Leaderboard

Popular Content

Showing content with the highest reputation on 06/22/20 in all areas

-

I would remove it, heat it up and remove the impulse Jewel. Then I would heat it up again and flatten it with a flat stake. Sent from my iPhone using Tapatalk Pro3 points

-

Also, where you are located might help. If in England you might want to get a Pultra, if in the U.S. there's plenty of Levin, Derbyshire, as well as Boley and Boley&Leinen. U.S. has Sherline if going more for clock stuff, elsewhere Unimat might be easier to find and find accessories for. Regardless, try to get something that takes 8mm collets (most Pultra are 10mm but can be adapted). Those are the most plentiful, and you never have too many collets. Sherline can take them with an adapter, and Unimat had a couple of spindle options, one of which takes them.2 points

-

Do you want one for watch work or clock work. What do you intend to do on it. do you want a direct motor driven or a foot controlled. You need to ask yourself this so we can advise you.2 points

-

Well who would have thought it. That thick gummy nastiness I keep finding in old watches actually comes from mythical technicoloured horned equines. I'll need to remember to keep it and bottle it next time.2 points

-

Get a WW 8mm Pearless. Good lathe and easy to find on eBay. Of course, as was said previously, G Boley and others are always available on eBay. Some day I may sell one of my 13 lathes:) Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

1 point

-

Neither I nor Daniel have lathe to do the modification. he can modify J & G with a broach and I haven't come across anything suitable yet, begining to look into other options.1 point

-

1 point

-

Use a japanese style case knife with an appropriate and well dressed tip.1 point

-

When you have experience in making staffs, it isn't easy and you will have many mistakes, not many watch repairers can make staffs. There is no need for a Jacot tool, every thing can be done with the lathe.1 point

-

I have got some with J>140 but A~620, One would think to cut out a pivot on it at 580 on lathe. The measurements you gave are inexact too. To do without lathe, we both should do better homework. I have set aside a number of possible candidates.1 point

-

There are a bunch of things to consider, I've found it's nice to have a couple of different size machines for doing different things. For turning balance staffs a 6mm Geneva pattern lathe with loads of collets and some useful accessories would be able to do a great job on balance staffs. These are cheaper than 8mm lathes because 6mm collets can't be bought new - though if you also had an accurate larger lathe it could be possible to make many accessories (..though while possible, really concentric collets aren't quite so easy to make). In 8mm there are more choices and new collets are available at a range of prices and quality levels. Collets are generally more important than the machine, some people get round this by working more with "wax chucks" and turning between centres. The WW lathes are more rigid (and seemingly likely to have a flip-over tool-rest - pretty handy to have) but a Geneva lathe is arguable slightly ergonomically different because the bed is narrower. The available accessories are more or less the same but the available accessories differ based on location, partly the popularity of either lathe pattern but also historic social circumstances and approaches to spending money of past generations, and trends in repairing parts vs replacing them - some elaborate accessories seem more available outside the UK.. for example, in the UK I see more re-pivoting tailstock accessories for Geneva lathes but I've just bought a grinding attachment for my WW lathe - haven't seen one for a Geneva lathe during casual looking.. The 10mm lathes are also nice but arguably more suitable for clocks or the less delicate parts of watch repair, like wheel cutting. One of my friends uses a really complete 6mm lathe for balance staffs and similar stuff, a 10mm Pultra for clocks and small gear cutting, and a South bend for anything bigger (such as turning work on accessories or tooling). I'll add technique too.. From reading other forums I've seen there are some people in a camp of producing balance staffs with Sherline lathes - using the compound slide and making parts to numbers rather than the usual hand turning method, this is somewhat as balance staffs would have been made on automated machines.. A new Sherline is probably better than a WW 8mm lathe for that method. The accessories are usually more important than the lathe, sometimes people buy sets to pick the best bits then re-sell. Accessories can usually be switched (with some exceptions or work arounds) between different examples of the same type of lathe, and it can be much more expensive to buy collets separately. With Collets vs wax chucks and centres.. a full set of collets is handy, and is the most simple way of working. Wax chucks are slower and require a bit of practice but are cheap and arguably more accurate. For example, you could have a 2.5mm collet and a stock of 2.5mm blued steel, then turn staffs "in-one" - possibly performing adjustments with a wax chuck or a jacot tool. You could also use one size of steel and collet to turn blank staffs to turn between centres (but this is quite a skilled method of working). The other sizes of collets are useful for turning staffs one end at a time, or for gripping other parts for working/ repairing them.. but much of that could also be done with wax chucks.. Despite this, I don't think many a pro would justify the extra time for wax chucks over just buying a full set of collets - mostly time vs money. Beyond this, a larger lathe is also handy, sometimes they aren't so expensive but it's a case of finding such a lathe which is being sold for unfortunate reasons/ lack of need/ space rather than because it's worn out.. for larger lathes I'm not a fan of the Myford 7 outside of collectors circles. My own setup is a 8mm Geneva pattern lathe - for balance staffs/ delicate work, 8mm WW lathe - for less delicate work or to more easily find/fit some accessories, large bench lathe which resembles a massive WW lathe - for gear cutting, threading, making tools, etc, and a chinese 7x10 lathe - useful for making metric stuff like threading hobs for the bench lathe - if I can't get some time on a bigger machine.1 point

