Leaderboard

Popular Content

Showing content with the highest reputation on 11/10/20 in all areas

-

Well I've started on my knocked up poise tool that seems to be going quite well. I think I have identified at least two heavy spots. I think the blades might be slightly magnetised as the balance can get pulled towards the blades, so I will address that later before I start taking any weight of the balance. VID_20201110_085935368.mp43 points

-

My recent flea market trip yield this great 'Oriental Watch'. I is a housed in a 3 piece case and has a nice jeweled movement inside. After a little bit of work it is running quite well. I cannot find much information on it other than there is an Oriental Watch Ltd. located in Hong Kong. My thinking is this was an in store product sold sometime back in the 1940's. Anyone every see or hear of this maker?2 points

-

That is a lot of coding. If you code correctly in the first place, only one monitor needed:)2 points

-

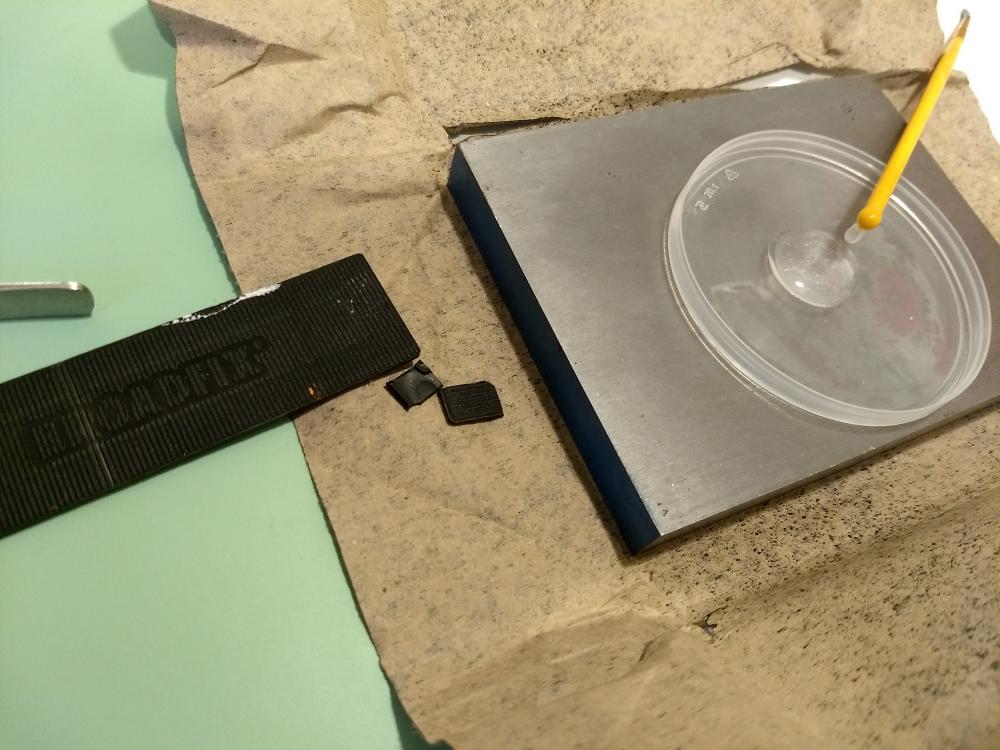

So, the super glue with a carriage bolt nut worked amazingly well. I used a carriage bolt nut because of the large surface area on the flat bottom. Acetone removed the super glue in about 30 minutes. Thank you for your brilliant help!2 points

