Leaderboard

Popular Content

Showing content with the highest reputation on 01/25/21 in all areas

-

3 points

-

Vostok 2409 Service Walkthrough Disassembly Pictures (Please sort by name in ascending order) Vostok 2409 Service Walkthrough Assembly Pictures (Please sort by name in ascending order) Being able to service the ETA calibre 2824-2 was a long-term goal and a dream when I started servicing and repairing watches some years ago. However, my first “calibre love” was the Vostok 2409; a reliable Soviet/Russian 17 jewels manual workhorse without any complications which has been around since 1970. It is still in production and found in Vostok’s Komandirskie series of watches, by some called the AK-47s of the watch world, together with its bigger brother the Vostok Amphibian dive watch. Modern-day Vostok Amphibians use the automatic Vostok 2415 (w/o date complication) and 2416 (with date complication) calibres, but the Amphibian that I’m servicing in this walkthrough, an Albatross Radio Room, popular among collectors, is from the 1980s and in those days the manual 2409, as well as its predecessor 2209, was commonly used in the Amphibians as well as the Komandirskies. While I was servicing this watch, I noticed that the crystal didn’t fit perfectly in the watch case. Being a serious dive watch originally designed for the Soviet navy this was, of course, unacceptable, so I replaced the crystal and video recorded the event in my “Bergeon No 5500 Crystal Press Review”. For me, the 2409 was a great movement to get started with as it probably is the most affordable movement on the planet, and spare parts are readily available and cost next to nothing. A lost or damaged part never spells financial disaster. Also, eBay offers an abundance of used Vostok watches in decent condition housing this movement for as little as $20 and sometimes less. A brand new Vostok 2409 (www.meranom.com) can be had for as little as $27. Be aware that, almost without exception, the eBay listings always state that these Vostok watches have been serviced, but in my experience they never are. Well, maybe dipped in a can of naphtha, left to dry and then injected with a bit of oil here and there. I’ve seen horrible examples! A somewhat tricky bit about the 2409 is to remove and replace the anti-shock springs. For this, I use a self-made tool made from peg wood. It’s shown in one of the assembly pictures together with a description of how I made it. A very similar tool is demonstrated in this video. Later, as I was working myself through Mark Lovick’s watchrepairlessons.com courses, I trained with the Unitas 6498 pocket watch movement which is the selected movement for the courses. In all honesty, from a learning point, the Unitas 6498 would have been an easier movement to get started with (especially the anti-shock springs), but the tinkering with the Vostok 2409 was a low-cost and fun way to get started and made me better prepared for the courses which answered a bunch of questions and was amazingly instructive. Eventually, I plan to publish a “Vostok 2414 Service Walkthrough”. The 2414 is identical to the 2409 but adds a very uncomplicated date complication. So, if you want a whole lot of fun for next to nothing when it comes to money, there is no other movement I would recommend before the Vostok 24XX movements, and the 2409 is a great starting point if you have a desire to begin tinkering with watches. Be warned though; tinkering may take over a substantial chunk of your life!1 point

-

Just fixed up my old YEMA Jump hour from 1975ish. As shown earlier I polished through the chrome and had to re-plate it, and did a full service on it as well. This bad boy will be going for years to come ? 582951535_Untitled2_1080p.mp41 point

-

1 point

-

1 point

-

1 point

-

Marc is right on the money, spring bar bender. I have a bergeon made one of this, the most useless tool in my bag.?1 point

-

A host of faults in escapement can cause what you are describing. As said broken staff or cracked jewel or end stone, hairspring issues, excess side shakes on any arbour in escapement, inadequate end shake, hairspring ,roller table or balance rim rubbing,depthing ...etc. Save us all a lot of guessing please, routinely remove the balance wheel and end stone to check all under good magnification. As you gain experience, you learn a few tests and tricks to find faults, even then nothing beats visual check under high magnification. Are you sure the oscilator is in beat. Do you know how to check shakes? See if staff pivot stays inside its jewel hole. Good luck.1 point

