Leaderboard

Popular Content

Showing content with the highest reputation on 02/23/21 in all areas

-

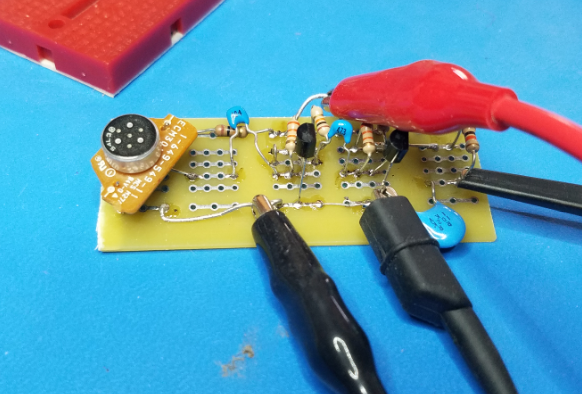

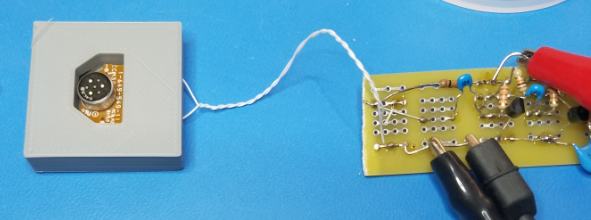

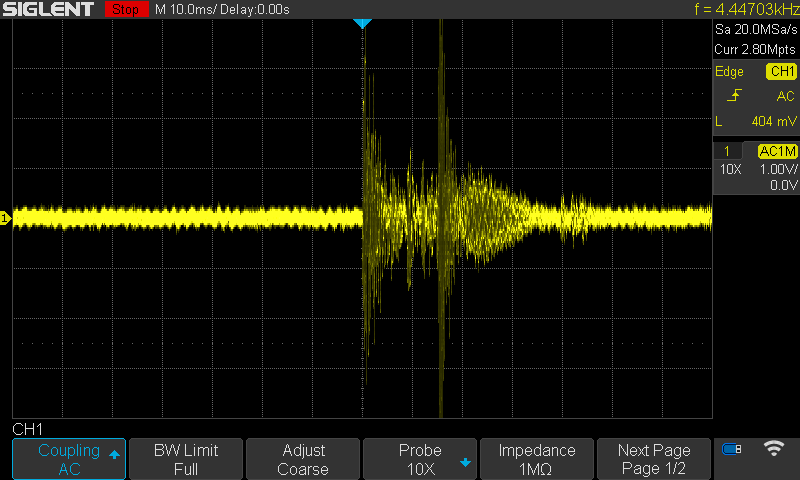

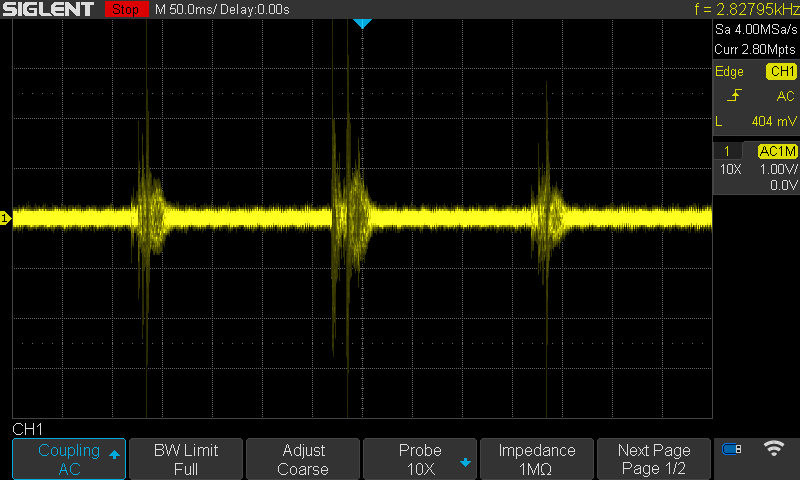

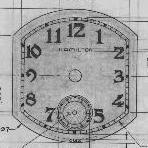

With a set blued steel mainspring that's in desperate need of being replaced you can still verify that a watch is functional and you would have more than 160° of amplitude. At least for a little while it's not going to have the running time of a mainspring that's in proper condition. You repeating pattern could be magnetism or something in the gear train. I'm attaching an image it will differ depending upon the gear ratios of the particular watch but ill give you an idea. Then the picture came out of a manual for timing machine. Even though it's an older machine 90% of the manual is still relevant for modern timing machines well worth the read I'm attaching that also. Then your amplitude and the way the rest of the watch looks just doesn't look quite right. Usually a really low amplitude everything gets magnified beat looks really bad everything will just look bad euros almost looks to good for that low of amplitude. Which is one of the reasons I'd like to see timing and more than one position which you should always do anyway. Plus the oscilloscope view. 1556614207_GreinerMicromatTimingmachine.pdf3 points

-

2 points

-

Well, this was some potentially very, very good news ? I have no idea what brand my Jacot tool is. However, the fork in the picture on the page you linked to looks exactly like the one on my tool. Getting my tools out for some measuring, keeping my fingers crossed, hard! (I'll be back...). BTW, @nickelsilver I truly appreciate you sharing your knowledge, experience and support! IMO, WRT should award you Most Valuable Professional-WRT:er ???2 points

-

Thank you I have had a large bruichladdie malt and am taking the K and D idea to a search now lol and chuckling also let’s see what I can find many thanks again A1 point

-

Good now you are in there the hard part starts take plenty of pictures during the dis assembly, do not rely on your memory alone, the chrono is a complex beastie.1 point

-

Yes I agree with the other comments, The dial feet have broken off. New ones can be soldered on or glued on although with the glue on ones you have to be careful of the calendar work for clearance. I built my own tool for the job and never had a dial spoiled. Common fault on Seiko's Mine is the LH one the RH one is a Horotec .1 point

