Leaderboard

Popular Content

Showing content with the highest reputation on 07/24/20 in all areas

-

3 points

-

Sorry for being OT, but I just can't help myself! Success is not final. Failure is not fatal. It is the courage to continue that counts. ~ Winston Churchill3 points

-

Grab the arbor with a pinvice or barrel arbor holder (really just a glorified pinvice) and turn clockwise while keeping firm pressure against the spring. It should open up and take the arbor.2 points

-

It was not my intention to butt heads with anyone or derail the topic. I don't frequent this board nor contribute (which I plan on rectifying soon) as much as some of you and I have nothing but the highest of respect for those that do, and I understand @jdm to be one of them. I hope there to not be any hard feelings nor any animosity going forward.2 points

-

2 points

-

I hope you don't mind if I upload it once again here. hector's_magic.mp42 points

-

When I was young someone told me "You have not lost until you give up". I often think about that when a task or situation feels daunting.2 points

-

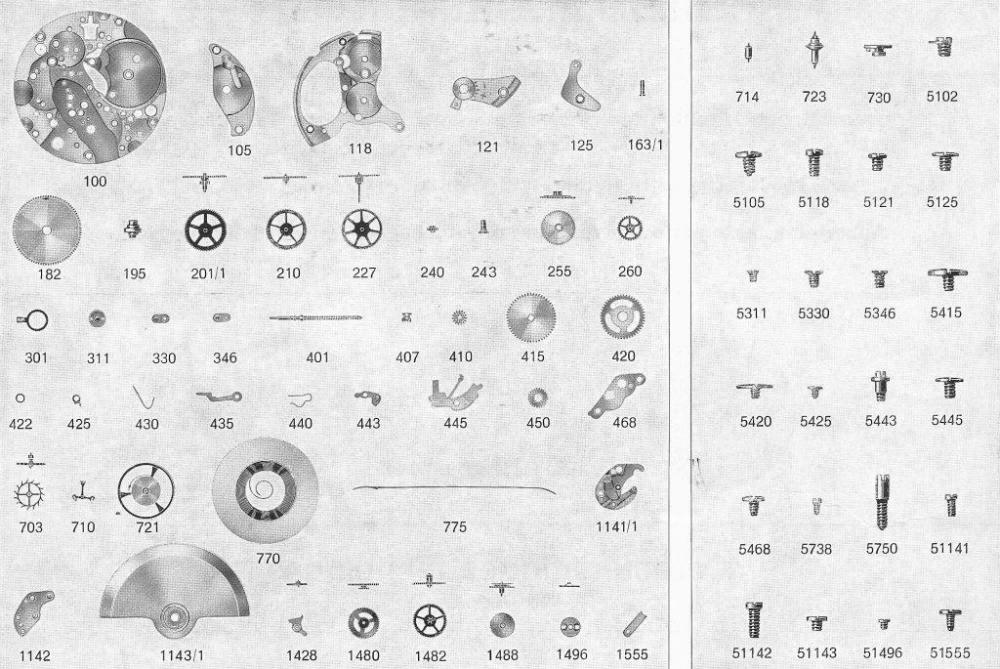

Hi When I install the minute hand, its sitting tight enough on the minute wheel (tested manually by turning with a tool). If I tighten the canon pinion more, I'm not able to turn hands by crown. Do I have to tighten the wheel 240, sitting above 210, marked red? If so, how? Right now, 240 is sitting loose. Kind regards Khan1 point

