Leaderboard

Popular Content

Showing content with the highest reputation on 08/29/20 in all areas

-

As far as I've been able to determine: There's two different systems of stem measurement, metric, and "Tap size" which is one of those traditional and strange bigger-is-smaller systems like wire gauges. Unfortunately, they also get used interchangeably, so sometimes a place that uses metric will express it as "Tap 9" when they mean 0.9mm, or both, like Cousins. If they say "mm", I'd go with that. If they say "Tap" and don't also list the size in mm, it's hard to be sure. Esslinger uses the old up-is-down Tap system as they show in their Tap size table. I tend to only buy from sellers that explicitly list in mm, or when I know that the stem they are selling on ebay is the correct diameter based on the movement number because they only come in one diameter. Also, sometimes you just have to buy stuff to measure it and find out for sure. Sometimes you order a part and it's the wrong size. It took me awhile to figure this out. It's one of the learning costs I've accepted. The sellers don't always have or are willing/able to find out the measurement you need. I've tried to find out all sorts of measurements for crystals and pushers, and there's no real way of knowing without ordering it to find out. Apparently the old-time watchmakers just know this stuff, which I guess you would after a lifetime of ordering different parts and establishing supplier relationships.3 points

-

I think I found some of the problem but still got more to look at. Here is the 2nd wheel and you can see the rust on the gear which I guess I miss first time around. There maybe be other problems I have over look but this has to be fixed. I have already scape some off but still got more to do.I would just replace it with another one but I don't have another 2nd wheel with a extended pivot in stock so I'm taking my time and scrap this off best I can.2 points

-

Ok, was looking for the Ansonia link. I have this Ansonia cast iron clock. I got it about 55 years ago. The case was very rusty and as an apprentice in a scientific instrument manufacturers at the time I had access to stove enamelling, so stripped the case and re-finished it.....2 points

-

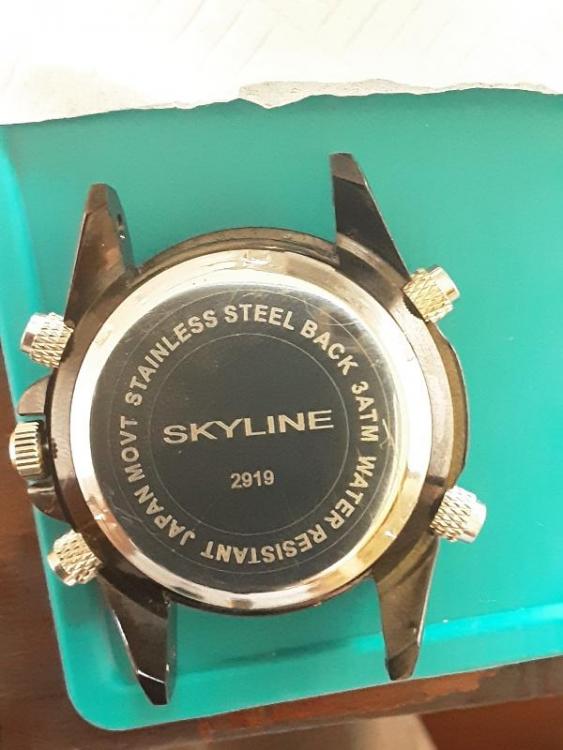

If you're given one of these... Don't panic, there is few notes to help you out in this democratic battery or repair, just turn it over. Now, don't be fooled (as I did) by the notches on the caseback. It's a snapback type with a prying tab at 1H. The round spot by the stem is there only to fool you again. You can press it until blue in the face and nothing would happen. Bravely remove all six screws and lift the plastic plate and PCB underneath. The writing say "Good luck daring further". No, really it says Lithium Battery. There you're presented with a top of line PC21 module. Pay attention to the rectangular LCD contacts at 11 and 1 hours as they fall if you turn the module upside down, there is also a round silicone dot to press on the battery, not pictured. Replace battery and close it, figure out and set the digital if you can, and return it with a smile.1 point