-

1 point

-

I actually haven't ever ordered from them! Everything I have of their's I got secondhand. I'm sure they'll follow up.1 point

-

1 point

-

The rooster is Steiner's logo, you have a Steiner! The older ones look like pretty much all other Jacots, the more modern ones are more streamlined.1 point

-

According to the link below you're supposed to hit 47 hours you're running a little short. What I find interesting about companies like ETA is if you Can find their manufacturing information documentation It gives you all sorts of interesting specifications unfortunately I don't have anything for the 27 series so currently I'm looking at a 2660. The run time is Not as long but what's interesting is all they care about is what is it doing at the end of 24 hours. So even though they specify these long run times in the specifications they only care about 24 hours. In this particular case this watch could be 190° With vertical 6 o'clock up. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&ETA_27891 point

-

Usually for clock wheels because they're so large they put them in a lathe and usually just polish a free hand. Or as mentioned there are adapters for the lathe. Then there are tools but they're usually a bit more pricey which is why typically clock people are cheap it typically don't see them. If you Google pivot polishing clocks is quite a bit here's a couple of interesting links. https://www.davewestclocks.co.uk/pivot.polishing for clocks.htm And I can give it to you but if you look at YouTube of course there's videos. I saw one set polishing pivots by hand I assume they would the hand doing it in a lathe and I was wrong there actually hands spinning the wheel while there? It sounds more like their filing the pivots or to skip over that video. Then the next link? As you scroll down you'll find an interesting PDF on burnishing. While it's aimed at clocks it's still interesting. Then scroll all the way to the bottom and look at the last two PDFs. The last two shows what happens when you have too much time on your hand and give access to electron microscope. Clock pivots are interesting because typically their steel on brass. I don't know of anything in the here would apply to steal on Sapphire. But I don't have time to read them right now I'm sure I've read those of long time ago probably the last time I was doing a clock. https://abouttime-clockmaking.com/articles1 point