-

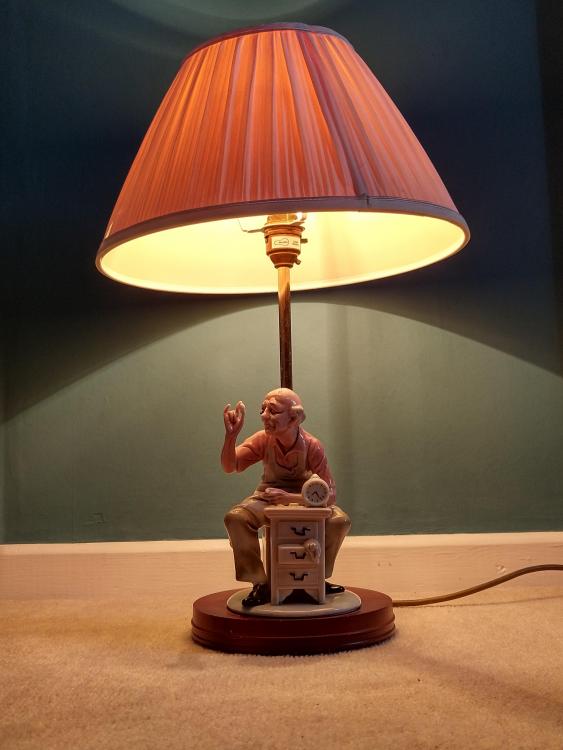

May be the patent application was for the lock? And where is the key? Then they may have spent the related fee in at the pub instead? Difficult questions, I know. I know the model, he's my watchmaking mentor, portraied 30 years ago.1 point

-

The alum powder arrived and it's performed remarkably well. I was a little sceptical but I've successfully managed to 'dissolve' the stuck screw thread and I've got some spare parts lined up. I'm quite looking forward to trying to get it back together in one piece. I'm feeling that its going to be slightly more complicated than taking it apart...1 point

-

Is this an AS-2066 you're dealing with. If the stem (I know you use the term 'staff') isn't moving as it should and allowing you to move to a position to change the hands then clearly there must be a problem with the keyless works in some way. A good bet would then to look at, say, https://www.youtube.com/watch?v=WM5gD6PQm5Y around the 13:30 mark and compare where your keyless works are compromised.1 point

-

1 point

-

Gentelman indeed. I do pull his legs occasionally, he just lets me get by with it.1 point

-

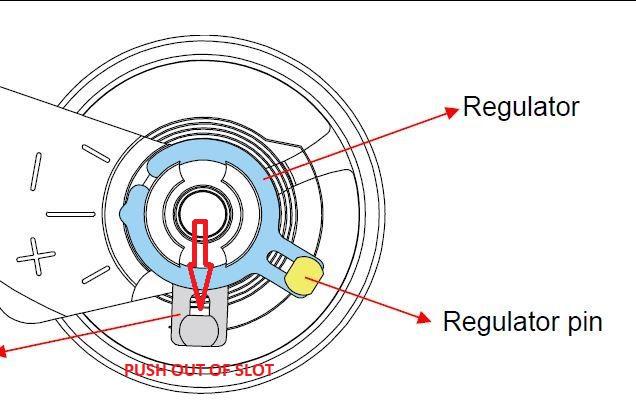

Come on guys!... 2fancy has a problem with his hairspring, so it's not about who is ultimately right. Personally I try not to make absolute statements to say something 'can't be done' as someone will prove otherwise. I like to get the hairspring off the balance cock, so just the hairspring, collet and stud are present, then I'll see just how out of round it is. I place the hairspring on top of the balance cock, position the stud over the stud carrier and the collet in the centre of the jewel and see if the hairsprings outer curve marries up with the regulator pins. I get a good idea what needs tweaking then. Personally, I would try removing the hairspring collet from the balance staff, regardless of what I'm told can or can't be done. The experience of it is worth the cost of a donor balance1 point

-

Part No 240 is your offset canon pinion and drives the minute hand. Do not oil 240, grease it.1 point

-

I had a similar thing happen to me with a 9 ct case and snap back. Some metal was shaved off and it didn't snap on anymore. I took it to a guy in Hatton Garden, London last week and he fixed it for me. It wasn't easy, but he reshaped the back of the case slightly and built it up with a little more gold. I was really impressed. If you want his contact details, message me. What drew me to him was on his website he said "No repair is impossible". Which I thought was a bold statement, but liked that attitude. I like to fix most things myself, but sometimes more damage can be done, if I don't know my limitations. In this case (pardon the pun) I knew I needed some help from someone who has experience with these problems. Good fortune with repairing it..1 point

-

Welcome to Jdm's club captCalvin, this should teach you to run and fast as soon as jdm starts the next debate in a min.1 point