-

Just looked on ebay, I think I counted three that are good but all over £1,000. The watchmakers lathe I had was a Boley with various accessories with a foot control.1 point

-

For what is worth. In the same junk bag there was another quite same watch, this one had no marking at all on the plate. Evidently the factory could not get sterile modules all the time. They are true workhorses, 30 years (or more) later all what they needed was a new battery. Too bad they are really too ugly to picture.1 point

-

Hi That is a good question and I am sure you will get many varied opinions as to which are the best and for what purpose. I have never used or had a bad lathe as like I said depends on use. I used a Myford 7 floor standing lathe in my youth for turning shafts, rivits etc and I dare say in the right hands could have been used for clock work. I myself have three a watchmakers 6.5mm. An American pattern (no name) with both collets and a bernerd chuck, cross slide and tail stock with drilling attachment and a model maker lathe with 4 jaw independent chuck , All three are use ful but for general work and versatility the American pattern is the all rounder.1 point

-

I’ve never heard of anyone quenching a screw after heating it for the purpose of loosening it. You shouldn’t be heating it to the point where you can quench it to set the temper. Unless you are maybe suggesting that the sudden change in temperature helps to break down the bonding between the screw and screw hole.1 point

-

All of the ones I've used have had one, in the sense there is one hole in the pulley for the drive finger. But, on most of the more modern tools the drive finger is actually two fingers that are sort of hinged; you can use both, you can sometimes fit a wheel spoke between them (but they are close together), or you can hinge one up out of the way and use just one. The fact that they are hinged makes it easy to adjust.1 point

-

If it looks like the above, then it is indeed an FHF Ranfft is a good resource for this kind of thing. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Standard_96 There are a few other places to try too, for example. https://www.ccwatchmaker.com/list-of-trademarks1.html1 point

-

1 point

-

I must admit that this was my reaction when I saw the sort of price that they are/were commanding on eBay, so did a bit of research. NSA stands for 'Novavit S.A.' and they were probably the most high class, prestigious Swiss watch bracelet maker in the 1960's/70's, their bracelets being fitted to Breitling, Rolex and Omega watches at the time. One seller on eBay currently has four replacement links for sale at just under £70 and another seller has a rather battered 'used' bracelet, the same as mine, with no end links and a missing clasp spring for £160!! You might just be right about the Unicorn Poo!1 point

