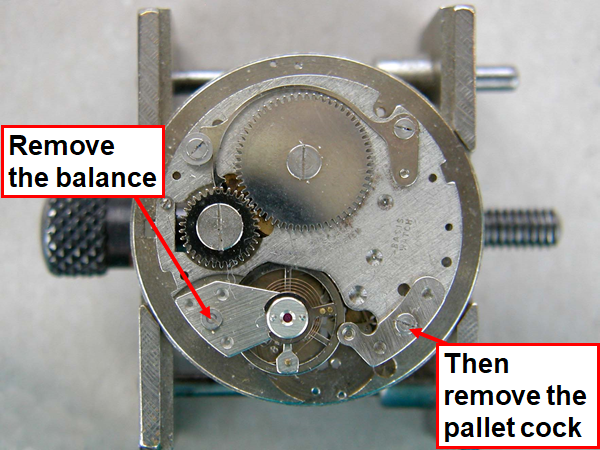

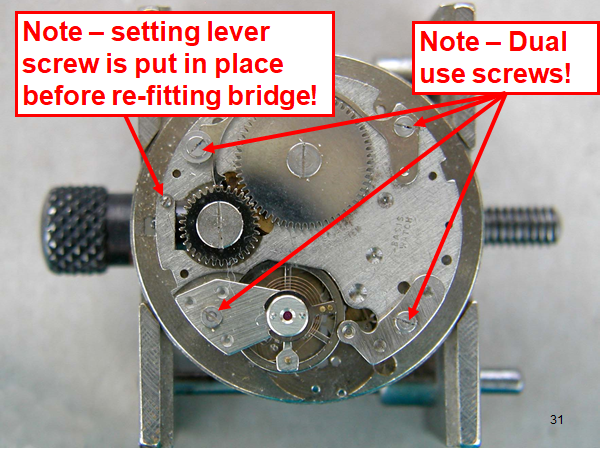

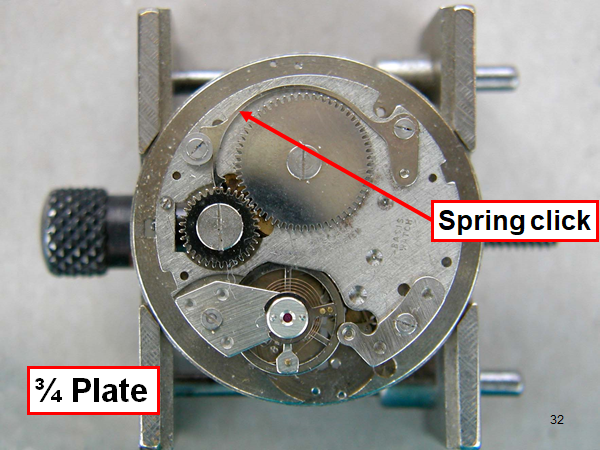

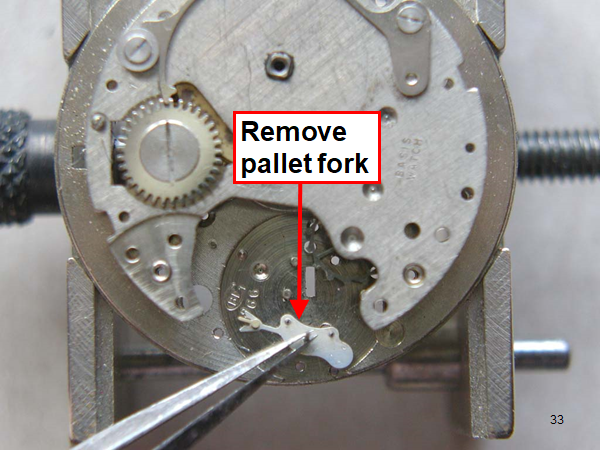

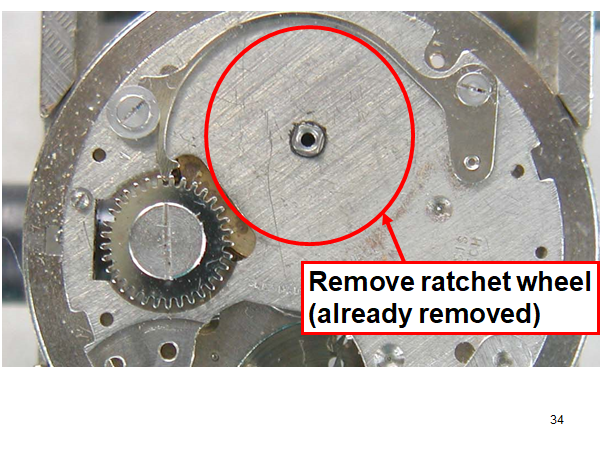

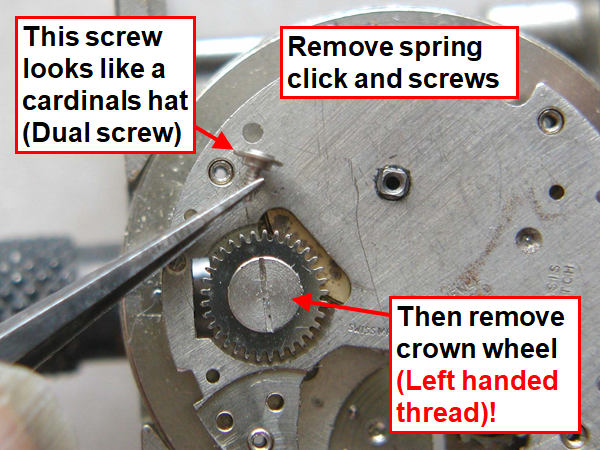

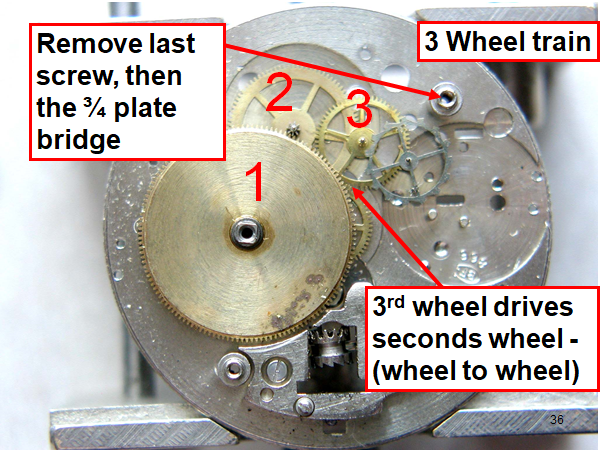

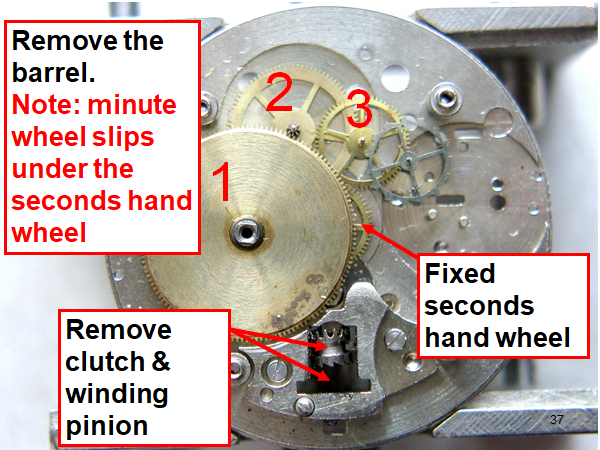

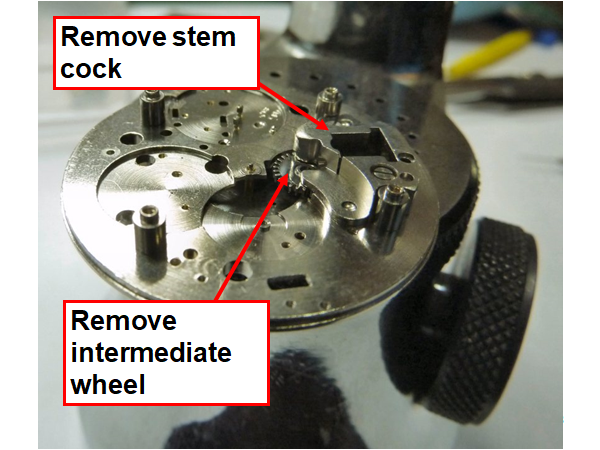

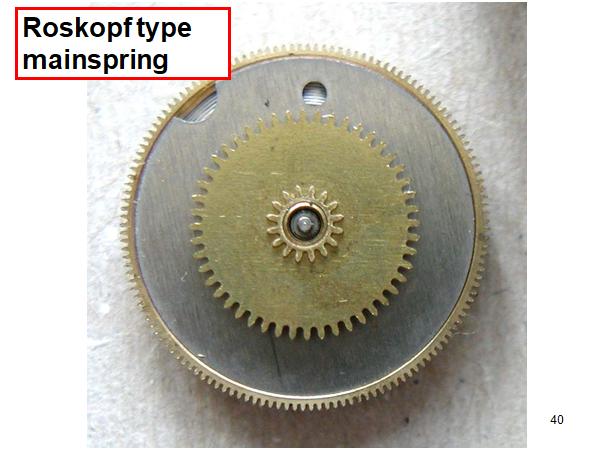

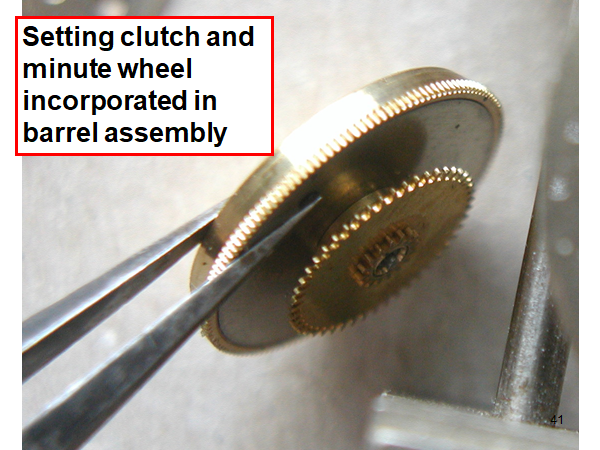

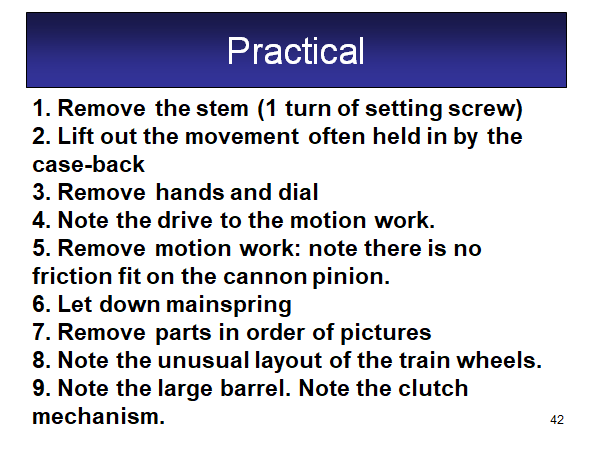

Hi, I teach watchmaking to complete beginners at Epping Forest Horology Centre, close to Epping and this is one of the lessons on the BFG 866. I wanted to show my class a classic pin pallet (Roskopf) movement and how to service it, as many watchmakers won't touch these watches as they hold no monetary value. Turn the setting lever screw 1 to 1 and a half turns to release the winding stem A piece of watch paper or small plastic jiffy bag to protect the dial, whilst removing the hands The driving pinion is part of the friction fitted minute wheel on top of the barrel. This work in a similar way to a friction fitted canon pinion to set the watch hands Remove the keyless work: setting lever, held in place by the setting lever screw, screwed from the other side of the mainplate, then the yoke, which sits on top of the clutch (castle) and also the winding pinion. I have three other lessons on this movement that cover bringing the watch 'into beat' as well as taking apart the friction fitted minute wheel from the barrel, lubricating and staking back on to achieve the correct friction setting and finally how to remove the centre seconds wheel safely and refit using a staking set. Many people leave the friction fitted minute wheel on top of the barrel, not realising the amount of old grease that can't be cleaned out from it, as well as not removing the wheel of the centre seconds arbor and again not cleaning out the pipe which has old grease inside. Hope you enjoyed the tutorial? More to come....1 point

-

Here's a PowerPoint of removing a refitting the so called 'fixed' centre seconds wheel, which should be removed, cleaned and properly lubricated. Enjoy Lesson 21. Baumgartner 866 Removing centre second wheel and oiling movement.pptx1 point

