Leaderboard

Popular Content

Showing content with the highest reputation on 07/25/20 in all areas

-

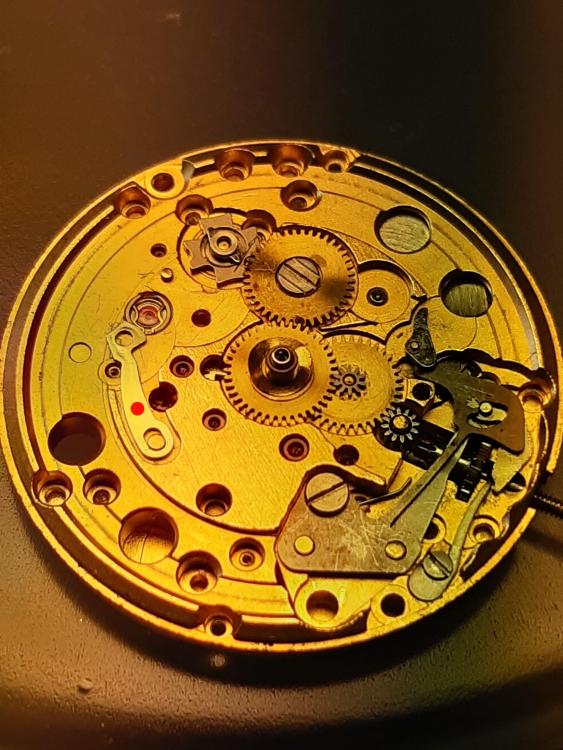

The other day I was flipping through some auction sites and stumbled across an offer to buy a Moeris pocket watch movement for about €19 (22$). Took a look at it and thought it would be a shame not to bid on it. The UNITAS 6498 is a quite nice movement and been cloned by many Chinese companies. Later on it became named ETA 6498. Most people start their practice career working on a ETA 6497 clone which is a cousin to this movement, they are slightly different in the layout. So here is a PDF as a small introduction to the UNITAS / ETA 6498 which shows my standard service approach to a movement like this and a small tutorial in how it ends up in a Chinese watch case. The PDF is optimized for use online to save server space. ETA 6498 Service Notes.pdf And here are some example shots from my service notes.3 points

-

Dial Up & Dial down variances I have found is usually is either too much end shake or the the H/S is not flat . I would would check the end shake and if OK re-clean the balance assembly and re-lube the cap jewels.2 points

-

Almost all done. Just need to sort the cutters out to get the drawer filled up2 points