-

Some of my recent horological insanity. No idea why this appealed, its just a cheap quartz jump hour, but I figured it was worth 0.99p Blue dial.. Say no more.. also from the penny lots on ebay. That damaged bezel might require some creativity. .. and a Timex.. because you can never have too many Timexes (apparently).1 point

-

That is 4F/8F modules have a motor dedicated to the (perpetual) date function, and no manual quick setting. Expensive for the buyer but cheap for TH to manufacture. Torque, especially in quartz module, is a limited and very valuable resource, you need more torque to ramp up against the slope of an instantaneous change mechanism. Unfortunately in mechanical mov't more torque means fitting a stronger mainspring, that is thicker, so you have to sacrifice power reserve with a same size barrel size. Result, we have the much revered ETA 2824-2 beating 28.800, instantaneous date change, and 38 hours power reserve. Compare to the humble Seiko 7S26/4R which deliver 42 hours, with the compromise of slower beating rate (which actually will make it last longer), and a date and day which is so slow, to cause a great nightly discomfort to the OCD buyer. On quartz modules torque is not there at all, so either add some comlication to accumulate torque, or fit an additional motor.1 point

-

Today I received this beautiful Omega Genève from 1968 with blue dial. Iit was sold as not running, but with the optical condition and the ridiculously low price I just couldn't say no When I opened it a screw fell right out the movement. I noticed that it should hold one of the caseclamps in place, which was missing. I guessed that the caseclamp made its way into the train of wheels, causing the watch to stop. So I carefully shaked the watch and volià, the clamp fell out and the movement began to run. I resecured the clamp with the screw. The movement looks really dirty though, so it will definitly benefit from a service. The results on the timegrapher confirmed that, so there is still work to do I also fittet an original Omega buckle to the strap.1 point

-

Just picked this up for 25.00. has a split stem and the seller thought the stem was broken but it just needed pushed back in to reconnect Sent from my SM-N975U using Tapatalk1 point