-

Hey guys. Been occupied by other things lathely, namely getting an old lathe up and running here at work... It's quite beat and abused but Its a high quality Hardinge lathe. I rebuilt the compound (which clips onto the dovetail way as it's a lower-end second-operation lathe) so it has limited travel. The angle scale (which is under the top of the compound and visible through a magnifying glass built in) was completely covered in rust and grease. Now it's visible... It came in handy to set ~2 degrees of taper for my tack! I also took the excessive lash out of the compound ways so they are nice and tight now. This is a sweet lathe with a 3-jaw chuck as well as an assortment of 5C collets. I learned from a master tool and die maker on the high end version of this- the tool room lathe, with a proper apron able to cut inch and metric threads. This is it's lesser cousin. A brass rod was tapered as thin as I could and then finished with sand paper as it was deflecting from the tool of course and not cutting as it got thin... I pressed it into a 1" slug of aluminum. A bit of tubing to keep it safe and a recycled container and we are done! Anyway, here's the tack:1 point

-

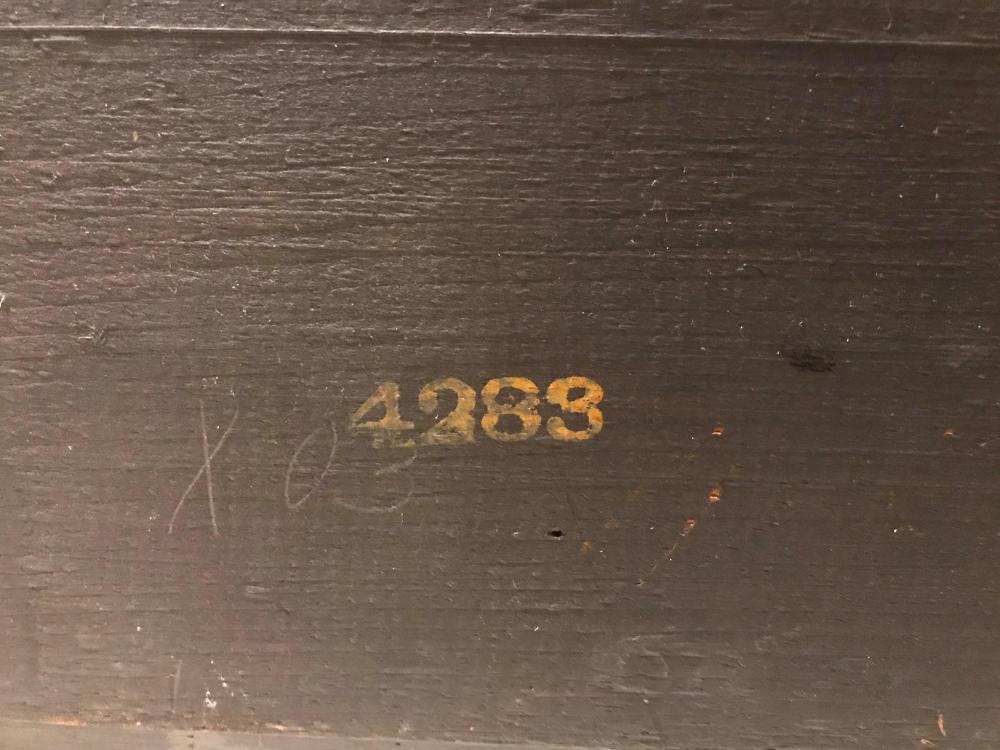

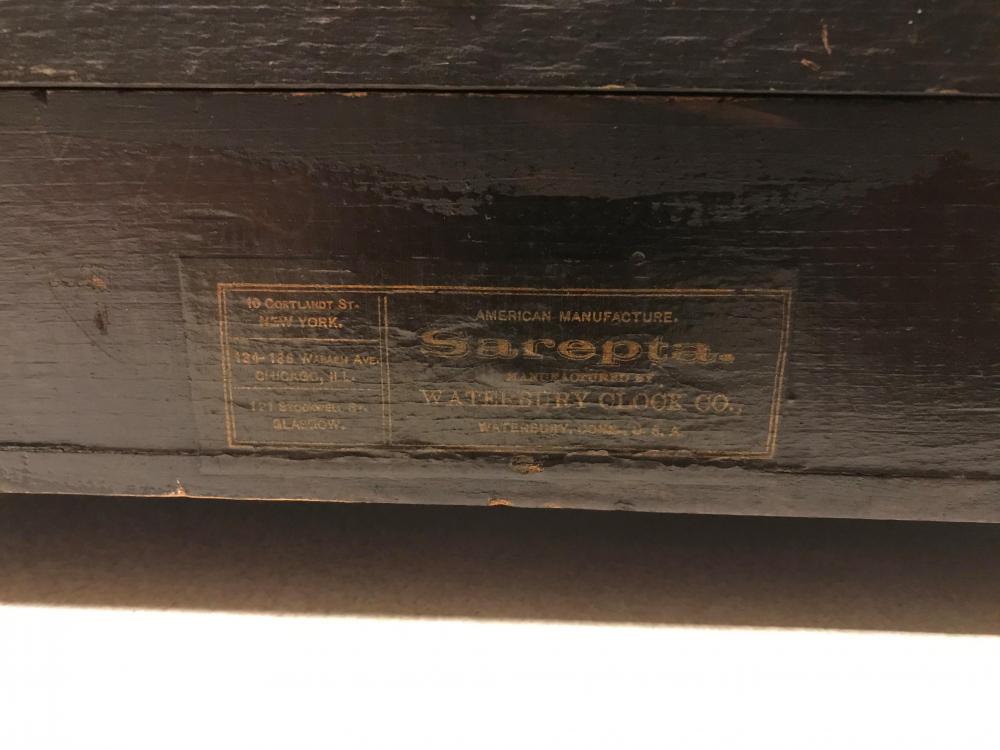

Hello I have tried to find information regarding the clock I recently received but have found nothing but a couple of images. My clock is a wood case with faux marbling effect in brown tones. There is a label on the back of the clock stating SAREPTA Waterbury Clock Company. Also on the label are three address one for NY, one for Chicago and one for Glasgow Scotland. The number 4283 is stamped on the back of the clock case. The entire back of the clock comes off to reveal the clock works. The actual works are small in size. The clock strikes on the hour and half hour. There are no identifying markings on the clock dial. The time regulator is located in the number 12 on the dial, however, the pendulum also has an rolling thread in the middle of it. Not sure the pendulum is original. Any help dating my clock would be great. Also the brass on the face and the feet is very tarnished. Does it hurt the value cleaning the brass? Thank you.1 point