-

The balance wheel should exibit temperature isochronism, a lot of development over the last hundred+ years to prevent alteration in frequency from temperature. If you're wearing your watch outside your parka (so you can see it) in the arctic, you'll want to get your watch serviced with an oil that's designed for low temperature, it has a different viscosity so it has correct performance at the target temperature range. Cold weather would in theory thicken regular watch oils and slow the watch, you'd have to measure to determine how much (outside the regular variability of your watch)1 point

-

1 point

-

*GASP!* Oh my, indeed! Is that a repeater? I'd almost be afraid to work on that. Good thing it's running. That's a sizable fortune in a small package.1 point

-

1 point

-

And worth a bloody fortune!! (Current value for similar about US$12,000)1 point

-

1 point

-

I took this idea from "canthus" Using a 4-40 tap, I put threads in the nail clippers. Then I printed a knurled knob to attach to a 4-40 screw. I used a knurled threaded insert is the "tightener" adjacent to the clippers. Seems to operate as expected. If I do this again, I will use finer threads (did not have a finer tap on hand). canthus tool post1 point

-

Like the knurled knob. As I said in my post, the lower arm can still flex a bit if squeezed hard against the stop screw. I had in mind to stiffen up the arms to prevent this but not got round to it yet. Bergeon haven't contacted me yet! Soon be available from China no doubt! ??1 point

-

1 point

-

nice to meet you paul you,ll be getting lots of questions from me i just started as a hobby.1 point

-

Thank you Paul for your introduction and welcome to this friendly forum.1 point

-

Hello and welcome to the forum Paul. I am sure your experience will be useful.1 point

-

Hi Mike needle noses will work ok but you don't have the same control, with the tool its micrometer adjustment . If you are going to use needle nose pliers stick somthing over the serrations or file them smooth. Or alternativly make a tool with a slot in it to fit the upper spring block with a longish handle. As far as the wheels are concerned the center wheel that carries the hour wheel etc will have hole in it for the pin to hold the hands on so put that bit through the front plate first and start from there fitting the other wheels as you go. once the back plate is on check the rotation of the wheels and then fit the anchor/pallet. once done then reassemble the wheels on the front plate1 point

-

hi and welcome. and with 30 years experience you may be able to answer a few questuins as well gary1 point

-

Notice the quote above rubbed in jewels or burnished in jewels? Plus look at the color of them those are natural stones they always have flaws in them or can always have. You need to look very carefully at the hole itself is it nice and shiny does the crack extended in such a way that you can see it. Look at the pivots do they have score marks where the crack scored cut into the pivot? What unlikely the answer is the jewels look fine at least from a bearing point of view and the pivots are fine. Then notice the color the jewels which by the way can be any color but these are clear? Modern jewels are a nice pretty intense red color which means you're going to change the look of the watch. Probably nobody cares here if you are restoring something nice it would look really bad. Then I'm attaching an image jewel on the last is a burnished in jewel. Instead have a straight sides like the modern jewel the sides are tapered. You can actually modify relatively easy modern jewels to that shape. But you require additional tools to do the burnishing and sometimes it breaks off no matter how careful you are. Or you can replace it with the modern jewel which is what the picture showing.. But you have to open up the whole large enough so it's nice and smooth for the modern jewel. Which means usually there physically bigger than what was there before. Then in addition to all of that the watch is old enough that the whole sizes might not correspond to standard jewel slices of today perhaps. Then have you looked up the cost of those tools is this watch worth it. Then the tool at your link I have the Swiss version is an outstanding tool. Personally I think it's almost a must have for doing jewels as it makes it really easy to push them get them exactly where they have to be. But you still have a problem? The problem is modern jewels require a very specific hole size. That's usually made by a tool from the same company that makes the jewels and that means basically you have to have both. Normally what most people do is buy a tool like at this link. Notice the price looks quite reasonable right now check back when the auctions completed it's going to be quite a bit higher as a guess https://www.ebay.co.uk/itm/Seitz-Jeweling-Set-for-Watchmaker-Swiss/373424385098 To understand the tool above which looks in a really outstanding condition normally log a little bits and pieces go missing with time or whenever there. The most important aspect of this tool is the reamers which I circled in the image. Then to understand the tool I've also attached the PDF manual for it. Basically wouldn't need the tool above if you have this one. I just think the tool above is much nicer for adjusting jewels. seitz BOOK.pdf1 point

