Leaderboard

Popular Content

Showing content with the highest reputation on 10/13/20 in all areas

-

Hi Ammar, I preume you are talking about the jewel assembly, no shock protection just end stones. Its easy if you go about it the right way. 1- Unscrew stud screw, push on stud a little to make sure its loose enough to come out, all while the cock is still on mainplate. 2- Take balalnce& cock assembly out, flip it over and lay on hard flat surface with the balance on top, turn the boot to release the hairspring, You can flip the cock over again so balance would be dangling down, hold the assembly about a CM or less above bench, push the stud out, balance falls out, one CM drop would not damage the hairspring,specially if dropped on tissue paper. There are two little screws holding the end stone plate, break easy, I soak the cock assembly in coca-cold over two nights, coke will penertate the screw thread so screws can be remove with incredible ease. Dress a driver blade for perfect fit into slit of the two screws. This method is prefered since you can check the jewel and end stone as well as good access to peg. Good luck.2 points

-

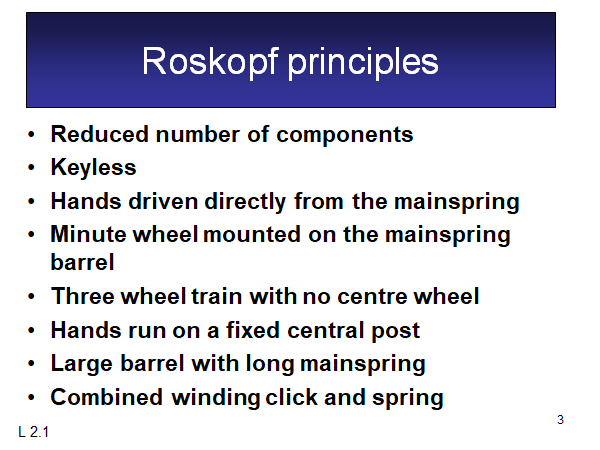

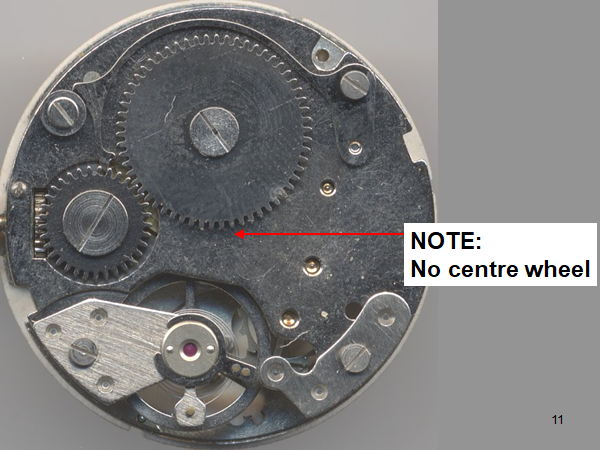

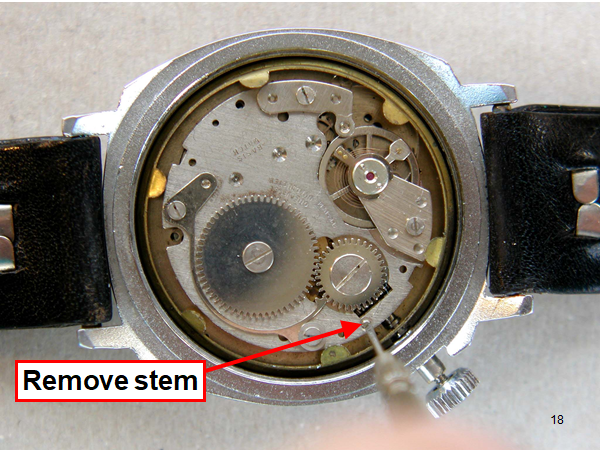

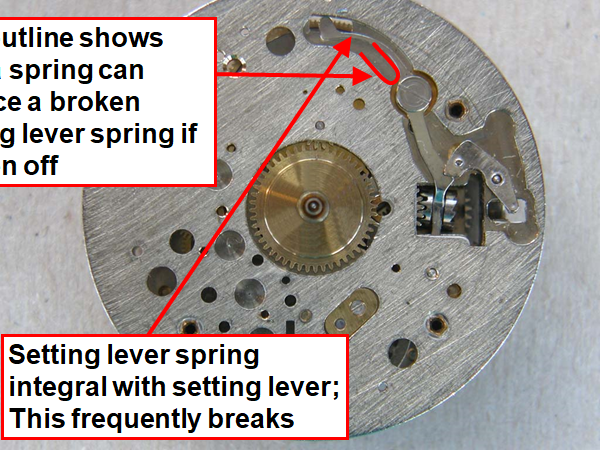

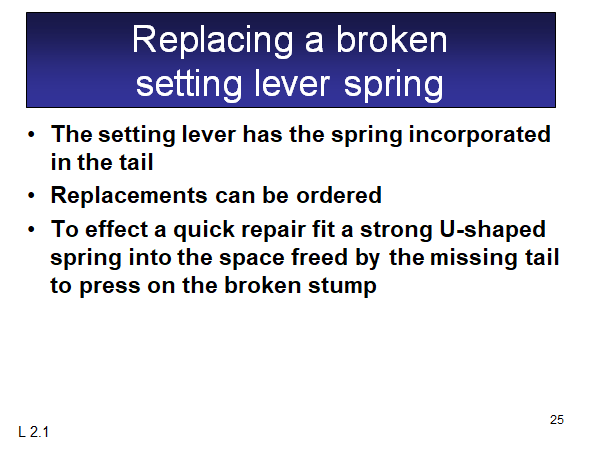

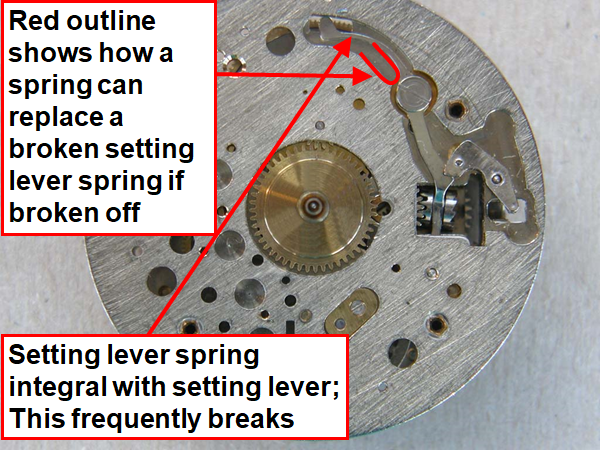

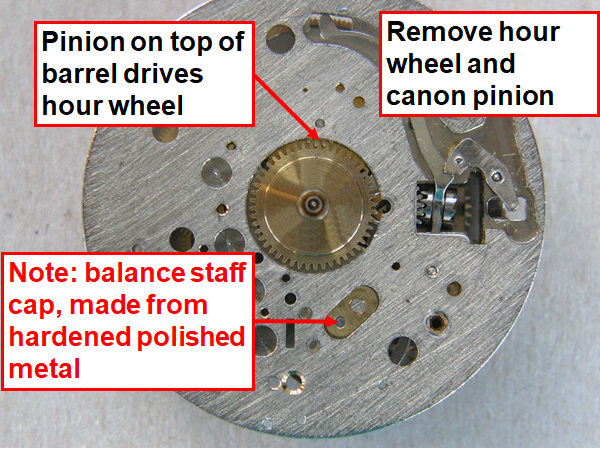

