Leaderboard

Popular Content

Showing content with the highest reputation on 07/21/20 in all areas

-

Here are the mainspring winder sizes. Caliber Barrel Arbor 2000 7.34 1.63 2671 7.35 1.65 2235 8.04 1.80 8500-1 9.30 1.90 8500-2 9.30 2.28 8200 9.91 2.65 C07111 10.90 1.50 3135/2824 10.91 2.44 2892/2836 10.90 2.44 7750 12.00 2.73 Notes: Accurate to +/- 0.02 2000 and 2671 differ by winding direction 3135 and 2892 differ by arbor shape, 3135 has a cut out section and 2892 does not, I have no ideas why.3 points

-

Archer (from the link above) is an outstanding watchmaker and is very generous with his time and knowledge on at least a couple of forums. I will say though, that the spring he shows that is "out of flat" and thus needs to be replaced, is absolutely A-OK. If you have a spare spring around, nice and flat, put it in the barrel, grab the arbor with a pinvice and wind it up without the cap on. You'll find that it wants to go everywhere except around the arbor. This is why there is wear on barrel bottoms and caps, and why the sides of high grade mainsprings are well finished, one reason why the spring needs to be lubricated, and why some really high end makers actually add hardened steel discs above and below the spring (I think one even used sapphire discs). Of course this has been an argument I've had with pro watchmakers over the years, to the extent of purposely distorting a mainspring and comparing amplitudes and running reserves to prove the point. Yes, when very distorted in the flat it can pose a problem, but a slight out of flat laying unwound on the table is no problem.3 points

-

as a reminder if the timing machine has dots all over the place then the numbers mean nothing. When Chinese machines work they work really well when they don't work they like to give you numbers I guess to make you feel good but if you can't see you something that resembles the waveform of lines the numbers are worthless. then is this a clone or a real eta? Also does it have a – number after it and what kind a regulation system does it have like perhaps etachron?3 points

-

Depends of which one? I been playing around with the reversers a bit. The V105 is probably something like Moebius 9010 in an alcohol solution, this makes it easier to just get that small amount of lubricant needed for the small levers inside the reverser. Nowadays i just put a microscopic dot into the reverser and blow with air so it circulates, the centripental forces will do the deed for you to spread the lubricant around, with this method practice makes perfect. The most important stage is however asusual to clean the reversers rigidly, when you think their clean, clean again. I use One-Dip solution and epilame. Just keep in mind to keep track of the small pinions which come loose during the cleaning process. Here is one quick and dirty PDF. Reverser.pdf And live comment from the from lab, "One always need a bunch of setups to try out your theories on"2 points

-

@matabog The theory is that If the arbor is too small to catch the hook you can carefully shaped the first turn to make it tighter. I've not had any success with this as I've always chickened out in fear of breaking the spring and hand wound.2 points

-

And even if there where no click the arbour hook and barrel wall cut will tell you the same. Observe, reason, conclude.2 points

-

Are you sure that you used the correct screw for the end float adjustment and not the one with the slight chamfer on the head?........With every single one of these that I have worked on the balance can be locked by tightening the screw too much...... In true 'Blue Peter' fashion, here's some I did earlier......2 points