-

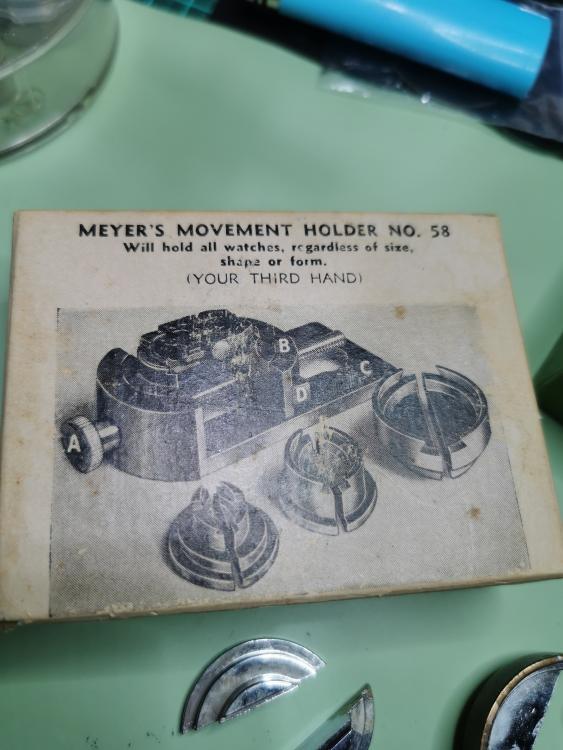

Hi all, I have been using this Meyers movement holder no58 that I perchased here in Australia for a while now and I must say, they don't make things like they use to. It's easy to set up and it holds all movements regardless of sizes, shapes or form. I have a Seiko 6309 plate in there that I just jeweled the barrel arbor port in there and the other movement plate is an omega 485 ladies movement plate. It has 4 different clamps that slide in and a quick release button where my finger is. It does not rock or come loose. The movements have no sharp corners intruding into the plate because the clamps are rounded. I have about 10 different movement holders including bergeon and this beats all hands down. What do you think?1 point

-

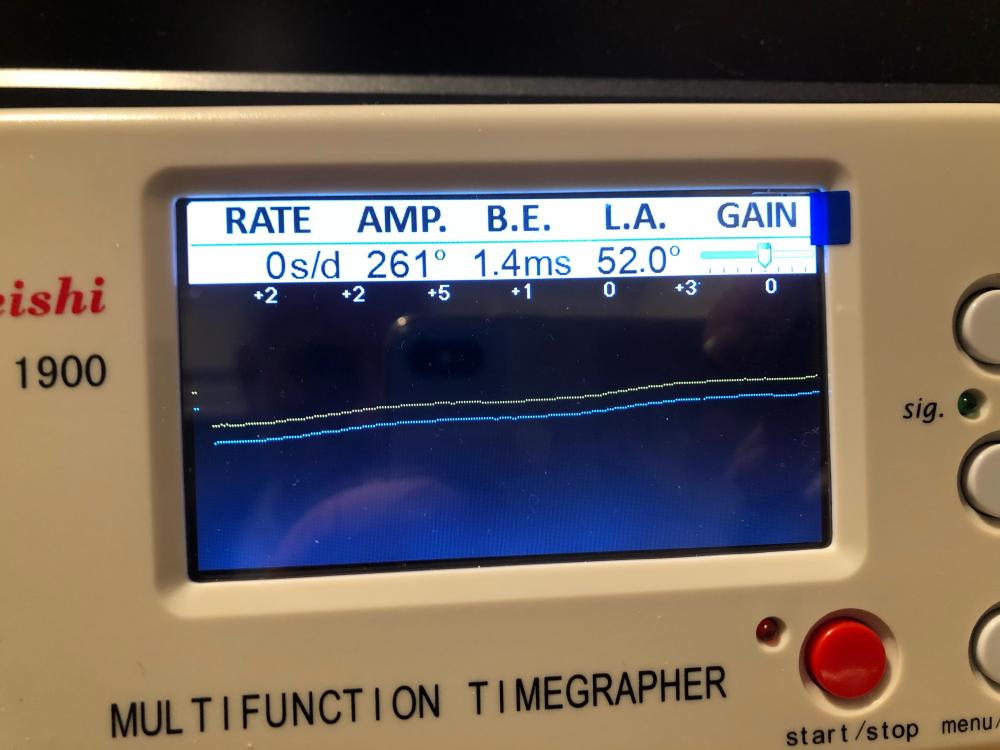

Well, I did some static poising tonight and I made some progress with that, taking out some heavy spots. Rate overall has increased with the lightened balance. However...... the amplitude in vertical positions is still dropping off the face of a cliff, down to 190 degrees (-80 SPD) from 260 degrees (2 SPD) in horizontal. One thing I have noticed is that horizontal amplitude quickly drops from 270 to 250 after full wind, within a space of about 20 seconds. Scratching my head now.1 point

-

Well, lets see the drawings that do exist and go from there. I can certainly make these by hand, but I'm not making 40 of them that way...1 point

