Leaderboard

Popular Content

Showing content with the highest reputation on 08/14/20 in Posts

-

3 points

-

2 points

-

Before you try cracking the back open with the knife method try unscrewing first. Because if you insert the knife method on a screw back and get the thing cross threaded you're in big trouble. Usually if it's a pop off back there will be some sort of indication of where the knife goes. Occasionally overenthusiastic people will attempt to pry a screw back off and you will have Markings which look like the back should pop off but it doesn't. Then if casually you can't unscrew it there are tools to help you with that because sometimes he gets screwed on really tight.2 points

-

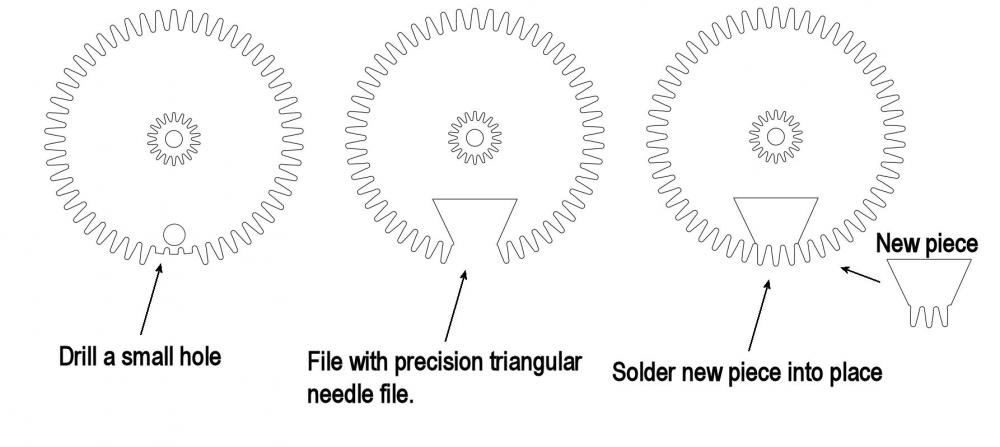

I think @oldhippy is right. From wrestling with hairsprings this is one of the trickiest repairs to do, and when doing it one whish one saved the previous discarded part in the “good to have in the future box”. When it comes to replacing the teeth the donor piece has to come from a wheel not only with the same diameter but also the same type of teeth and depth on them, this is so you will get the correct amount of freedom for the wheels to rotate in a correct way. Even small differences like these ones will make the wheels not to run correctly in the length. Another thing to consider is how to put the new piece in place. One should avoid making a rectangular shape to fit with and instead make a “dove tail” shape with a precision triangular file. Since the teeth on the wheel is subjected to lateral driving pressures a rectangular shape will eventually cause it to wriggle free and fall out, the solder hasn’t a very good mechanical resistance. This is just some small tips and tricks to think of when repairing wheels.2 points

-

Hi Certina was founded about 1888 by Adolf and Alfred Kurth, The K is for Kurth placed on crowns of early Certina watches. Hope this helps2 points

-

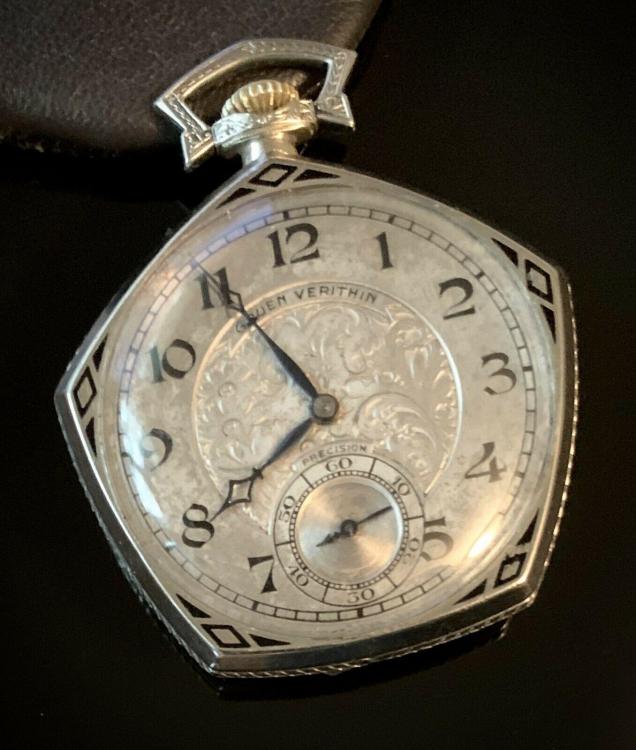

So, here's kind of a fun story: A few weeks ago, I purchased a Gruen Verithin Pentagon pocket watch in filled white gold. It had a distinctive engraving inside of its caseback that read "Leland S. Offer, Los Angeles, Calif." Based on the serial number of its case and movement, and with the assistance of some Gruen experts, I was able to date this watch to 1922 or 1923. Because I was curious and like a good story, I researched the original owner, one Leland Stanford Offer, who was a successful salesman living near Los Angeles at the time he purchased the Pentagon. Using Ancestry.com, I was able to learn the names of Leland S. Offer's living descendants. With the help of Google and some paid people searches, I was able to get in contact with Leland S. Offer's living grandson and one of Leland S. Offer's living great-grandnephews. I mailed the great-grandnephew Leland S. Offer's Gruen Pentagon, and the current plan is for the great-grandnephew and I to surprise Leland S. Offer's living grandson with his grandfather's watch on a Zoom videoconference later this week. I was happy to reunite this family with the pocketwatch free of charge, but the great-grandnephew insisted on covering my expenses. Because of this, I've been on the lookout for a nice replacement Gruen Pentagon pocketwatch. I had been lusting after a 14k or filled green gold Pentagon, but earlier today I found a really nice solid 14k white gold specimen that was nicely engraved and featured pretty black enamel painting on its case. Here's the replacement Gruen Pentagon that is on its way to me now: I plan on polishing and heat bluing the hands from this watch. I would like to overhaul it myself, but I don't know if I have the skills to attempt this yet. I've been practicing on Seiko NH36A movements and the experience has, to say the least, been humbling. There's something about the super thin and delicate layers of aluminum in the NH36A movement that I can't help but destroy.2 points