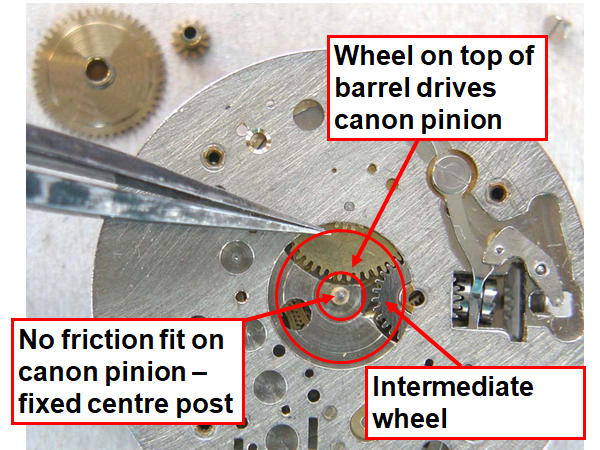

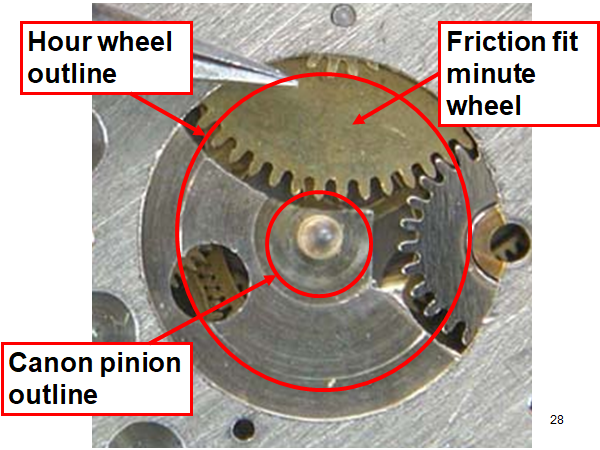

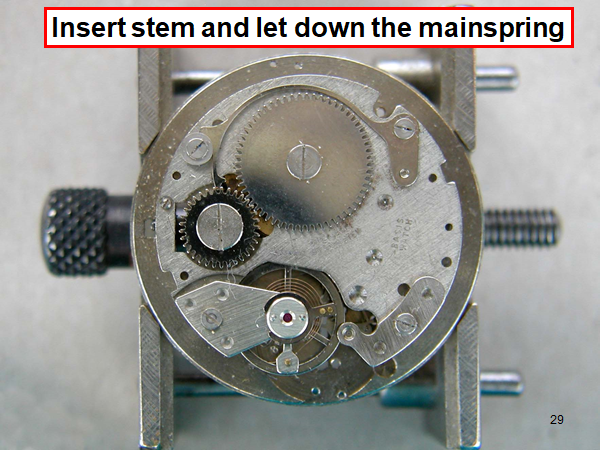

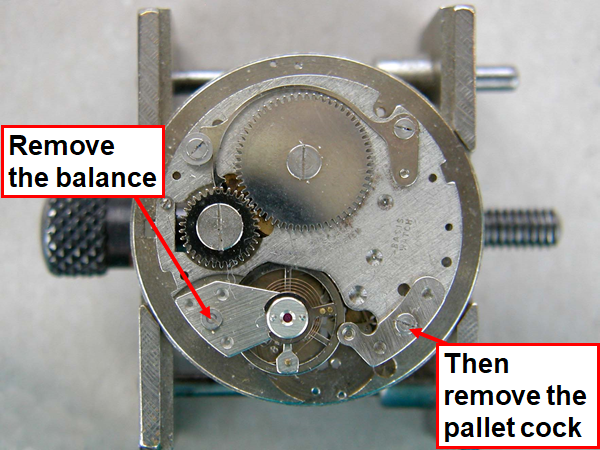

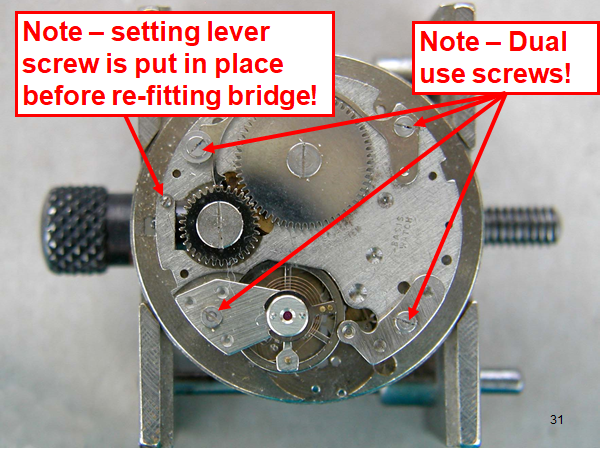

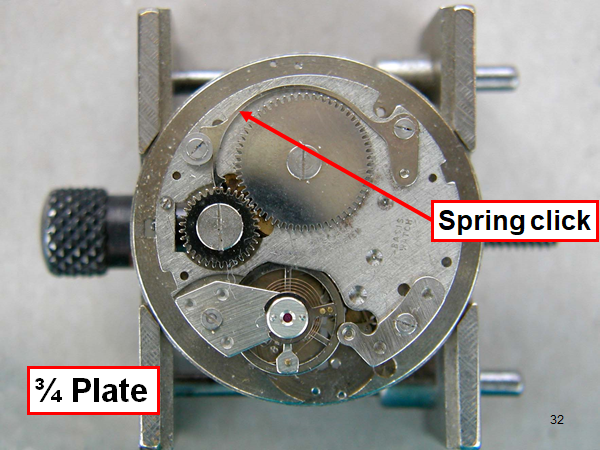

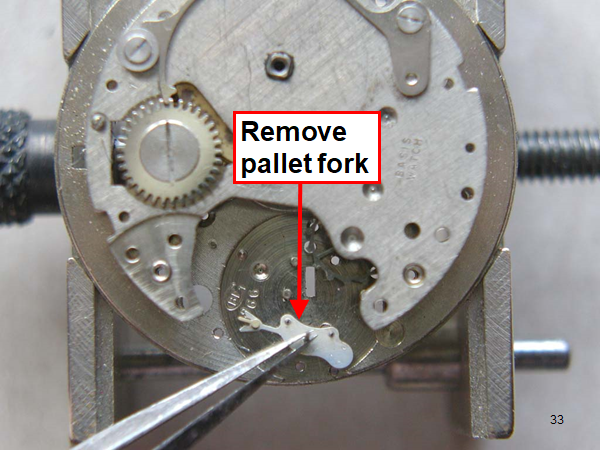

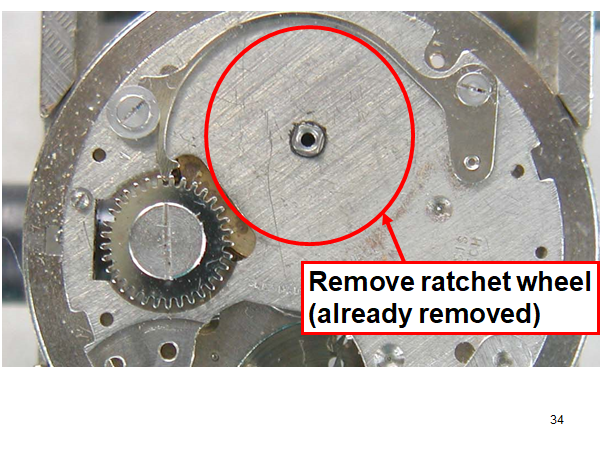

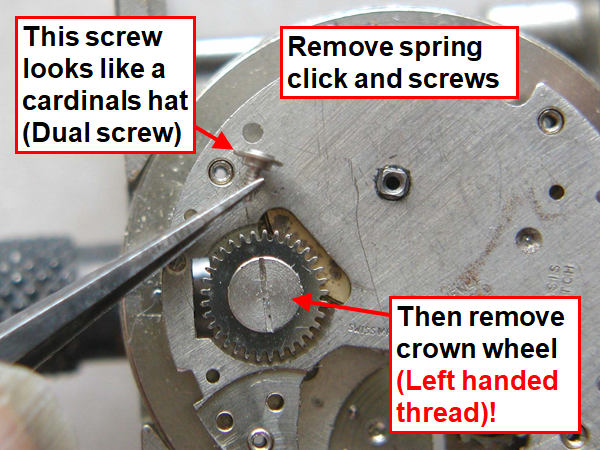

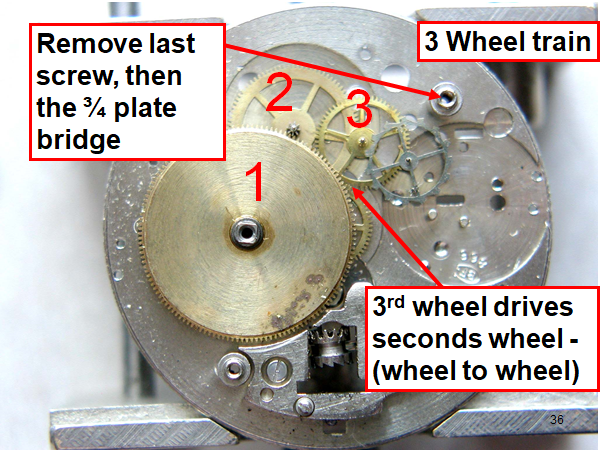

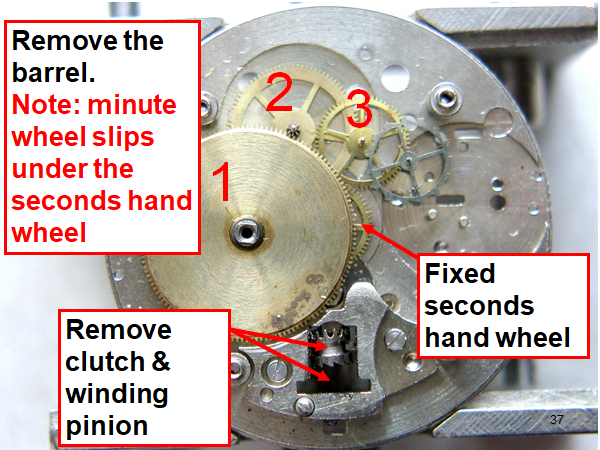

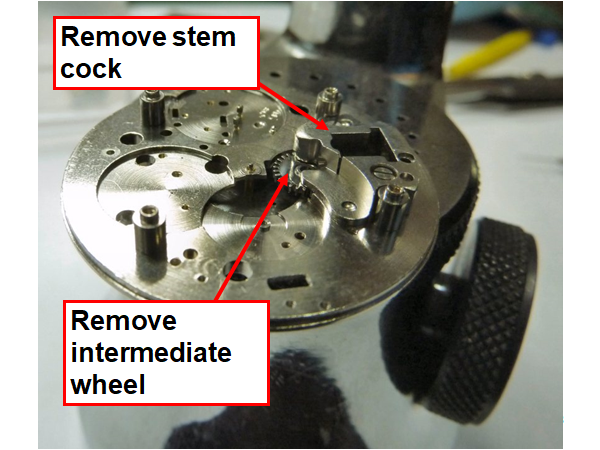

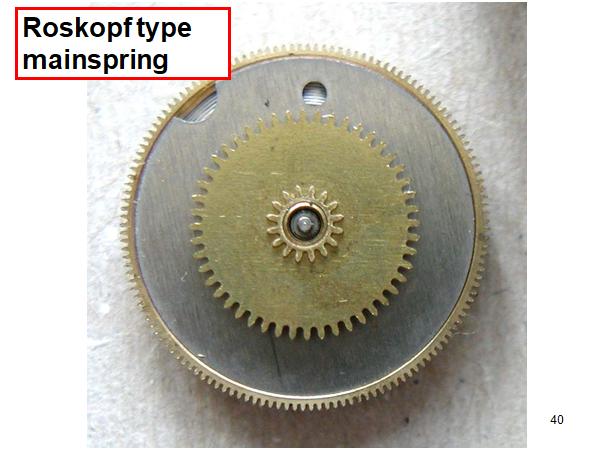

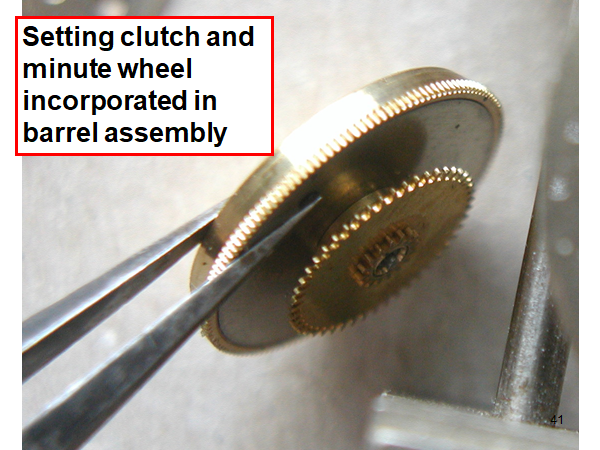

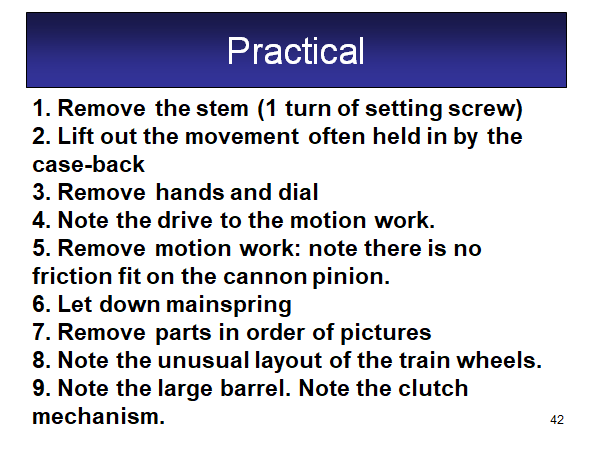

Hi, I teach watchmaking to complete beginners at Epping Forest Horology Centre, close to Epping and this is one of the lessons on the BFG 866. I wanted to show my class a classic pin pallet (Roskopf) movement and how to service it, as many watchmakers won't touch these watches as they hold no monetary value. Turn the setting lever screw 1 to 1 and a half turns to release the winding stem A piece of watch paper or small plastic jiffy bag to protect the dial, whilst removing the hands The driving pinion is part of the friction fitted minute wheel on top of the barrel. This work in a similar way to a friction fitted canon pinion to set the watch hands Remove the keyless work: setting lever, held in place by the setting lever screw, screwed from the other side of the mainplate, then the yoke, which sits on top of the clutch (castle) and also the winding pinion. I have three other lessons on this movement that cover bringing the watch 'into beat' as well as taking apart the friction fitted minute wheel from the barrel, lubricating and staking back on to achieve the correct friction setting and finally how to remove the centre seconds wheel safely and refit using a staking set. Many people leave the friction fitted minute wheel on top of the barrel, not realising the amount of old grease that can't be cleaned out from it, as well as not removing the wheel of the centre seconds arbor and again not cleaning out the pipe which has old grease inside. Hope you enjoyed the tutorial? More to come....1 point