-

I think it may be more complicated than you think (or less depending on your perspective) as those appear to be rubbed in jewels rather than friction fit.1 point

-

If you're really stuck try installing each wheel in isolation and check that each spins freely with no more than a puff of air from a blower. If they do then build the train up one wheel at a time, testing freedom with the blower after each wheel. If you get to the point where the complete train is installed up to and including the escape wheel, then with the pallet fork and click out you should be able to spin the whole train (including the M/S barrel) in both directions using a puff of air on the escape wheel. Next install the click and wind just one or two clicks of power into the M/S, no more. The train should spin freely, and if you're lucky you should see the escape wheel reverse maybe a half turn before it stops. This systematic approach should help to identify exactly where in the train the losses are occurring, if that is where the problem lies. Before you install the M/S into the barrel you should try installing the arbor and the lid (empty barrel) and check the end and side shake of the arbor in the barrel. The barrel should spin freely on the arbor, but with minimal end and side shake, any excess of which would indicate excessive wear. If you get to this point and the M/S is correct and in good order then it's fairly safe to assume that the excessive power loss is associated with the pallet (check pivots which should be run dry and undamaged, pallet stones which should be spotless and not scored, and lubrication), or with the balance pivots. A quick check for losses in the balance can be made by installing the balance without the pallet fork. From its rest position carefully turn the balance wheel through about 300 degrees of rotation and then release it. Time how long it takes to come to a complete rest, you should be looking at times in the order of two to three minutes or more, and its decrease in amplitude should be gradual and consistent until it stops. If it comes to a sudden stop or comes to rest in much less than a couple of minutes then end shakes, side shakes, and condition of jewels and pivots need checking. If all the above is good and the problem persists then it's just possible that there is an issue with the escapement geometry (position of banking, position of pallet jewels, height of engagement between the pallet stones and the escape wheel teeth, engagement of impulse pin with pallet fork, roller and guard pin, etc) however, these are things that would have been sufficiently correct for the movement to have performed to factory specs when it was new, and which don't normally go out of adjustment unless someone else has been playing with them, which is a whole other can of worms.1 point

-

Those airbrush results look great! what kind of paint are you using? @Tudor, when you are tinting lume with coffee, is that with water-based PVA binder? What lume tints work well with solvent-based mediums?1 point

-

In case your measured diameter will be Ø145, not Ø125, let me know and I will provide another part number for the staff (way less expensive than 35 EUR)1 point

-

IT certainly is I did in the past use jewelers pliers with fine jaws but the control was not good with this tool you can get micrometer adjustment, would use nothing else to adjust these clocks.1 point