-

2 points

-

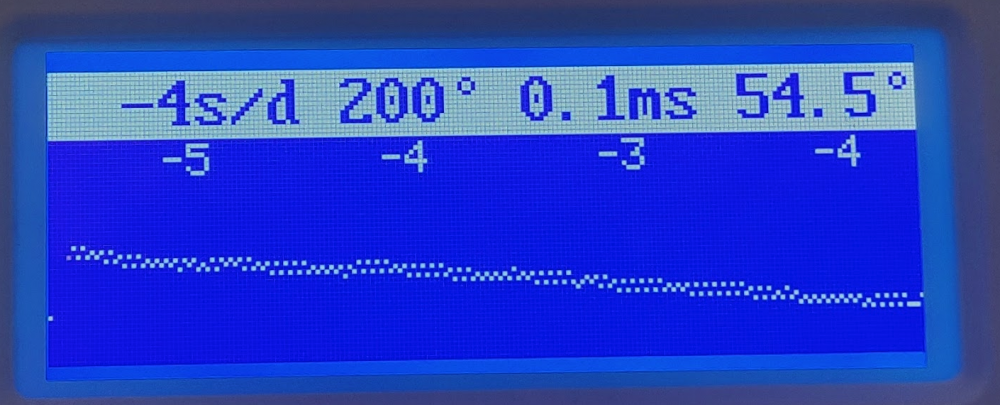

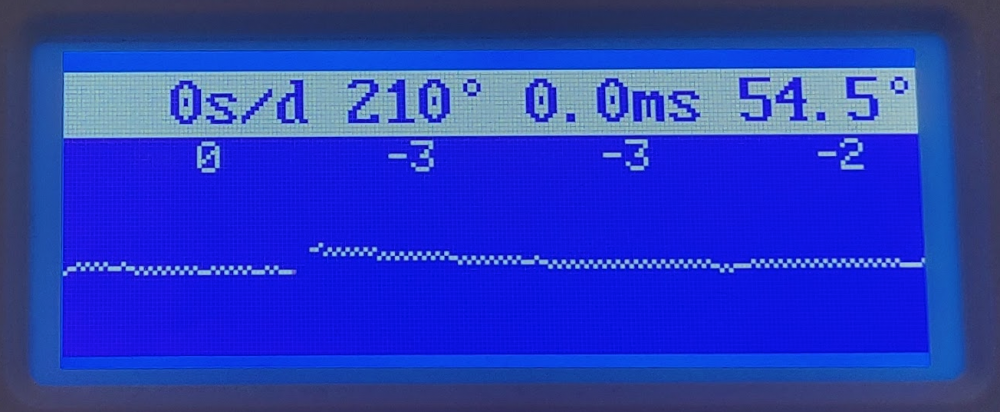

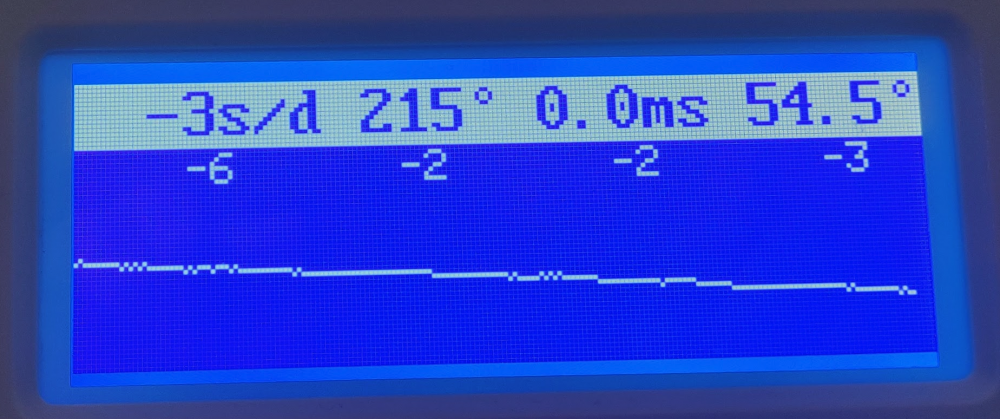

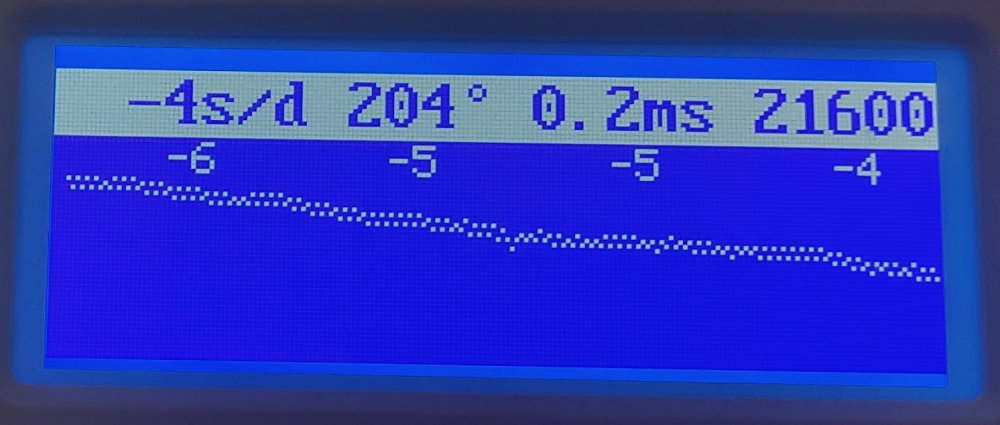

Hey all, Thanks for all the replies and suggestions. To begin, I took out, wiped off oil with Rodico and re-lubricated cap jewel, making sure to lubricate the flat side, which would contact the pivot. I then set it and took care make sure the spring was secured in place. Here are the readings: Pendant Down: Dial Down: Dial Up: Pendant Up: So I know there is low amplitude, but it does seem like the escapement itself is working decently well. I wound the watch by winding the ratchet wheel with a screwdriver. I think the weird readings were caused by my positioning of the cased watch on the timegrapher, as when I have the crown facing right, the readings come out dirty, and when facing left (away from spring handle as pictured), the readings come out clean. Pretty strange to me, but I guess there was some kind of interference or shaking with the crown? I think my amplitude issues might be mainspring related, as this was my first time servicing a mainspring and I definitely didn't give it the best clean possible. The positive thing is, the amplitude is about 50-70 degrees better than what it was before the overhaul1 point

-

@VWatchie Sorry, I was really busy at work yesterday and only just saw your request. The inner handle diameter is 11.76 but I measured the outer winder diameter at 11.8. I guess my measuring skills need some work!1 point

