Leaderboard

Popular Content

Showing content with the highest reputation on 08/08/20 in all areas

-

That an SII PC10 quartz module with markings erased to conceal this secret information. Stem 354.0304 points

-

I remember my dad saying he got Mad magazine for 25c when he was a kid; this was the early 80s and he got those in the mid 50s, they were 2 dollars when I was a kid. That was my mental conversion then. A few years back I found a small notebook in a fleamarket with pay rates per day for watchmakers in Switzerland; it was from the 50s. I did a lot of searching converting francs over time and kept coming up with low figures, like no way they made so little. Was talking with a slightly elder watchmaker friend who's a bit of a historian, he told me how it was. Back then Switzerland made a lot of stuff, very well, and it wasn't cheap, but they didn't make much on it nonetheless 50-60 years ago. 6 day work weeks, 10-14 hour days, and what blew my mind- about half one's earnings went to food. Food was damn expensive. It really made a mark on me; when I see an A. Schild blah blah movement from 1955 with mirror polished screws, mirror polished pinions that rival Patek, ratchet and crown wheels that are so beautiful with swirls and cupped mirror polish, and it was a cheap-ish movement then, and Patek's pinions are less good now- argh I get worked up. It's probably why I make a lot of parts for watches where I don't tell the owner they were broken because they'd refuse the true cost of the repairs. Those old movements were made with real skill and pride and almost out of desperation, but no corners cut; they all deserve to keep ticking.3 points

-

It was 165 but the Chinese machine doubled it, as sometime happens when under 200. Personally I would call it fine and move on with other mov's but if you feel the urge consider inspecting all jewels and pivots under a microscope, using less oil, use 9415 on the pallets, and polish the inner side of the pallets where the impulse jewel touches. The latter is certainly too advanced for a beginner but fair to mention.2 points

-

as a reminder this is an American pocket watch swapping the jewels around doesn't always work because they're not always the same size. Then bent pivot shouldn't be an issue for a new balance staff hopefully. pocket watch database is a good source for watch parts. If it's an Elgin watch you know the grade number this is another place to look although it does have a minor issue. http://www.elginwatchparts.com/Script_Find_Grade.php the minor issue is there's a reference to the notes found at the bottom of the page. Like for instance those balance hole jewels that somebody claimed were identical don't appear to be identical depending upon your serial number. Then there's a reference the balance staffs but that refers you to another section that doesn't exist on this page. if you're going to work on American pocket watches there is a definite must-have reference book that almost no one has ever heard of which is Swartchild & Co Chart Book for American Balance Staffs. There is also a second book that has the jewels listed. I miss snip out the section on the balance staffs for you. https://www.ebay.com/itm/Swartchild-Co-Chart-Book-for-American-Balance-Staffs-reprint/162769575312?hash=item25e5d29d90:g:zhoAAOSw1HtfGEpv then I'm attaching another image another way to tell if your staff is sized correctly for the whole although you do need to do this test before you've attached the balance wheel it's a little hard with the balance wheel on.2 points