-

1 point

-

Part 3 is a sort of redemption, or at least some lessons learned. The donor arrived about six weeks later (thank you Covid) and I quickly transferred the balance complete. The wavy traces quickly returned. So I stripped the movement again, paying close attention to the barrel arbor bearings. Looking closely, I could see that the barrel had actually been scraping the bottom of the barrel bridge. Manipulating the barrel with the bridge on and the train removed, I could also see that, under torque, the barrel would foul both the bridge and possibly the mainplate. Swapping in the donor movement bridge, the wavy traces continued. The free running of the train was okay with the pallets removed, but, turning my attention to the mainplate barrel arbor bushing, I could see this was slightly out of round. Under torque, the barrel would still hit the bridge. So that was it. I could not close the barrel arbor bearing hole, so after repeated reassemblies and inspections, I became convinced that the original movement was a goner. Thankfully, I had the donor, which I decided to service and install in the watch. In truth, the donor looked to have very little wear - I am unsure what kielbosched it in the first place. I serviced the donor and prepared to install the balance complete. Here tragedy struck again, as it appears that one of the problems in the donor was that the regulator arm was improperly seated in the balance cock, or the pins were just too short. Closing the regulator pins, the hairspring caught the closing arm and became kinked in the terminal curve. Here I finally did Mark's video justice, carefully massaging the hairspring until it was again smooth throughout the curve. A final hurdle: the balance on the donor movement had no endshake - none at all. Having watched Mark's video on unexpected endshake problems, I looked for a shim under the balance cock. Sure enough, Minsk Watch Factory had indeed made a shim under the cock, near the screw, which I had flattened as I had rubbed the tarnished mainplate with pegwood. So I got my screwdriver, and made a painful jab into my newly-cleaned donor movement. Reinstalling the cock, it ran strongly! Hurrah. Here are the results, positive and negative. On the positive, the watch runs strongly and relatively straight in all positions. There is also relatively little positional error (maybe 5-10 seconds a day, but I can live with that). But here's the heartbreaking thing. This donor, this seemingly babied donor with no major signs of wear, has exactly the same problem of wavy traces and variable amplitude as the original movement! It's less pronounced, sure, but it's there - a 15-20 degree variability in amplitude at seemingly random intervals, with the associated wavy lines. A reflection on that below. Battle-ready once again, but not without difficulty. Another charm(?) of the Luch is that the dial does not sit flush with the movement, so you need to be extremely careful when seating the hands to make sure they won't hit the dial. And back on my wrist, at long last. So, a summary. Why should you, an absolute beginner, try to diagnose and fix a battered Russian watch that hasn't been opened since Gorbachev? Well, first, you won't break the bank. These are plentiful, and if you get a plain dial they are cheap as chips. Second, you will use a lot of Mark's lessons. Not just chapter 2, but 3 as well. I watched every single video repeatedly, and tried to apply them all. If not for his video on barrel arbor bearing wear, I would never have found the problem. Last, I practiced a lot - a lot - of skills. I'm still bad, but getting this Luch back on my wrist has made me feel like I'm on the road to being a real watchmaker, whatever that means. And why should you avoid articles like this? One reason: poor, inconsistent build quality. From the shim, to the regulator pins of incorrect length, to the badly-seated dial, it doesn't take a George Daniels to see that these things were absolutely slapped together. This makes them hard to work on and diagnose. And even when you find a good donor that was seemingly retired after only a few years in service, you may find that it has the same fundamental problems as the donor you thought was deeply, unusually defective. So just live with it, and know when good is good enough. Don't make perfect the enemy of the acceptable, because they sure didn't when they built these things in the first place. So that's it. If you're exceptionally patient or you didn't have anything better to do tonight, thanks for reading this far. And thanks to the people on this forum for helping me out with this project - I am very glad I joined. Cheers!1 point