-

You might try International Dial Company. I have not used them, but I see them referenced on the vintage watch forums.1 point

-

You're an absolute genius! Never would I have thought it would be a screw down bezel. Put it upside down in a movement holder that grabbed exactly where the bezel inverts and viola! Thank you so much1 point

-

1 point

-

By avgas you mean kerosene I guess? Why not, I don't think it will hurt anything, but getting all of that cleaned off would eat a lot of solvent or cleaning solution.1 point

-

Many thanks for all of the help with this question. Stem extension did the trick brilliantly. Completed and fixed with some thread adhesive and it appears to be holding well.1 point

-

Thanks, very interesting, but I have no recollection of ever seeing a paper label with the clock. Some close up pics which might throw some light on it..... Movement..... And dial..1 point

-

Run the movement with the pallet jewels dry for some minutes, this allows the escape teeth to scrape off the epilame from them and that non-epilamed "track" holds the oil.1 point

-

Agreed that a tool like the gauge in the link is best to measure stems and crowns but it is pricey. I chose instead to buy eight stem extenders in different sizes, about a dollar apiece. They come from Esslinger in individual bags marked both tap and mm. I try different sizes for the stem or crown I’m measuring until one fits. I’ve never used a stem extender but I guess an added benefit would be always having one on hand. Mike1 point

-

1 point

-

1 point

-

Hi Just a thought the bezel could be screwed on, try using a sticky ball to unscrew it.1 point