-

I ended up buying a Meylan stopwatch that has a broken staff. It was under $10 shipped and taxed so I figured it was worth the lessons it held within. It has a broken staff. This probably happened whenever these things were banged around, as the solid balance is pretty beefy. I decided to remove the staff just to see what it was like. It is a rather conventional friction-fit design so it was pretty easy to punch it out. I may even make a staff for it someday soon. Being that has a minimum number of critical dimensions, it should be relatively easy to make. The balance shoulder and hairspring shoulder are the same dimension. And the one-piece double-roller has the other critical dimension. The pivot is a rather massive .14mm. If I can find a pre-made staff for it I probably won't fire up the lathe. We'll see on that one. As I said above, these things probably broke a lot of staffs so there should be some parts out there. I'll report back if I find either on the bay or dangling on the end of a piece of wire (As my old friend Charley used to tell me.). Cheers all.1 point

-

Hello Fredric, condolences on you loss my friend but lets hope this community can help you on both counts and always remember the world is a large place but you will always have many friends some you will talk to see and meet, some you will never see and never meet but will talk to. we are always here, welcome friend.1 point

-

1 point

-

Hello Frederic and welcome. Thank you for your touching and personal introduction. I'm sure everyone here offers their deepest sympathy. They are a very friendly and supportive bunch. Here's hoping that you find some comfort in your new (old) hobby.1 point

-

1 point

-

Hi, from a neighbour to your south. My deepest condolences. Feel free to ask anything from your new found family and friends.1 point

-

Thank you for your introduction and welcome to this friendly forum. So sorry for your loss. You will have lots of friends here.1 point

-

A bargain and a great result. Well worth the effort. Many thanks for putting the tutorial together.1 point

-

Many thanks wls for your reply, much appreciated. The clock does need a clean, particularly the dust inside the cabinet. I’ve only had the clock a few days and over a twelve hour period she gained eight minutes, the “time lever” for setting the “time accuracy” being set to F. At the time I took the photograph I had set the lever to S and over a further twelve hour period she correspondingly lost approximately six minutes. Today I have the lever set at the mid point so will be interesting to see the outcome. When you mention the “cylinder platform needs a service” is that the mechanism at the top of the clock which I have been adjusting via the lever ? The glass appears to be original, heavy but dirty around the edges. I suspected my carriage clock to be at the cheaper end of those produced but it does have a look of quality. Maybe that says something about it’s age. Nevertheless it’s nice to know that it is an original piece - many thanks for your time. I’ve attached of a photo of my previous favourite mechanical clock but the carriage clock is the one I look at first !1 point

-

Depending where you are probably 500-700 euros/dollars/francs, maybe more, if less, probably a good sign you want someone else. The Valjoux 72 is an excellent chronograph movement, used by many makers including Patek and Rolex. It's definitely worth servicing.1 point

-

Hi! I got this vintage milling machine (gearwheel cutting machine) some time ago and restored it a bit. It was rusty and totally stuck, now looks a lot better and everything works smooth Still some cutting discs and the chest are waiting to get polished/sanded/painted. Do you think this antique tool still come in handy in contemporary watchmaker’s workshop from time to time? I know it looks the best on the shelf under a glass cover but can still do the job if necessary1 point

-

Never thought about that but think I've always intuitively been doing it. Very perceptive of you to be able to put words on it!1 point

-

It does appear to be epilamed, otherwise you would see oil on other areas of the escape teeth and possibly on other surfaces of the pallet. It may be a little heavy, I wouldn't want that much on a tiny 5 ligne LeCoultre escapement, but for a high beat modern watch, with epilame, is OK to me.1 point

-

Sorry I didn't spent all the time as you did on the Bergeon literature while pondering on this issue. Or I simply misunderstood. Sure I deserve being called names by such a smart person, thank you for teaching me1 point

-

Haha a hot point of debate till this day I'm afraid. Some would say overoiled and others might say otherwise. Even established brands have differing practices. Rolex might want this amount of lubricant on there but Swatch limits to a maximum of a wedge filling 3/4 of the gap between tooth and impulse face for example. I wouldn't use this much lubrication myself but I wouldn't knock this watchmaker for doing so. In fact I rather think he did a pretty neat job. I've looked at the escapments in my friends brand new Grand Seiko and Tudor watches and they've far messier applications. They both ran just fine with more than acceptable amplitudes on the timegrapher. The important thing is we're all in agreement that the lubrication must not migrate away from working surfaces or into areas that will degrade performance. Everything else is give and take.1 point

-

Hi 2fancy! Could you rotate the balance a little so that we can see a close-up the balance stud area? And also, could you flip the balance cock over and get a close-up of the balance stud?1 point

-

I was looking at the OP photos. Could it be that it's only the hairspring stud that's rotated? Maybe it's just as simple as rotating it back and getting the hairspring back in the regulator. Please take another look and advise.1 point

-

1 point

-

The common terminology for the parts of this type of main spring winder is as follows: Funny you should have a problem with this as you didn't when we discussed this a few days ago. You're just being silly! No, far from it, but good enough to make me pull the trigger. Now I just have to wait for a week instead of a month (or more).1 point