-

I'm unaware of a stand alone tool like the jacot for clocks*. There are lathe accessories that do the same thing that are suited to clock sizes up to a point. A normal jacot will do from about 0.04mm (some, even some Steiner, start at 0.07mm) up to around 0.30mm, and have a special runner for tapered long pivots for 4th wheels. There's usually two runners for the normal pivots, one end with the beds, the other with lantern discs to work the pivot ends. Some will have an extra runner, with beds on both sides, for working on larger (center wheel) pivots. The runners are matched to the tool, no mixing around. But to sum up, a Jacot is for watches, most will be ok for pretty much any pivot size, with the possible exception of center wheels. *there's a very excellent tool for clock pivots called a Rollimat. It uses a carbide wheel for finishing, and through a very clever design spins the wheel and bed around the pivot. This is basically how clock and watch pivots are finished industrially, except in those machines the wheel and disc spin while the bed is stationary. They're very expensive but for someone doing more than 2-3 clocks per week pay for themselves in short order.1 point

-

Never use hand power tools when repairing clocks. You have very little or no control and they can do irreversible damage.1 point

-

Hi Hector Nice job To remove the burr and create an oil sink I personaly use a drill bit in a pin vice for more control the same applies to the burrs posted by Old Hippy best used manually on delicate jobs. Ok in the dremel for milling etc.1 point

-

That's good for a first attempt, always check for end shake and make sure the wheels run free, it's a good idea when all is done to put the wheels between the plates and tighten then check on the running as I said to make sure they run free try it at different angles and if all is well that will be a good job done. If you have a clock movement with lantern pinions that is this type the holes for the wheels are meant to have a loose fitting. That is this type.1 point

-

Hi @Graziano! Honestly, you cheered me up a lot with your answer, thank you. Interesting that I couldn’t find anything about this on internet, maybe because I wouldn’t pay attention to topics about setting hands. As you recommend, the movement holder is ordered. For delivery reasons I’ve taken this one https://www.ebay.com/itm/193909107883 It doesn’t look as good, but I believe it will do. Cheers Jakub1 point

-

I agree with John, even with a set steel spring you might be missing 10-20 degrees of amplitude, but not much more. At WOSTEP they spend a lot of time on barrel inspection*, adjusting, and maintenance. It is very important. But I find that most watchmakers, both professional and amateur, go straight to changing the spring or barrel complete when 49/50 times it's something or combination of things else (one of the combination may well be the spring too of course). I've never seen a watch that was in just decent but worn condition miss 100 degrees from a tired mainspring. Wrong mainspring, yes, if it's 0.02mm thinner than it's supposed to be, or 0.1mm too high and rubbing the lid and barrel bottom. *they also spend a lot of time on adjusting the escapement, which is another thing some folks who have a little more experience go straight to. The issue, or a large part of it, is often in between these two extremes. This is totally an indication of the train freedom, and very much not an indication of mainspring condition. I don't know which caliber of Longines you are working on; some from the mid 20th century have friction spring for the sweep seconds which may cause what you describe. But if you don't have a friction spring, after a few clicks of power the train should spin up, then watching the escape wheel it will reverse. This is from the momentum of the train and the backlash in the gearing. It's normally checked with the train unlubricated; the oil can have just enough damping effect to keep the reversal from occurring, but the train should come to a gradual halt, not in spurts. If this is an actual Longines caliber, they are some of the nicest movements of the last century. And the old Greiner manual that John posted is excellent. Well worth printing out and reading all the way through. Even if it seems like a lot of it is hard to grasp, it will work its way into your thinking and you'll find yourself going back and understanding more each time.1 point