-

I was thinking about this a few months ago and produced some (rough) drawings of an adjustable tool. A selection of barrels sizes can be used with a selection of arbor sizes (and directions) to create a set that would be universal. You would only need one handle and one winder also to keep manufacturing down. I'd be happy to collaborate on a project.1 point

-

Hi This is the machine I build it uses a 12v battery charger as a supply because it has an over current feature, Its quite simple also attached are examples of the solder joint and note the dial face is unmarked. So to do a quality job does not need a degree in Neuclear science. Its just a simple adeptation of Dirk Fassbenders machins inspire by the one in Wesley R Doors book on Rettrofitting. As mentioned before cost £25. and a few hours work.1 point

-

Not much challenge in that, now is there... (from the engineer that can't see the top of his desk)1 point

-

Thanks for the comment! I've found similar things in my experiments since this post, and I also really like the staking set idea. I see that you're a new member as well, so welcome to the forum! I hope that it's as rewarding for you as it has been for many of us here. Great to have you aboard.1 point

-

So there nothing to do with horology. A funny place to keep such things. I would have thought you are using valuable space and it makes it easier to misplace parts.1 point

-

1 point

-

I Have an Orion 250i welder and have briefly looked into this. I used some old tag water damaged dials. Using it in pulse mode, i found it did more harm than good so i put it down to the zinc content. i plan to try using tack mode with the below. If i get time, i plan to dig out my old staking set and replace the punch guide with a delrin or similar non conductive one and my idea is to end up with a holed type punch (positive) that can clamp the foot into and the base (negative) that i can make attach a clamp for the back of the dial. Also, the beauty of using a staking set is it has centre punch for centering exactly where it was originally. One thing with the Orion, the power settings are precise and consistant and that should help with adjusting for different dial thicknesses. I'm thinking the way forward is using tack mode and solder, with which type i don't know but i think in paste form will be easier. i still have a few dials to experiment on.1 point

-

Only 2, amateur. My home office setup has 4. For work I use 1 for my code, 1 for what I'm coding, 1 has the log messages and the last is used as overflow if I need to reference code from another project or watch youtube!1 point

-

I set the inner( female) stem with its slot vertical, set the males stem vertical too so as to fit into female slot, as you lower the movement over it. Another common approach is to go by the feel. set the inner vertical insert the outer into the tube, try to feel where the two mate, push in. ( sorry how else you guys say this)1 point

-

I just checked and that heavy spot indicated in the video is below the balance pivot when the watch is midway between PD and PL (The two positions with the equally slowest rate, -65). I think that's expected and it's starting to make sense.1 point

-

while static poising in the watch is not good dynamic poising is. So providing you are not trying to adjust for watch that really should be statically poise and just doing the final poise or you're really obsessed with timekeeping then you can go with dynamic poising. But I found typically with pocket watches statically poising gets me so closer is no point in doing dynamic poising.1 point

-

Like Tudor suggests, first you have to turn the crown in the winding direction to take pressure off the click. Then you should be able to release it.1 point

-

1 point

-

1 point

-

Given that the entire 404 concept was your doing, I'm fairly certain you own the largest collection of 404 denizens, and now likely the single most valuable 404 score, I think you get the crown. And the scepter. And the blingy egg thing. I need to start paying closer attention to those listings with blurry photos!1 point

-

attempting to use the watch as a substitution for poising tool is very bad. while casually it might seem like the right thing balance wheel resting on the poising tool has almost 0 friction as in a watch there's going to be more friction. I'm still in favor of you doing static poising just because it's easy to do as long as you don't get carried away with your drill and turn your balance wheel and the Swiss cheese there isn't going to be much harm. But if you don't have a poising tool. Is something else we can do the only reason I did not recommend it is because I still think you're having an issue and it's not a poising issue so using this next method the fixed an issue that's not a poising issue is going to have problems there's another way to poise a watch or verify that the watch is poised that's something called dynamic poising. This is where the watch is all back together the balance wheels in the watch you adjust the amplitude to about 180° you want it low ideally because everything gets magnified as the amplitude goes down. Then you time the watch in eight pendant or crown positions. some people only do for positions but it's much better if you would actually do eight positions. Then you write all the numbers down and we might build get a clue whether you really have a poising issue or not.1 point