-

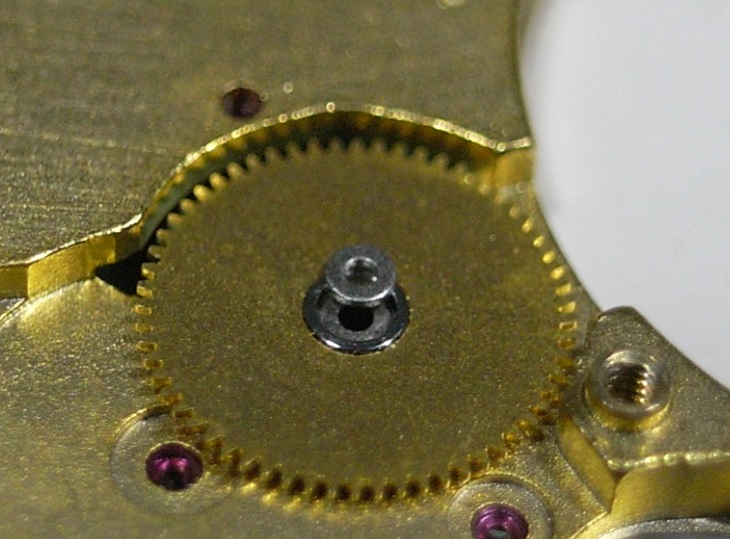

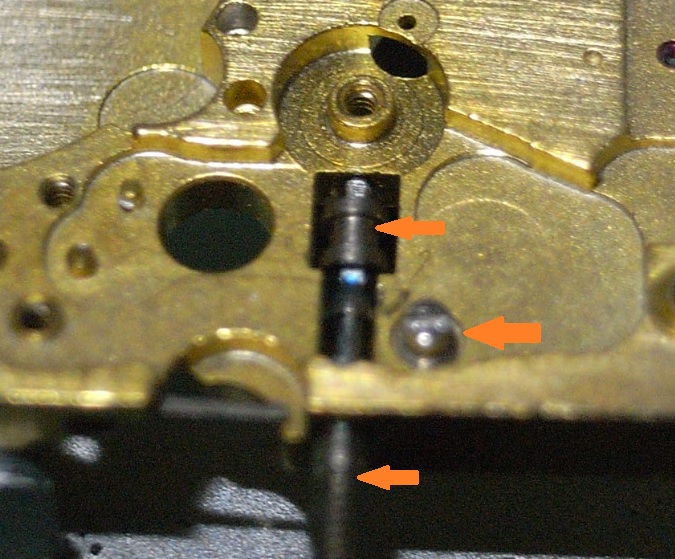

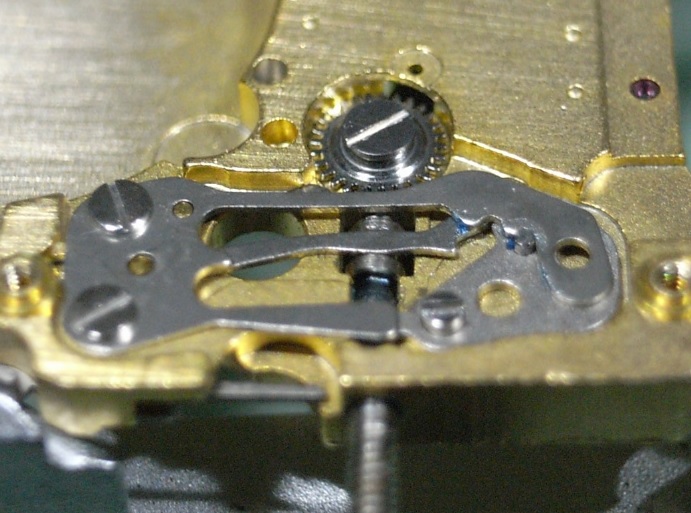

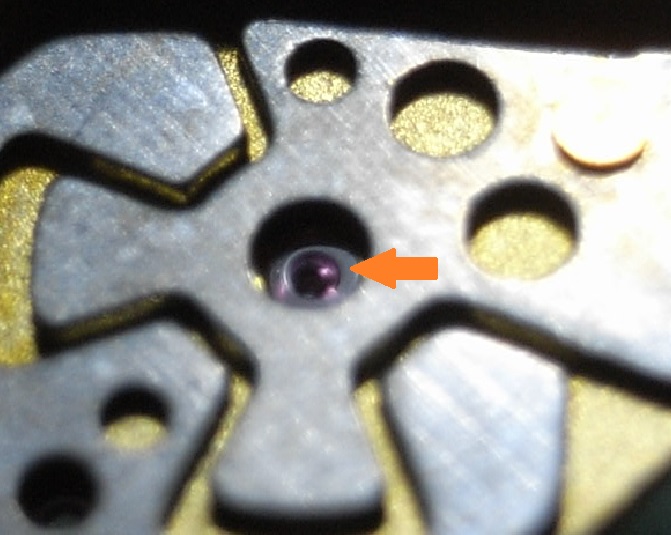

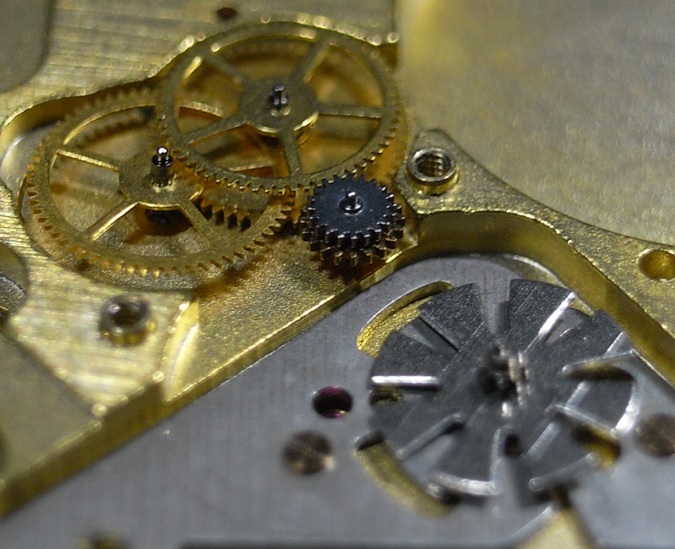

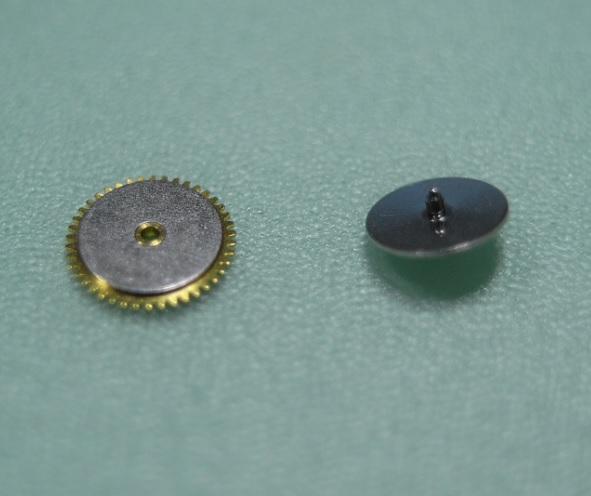

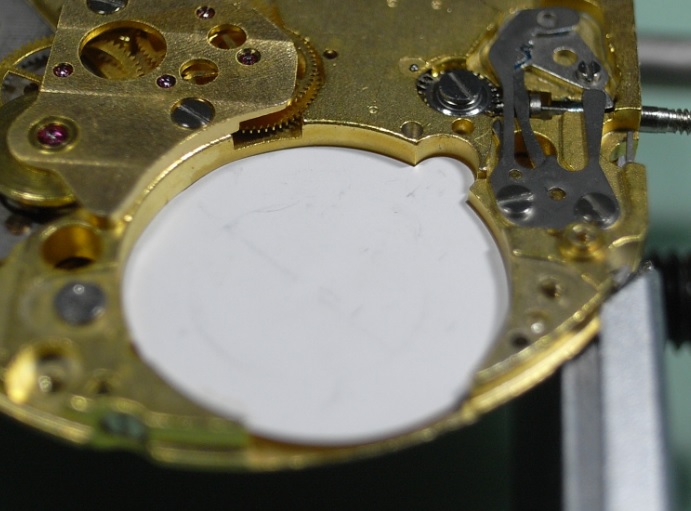

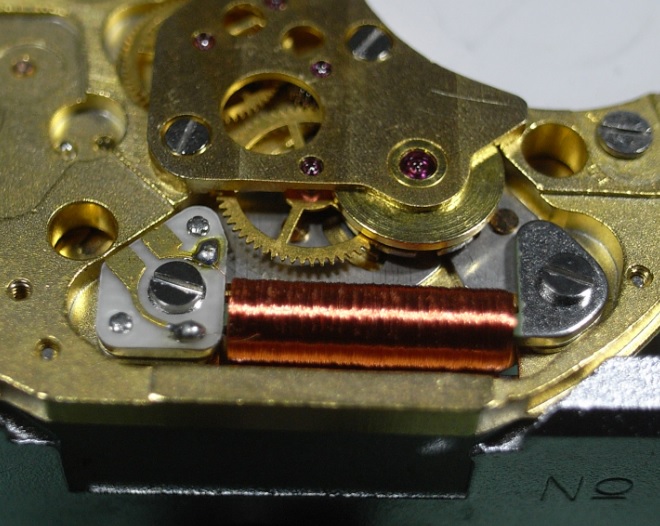

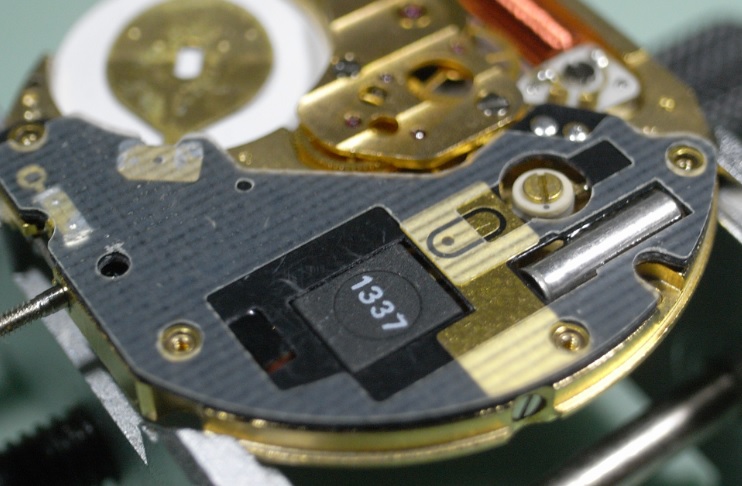

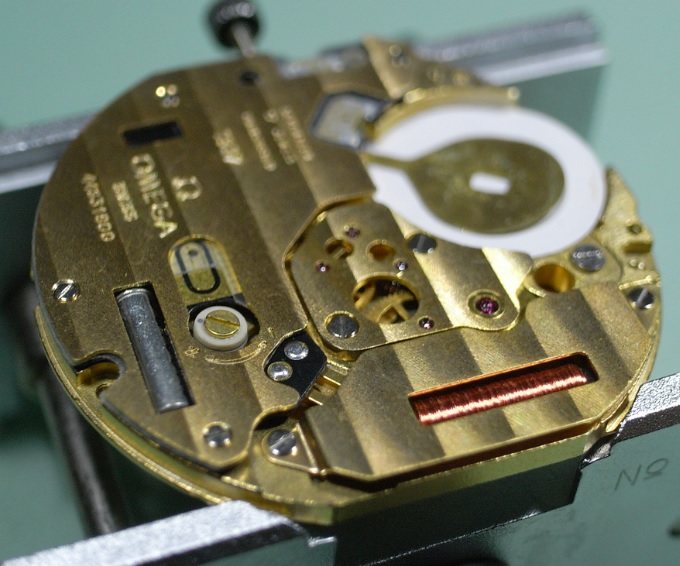

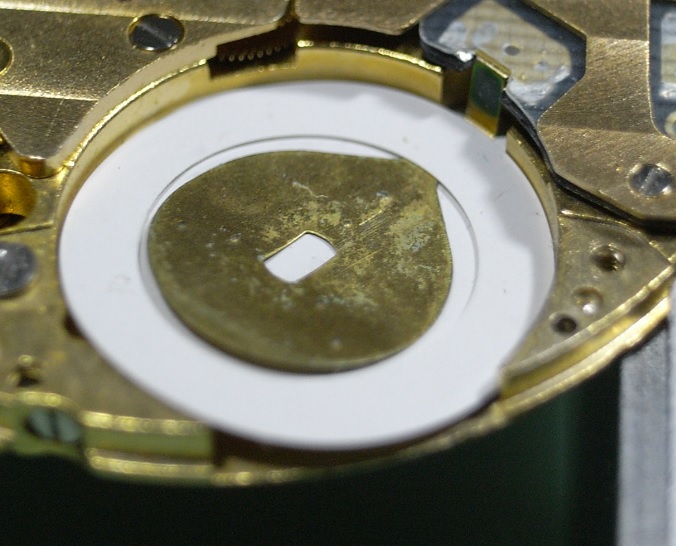

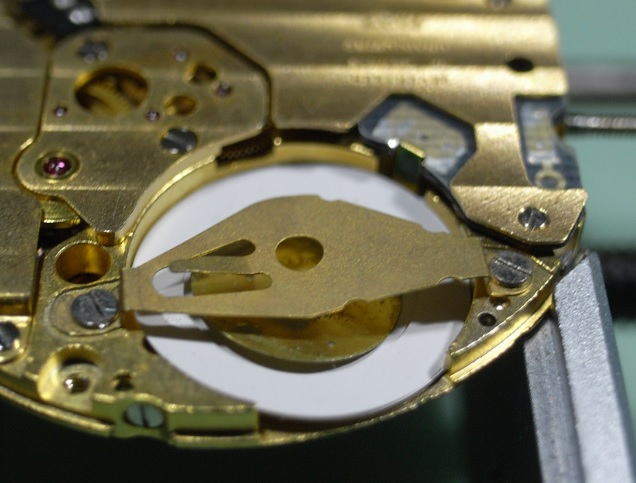

Unfortunately I do not have an exploded diagram of this movement, with the correct terminology for the parts or the factory oiling procedures. The following is my own procedure for assembly, and I will leave the oiling to your own discretion. Personally I used Moebius Quartz Oil and Moebius 9501 for the Keyless Work. If anyone has a copy of the 1337 Technical Document please upload it to assist others. Assembly I started with the Keyless