-

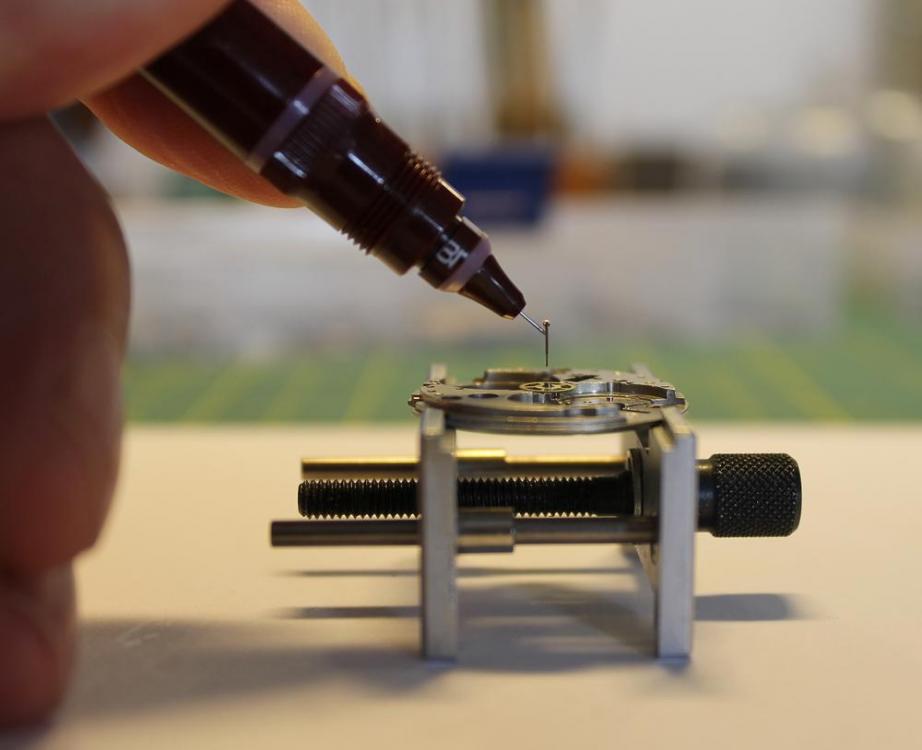

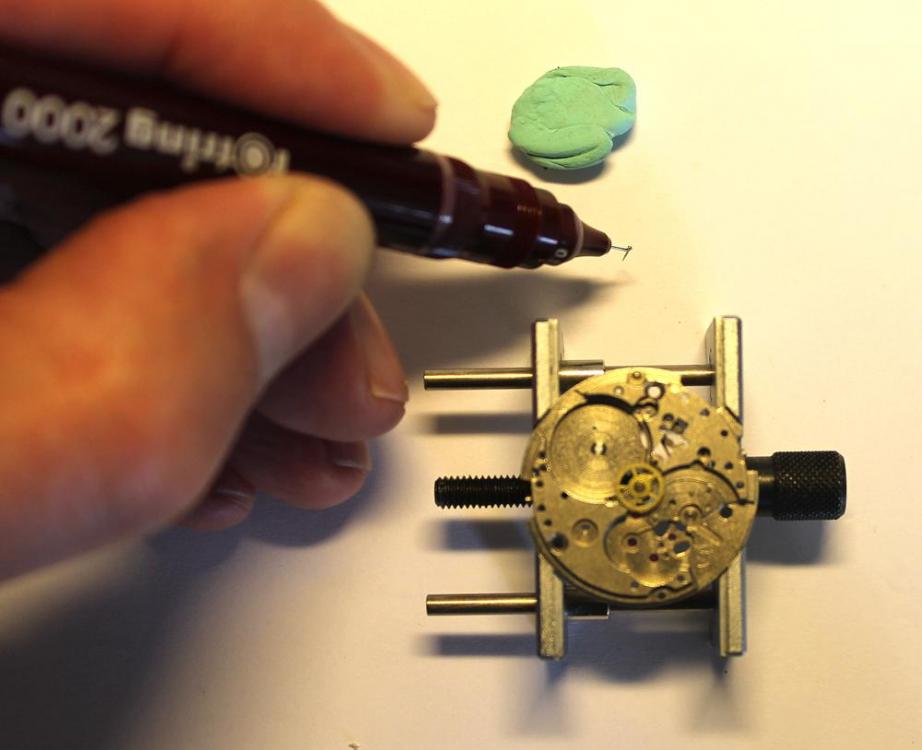

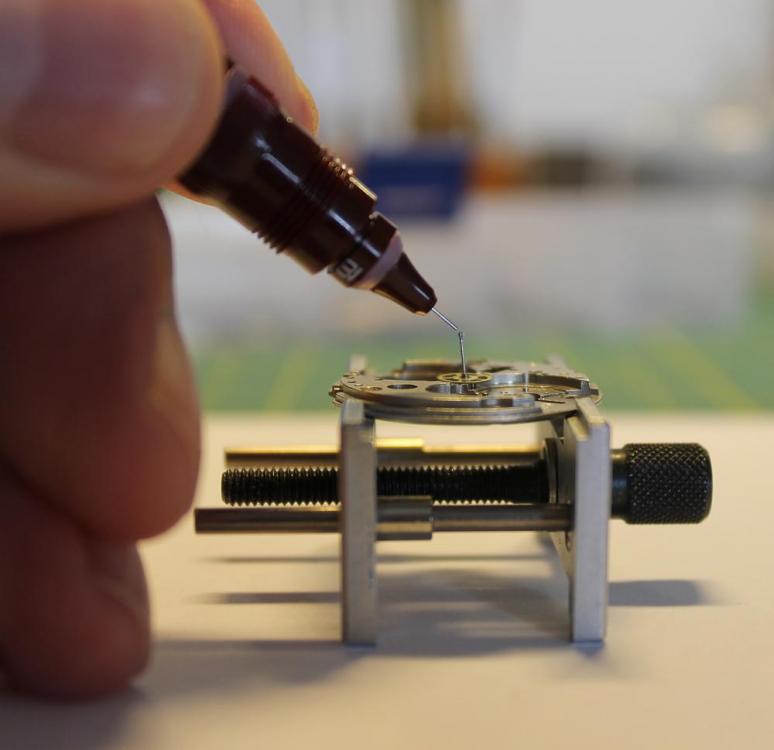

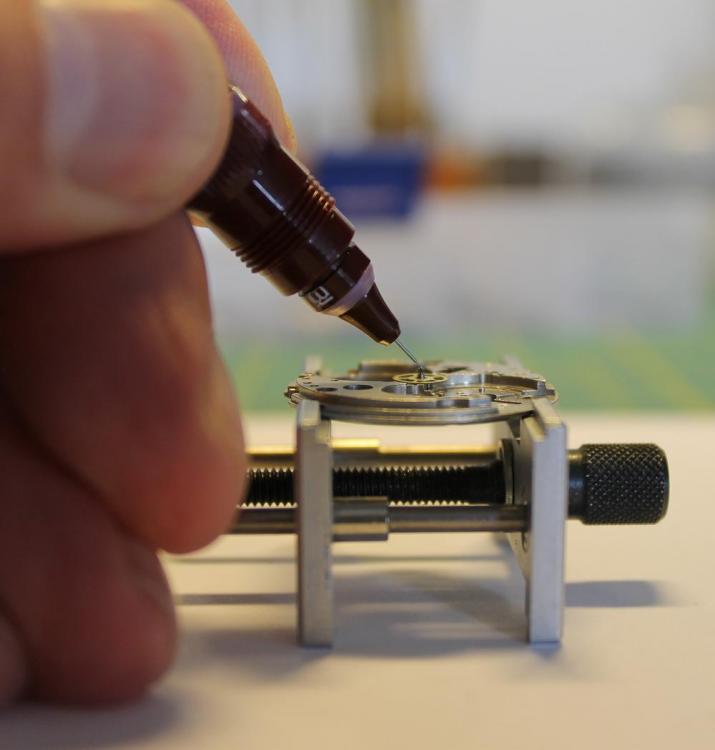

There are many ways leading to Rome and whether to lubricate or not can be up for debate I normally do lubricate the seconds pinion and indirectly the dog-leg leaf-spring. For this job I'm using a 0.13mm new, but old-fashion Rotring pen with some light oil in the reservoir. I'm not using Moebius, but Dr.Tillwich 1-3 oil. Just for the purpose of demonstration I took an empty 2409 main plate with the center-wheel inserted. Normally the small tip of the Rotring pen is wet enough, due to the capillary working of the oil, to pick up the seconds pinion; You can run the pen past the pinion and this will lubricate the pinion, if ever so slightly. I than insert the pinion and push it carefully down the shaft of the center-wheel. The gently push on top of the seconds-pinion will lubricate the top of the pinion ..... and therefor indirectly the tip of dog-leg leaf spring. The dog-leg leaf-spring can cause a variety of problems such as irregular amplitude, low amplitude, "dropping" second-hand when tilting the watch or a jittering second-hand. It needs therefore to be adjusted such that it just touches the top of the seconds-hand pinion, easy to be lift up but enough "push" to provide just enough friction to let the seconds-hand to run smoothly. Anyway, it's up to the watch repairer to decide how & what .... Just my two cents1 point