-

Since I have no interest in woman watches (my wrist is to big) I thought I would give some non working ones away. There is a Vulcain, Timex, 3 Seikos, 2 Walthams , a Bulova, and an Elgin. I'll even pay the shipping. (U.S. only please) DM me with your name and in a week I'll put the names on a slip of paper and the first one my dog eats gets the watches. If you are new and for whatever reason you can't afford practice watches DM me and I can send you some cheep watches to practice on. I may be able to find some old tools for you also.1 point

-

The trick with this one is holding that case to do the "unscrewing". Is it a silver case? If it's brass, or better plated steel, you might be able to hold the case (with aluminum shims for protection) in a lathe chuck while you get medieval on the back gluing the nut does work, although I have not ever reached that pinnacle of watch repair (yet). Another consideration: IF the threads on the cover are female, heating the cover gently (alcohol lamp) should expand it enough to use the sticky ball. If the threads are male, you need to shrink the cover, which you can do by inverting a can of "air" used for cleaning keyboards etc. and spraying it with the freezing cold liquid. Perhaps consider a strap wrench, since it's smooth. (just an idea) When the cover and midcase are the same material, and especially when it's soft, the threads can gall and be nearly as strong as a weld. I did the 'freeze trick' with a Titanium back on a Titanium mid case not too long ago and it worked surprisingly well, considering the force exerted (using the correct tool) prior to freezing, which did not budge it. After freezing, the sticky ball took it right off like butter. Then, once it's apart, you need to clean, perfect and polish the threads on both sides, and apply a few drops of your favorite grease so next century, the next guy can get it open. Good luck.1 point

-

1 point

-

1 point

-

Done loads of very small ladies watches. Basically endorse comments above. Only advice I can give is take great care when handling the balance as the hairsprings are extremely delicate and very easily damaged (a super sensitive hand is required to correct !!).1 point

-

Hi Ammar nothing ventured nothing gained, Granted they are more fiddly than gents watches but the same rules apply. Document what you do (photos) at each stage and take your time and most of all be carefull, They are quite a bit smaller therefore finer engineered and by such easily broken, but having done it and got a worker the experience gained . is well worth the effort The last one I did was ladies ball watch the size of a marble with a broken balance took a day or two but worth the effort. wish you good luck.1 point

-

Yes; at least mine is that way. Push to read the time. Still eats batteries faster than anything. I thought about making a back pack loaded with D batteries and a cable to the movement...1 point

-

Hi You can either use a sticky ball and try that or superglue a large nut to the back and use a spanner to turn the back off. The nut can be removed using acetone (nail polish remover). Never had a problem with this method on stubborn back .1 point