-

Ok, So the screwdrivers, tweezers ect arrived today. Could not wait to start! Have got a Fortis as first project, that seems to come from a lot of sparepart watches. It has the FHF 96ST movement. Looks brand new, and was sold as a non runner. It is missing the stem. And the dial looked loose. Pried up the case lid. And the movment fell out. So, I tried to wind the barrel a little with a screwdriver. No surplice there, It didn't run. After a little closer look. I saw the balance jewel is missing. Also looked like the pivot might be broken. Bit exited, I started with removing the hands. Had little trouble there. The houerhand was pried to dial face. But after a little more fiddling than expected. I got it off. For my life. I couldn't find the screws to the dial. Turns out it was glued on to the movement.. Even more intresting! But got that off too, with little "fiddling" Tried to get it running again. But noticed that the balance looked out of alignment. Time to bring out the new "chunky" Bergeon screwdrivers! (love them already) With a "some" intresting trying out different work positions, shifting between 4x and 10x loupe. Half scared to mess up the balance, possibly even more. Still exited. But with some fueling with the tweezers. Tha balance came out in one piece with the hair spring. Im not sure why its called hairspring. It sure is thinner than a hair.. After som try and tribulations with the loupe. I managed to notice that the lower pivot on the balance staff is ok. Had hard time to see if the upper pivot was existing. The hairspring is in the way. Im not sure how you guys do it? Im sure scared to mess up the hairspring! But eventually, I got a glimpse of it. Looked at the fork and timing wheel. It seemd to want to "tick". So I decided to remount the balance again. Well..That took some time. Again very fiddly! First time, I got the impulse jewel out of alignment. Took me a while to figure out. And even more time to reassemble with it in alignment. But got it there on the second try. Im not telling you about how long it took.. With everything back. I I tried to "kick" the balance. Veeerrry carefully. It wanted to go! With the missing to jewel in mind. I decided to give it "some" oil. Since it never has been up and running. It is probably very gummed up. So disassembly, cleaning and oiling have to be done anyway. So I thought it is the perfect first oiling effort, as I can clean upp my mess, anyway. Oiling. Jeez.. Those jewels is tiny!! Let say.. Comparing on what Ive seen on turitorials ect. My jewels isn't missing any lube.. But it started ticking!!! It definitely isn't strong ticking. But an houer later, writing this. It is still ticking! Mezmerasing! I call this evening a success! Some notes to self: 1. Im getting a bit shakier over the years. Loupes magnifies that too.. LOL! 2. Improve working position. Sitting on the floor isn't an option. So raising the office table some how, is needed. 3. I did like to use the loupe better without the head band. It was quicker to change between magnification. (have only 4x and 10x) 4. Amongst many other things. A microscope is now on the wishlist for the future wallet enlightener list. 4. When doing close up work. Don´t poke the nose with the screwdrivers.(unintentional, or not). The new Bergeon screwdrivers will be offended!! 5. Somehow, I need to find a correct jewel, spring ect. Find out if a jewel press is needed?. Hm. have to get a stem and crown too. 6. The only thing I got top quality tool to start with. Was the Bergeon screwdrivers. As the first set "stuff" needed. Didn't come cheap any way. But Im happy I got quality screwdrivers. So Im pondering if the wife get upset if I have them on the night table! Hm! 7. Today was a great day! lets make tomorrow even better! 8. Tomorrow is disassembly day. Remember to take maaany pictures!! 9. Get some sleep! /Johan1 point

-

This well know and done always identically. He lists any possible desirable item by copying the listing with the lowest price, but with a 15% discount. As seller name he places "do not buy - contact [email protected]", that changes often . He answers email swiftly telling that because of a bug Amazon will process the order manually and send an invoice for bank transfer payment. To add a bit of credibility he waits the following day to send the fake Amazon invoice with a reply address as amazon.it.259348523592638952348752892.023789465298359283685922632.com and the beneficiary details IOAN STELIAN MAILAT (a Romanian name) IBERCAJA BANCO, S.A. IBAN ES4920855687250330432670 BIC/SWIFT: CAZRES2Z SPAIN REF: 403-3508465-3272433 That's all I needed to flag domain name to the registrar, and provide the details to Spanish Police. Shame on you Ioan and your accomplices!1 point

-

Going through Marks course, I stripped, cleaned, reassembled and lubricated my Seagull ST36. I then tested the movement in 6 positions. The initial amplitude was quite low. 184 to 211. I let the watch run overnight. When I retested the watch in the morning, the amplitude was quite high, 329, so I demagnetized, regulated the movement and retested in 6 positions. Here are my current results: Position Rate Amplitude Beat Error DD +5 247 0.0 DU +3 252 0.0 CD -11 224 0.0 CU -3 219 0.0 CL -10 220 0.1 CR -3 222 0.1 I'm certain my first lubrication job was not the best. I would like to get the amplitude above 270. What should be my next steps? Should I just continue to strip, clean, reassemble and lubricate until my desired amplitude is achieved? Does the table above indicate where I should focus my attention? How much should the amplitude and rate change as the movement rests. Currently the movement is running +3 sec per day with 251 amplitude in Dial Up position. Thanks in advance for your hellp.1 point

-

I was reading this again and there is no way a .2 strength, 270mm long MS fits into a 9mm barrell. Beside .2 is way too strong especially for a ladie's. That before considering that the smaller height GR lists for holed end is 1.5. So you should measure it again. Woops Nickel "fast fingers" Silver beated me on the finish line!1 point

-

Are you sure about the dimensions? 0.2 thick is pocket watch territory, not ladies.1 point

-

Plus or minus a couple bucks, yes that's about the going price for white alloy replacements. Just like your staff, pinion and jewel issue, time to take out the old one, compare measurements to the referenced one including correct ends shapes, then compare those to the white alloy. Are you measuring using Dennison numbers or metric? I'd use metric. Can you say who the seller is? Because I have a couple reliable folks I get mine from.1 point