-

I guess we will not know until I try poising. I could in theory adjust the rate by say +50 seconds and that would give us approx +55 DU/DD, +15 PU/PR, -15 PD/PL. I tried the balance on its own by the way and couldn't really identify a heavy spot but it wouldn't spin for very long in a vertical sense. In horizontal it would spin for a long time.1 point

-

I think there is some confusion here. All of the pendant positions are slower than the dial positions. A “heavy spot” corresponds with a relatively speaking “light spot” on the opposite side. None of the other pendant positions show a faster rate. There is a 60 - 70 degree drop in the pendant positions which in my opinion is not simply the result of a poising issue as the positional variation is not horrendous.1 point

-

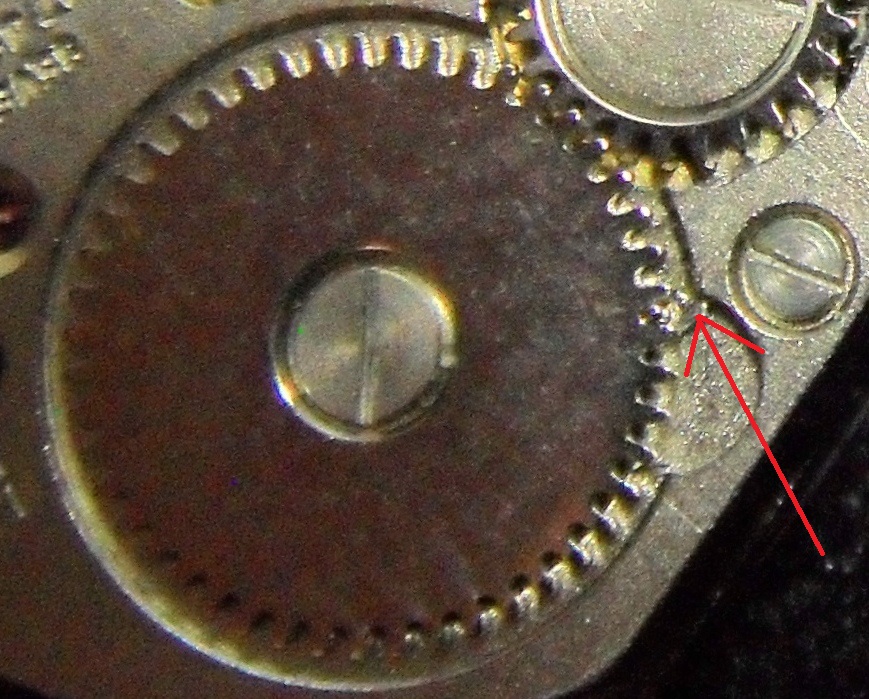

Looks like a large relief cut for the click- I would guess it swings into that cleared area. If you try to wind it, it should release the tension on the click, which can then be moved out of the tooth. Probably a pin in a hole under the wheel, so you can't remove the click all together either... I guess whatever you do, go slowly and carefully!1 point

-

Get yourself a tiny end mil, and a dividing head, and place some pocket dots around the dial you fill with lume material (perhaps of colors other than white too) Actually, maybe you can drill through the Fordite before you glue it up, although that may complicate the alignment process.. How about some thin glove leather with branded in hour markers?1 point

-

As I said, the little pocket watch was what caught my eye. It is obviously far from perfect, but it does have a complete balance (with a slight hairspring issue) and it does actually run.. for a short while, so It has potential. It was filthy, gummed up with old oil and dirt, the hands were bent and the dial has a tiny barely visible crack, but following a deep clean of the case and dial, a partial straightening of the hands, which I'm still not satisfied with, and a quick clean of the mechanism, it is starting to look like it may have some life left in it. It is stamped inside the lid with K14, so there is a chance that it might have a 14K gold case. The inner mechanism protector cover is stamped Cuivre (copper/brass), and the outer does have the appearance of gold (which doesn't show up so well on the camera). Plated or rolled gold almost invariably ends up with obvious spots where wear causes the base metal to show through, and this has none of those. It does have some obvious hairline scratches inside, to the metal is presumably relatively soft. I have no idea what the caliber is (can anybody identify it?), nor do I know where I'm going to find a crown and stem for it, but I'll have a root through my extensive junk pile stock of spares for the stem, and if I find something suitable, I'll see if I can get it going, and then track down a crown. Presumably if the case really is 14K then I'll need to at least find a matching plated one. If nothing else, it does add a bit of late Victorian or Georgian bling to the 404 club.1 point