-

Can't really tell just from the picture, but the entry stone could be a little deep. The lever escapment is complex, and really needs to be approached in a logical step by step manner. If you move that entry stone in, you will reduce the drop lock on the exit side, which may or may not be ok. If you then move that stone out to increase its drop lock (and total lock), you will increase the drop lock on the entry. Or, it won't unlock anymore at all, as the fork hits the banking pin before the escape tooth can come off the impulse surface of the exit stone. Adjustments to stone depth are often on the order of 0.005mm (5 microns). It's good to have a way to measure how far you've moved a stone; Bergeon makes a tool for this of course. I don't like it, I use a measuring microscope, and heat my fork on a brass plate and move the stone with with either an oiler or clean pegwood; oiler to move it out, wedging it behind the stone in the slot and twisting, pegwood to push in, holding the fork with stout nickel (or brass) tweezers. The plate has holes in it to accommodate the arbor. Fork upside down. I use an adjustable heating plate under the brass plate (bergeon), but you can do it with an alcohol lamp like most books show. Mark has a video on it. I recommend Jendritski's book Watch Adjustment for a good description of the checking and adjusting procedures. But to get you started- With the balance in, power on the movement -stop the balance with a finger (with finger cot), and rotate it slowly until an escape tooth drops off one side of the fork to the other -observe the depth of lock at exactly that point. It should be, as a rough rule, about 1/5 the width of the pallet impulse face (just as a length reference). If you move the fork with an oiler toward the balance, the escape tooth should not come off the locking surface. If it does, the stone needs to come out -continue turning, the lock should increase, this is the run-to-the-banking, or slide, as the fork continues to the banking. Check the fork horn freedom along this time, this is the fork horn hitting the face of the impulse jewel (the safety action before the guard pin takes over). The total lock now should be roughly 1/3 the width of the pallet face. -check that you have freedom between the guard pin here, using an oiler to move the fork from the banking. Continue around the safety roller moving the balance and the fork -do this on both sides, entry and exit. If you have good looking drop lock on both, but excessive total lock, move the bankings in to reduce. If you have excessive drop lock, move one or both stones in as needed, keeping in mind moving one has the same effect on the other (for drop lock). If the locks all look good, but you have no or little guard pin clearance on one side, you may have a bent pin. This goes for the fork horns too, but that's rare to have a problem there. If the guard pin looks nice and straight, and the safety roller isn't damaged, it may be that the bankings have been shifted, both, in one direction and the stones moved to adapt, but now the pin is contacting the roller sometimes. For a quick cheat- and this is really a cheat, meant for folks who know how to otherwise check things- - move the balance until the escapement drops. Check the fork safety (fork horn clearance). This is, or at least should be, a little larger than the guard pin clearance, so the maximum "safety action" the escapement will see. You can move the stone in until you are just on the verge of unlocking when checking this clearance. Most of the time this will work, especially on a modern piece, and you will have safe escapement function with the stones in the fork as far as they can safely go.2 points

-

Look at the arbor. There's a screw on one side, and the other is just a pivot. Now look at how the barrel fits into the movement. The ratchet wheel goes on one side, and the barrel has teeth that engage the train of wheels on the other. Knowing which way the arbor fits in the movement, look closely at it and you'll see the hook. Compare the direction of the hook to the spring, and it'll become self evident which way it needs to go in.2 points

-

I've grown up with a fascination for pocket watches. I like Elgins the best, especially those from the 19 teens. I've taken a couple of them apart in the past to see how the parts interacted with each other. I was never able to get any of them back together again, but saved all the parts to each just the same. After watch many You Tube videos I was convinced I could learn to be a successful hobbyist repairer. My latest accomplishment is to completely disassemble and reassemble Grade 303's. My current goal is to learn to repair the balance assembly. Nora2 points

-

It's likely 170° all the time, but being so low is confusing the Chinese algorithm. Sometime is touching or loose, likely in the balance / escapemente area, but it could be elsewhere too. Time to apply the usual stepped / excluding diagnostic.2 points

-

I've started trying to replace balance staffs in pocket watches. My first victim is an Elgin 0s model 2. I've got the correct tools for the job. Disassembly went fine, but after installing the new staff the balance wheel now has a slight twist to it and wobbles. I "tried to fix it" with a pair of parallel pliers but have only made it worse. It is now also out of balance. My questions are, What did I do to cause this? What steps should I take to avoid it again? Lastly how do I fix this one? Thank you in advance, Nora1 point

-

NOS reversers are unused but might be 20 yrs old so oil on them has long expired and sometimes dried, in which case you would need to clean the old oil and re-lube. The method you described above works just fine in such a case. I first thought of large font out of great respect for OH, hope he is comfortable with this font. Glad you are comfortable with small font as well. Regards1 point

-

I offer this to you as encouragement. Stop just secretly thinking about it. Buy a watch with the part you want to work on already broken and give it a try. you will get one of two results. It will still be broken in the same way as you started with or it will work out. I call it the rule of 50. 50% it will, 50% it won't. It's like the old adage "you won't know till you try. Worst case scenario, you try it and don't like it. In that case resell the movement and the tools for what you have into them, and move on.1 point

-

As a frequent seller on eBay, I feel your pain. My first Defy was described as working well, but the movement wouldn't wind and the date could not be set via the crown. My second Defy was described as original, but it had a nonoriginal crown and crystal that weren't evident from the provided photos. Please rest assured that I only return items if there are really significant errors between the photos and description and what I actually receive. /// I sell a lot of vintage camera lenses and equipment, and always err on the side of overdisclosing any flaws and providing more photographs rather than fewer.1 point