-

I don't know what yours looks like, but the typical design is a pin which is cross drilled at the end, with two fingers held on by a brass or mild steel rivet. Some tools have much simpler drive fingers, just a pin that has been bent 45 degrees, then bent back straight to make two straight sections that are separated by a few millimeters in height. By swiveling this you can get the drive finger into very small and quite large diameter wheels. The original design is handier as the two fingers can often span a single wheel spoke and are more easily adjusted- but generally they won't span a balance arm so it becomes effectively one finger. Replacing one of the fingers would be a pain, definitely doable but a pain. One that note yours should still work. The rivet holding the finger on the pin should be fairly tight, so there's some friction. I'm guessing you don't have a Steiner/Horia, but Horia sells spare parts (they are the only current producer that I know of, and while I haven't used a new one the old ones are the best I've seen). Looks like it's only 20 CHF! They are 1mm on the diameter that fits in the pulley. https://www.horia.ch/en/Products/Pivotinglathe/Accessories/Fork.html1 point

-

This problem comes up with other watches Rolex and Omega for instance. There are several watches from each of these companies where the base movement may run at one frequency others will run at other frequencies. Especially with Rolex unscrupulous sellers will put just about anything in the get the watch out the door claiming it running and not really pay attention to how well it's running. The simplistic of all of this is the balance wheel oscillated at its natural frequency with its hairspring of course the timing machine will pick this up you can regulated absolutely perfectly and If the gear train ratio doesn't match your screwed.1 point

-

If the mainspring barrel wasn't opened, that is the place to start! As statisticians say, "Rare things happen rarely," so it's best to look at the obvious things. There's a good chance that you have an old, "set" mainspring that simply isn't generating any force. Removing it, cleaning the barrel and arbor, and replacing it with a white alloy mainspring might cure what ails this watch. Many things make a small difference, but replacing a tired mainspring is the low-hanging fruit of amplitude.1 point

-

They all moved freely - although I didn't check with just one or two clicks of wind They seemed ok, but I will re-check The mainspring and barrel are the two things I did not open - although you indicate that the amplitude probably hasn't got much to do with this? Again, I didn't check with one or two clicks but it seemed ok - another thing to go back and check Yes, they are fine - removed shock springs and cleaned the endstones and oiled (9010) I dd peg them but probably not very well. Need to do them again. They weren't oiled afterward Probably not as well as I could as I haven't got the right gear yet. Soaked everything except balance and PF in Naptha over night. Agitated it all several times. Two rinses in IPA. PF and balance received same treatment but just for minutes rather than overnight. As far as I could ascertain - it was all oiled reasonably ok. I used 9010 on most pivots. 9415 on the PF exist stone and D5 on centre wheel pinion and high friction parts. All in all, an amateur job but I was trying to be diligent! I will re-check the other things you mentioned and re-peg the PF jewels.1 point

-

I had been doing this for years before realizing the importance this. Good point, and a very important point to start with!1 point

-

The difference between 19800 and 18000 is 1800 beats per hour. That is the difference of 360 seconds or -6 minutes an hour (based on a 18000bph standard) or about -5 minutes 25-30 seconds (based on a 19800bph standard). So you theory that the wrong balance complete was used is very likely. I suspect if a 19800 balance complete was installed you issue would resolve. Let us know how it goes.1 point

-

Hi there Jakub, this is a common problem and fixable .You can either source another seconds hand which will be aftermarket and i'm guessing you don't want to do that , or what you need to do is purchase a hand setting movement holder like this one https://www.ebay.com.au/itm/VTA-S-501-Handsetting-Tool-for-SEIKO-6138-6139-2020-VERSION-Orange-NEW/303671613901?hash=item46b43d19cd:g:VYAAAOSwdy1dymN1 whilst setting the hand you push the reset button to center it at 12 o'clock ,however be very careful not to crack the seconds hand post . The reset button needs to be kept depressed when fitting these to hold the relevant wheels in the correct position. Also have a read of this for 2nd approach https://thewatchbloke.co.uk/2016/11/04/seiko-61389-sweep-hand-issues/1 point

-

Lemania chrono? first attempt to service.? You are a brave man. Welcome to the forum. Regs Joe1 point

-

Along with watchmaker, I am interested too in the movement what is not working, does the balance move, do the gears turn when you move the oscilating weight, do the gear have broken teeth...?1 point