-

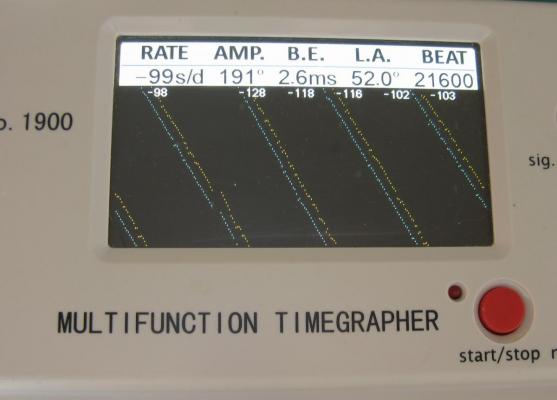

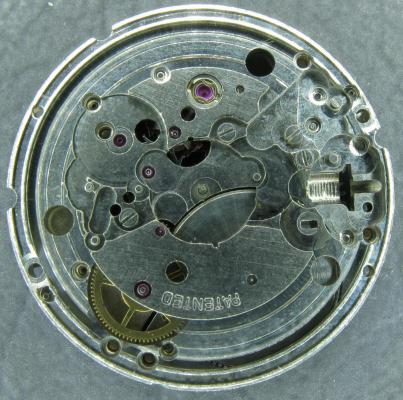

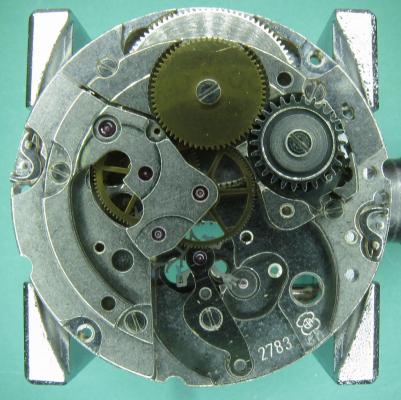

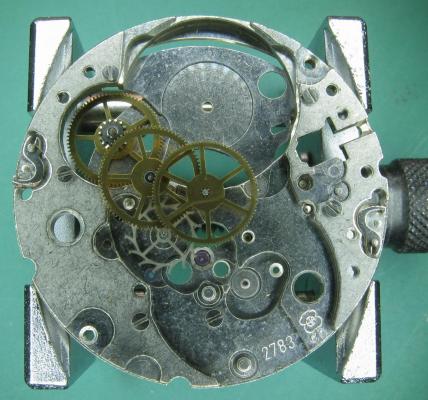

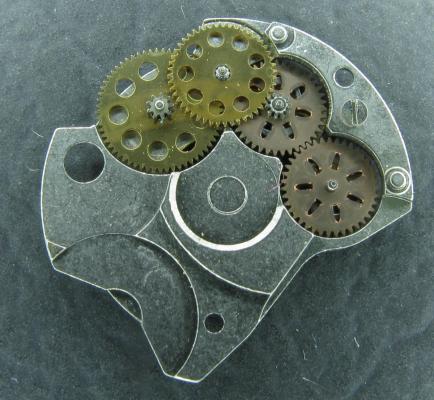

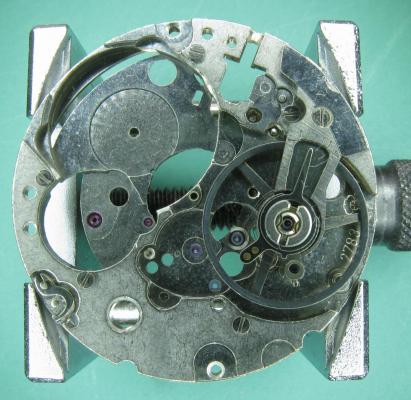

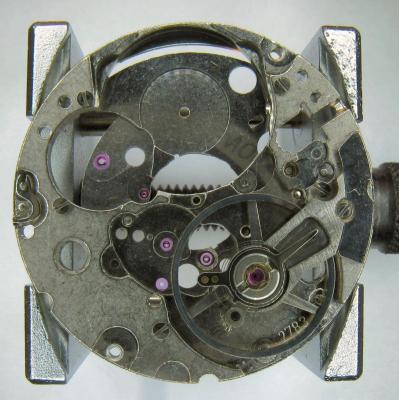

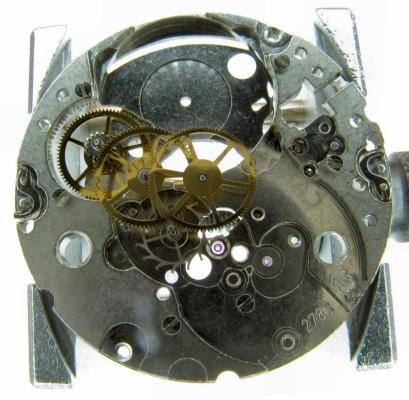

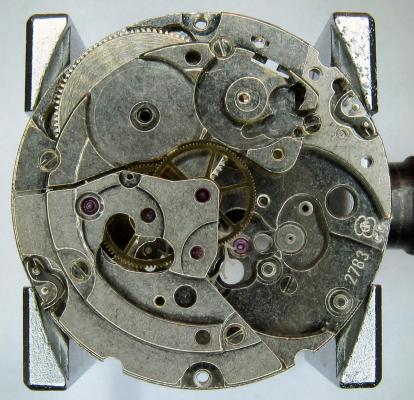

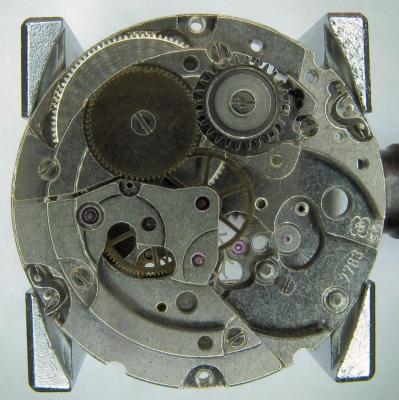

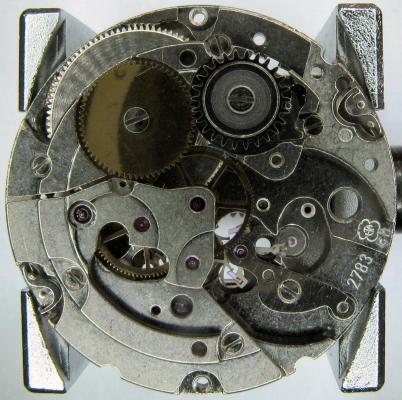

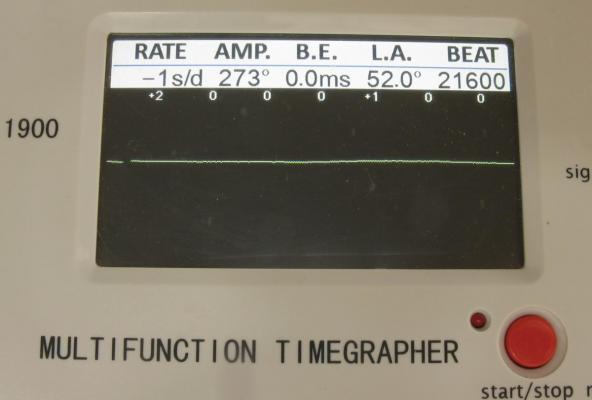

This is one that I picked up a while ago to restore and send on its way. A Cortebert 25 jewel auto probably from the 70's or early 80's. As you can see it was in need of a little TLC on the outside.... And by the look of it on the inside too. With the back off the movement looks pretty clean. It's an ETA 2783, a good solid workhorse, and apart from a couple of light scratches to the rotor and auto wind bridge, it doesn't appear to have been abused. With the auto bridge off the scratch can now be seen to extend to the ratchet wheel as well. Looks like someone slipped undoing the rotor screw and skated their screw driver almost to the edge of the movement. They must have been pushing quite hard. I guess they didn't get as far as trying to remove the dial. All pristine under here. Calendar works out of the way and layout of the key-less works exposed. Dial side stripped out. Just the balance pivot setting to come out. Flipped back over now and the balance and cock removed. With the remainder of the bridges, and the barrel out, the going train layout is revealed. This is the under side of the auto bridge with the reversing wheel cock removed to expose the two reverser wheels on the right, and two reduction gears on the left. The fully stripped auto bridge. I think that this might be the missing centre post that Tim was referring to in his post on the ETA 2873. And the balance and cock go back onto the main plate (minus the jewel settings) ready for the Elma. That's everything out of the cleaner and