-

1 point

-

1 point

-

How? If you order a new spring, it'll come in a little disc so you can just pop it into the barrel like nothing. It's also possible to hand wind them into the barrel without doing damage. It's easier than it sounds.1 point

-

A faulty reverser will probably not give that effect on the winding on a 2772, that is a quite robust construction which probably will rotate slow when the barrel wears and breaks a bit more. Nothing to worry about since the winder will surely but slowly wind the spring just by rocking, it doesn't always have to rotate like a mad Viking at midsummer.1 point

-

Unfortunate not. Hopefully he dose remember and gives us the link. May take sometime before he visits the forum site though.1 point

-

1 point

-

Hi There are procedures to follow when battery changing on there watches, some of them you need a degree to be able to follow them. Find attached the tech sheet on the last few pages there is the set up routine. enjoy the reading. cheers 7632_Seiko 7T62A, 7T92A, 7T94A Part 3 of 3 (3).pdf1 point

-

Hi well done so far Now you need to learn trueing the balance in the calipers and poising the balance. Firstly you need a pair of truing calipers or a truing jig so as to get the rim running flat then poise the balance in the jaws to check if there are heavy point, either of these being out of true will affect the timing rate . Pictures of the tools below.1 point

-

The deep end is an illusion. You can float in 3 feet of water and not touch the bottom doing so. You can float in 300 feet of water and never touch the bottom. Both feel the same way, so it then comes down to how far from shore do you feel comfortable being. Cheers!1 point

-

Quarts modules are there to baffle you with nonsensical behavior (from a mechanical point of view). Replacement is 65 GBP on Cousins if you want the watch to fully work, otherwise good luck!1 point

-

When I was looking at bezel removing tools before I came across one made by Omega that had good reviews but it was over £1000 and you had to have a Swatch account to buy it so that was not happening. Recently I noticed the Bergeon 7152 had good reviews but a set with 6 bezel removers is £840. I just stumbled across this Chinese bezel remover set which looks like both of them which is £130. I've studied the photos and it has got a lip for catching under the bezel. I'm normally wary of the Chinese tools but and at £130 I'm willing to give it a go. I'd just like a second opinion if anyone can offer their thoughts. The link to it is- www.wish.com/product/watch-bezel-ring-with-elastic-rubber-watch-bezel-ring-remove-tool-5d84798e05053e0e5f20d178?hide_login_modal=true&share=web1 point

-

Interesting mix of opinions here from experienced people... "Any time there is a disagreement between two rational parties, the answer lies in the middle". Also, "everything is gray, there is no black or white." Since the responses (here and elsewhere) range from "any deformation means replacement" to "don't worry about it you're fine", my takeaway is a little deformation isn't going to affect anything, but there's a curve of diminishing return with an assumed point where the cost of a new spring and the wear/performance intersect. Since there's a cost component, it's specific to each watch by value (market or sentimental). With an expensive watch with a high accuracy requirement or a sentimental watch without easy access to replacement parts, err on the side of a new spring. If it's a cheap watch that's not capable of especially high accuracy and the wear isn't that big of an issue (due to either a ready supply or replacement parts or a relatively low value), don't worry about it. Then draw a line between the two, and figure out where you fall on that line.1 point

-

Jump in the deep end! That's how winners roll! That's also how you break things, but you learn more and more quickly that way. Kudos.1 point

-

That is why I don't sell on Ebay. Too many chances of meeting a difficult buyer that expects more no matter the effort spent to provide an honest description and pictures. Just be aware that servicing at the manufacturer or official service center can easily set you back €600 plus any part they may find that needs replacement.1 point

-

Thanks a million, John. I managed to reduce the endshake to where I want it. It took a bit more torque than what I would normally put on a watch screw. Thanks for the service manual, Watchweasol. It was really helpful. Good to know how the factory did it.1 point

-

pallet folk jewl setting.pdf Not easy job see PDF. Also see this from a previous post which includes a pic of the tool I use.1 point