-

one of the problems as a beginner when you're learning watch repair is just how extreme do you want to go? Can we get you to fix the hairspring definitely can we teach you how to cut wheels manufacturer a watch from scratch sure but you going to have to buy some tools do some practicing and the watchmaking aspect that's going to take several years but we can definitely do is. But is it really what you want to be doing right now? unlike the newer Seiko where they're so cheap it's totally insane to replace the balance completes or even think about putting a balance staff it looks like the 7000 a can be disassembled. The separate balance staff is available which means it can be taken apart if somebody desires to. then if you do want to replace the balance complete its part number and cross references can be found at the link below http://cgi.julesborel.com/cgi-bin/matcgi2?ref=T_[EWFS then even if you're going to do a balance complete you still have to do a few things for us and yourself. Typically hairsprings get bent at the stud followed by the regulator pins and then a whole bunch of other places that we just don't want to discuss. None of us exactly are seeing the picture of what we need other than I can see the hairspring appears to be round the coils all look fine we just can't see the outer terminal curve. This is where I'm guessing the problem in this. So one of the ways we can see that is to look at the picture above which makes it look really simple and pop the stud out remove the balance complete give us a decent picture straight down and we can see where the problem is. You should be able to fix they hairspring attached to the balance wheel or at least close enough. Then if you get reasonably close you can practice putting it back into the balance bridge because of you get a balance complete a not up on the practice of doing that you might just destroy your balance complete before you even get back in the watch. So we have a lot of educational opportunities here.1 point

-

This thread is already too long so lots of post to read for someone who didn't follow it from the start. Posting a new thread for reassembly in watch repair help and advice subforum brings in more response. You are right that crystal is a goner. I soak and wash the case in solutiin of soap water, any old tooth brush will do. Beautiful watch. will work with you in every step of reassembly, be fun to see before and after pix. Regards1 point

-

As Mark had said take pictures as you go which is what I have done and was going do the same with the MS before it flew apart.1 point

-

When you unscrew the crown, when it gets to the last bit of threads all the force of the spring gets concentrated to that last bit of threads which will accelerate wear. A good way to prevent this is to push the crown in towards the case a bit as you're unscrewing, especially towards the end of the threading.1 point

-

Grab the arbor with a pinvice or barrel arbor holder (really just a glorified pinvice) and turn clockwise while keeping firm pressure against the spring. It should open up and take the arbor.1 point

-

Come on guys!... 2fancy has a problem with his hairspring, so it's not about who is ultimately right. Personally I try not to make absolute statements to say something 'can't be done' as someone will prove otherwise. I like to get the hairspring off the balance cock, so just the hairspring, collet and stud are present, then I'll see just how out of round it is. I place the hairspring on top of the balance cock, position the stud over the stud carrier and the collet in the centre of the jewel and see if the hairsprings outer curve marries up with the regulator pins. I get a good idea what needs tweaking then. Personally, I would try removing the hairspring collet from the balance staff, regardless of what I'm told can or can't be done. The experience of it is worth the cost of a donor balance1 point

-

1 point

-

I would like that. LOL I don't see it as a screw up, I'ts part of my learning style. Jump right in and see what skills I am lacking to get the job done. It's only screwed up if a professional says it's hopeless. Then it goes on the shelf for wile till I can prove them as having prejudged it's demise1 point

-

Hi OH Thanks for your reply, It is a 10" dial and there is no makers name. I had noticed the square screw heads on the movement but the screws holding the spandrels to the dial are round heads. Thanks for the advice re the bushing machine, in the past i've always re-bushed by hand, i do have a fair range of clock reamers and watchmakers lathe, but needs attaching to a board or my bench. What type of brass would you suggest for the bushings. The auction description did say that they thought the case was later than the movement, I believe the clock came from a country house/hall in Northumberland but no sure which. Again thanks for the advice Karlvonkoln I will post more pictures but it may be a while as I have two other longcase clocks, 1 wall clock and a mantel clock that I need to get finished for customers.1 point

-

1 point

-

1 point

-

Of course it does. Your watch is already accurate enough for collector's purposes and can probably made better with just demagnetization and regulation. Also be aware that service cost by a qualified processional can easy be three or four time the value of your watch or even a brand new Seiko 5.1 point

-

Watch repairs/makers have timing machines in order to be able to tell how the movement is preforming, gaining or losing time. That is the modern way of being able to adjust the movement’s time keeping; this is normally part of the service. You should have enquired what the servicing entailed, no harm in asking them.1 point

-

Normally it is part of the servicing. Otherwise the watchmaker won't know for sure if he did the right job or fixed whatever needed fixing on the watch.1 point

-

Was it an overconfident dentist? Yes, anything can be fixed. It's just a matter of skill, and some money to get the replacement parts. The tricky bit is the skill. Take it to a watchmaker/repairer with some credibility and he or she will take care of it for you. Send the bill to dentist!0 points