-

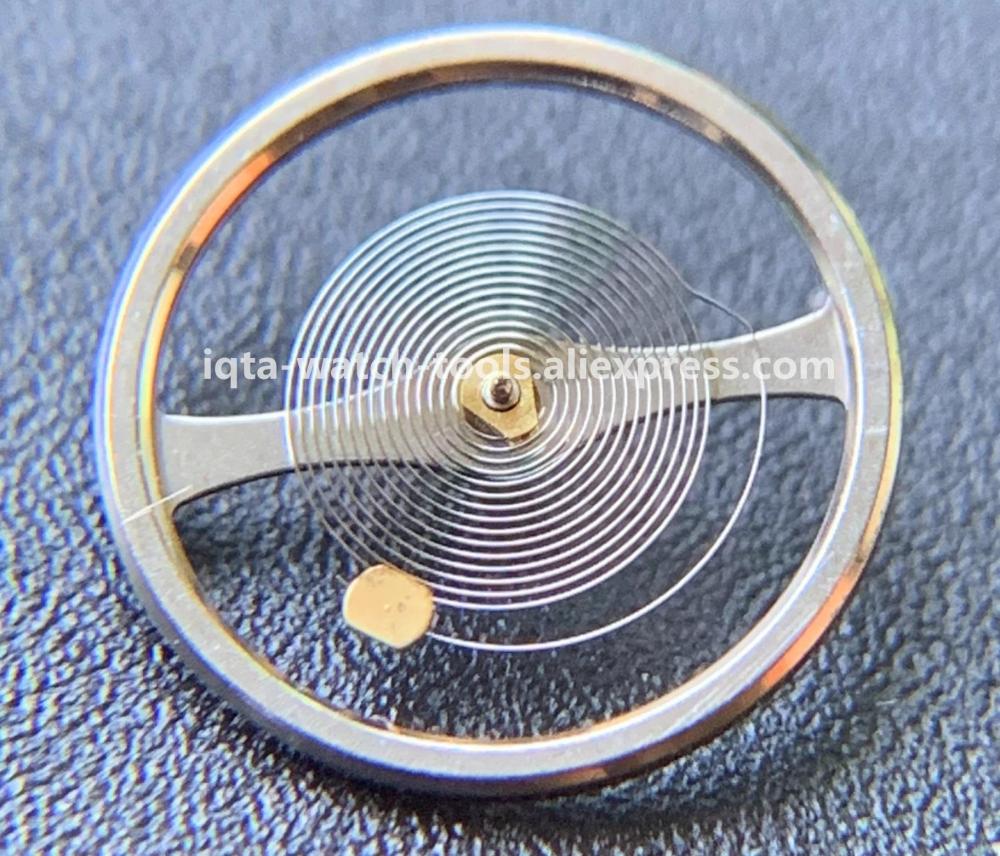

Okay my earlier assessment of an inner coil binding up at the stud appears to be incorrect. It seems that you do have a bit of a headache on your hands. I'm afraid I must ask you to detach the stud from its carrier to separate the balance complete from its bridge so we can get a clearer look at the hairspring in its relaxed state and tell you which spots might need correction. Here is how an intact balance complete should look like detached from the bridge:1 point

-

Like I said I will be making a post about my project in the projects section real soon. It's main focus will be on what can be achieved with the NH35 and similar movements in terms of positional consistency with some work. Although it will include pictures with the hairspring+collet removed from the balance as well as it put back together and running on a timegrapher, how it's done will not be elaborated on, reason being it was done the same way as you would any other movement: with hand levers, and it was not any harder nor more challenging than any other movement. Therefore such standard process does not warrant my explanation as it can already be referenced from numerous sources. I have read your statements and the one I take particular issue with was this one: It's written as a reply to Nucejoe, who, if asking this question, clearly knows that this is a measure one might take to correct a hairspring and was giving sound advice. Yet you state "Collet is not removable if you want to be able to use the balance again" as in "not possible without breakage", when in fact it comes off and goes back on as easily as any other. He was then misled into believing such a task is not possible on this caliber, as evidenced by his subsequent post recanting the earlier advice he gave and proposing a less than ideal solution. Who are you protecting from this "harmful information?" Or do you actually believe Seiko uses some special method for mounting collets to their balance wheels making them non-detachable without breakage? I believe as adults that when we want to learn how to do something, we should be given factual information about how to best approach it. We can decide for ourselves if it is something we are willing to try or if compromise is needed if for whatever reason the ideal solution is not achievable at our skill level or risk of failure is not tolerated. Withholding or giving erroneous information in an attempt to protect someone is what you do to kids. Doing so to an adult would be an insult to their intelligence. Well that's hardly fair isn't it if you checked out of the debate before I got a chance to make a rebuttal or closing statement?1 point