ready to go back together. The mainspring was in really good shape so after a very light application of grease, and a few dabs of 8213 in the barrel wall recesses it goes back into the barrel. The balance jewels are then installed with a bit of 9010 and the free movement of the balance wheel checked. Also the state of the hairspring and it's proximity to the balance cock is checked. All is well here so the balance and cock come back off and go to one side whilst the rest of the train goes together. Going train back in. I just love how bright and shiny it all comes out of the wash. Barrel and bridges back in place. HP1300 for the barrel pivots, 9020 for the second wheel, 9010 for the rest. With the ratchet wheel, crown wheel, and click in place I can now check the recoil on the escape wheel. All good. Pallets back in place and lock and draw checked, then a touch of 941 on the exit pallet, transferred to the escape wheel teeth by gently working the pallet fork manually. Then drop in the balance, and off she goes. It's then just a matter of reassembling the calendar works, key-less works, and the auto wind module, and the mechanics are done. And there's a nice drop of ETA goodness to confirm that all is well. A very gentle clean for the dial and hands, polishing of the case, and a new armoured crystal, and things look a whole lot better than they started. I hope that this proves useful to somebody. This has now had a 24 hour test drive and has managed to stay within a couple of seconds of spot on on the wrist. I really like the look of this one and it's a very comfy size, I almost decided to hang on to it but I just can't justify another at the moment, so it is now on eBay. If anyone is interested I will post up the item number although it should be easy enough to find. Marc.1 point

-

I think you need to consider "Buffing" See vid attached. Removing by hand using with different grades of emery paper seems slow.Also keeping everything square and with the correct shape will be difficult.1 point