-

ONLY ONE SOURCE ? If so, cough up the dough.Yes it does seem a bit pricey, but not totally out of line considering age and value of the watch. You might find a parts watch on ETSY, but it would be a total crapshoot.1 point

-

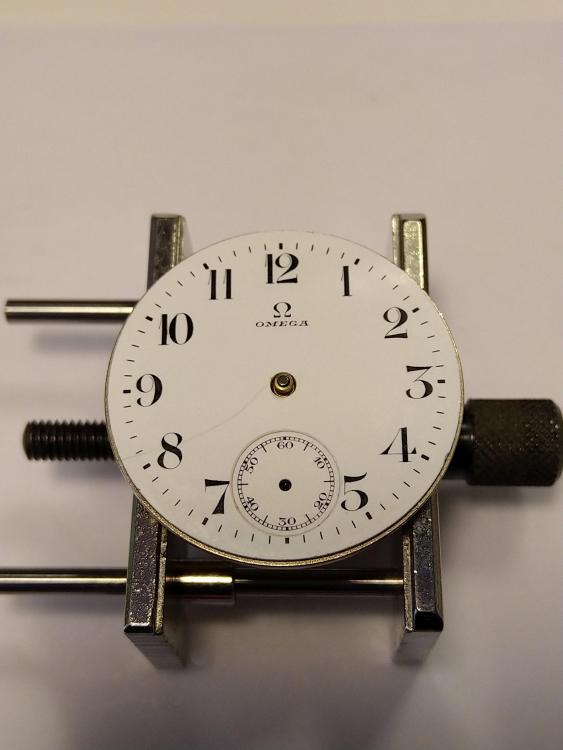

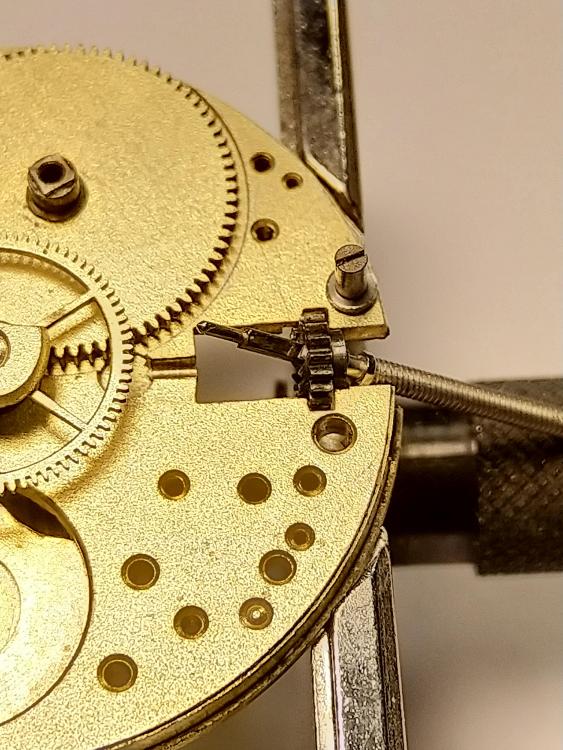

Last night I didn't really feel like watching some Netflix series so I silently returned to the watch workshop. Blind folded from some previous activities I stretched my arm into the box containing not so urgent fix watches/movements. Today the lucky turn had come to a nice little ladies Omega 13”’ movement, it passed its 100 year anniversary so I think it is time for a nice bath and service. Guess we just have to dive into it and see what we can do to it. Just to save space on this server I compiled everything in a web optimized PDF file. Omega 13 ligne.pdf And here are some snapps from the content. Enjoy! The finished result Freestyle assembly I still have a brainfart of this part name1 point

-

I'm not sure it's too critical. There are no wrong answers here. I used Molykote Dx as it's cheap, it works well, and it's what I had. Well I try to keep application of oils to pivots only as much as possible. Minimizes the risk of spreading.1 point

-

Apart from the grease/heavy oil aspect, silicone grease is very difficult to remove once applied. If it migrates to other parts there could be problems in store. I worked in the lubes industry and we avoided silicone whenever we could as we could not make other lubes on the same plant until it had been mechanically cleaned! There are oils (not watch types) that contain silicone but these are normally for larger mechanisms. HP1300 would be my choice, but if grease then 9501 as this is quite a soft/oily grease (silicone grease tends to be stiffer). Just my thoughts.1 point