-

Like everything else in watch repair there's probably a tool or something for doing something. First link is your crown gauge. Then sizing of stems that you mentioned is found on the second link. https://www.cousinsuk.com/product/crown-gauge?code=G0693 https://blog.esslinger.com/stem-tap-mm-size-cross-reference-chart/1 point

-

If you are refering to a Seitz jewelling tool, I don't think there are any reamers 5.0 mm diameter. I don't like the idea of reaming. It removes material and weakens the tube. I would put the tube of the hand in a slightly larger hole of an anvil block and insert any tapered tool and expand the hole. If you can't find a tool that fits, take a large iron nail and file it to a slight taper of about 2%. If the resulting hole ends up too big, you can shrink it by clamping the tube in a 3 jaw chuck.1 point

-

Bear in mind an hour hand usually has a tube, and broaching 0.5mm might leave little to no tube.1 point

-

Let off the power, pull the balance and fork. Peg the fork jewel holes. Stick the fork pivots and fork end in clean pithwood. Check the roller jewel for muck, and wipe off if necessary with fresh cut pegwood. See how it goes then.1 point

-

I don't know that movement, but most modern movements have the hairspring glued at the stud. When they de-glue from cleaning I usually use 2 part epoxy (Araldite for most continentals), 5 minute, to reglue. Last one I tried UV glue as I know the guy and if it doesn't work longterm it's not an issue. They aren't supposed[/] to unglue from normal cleaning but it happens.1 point

-

Be aware, AG is not a brand just an old denomination standard for Alkaline (1.5V) button batteries, as such these are never apt for watches (except some large Chinese quartz modules). For a quartz watch one should use SR (Silver Oxide) batteries with a 1.55V and longer lasting. Since AG sizes are the same as some watch batteries, and they cost marginally less, sometime these are incorrectly fitted "in lieu". Below a shameless copy from the internet of AG sizes: AG SERIES AND CORRESPONDING MODEL NUMBERS FOR EACH AG# AG0 Button Batteries: 379, LR521, LR63, 618, GP379 AG1 Button Batteries: 364, LR621, LR60, D364, LR620, 280-34 AG2 Button Batteries: 396, 397, LR59, LR726, 612, 196, D396, D397 AG3 Button Batteries: 384, 392, 192, LR41, LR736, L736, GP192, V36A AG4 Button Batteries: 376, 377, G4A, LR66, L626, LR626, GP77 AG5 Button Batteries: 393, 309, 193, LR754, LR48, D309, D393 AG6 Button Batteries: 370, 371, LR69, LR920, LR921, D370, D371 AG7 Button Batteries: 395, 399, LR926, LR927, LR57, D395, D399 AG8 Button Batteries: 381, 391, L1120, LR1120, L1121, LR1121, LR55, D381, D391 AG9 Button Batteries: 394, LR45, LR936, D394, GP394 AG10 Button Batteries: 389, 390, 189, L1130, LR1130, L1131, LR1131, LR54, D389, D390 AG11 Button Batteries: 361, 362, LR721, LR58, D361, D362 AG12 Button Batteries: 301, 386, L1142, LR1142, LR43, D301, D386 AG13 Button Batteries: 357, LR44, L1154, A76, PX76A, 303, D303, D3571 point

-

Hi I would not reccomend AG cells some are ok but not all, first check the cell with a meter, If the voltage is below 1.3 / 1.4 it is us. I personally always fit Renata batteries but get them from a trusted source ie Cousins.uk as there are even fake batteries on the market 8299_Miyota FSXX Series Parts List.pdf1 point

-

1 point

-

May the below could be a definitive solution. Before I get jumped on by counterfeiting apologists, just consider that it comes from Mark Lovick, the same guy that pays with his own money this forum where everyone is free to express his opinion.1 point

-

https://www.cousinsuk.com/category/moebius-fixodrop-fk This link will give you ther page on Cousins site regarding fixodrop/Epilame not only is it expensive, there are also hazzards in using it as explained in the following link http://watchmakingblog.com/2011/07/29/one-hazard-of-epilame/. I would suggest reading both and makining an informed descision cheers1 point