-

You need to find someone that has the ETA winders set to give you the dimmensions. What I know from a friend that bought only the 2824 winder - the arbor is 2,5mm. So I suppose the newer winders have smaller-diameter arbors. Which, I suppose, is good for the current calibers, but won't work for the older calibers (it won't catch the maisnpring, and the bigger-arbor winder will have a barrel too big). So you need to know what you're working on. I am satisfied with my Nivaflex set, together with the improv's I made on it, because I can use them for both older and newer calibers. About the left hand arbors... I use two consecutive barrels, the larger being smaller then the watch barrel - and I right-hand wind it in the smaller barrel and then push it in the bigger barrel. Then, I will finally push it in the watch barrel (I am talking about seikos, citizen and Orients). p.s. I also have #6 and #7 left hand winders, which are 3 and 3,5mm. But I don't have the 2,5mm arbor... so, depending on the watch arbor diameter, I use the left hand winders or the small barrel-big barrel improv. Good luck!1 point

-

I'm attaching a PDF it shows the complete listing of the standard winders and the barrel diameter not unfortunately the arbor diameter. Then there is the other little problem the numbers on barrel itself and the arbor? I'm going by memory but it appeared to me that the Eta sat and even the ones Rolex do not actually Mark what therefore they just have a number. So if you have the Eta sat and the standards set they will both have numbers conceivably the same number and yet they're not the same sized winder? As we have both sets at work if I remember tomorrow I will verify my memory. Then realistically what you need is one set of the barrels and three different winding handles. The old style and the new style for both the right-handed and the left. I assume that the left hand is in the new style versus the old? Then even if you had all of that occasionally you need a different winder for your mainspring I don't think there is a perfect set for all mainsprings. Because I've had incidents where none of the sets would 100% cover what I need to do. Bergeon Mainspring 7023 A B C.pdf1 point

-

In my book, The 80% you have already achieved is a prerequisit for the remaining 20%. .1 point

-

1 point

-

If your talking about the hook on the arbor then I will need to get better magnification which I have something coming it soon. Thanks!1 point

-

Hi Nora, There are actually a couple other threads here of people who went through the same thing, that is wobble after replacing a balance staff. Here is one: Another thing I can think of is maybe the wheel was damaged process of replacing the balance staff and needs to be poised. Here is an article talking about checking poise and poising a balance wheel: https://www.great-british-watch.co.uk/how-to-poise-a-balance-wheel/ Hope this is helpful!1 point

-

1 point

-

Hector - see the attached photo related to end shake on Timex electric such as the one you are working on. The loud sound is common to all of them. As you state it does at times depend on the angle the movement is in. If I wear one of my 'Electric' watches and leaving it on the night stand next to the bed, at some point it gets tossed to the carpeting on the floor so I can go back to sleep without hearing the 'ticking'.1 point

-

I have 2 theories why the cleaning machine is not cleaning properly. I noticed that L&R Extra Fine contains ammonium hydroxide and propanol. If it becomes contaminated with water, it would react with oil and produce a soap by a process of saponification. The reason for the fluid turning green may also be evidence of the presence of water in the fluid. The gummy residue is soap scum. My second theory is the rotation of the basket is too fast, and the level of fluid in the jar is not high enough to prevent the fluid inside the basket from being spun out. Hence the centre of the basket is actually running dry. Perhaps a chemist and physicist can confirm my hypothesis.1 point