Work... Lubricate the Stem and install the Sliding Pinion and Stem. Also screw in the Setting Lever Screw. Install the Yoke and place the arm into the slot in the Sliding Pinion, and replace the Setting Lever. Install the Setting Wheel and fasten down. The last part of the Keyless Work to be installed is the Setting Lever Spring. Next install the train... Install the Minute Wheel, being sure to replace the small washer. Install the Intermediate Wheel and the Second Wheel Driving Pinion. Next install the Second Wheel. The lower jewel for Rotor is a blind pivot point, this needs to be lubricated BEFORE installing the Rotor. Install the Rotor. And lastly install the Third Wheel. Carefully install the Train Bridge, be careful to check the free running of the train before tightening fully. Next flip the movement over and proceed to install the Motion and Calendar Work. Firstly make sure the Magnetic Friction Wheels (Cannon Pinion) are very clean. Especially the flat plates between the wheels. Install the Magnetic Friction Wheels (Cannon Pinion) Then install the Calendar Setting Wheel. Next install the Motion Work Setting Wheel. Install the Intermediate Date Wheel. Lastly is the Date Indicator Driving Wheel and the Hour Wheel. Now all the wheels are installed you have to time the Calendar Setting Wheel, Intermediate Date Wheel, and Date Indicator Driving Wheel. This will take some study to setup correctly without the documentation; but take your time and you'll find it will become obvious how these wheels interact with each other. Once you have set the timing up, replace the Calendar Ring and Date Indicator Maintaining Plate. Then gently hold the plate down with a piece of Pegwood, and with the Crown in the second position, work the wheels and test that the pivots are located in their jewels and the timing of the Calendar Work is correct. Once you are completely satisfied that everything is working as intended, screw down the plate. Flip the movement over again and replace the Battery Insulator. Install the Coil. Install the Circuit and Circuit Insulator. Replace the Electronic Module Cover. Next replace the Coil Protector. Install the Battery Insulating Ring. Install the Battery Clamp. Please Note: The Battery for this movement is the 391/381. Lastly install the Dial and Hands. This completes the assembly of the Omega 1337 Movement. I hope this walkthrough gives you the confidence, steps and reference photos to tackle this movement yourself.1 point

-

Drill a hole in the side and I like to have two of the same when one fogs up the other is ready to go. The hole helps. Sent from my iPhone using Tapatalk1 point

-

Clean it with Rain-X (anti fog version) or some other anti fog cleaner?1 point

.thumb.jpg.437f1cf49daa091b8af2724e0be2074b.jpg)

.thumb.jpg.993c79bb405dc168ff24798f6aae263f.jpg)