-

Use your browser's translate function to read this informative German article on Tenor Dorly: https://uhrforum.de/threads/die-retrofuturistische-difor-automatique-1973-und-die-scheibenmechanik-des-td-1393.308337/1 point

-

Hi have a look ar http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&69&2uswk&TD_1393 contains a bit of infornmation.1 point

-

Hi! Haven't had much time for watchmaking practice, for way to long time!! But finally!!! Well almost done with the st 96 project. First started. And first finished. And, im very pleased! I have to say, it was very frustrating at times. Many small issues. Most done by my own "fine" work.. ? I did source a replacement balance. Or, I got offered by a gentleman. So, I did install it. But the watch did not run very clean at all. With low aptitude. Was a bit concerned, to say at least. But I managed to get it to work reasonable on the timegrapgher. So I decided to but the cannon pinion back, diel and case it. Well.. It isn't going to be easy, is it? ? Somehow, I do not really now how. The tub shaft on the center wheel. Was wrong.. I have no clue. But the cannon pinion was rattling loose fit.. When I realized. Well. some cussing did happen.. ? So, thank god. There is a donor movment to rob parts from. Bit disheartening to have to strip it back again..But decided I will improve the running quality, as much as possible. Well, at my skill level anyway.. ? That had to be the goal. And the possibility to "play" with my new ultrasonic cleaner. So, stripped it down again. Inspected it all carefully. But could not see any obvious problem. Put the wheel train and bridges in the sonic boom cleaner (sounds funnier, as an old aviation techie) So far, I have no real Watch cleaning fluid. But tried som 3M industrial cleaning fluid. Dunked a bit in a jar. And set the heater to 50 Celsius. And let it sit for 20 minutes. Rinced it carefully in isopropanol. Have to say, everything came out cleaner and shinier than before. Tried to clean the jewels with peg wood. But..he.. How do you guys get that done? Tried to sharpen as fine tip as humanly possible. But couldn't get it tru the jewels.. Assembly went well. Except the train bridge. Took a long time to get the timing wheel to align. But when that was fixed. Everything whent fine.. Now, having a beer, watching the timegrapher ticking a way with a slow variation of +- 4 seconds average. With that, Im a very happy camper!! ? Casing, dial and hands. Is tomorrows project. And BIG! thank you to all who has cheered on, answered my nooby question. HSL has to be mentioned extra nice ty! As he as donated a spare movment. Extra screws.. (don't ask.. ? ) Cheers all! And I wish you all a nice weekend with no pings! ?1 point

-

1 point

-

Mark mentioned in one of his videos that this pops up from time to time - specifically with Seiko. I think maybe the Swiss are still mad at Seiko for the whole quartz crisis thing. Lol. But in all seriousness, Mark indicated that sometimes he'll mix and match an arbor from one winder-body with another but that doing so is less than ideal because the shaft diameter won't be right and the operation will be sub-optimal at best. If I found this to be the case I would probably either turn a custom winder-body out of a chunk of brass bar, or, depending upon the variance, use something to shim the arbor so it fit the body better. Depending upon the application it's amazing how good of an action you can get using polyimide tape to shim a rod so it fits a bore better. I have a Chinese hand setting press. It's actually made pretty well but the one part that was sloppier than I'd like was the fit of the pusher to the bore it slides in. I used a bit of polyimide tape on the rod and now it fits the bore great, but still slides smoothly (and now stays nice and straight through the bore).1 point

-

I started a new topic because this isn't any ordinary Timex...this one actually has jewels and 21 of them, lol. Also to my surprise, I noticed a little cote de geneve in there, wow, just wow...Apparently, Timex felt the need to add this but NOT use screws so I can service it the right way? No words there, haha. The following pictures show a 1969 21 Jewel Manual Wind before and after the watchpocolipse;) Man, did this one need a lot of work. The stem was literally rusted out towards the crown and it was wound tight. This one took a longer bath than the others and the "swish" was more aggressive;) In the end, I ended up with another beautiful watch and it too keeps very good time! (+/- 9 sec day so far) In between projects, I serviced a Helbros as well....will post it up soon.1 point

-

1 point