-

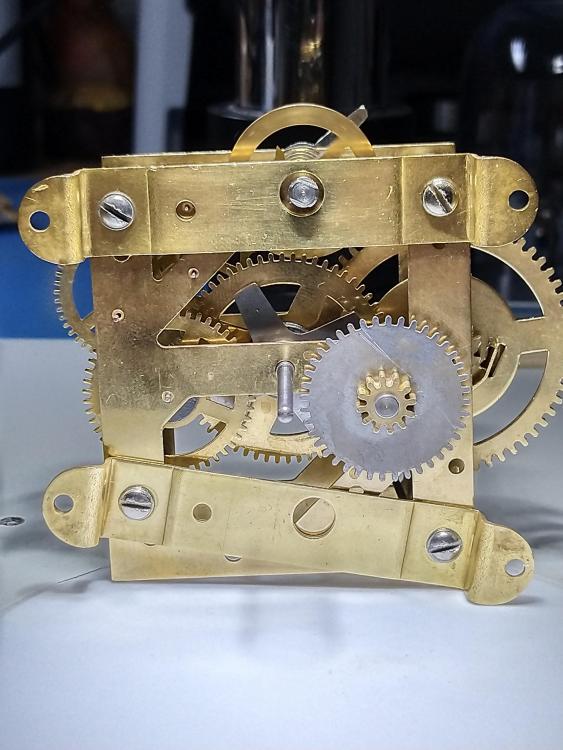

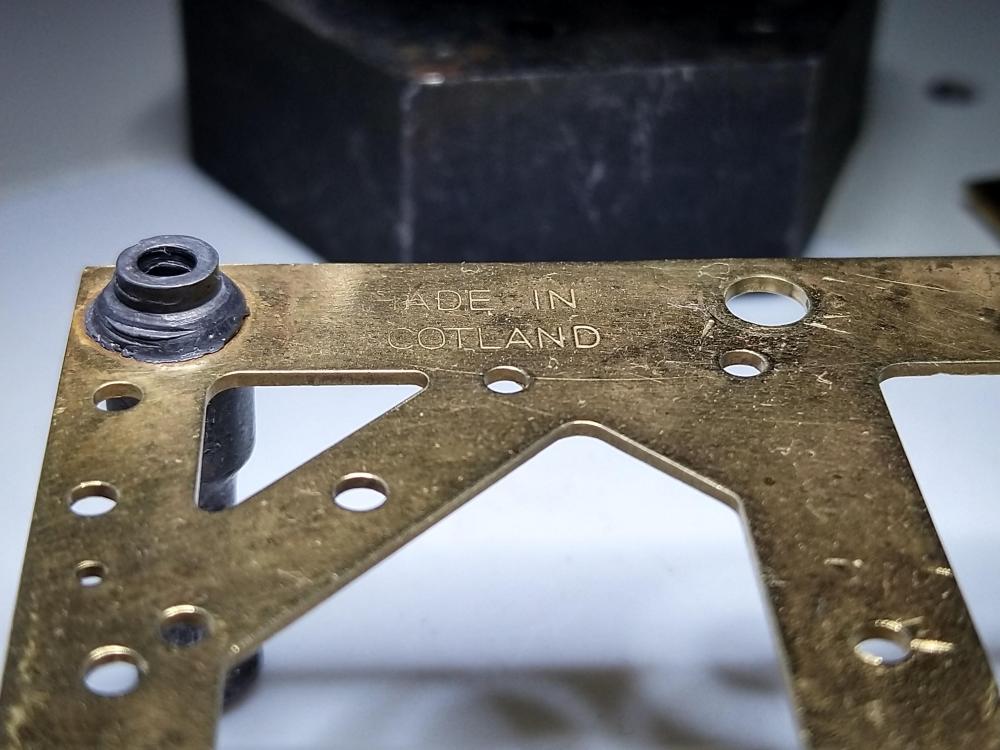

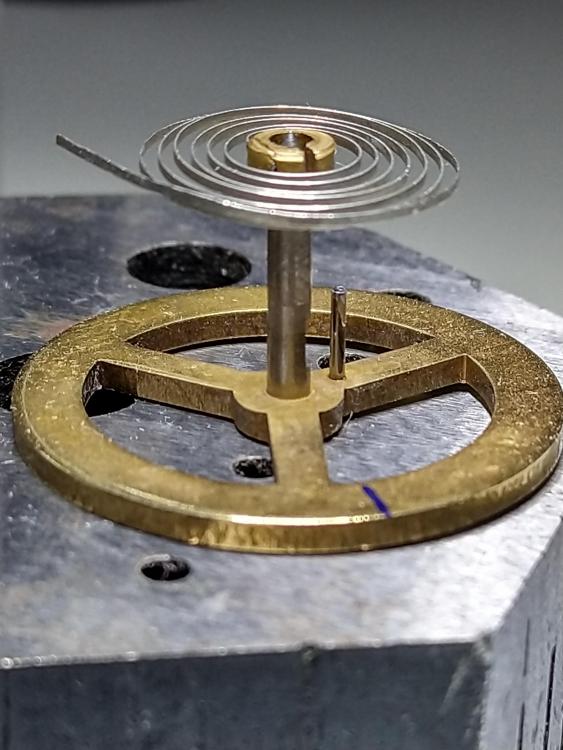

The best I could do with the hairspring, not perfect, but after so many defeat I call it a draw: The place where this wonderful piece of beauty was made, the person who operated the hammer did not have his morning haggis so M and S are missing: The movement together: I had no faith - plus a was lazy and did other important things as playing computer games -, that's why it was sitting on my bench and I did not touch it for a week or so, and i don't know if it is in beat, but it actually works! : time_savings_clock_movement.mp41 point

