Leaderboard

Popular Content

Showing content with the highest reputation on 10/18/20 in all areas

-

5 points

-

You definitely need one to work on movements, much more than an expensive balance tack, which main function is to distort the hairspring. There are parameter and visual information as discussed here so many times, than no application based on the embedded microphone will ever show.2 points

-

Out of curiosity did the professional watchmaker return the watch running 30 minutes a day fast? Was there a reason for cleaning the balance wheel? Did it look like it was having a problem? Then I don't suppose you have a timing machine? Even though if you're running that fast the typical timing machine is not going to work. It would've been nice to have one more picture Of the watch without the balance wheel in the watch. Another source of noise problems could be the screws holding the pallet fork bridge in place. Then thank you for the pictures you didn't give us as they reveal something interesting. Did you notice the roller jewel it is in alignment with the balance arms? That makes it insanely easy to put this watch in beat. If the first picture is the balance wheel of no power the arm of the balance wheel should be over the pallet fork jewel and it's not by quite a bit. Then as pointed out by rodabod It's usually best to look at the balance wheel in the watch as that is usually where the problem is.2 points

-

I have only ever used glue with flat acrylic crystals. Never needed it with domed and never had any issues with water ingress or popping out. A correctly sized crystal will fit securely without rotating, but it does need to be a tight fit which is why I asked about the type of press you used. I have always struggled to get sufficient compression using a claw type tool, and if you simply push the crystal in with force from above you will have difficulty unless it is a tension ring crystal which can only be installed that way. The best way to install a standard acrylic crystal (and I believe the way they were designed to be installed) is to apply a compressive force between the centre of the underside and the perimeter of the top of the crystal. This effectively increases the doming of the crystal and reduces the circumference of the skirt. Apply enough pressure and crystal will fit straight into the rebate without any force. Then when you release the pressure the crystal resumes its shape and firmly grips the case. There are both plier presses and screw operated presses designed to do this. I use a Robur screw press which is excellent.2 points

-

To learn. Bring the work up to eye level, or sit lower. Have your forearms supported on the bench. Look at the pinions by the side with an eye piece that does not require to get too close. You will see which ones are sloped, gently bring them to the hole with fine tweezers or a toothpick. That may need to be done in a certain order. Eventually they all will go in.2 points

-

I've had this clock about 2 Years and have only just got round to servicing it, the earliest service mark I found was on the reverse of the dial and dated oct 1913, its a very compact little bracket clock and stands just over 14 inches high, its a triple fusee with the going train fusee cone reversed so that all three cones fit in a small space, the going train has maintaining power, and the escapement is a anchor, I have two other double fusee clocks with the exact same engraved dials both those are very similar and make me think they are from the same manufacturer, but all are unsigned. From what I have read it is very difficult to distinguish English or German manufacture from this period, and a lot of English makers had given up the Ghost and bought in German movements to recase for domestic sale. What are the things to look out for that would make you say that's English or German ?1 point

-

Since I have no interest in woman watches (my wrist is to big) I thought I would give some non working ones away. There is a Vulcain, Timex, 3 Seikos, 2 Walthams , a Bulova, and an Elgin. I'll even pay the shipping. (U.S. only please) DM me with your name and in a week I'll put the names on a slip of paper and the first one my dog eats gets the watches. If you are new and for whatever reason you can't afford practice watches DM me and I can send you some cheep watches to practice on. I may be able to find some old tools for you also.1 point

-

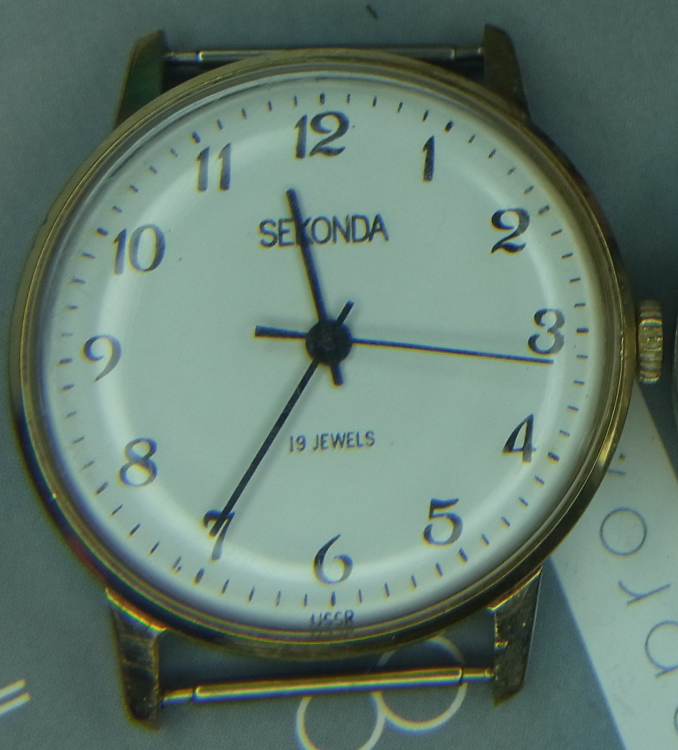

A little bit of USSR era quartz magic. A rather similar companion piece to the uncomplaining horse lineament and baby oil treated 19 jewel number I am currently experimenting on. Almost certainly jewelled, and for a whopping 99p you can't complain really. OK maybe you can... the strap is terrible, but cleaned up and placed on a simple brown leather one I think it will look pretty good.1 point

-

1 point

-

You first remove the small clip holding it in place, the clip can be seen at page 12, part number 35 in the attached PDF. CT_955132_FDE_491861_10.pdf. Then you just twist and lift.1 point

-

I was at the art supply store recently (picking up a huge work mat and rolled paper sold for smearing pastels that works well for cleaning jewels n stuff for a lot less than “watch” supplies) I saw purified linseed oil, purified almond oil, and others, used for preparing oil paints. And not terribly expensive. It got me thinking since I was about to drop a Hondo on teeny tiny vials of the finest oils extracted from the worlds deadliest snakes of Switzerland. SSO (Swiss Snake Oil) inbound...1 point

-

Should then go back there for the watchmaker then. Please post a timegrapher picture.1 point

-

.... basically, I would not recommend manipulating the spring based on the limited information available so far.1 point

-

It’s hard to judge the coil spacing when a balance is sitting loosely, resting on a balance cock. It needs to be inspected under high magnification and lots of light while installed.1 point

-

1 point

-

Hi Khan, Coil looks too close to stud so it can hit the stud upon expansion, judging by the picture, the free section of terminal curve( between regulator arm and stud) is too close to coil too. Center the coil.1 point

-

0 points