-

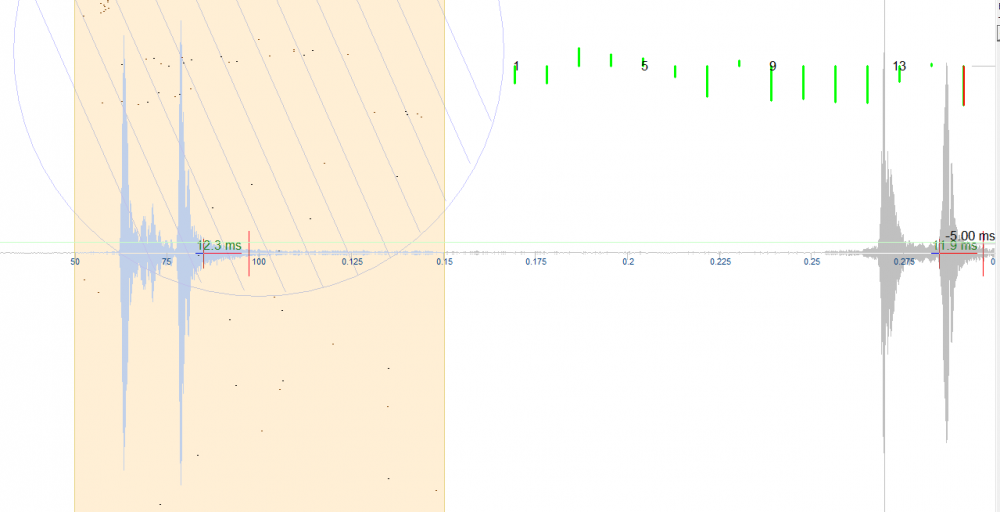

I was recovering from my second covid shot and did not participate in the recent activity on this thread. I am sorry about CWRNH's problems with the preamp he built, which are now resolved it appears. Thanks to those who helped to solve the problems. CWRNH's circuit is based on my circuit, which is based on svorkoetter's original design. My circuit is described in the preamp noise article at wlysenko.blogspot.com (click on link at the bottom of the page). The schematic in my article is for my version 15 of the preamp. The latest version (no. 16) is the same except that C3 and C5 are now 0.1 uF instead of 0.47 uF and C7 is now 0.03 uF instead of 0.1 uF. These changes improve the frequency response and lower the noise a bit. Question for CWRNH: Why are you using an LT1115 for the buffer stage? The data sheet says this part has the lowest voltage noise, which is good, of course, but this device is not recommended for use as a voltage follower. LittleWatchShop questioned the need for the 680 ohm resistor in the buffer stage (the data sheet uses 600 ohm in their example). It seems the AD797 opamp, which is what I used, likes to run at a high current. At high current, the voltage noise is lower, which is what we want, at the expense of some current noise. I hope people continue to look at improving the microphone. My microphone is nearly identical to the original svorkoetter design. I found that it picks up sounds in the room all too well. If I listen to the output with headphones, I can hear my own breathing! I think we want something that is sensitive to watch vibrations but not to sounds in the air.1 point

-

1 point

-

Welcome to the forum. To replace the crown & stem a donor movement off eBay could be where you will find an exact replacement. Material houses such as Cousins sell crowns and straps of various sizes but not fancy. For the stem you need to know it’s calibur.1 point

-

Welcome here. Have a read to the topic below. Even if it's an expensive watch your best chances are buying a donor watch on Ebay. The strap is also available there at an exaggerated price.1 point

-

Hi Lui, I'll post a Powerpoint of that fixed centre (seconds) wheel removal and refitting sometime tomorrow.1 point

-

1 point

-

1 point

-

A Ladies Glashütte 17 jewel all the way from sunny Boden Edelstahl. That's as close to a German joke as I can muster. Boden: Edenstahl translates as Bottom: stainless steel, but Boden Edelstahl does sound very like an idyllic spot in the Black Forest. Glashütte is in fact a town in Lower Saxony from which the watch manufacturer takes its name. It is 14k plated, shock-proofed (stoßgesichert) and probably from the 1970s to judge by the design. It is a non runner, and not quite in the same price bracket as its modern counterparts which start some where north of £5,000. In fact this particular little example easily qualifies for the 404 club. My guess is that it probably has a Gub 77 or related movement in it, which should make for an interesting service or repair.1 point

-

I use my wife whenever I've lost a part and I'm devastated. She has the eyes of a hawk and has an eerie ability to find any part no matter how small in minutes. She definitely gets a kick out of it. The record is a cap jewel anti-shock spring for the escape wheel pivot of a Seiko cal. 7S36B. It is smaller than a spec of dust. I think she was sent to me for this very reason. Bless her and I try to treat her really well so that she won't get any second thoughts about me. Couldn't do watches without her! She has a sister who's single if anyone is interested ?1 point

-

Well, I have given up on the original hands for the moment. Mostly because the replacements hands arrived and they look pretty darned good and of course fit properly. The tip of the minute hand required a bit of gentle bending around some peg wood to get the same curvature of the original, and the hour hand required a little reaming of the mounting hole with a broach, but success! They are a little wider than the originals, and at the moment the lume is bright white. I bought a second set of the same hands to experiment with aging the lume. I know many have used coffee or tea to accomplish the effect, but I am also a budding fountain pen user and have a collection of a few different inks that might do the trick very well, especially when watered down. Here it is in its current state. It is keeping good time at about +15 seconds per day. I am still regulating it using the Watch Tracker app. It is effective but takes a few days of readings between adjustments. Im very happy with the transformation and the fact that it is all nice and tight in the right places. Thanks for all of the helpful suggestions and I will report back if I am able to restore the original hands to a useable condition. Another project!1 point

-

On behalf of "Watch Repair Talk" moderators, I would like to extend a warm welcome to all new members. This is a friendly place with plenty of knowledgeable people who have varying degrees of horological expertise, the great thing is they are willing to share that invaluable knowledge and help one another. To help us keep things running smoothly, I would ask all new members to read the forum rules and place their posts in the correct sections.1 point