-

I've been wearing this watch for about a week. It's keeping pretty good time, less than 10 seconds a day. But my problem now is that when the watch is tilted at a certain angle, the ticking becomes really loud, like a time bomb about to go off. Like when I bend down to tie my shoelaces, that's about an arm's length away. I noticed that there is excessive endshake of the balance wheel which is probably causing the wheel to knock against something. This is probably a question for JerseyMo. Is there any way to reduce the endshake? In other Timex watches with a conical pivot, the end screw could be adjusted to adjust the endshake. But in this watch, it appears to be a jewel, with no means for adjustment. 20200719_203917.mp41 point

-

I would be curious as to what a typical American pocket watch is? I think you'll find the video at the link below interesting it shows a nice simple method how to figure out the lift angle. Of the pocket watches that I've done 36° is a bit on the low side. On my list 38° is the lowest and I guess a six size is not a pocket watch because I have a couple of those that were 62°. I would say on average closer to 45° would be a better average for American pocket watches. https://youtu.be/-Xgcck692js1 point

-

@HSL demonstrated how he disassemble, clean and lubes reversers. I am looking for his post, hopeful to find it and will inform you. Considering your watch is a Tudor, I personally prefer and recommend new replacement.1 point

-

After the Timex setback at lunchtime, I decided to take a look at a couple of first generation LCD watches. None of your fancy Casio G-Shocks here, these are watches with "LCD Processors" in them. Well that is what the PCB silkscreen on the Odyssey says any way. A Citizen Chrystron LC and an Odyssey Executive 25 Alarm. The Citizen is the Rolls Royce of the two, and the Odyssey is more of a Ford Escort, but none the less they now both work. Battery corrosion was causing issues in both, and the Citizen needed a new quartz crystal. A little TLC, consisting mainly of some light rubbing with a fibreglass pen, cotton buds and some denatured alcohol was also required. The light in the Odyssey seems to be dead, so I may have to address that somehow. White LEDs wont work directly on the 1.5V cell, so some "magic" may be needed. I'll have to have a think about that.1 point

-

There are many ways to measure time. I've been observing this little brown, red, white and grey faced "watcher" for a over a month, and she has been watching me with equal intensity. She tolerates my presence, but I don't want to disturb her, particularly now that all that time sitting around on her eggs has finally paid off. The grey wagtail by comparison has already fledged with their dumpy little fellow (who was initially taking turns to sleep on the dusty path in the sun and hopping and flapping about indignantly waiting for mother to bring him lunch), now flying with ease. Mrs red legged partridge on the other hand seems to be leaving things a little late. Lets hope her offspring make rapid progress, as the summer here can be short, and unpredictable. So far it has been very pleasant. Warm without being too hot, and as a result there should be plenty to fill those hungry mouths. I suspect some more of my garden seedlings are likely to end up in those fluffy little bellies. Well you know what they say. "One for the mouse, one for the crow, one to rot and one to grow".. well in this case, maybe not the crow, but the partridge instead.1 point

-

Thanks @VWatchie; some movements are what they are. Not all of them are high flyers but can still be very good & accurate runners. Looking at the pretty constant positional amplitude and corresponding daily rate, this is one of them! There aren't many watches which receive as much TLC as this one and therefor it will serve you well ..... that's an universal thing I commend you for your pursuant and dedication; Well Done !!1 point

-

Not to brag or anything... but my question about the arbors being too thick for some Mainsprings was featured in one of Marks videos. Bogdan1 point

-

I know that everyone and every text says to never wind in by hand but every watchmaker has done it out of necessity at some point. If the spring is not too tall in regards to barrel diameter it really can be done without distorting it. Think of a typical clock barrel, might be 20mm tall and 35mm diameter. Pretty close height to diameter ratio. Taking the spring out requires a winder- as does putting it in. A typical watch barrel might be a depth (spring height) of 1.3mm with a diameter of 10 or 11mm. We take the spring out without a winder without damaging it. It can go back in too, winderless. But you do have to "wind"it. On a t-end spring get your t in the slot, and wrap around 180 degrees, in, wrap 180 degrees, in, untill you're in. As long as the height to diameter ratio isn't to small the risk is low- with a bit of practice. I used to demonstrate this to students and show that the spring remains flat after multiple in-and-outs. They got it too after a few tries. If course winder is always best but really with t-ends (or worse- seperate t pieces) handwinding is ok if done with care.1 point

-

1 point

.thumb.jpg.4ff9d143a0288e175bd40d1361cdf550.jpg)