-

Hi again @aoleite Whilst there is a general standardisation that manufacturer and a model indication appears under the balance, the latter aspect varies depending on the whim of the manufacturer. Here is the ID from a 1902: As you can see it has the same 1902/03 you see. My guess in your case is that the addition of a day came sometime down the road and with a large stock of existing general 1902/03 plates AS just added a 1906 stamp underneath to indicate the specific model. That is your model i.e. you specifically have a 1906 but this is based on the 1902 (as is the 1903). This guess is also informed by the fact that I can find an AS with just a 1903 stamp on!: In this case AS just stamped the exact model on ... the assumption to me here being that AS had a large order of 1903s to complete and thus it was viable to change tooling to put the exact model on for that run! The point is don't worry about how those IDs are appearing on your particular movement. A movement can only be one model because of its makeup and we're saying yours is definitely a 1906. But of course that just means changes on the dial side because of the day and date aspect. The bridge/workings side should be the same for any 1906 (don't worry about watch brand markings on rotor or similar); where do you feel you're seeing differences? If it helps here are pictures from a service of a 1906: https://watchguy.co.uk/cgi-bin/library?action=show_photos&wat_id=1267. This might give you the confidence to see what's involved. My gut instinct is there are no pieces missing on your movement by the way. Why would there be unless someone disassembled the movement and missed out a random part on reassembly it. Is that likely? Far more likely the movement just needs a good service. Anyway, what's the current situation? Is it fully wound but not beating? Does it wind but noticeable slip so the mainspring isn't holding power? Have you an air puffer you can gently coax the balance wheel with ... does this oscillate smoothly? If you do take anything apart take lots of pictures. When you're starting out it's easy to think "I'll remember where that goes" but that confidence can fade weeks later when reassembling! ?1 point

-

Hi @aoleite. I'm conscious I'm in danger of just repeating what Joe has already said but noting you're a newcomer let me expand a bit on Joe's information: - Watches usually come in 'families'. So a watch movement will typically have a base model. Additions - auto wind mechanism, day, date and so forth give rise to different model numbers in that family. But typically they are building on a base. - In terms of finding useful information on a movement, and that family information, then the ranfft.de website is a goldmine! - Here's the information for your movement as an example: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&AS_1906. As a 1906 this means a 21600A/h automatic movement with day and date functions. - And because of the family nature of movements it means that in a lot of cases (but not all) things are modular ... the additions just build on the base. It also means that base parts are interchangeable. - It also means if you can't find information on your exact movement number then searching around the family can bring results. Go to YouTube and search for, say, "as 1906 movement" and nothing much useful comes up. ? But now swap that 1906 to 1900 in your search phrase and you'll find a lovely three part video series directly related to your base movement! ?1 point

-

There are already a few threads on here discussing this. Mark also made a video. As you say, size is important. Get the size you think you need, and one size bigger. You can rub down the o.d. if necessary. The press you have with the angular contact dies should do the job if the crystal is the right size. The claw tool is the wrong one for this job. You need to get the crystal lined up with the bezel, and the pressure from the die needs to be equal all around.1 point

-

I believe it's a friction fit, and you'd use a presto type remover, such as the bergeon #3 such as this.... https://www.esslinger.com/bergeon-3-presto-sweep-wheel-remover-5-spoke/?gclid=Cj0KCQjwqYfWBRDPARIsABjQRYynR8V4bP1125CP31SBYBzNXme7zIwq55lXmLnkG_NIwPNH_nrUgY0aAkwxEALw_wcB1 point

-

Thanks guys. Rather than getting new brushes I've just done as suggested and cleaned everything. Now working as good as new - well, as good as a decades old machine anyway. Pity the speed control no longer works very well;). Stephen1 point

-

And as you can guess, none on Ebay in Australia. Ahhh, to live in the colonies........0 points

.jpg.ea9317193077ab5e53994cb0fc5150f7.jpg)