-

I recommend that one places the mov,t in an holder instead that directly in the claws of the microphone. The spring is strong and having it jump out wouldn't be a nice surprise.1 point

-

Try some technique. First, by all means bring work to shoulder height, forearms or at least elbow must rest on the bench. For this particular task the plates have one or two small locating posts. Bring plates holes into one and place a pegwood stick over it, hold with left hand. Right hand places the screw to the nearest hole with tweezers and then gets the driver, which must be dressed right for a Seiko screw, that means the tip has a noticeable flat edge. It must wedge to the slot top edges. If the screw wobbles side to side with the driver in the slot that means the nose must be flattened more, With one screw in place the opposite one should follow easily. Do not locate the day finger into the wheel teetch until all screws are in but still lose. I tried to describe more practical tips in my walk-throughout for the 6R15 which is practically the same mov't1 point

-

A really nice website for American pocket watches once you have a serial number is found at the link below. Also nice with Elgin watches the parts list is available there. I don't suppose you can get another picture of the movement preferably the angle? It may just be a lighting issue but I'm not seeing the hairspring for the balance wheel? I can see the stud it still there somebody rotated the regulator all the way to one extreme is interesting?. They hairspring may be hiding under the balance bridge but it's I'm not seeing it? https://pocketwatchdatabase.com/search/result/elgin/97858221 point

-

1 point

-

Just in case anyone missed it. Watch Repair Channel now covers the Poljot cal, 3133:1 point

-

Not an issue to Europe. My standard with unregistered mail is 10 days but I have got packags in less than a week sometime.1 point

-

If it was in a sealed factory pack, and it's not now, it would be a very kind seller to take it back. Add to that the fact that you weren't sure if half the staff was missing, as well as the roller jewel, from my view it's entirely possible the staff was "whole" before the pack was opened. Sorry if that sounds harsh.1 point

-

Hi well done , Persistance pays off. Some times with watches they are not always correct, other repairs etc have probably taken place and non correct parts used , which when the next repairer tries to do things by the book he encounters difficulties as in you case. but once again well done1 point

-

Nowdays most deliver 1 small container luminous powder, 1 small bottle of accrylic varnish and one small bottle acrylic thinner to get the right consistency.1 point

-

I do 7750s all day. Id be happy to help. Sent from my SM-G950U using Tapatalk1 point

-

That video above shows Rolex hands which are made of solid white gold and responds well to polishing. Most hands on the other hand (pun not intended) are plated brass which do not as the plating can easily be worn through. Use of rotary tool not recommended.1 point

-

One trick I learnt is to use balsa wood. Get a block of balsa and press the hand into the end grain of the wood until it is practically inlaid into the wood. I usually polish the hands by hand with Autosol using a piece of pegwood for rubbing. Knowing what the material the hands are made of is really important. Brass is very soft. Using too much pressure will bend it. Steels are brittle and can break, especially those hollowed ones for holding luminous paint. When using rotary tools to polish, use very low speeds and light pressure. I don't like dremel tools. I prefer to use a dental lab micromotor which has better torque, speed control and less vibration. Don't use tools that can catch the edge of the hands, like a cotton mop or felt. Use silicone polishers. I just can't work with conventional lume paste. The solvents evaporate so quickly that it's hard to get a smooth layer. I prefer using a UV cured paste. I use UV nail varnish and add lume powder to a consistency I like. Use a large oiler to spread the paste in 1 smooth stroke, using very light pressure almost not touching the hand with the oiler. Excess paste can be removed with the oiler. Then cure it in a UV nail dryer for 2 minutes.1 point

-

The first question you need to ask yourself is “what are these hands made from?” There’s no good polishing plated hands. And the same usually applies to blued hands too. Then there is the finish - grained, satin, mirror finish.... For holding them while finishing, I either use pithwood and hold them on it with tweezers, or I hold them on a soft cutting mat with the collet hanging over the edge. If you have not practiced finishing larger pieces of steel then I would do this first. It’s very common do see it done improperly these days with the most common issue possibly being rounded edges/corners. Personally, I would never use a powered tool for finishing hands. Can’t understand why you would want to do that.1 point

-

1 point

-

1 point

-

Please post a picture of the face, if the dial is larger than the case opening it is a front loader as mentioned above, bezel or not.1 point

-

1 point

-

Have a look at this: https://adjustingvintagewatches.com/restoring-enamel-watch-bridges/1 point

-

1 point

-

Hello all, Thanks for the link to my site. To really find out about these watches and all the innovations in them have a look at my page on shock and water protected watches: https://www.helvetiahistory.co.uk/1930s-sports-watches The Abercrombie and Fitch watches are under the 'other brand names' at the bottom. Including a picture of your watch I believe from when it was on eBay. These watches were developed and completely manufactured by Helvetia, incorporating more water and shock proof features over the years, though sometimes sold under other names e.g. Huber and Aero. Thanks. Carl1 point