-

We had another member recently looking for reassurance about using Seiko lubricants, but no amount of good reasoning prevented him from spending on that. Probably caused by blind faith in written material over relying on other's experience when it comes to a question asked many times on this forum alone. I use 8301 there. A bit messy and natural based, still better than leaving it dry like the factory does.1 point

-

I wouldn't follow the Seiko guide too closely. There's the obviously questionable suggestion that you oil the pallet pivots, and there's the use of "S-6" in parts of the train. That's a grease, and I know of no other manufacturer that call for the use of grease in any part of the train in any caliber this size. I would improvise and use HP1300 there like any other automatic device. I would however use some grease on pawl and ratchet teeth on the second reduction wheel. I can see that wearing down over time without a heavier lubricant.1 point

-

It made a mark on me too. It's why, if I stumble upon a particularly well-crafted movement in a really nice watch that is advertised as "non-running" or "for parts", I try to procure it and restore it. Before scrappers come to get it, if I can. They'll just melt the case and sell the movement for jewelry parts. So many were beautiful works of art, as well as marvelous mechanisms for their time. And the craftsmanship that went into them! It so very different from the computer-designed components we see today. Computers do not have an eye for aesthetics. But long ago, humans were combining aesthetics and accuracy in lovely ways. And some of those artisans struggled to keep bread and cheese on their table.1 point

-

Great, thank you. I'm still trying to parse all this lingo. Tap 10 refers to the diameter and 354-130 is their internal catalog reference for the particular shape of the tip?1 point

-

1 point

-

btw-!!!check your stuff as soon as it arrives. keep your shipping box and packaging in case of a return is needed. I had a incorrect stem show up. it'll save you not much money but a little hassle if and when you do.1 point

-

was just typing to that effect. Tap 10 is correct. the two are identical. you'll have to cut to length.1 point

-

https://www.esslinger.com/hattori-japan-watch-movement-pc10-quartz-movements-overall-height-4-5mm/1 point

-

The Limit almost certainly will contain an AS2066 movement Andy....1 point

-

Thank you all for the useful information! I have found the definite problem that is causing it to bind. The pivot is indeed to large for the hole in the jewel. I took one of the other staffs with the same sized pivots and tried putting it in the hole with the balance cock flipped over. It comes nowhere near the shoulder, but binds up on the pivot itself The staffs that I've got are generic from an eBay store. I don't mind the outcome. I have learned a lot about what more I need to learn /get to make it happen. I'll come back to it again as a future project.1 point

-

1 point

-

Is staff replaced with the right one? Are jewels, pivots and the cock perfect? A host of possible causes are to be checked in the hopes of finding the fault. Regards1 point

-

when you replace the staff did you measure the old staff versus the new staff? then what was the actual staff number you used? Also are you aware of that Elgin staff numbers are not unique parts? In other words typically with each of their balance staffs the pivots sizes could very. So for instance for the grade 303 your staff numbers 2802 which came in four different pivots sizes. unfortunately unlike Swiss watches where one staff is probably the right staff American pocket watch staff replacement has issues. It's why it's very important to measure all of the dimensions of the old versus new staff to avoid unpleasant surprises. That's because there are variations in sizing not just with the pivots size. Then a lot of times with modern replacement staff's rather than having four different pivots sizes they will just have a large size and allow the watchmaker to reduce the pivots to fit their watch.1 point

-

why does it matter if the cause is natural or not? Here is one of my favorite watches When it came in there was no crystal, missing hands and very rusted movement. Now it shows the scars of time just like me. Faded some and took some work to get ticking again. It cost me less than one dollar to purchase and only $45 to have it fully serviced. The mainspring arbor was rusted and needed replacement. it cost me $45. Of course it is all a matter of preferences.1 point

-

Not some actual "hands on" progress on the movment today. But some more good info collected! Found this! It certainly clears a few things for me. So it is the same movment as the FHF 96. So I think I let it in this thread. For future rerference on this movment. Hopefully it helps some more ppl. (hope it is ok to share this) Another pleasant news. Is HSL has offered to donate a spare movment. Im humbled of his offer. I offered to pay something for it. But he galantly refuse! Thank you HSL. It will defenetly help my skills move forward!1 point

-

Hi In addition to all the sterling advise you may find the attached document useful in future. TZIllustratedGlossary (2).pdf1 point

-

I made this for anybody getting started, feel free to share. Recommended Lubricants for Getting Started.pdf1 point