-

1 point

-

I found an identical Minerva stopwatch on the bay. After replacing the broken spring under the dial it came time to figure out the setting of the hands. It was a bit tricky trying to get things to line up as I lowered the dial/cams over their respective posts. I ended up Scotch-taping the hands at the 12:00 position while I maneuvered the dial into place. Believe it or not, it worked. The dial screws were the cam style. It took some force to engage, but ended up grabbing. While it seems there is little interest in stopwatches, I find them rather interesting. They're probably used as much or more in the general population than their time-telling counterpart, the pocket watch. And despite having only 7 jewels, the Minerva movement is pretty well made. Not particularly valuable mind you, but neat. Cheers all.1 point

-

1 point

-

I had a client who suffered the same dilema and did not want to purchase an assortment of pins on the off chance we could find one to fit. So I resorted to loctite thread locker which cured the problem and the watch is still being worn 2 years on. Not the most satisfying repair but he was very happy with the job.1 point

-

I have a link of someone who claims to have roller jewel's providing you can give him the size. https://www.daveswatchparts.com/Jewels.html then looking at eBay yours assortment and what is that I see in the middle? as they were a must have tool at one time plus they often go unrecognized by any of the new watchmakers they are lurking out there on eBay UNICEF to go looking for them. https://www.ebay.com/itm/Lot-of-10-Vintage-Watch-Repair-Tools-Lot-33/143661067677?hash=item2172dded9d:g:-VoAAOSwdwpfFIz3 then here's the Elgin version which I have all by itself. https://www.ebay.com/itm/Vintage-Elgin-Pocket-Watch-Roller-Jewel-Gauge-Tool-Watchmaker-Bench-Favorite/373120661004?hash=item56dfb9760c:g:vPUAAOSwm8FfFK9b1 point

-

I had a HS looking similar to this (I guess) and was very much helped by this post by @nickelsilver. Not saying that's all you need to do, but might come handy at a later stage. Good luck!1 point

-

https://a.aliexpress.com/_d6ThBoH I'm not sure if this link works. AliX app changed something.1 point

-

Compuchron? Check out picture of movement at the bottom of this page: http://www.crazywatches.pl/compuchron-hughes-aircraft-led-19761 point

-

1 point

-

Just testing my contraption with some random stuff in my clinic. Using plain water only. Notice the huge vortex. Some anti-vortex baffles will definitely be necessary. Everything comes out magnetized but the good news is that the magnetic stirrer itself can be used to demagnetize the items. 20200722_100602.mp41 point

-

Thank you @Nora! My post was meant as a friendly encouragement as well but I don't think it came through all that well. I'm deeply impressed that you would go for this rather tricky operation so soon. Watch repairing has many, many challenges, and I guess it takes a while before you've taken on most of them. Next on my list of challenges will be dynamic posing and resetting/adjusting pallet stones. Before this I was happy to succeed with replacing jewel bearings, adjusting end shake, and adjusting a hairspring. "They" say there's nothing magical about mechanical watches and Precision Mechanics, but I somehow hope I'll never get to realize it Good luck!1 point

-

Here are the mainspring winder sizes. Caliber Barrel Arbor 2000 7.34 1.63 2671 7.35 1.65 2235 8.04 1.80 8500-1 9.30 1.90 8500-2 9.30 2.28 8200 9.91 2.65 C07111 10.90 1.50 3135/2824 10.91 2.44 2892/2836 10.90 2.44 7750 12.00 2.73 Notes: Accurate to +/- 0.02 2000 and 2671 differ by winding direction 3135 and 2892 differ by arbor shape, 3135 has a cut out section and 2892 does not, I have no ideas why.1 point

-

After getting the go-ahead (with indemnification) to use a bit more force from the stopwatch's owner, I pried a bit more aggressively. The dial did come off with the hands still attached to their lower cam pieces. It turns out there is a broken coil spring under the dial. That's what we figured based on the action, or lack thereof, of the main button (Crown). I'll probably have to buy a parts watch to get one. The next tricky part will be in re-setting the dial/hand unit. Surely the cams must be set just right relative to the return to zero position. Hopefully I'll figure that one out. Cheers. Images included for the curious.1 point