Leaderboard

Popular Content

Showing content with the highest reputation on 06/04/20 in all areas

-

3 points

-

WD-40 was formulated as a water displacement (the WD). It's mostly solvent, with a tiny bit of oil. It "works" as a lubricant because it loosens up old dried oil or grease, but it's a short lived fix. The solvent can help free stuck screws and bolts and such, but there are better specific products. It has almost zero rust preventative qualities. It DOES have terrific marketing and a dedicated fan base despite its shortcomings.2 points

-

2 points

-

2 points

-

Penetrating oil applied to the screw and let soak for a day even two, is the norm to loosen it. You should not resort to excess force as it may break thus creating a bigger headache. A picture always helps. Use of heat and other approaches may become neccessary.2 points

-

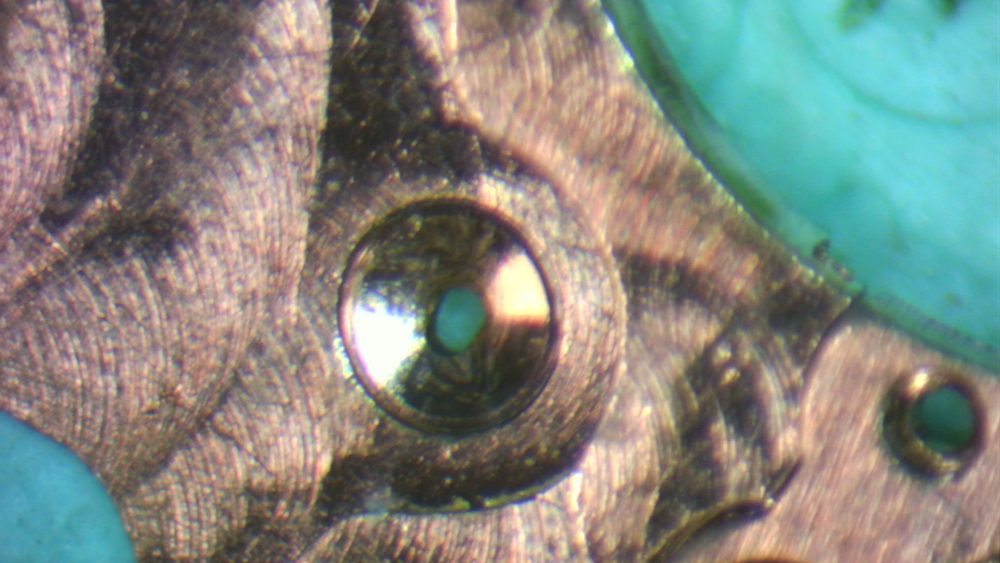

Here's the 1st part of a service walk-throughout of this 10.5''' pin pallet mov't which was barely running. It's built with some unusual characteristics for this class, like the ratchet wheel on dial side, the abundance of parts, and the use of four tally upping jewels beside the shock protection, perhaps an attempt to compete with Swiss lever mov'ts by boasting 23 jewels. I apologize for the mediocre quality of the pictures or any inaccuracy. I didn't find a service sheet, but that is not big deal really. Starting from the dial side we remove two tiny screws and the top calendar plate. Here we need to be cautious with the finger spring. You can place some rodico on it and lift where it's curved. Then remove the finger and the brass plate. Lots of more parts are now revealed, off it goes the date ring, date wheel, hour wheel, and the rocking bar Not less than three pinions on the bar, and that is without a quick-setting mechanism. Sorry I did not picture the setting spring, which is not difficult to remove safely. Having full access to the click we can now let the mainspring down. The next "dangerous" item is the click spring, again use caution. After the click we remove the setting wheel, cannon pinion, and the small plate holding two cap jewels, the lower anti-shock, according to the part list they are different from up and down sides don't mix them up. By noting the four no-function jewels around the date wheel machining we're done with this side. After pulling the stem out and storing the sliding wheel we can then flip the main plate, remove the upper anti-shock device and the balance. The massive cock it's a bit fiddly to lift. Also be aware that the dial screw can be completely removed, it's a good a idea to do that to avoid these falling at some point. Removing the pallet bridge and pallet I didn't noticed immediately but a pin had snapped. Maybe that happened in the washing jar, but the pin was nowhere to be found ?!? Fortunately a spare pallet fork was available to order. It should be also possible to make a a new, I hope to be able to cover that in a future posting. Remove the train bridge. It's possible that the barrel bridge is to be done first, but I had no problem anyway. Remove seconds, third and the escape wheels. In the best Swiss style there is no screw like another. After removing the barrel bridge we start seeing oil having left around. The thick center wheel bridge is removed with the wheel, lastly is setting lever screw and lever. I don't know why I pictured the sliding wheel with them. Opening the barrel we see that the last repairer, decades ago. liked to use a lot of grease in there. I don't guess on a mainspring's condition by its uncoiled shape, but just get a new one when possible. Washable parts go into my special machine, which is a small jam jar. First bath is horological ammonia solution, rinsed with petroleum ether, followed by distilled water rinse that is repeated until no floating particles can be seen against the light. Last rinse is with IPA. To be continued.1 point

-

Pedantic is good. I didn't even get the complications right, it does indeed appear to be a 2414 day only rather than a 2429 day date. As to "brown", how could we have survived the 1970s without brown? Even Rolex were not immune to the 1970s brown phase I actually think the Slava carries it off a little better, but others may disagree.1 point

-

1 point

-

W W is right, if you show a picture of the cock laid upside down, we have a chance to figure out how to detach the HS and if the collet is removable then sorting the HS out and shaping an end curve isn't a tough task. A top view with balance pivot inside the jewel hole, would be helpful.1 point

-

Here is the latest watch I’m pleased to have completed for my collection. I bought this watch in a pretty poor condition described as runs intermittently and in need of a crystal. Well, that was not very accurate. One of the dual springs was snapped, the lower Inca lyre spring was snapped and by fortune the cap stone was found in the works. That explains the intermittent running [emoji23] Anyway, here it is, 2 new mainspring, a new gilt ring crystal and a nice brown leather strap. I only wish it was larger in diameter. Sent from my iPhone using Tapatalk1 point

-

Hi I have attached the tech sheets for the tissot models as there seems to be a lot of parts which are common across the range. The balance complete is 720 without spring and 721 with spring attached, so by the fact it is supplied as a spare it is detachable. the spring its self does not look too bad and most probably be re curved ok. If you could supply a picture of the balance and cock laid upside down so members can see the attachment it would be a great help. cheers 2790_Tissot 781.1,782.1,783.1,784.1 (4).pdf 2789_Tissot 781,782,783,784 (2).pdf 2791_Tissot 783.2,784.2 (1).pdf1 point

-

regular wd 40 is not a penitating oil ! they do sell one now. there are many penitrating oils avaiable. use them. vin1 point

-

Very nice. I have a couple of Elgin movements waiting in the wings, though currently I'm much busier in the garden than I am on the work bench, so they may not make an appearance before the winter. Time will tell. They certainly drove Elgin and a lot of other US manufacturers out of business, although you could argue that the competition from the likes of American Time Corporation (Timex) and others, for example Westclox might have been as much of a factor in this as the competition from Switzerland. Jewelled timepieces, not made in the USA were certainly far more of a predominantly Swiss product on the shelves of the US stores in the later half of the twentieth century. This might have been as much to do with a dislike of Japanese, USSR, Chinese Indian and German engineering as much as anything else though, since these countries still produced large numbers of jewelled mechanisms, and indeed in some cases produced mechanisms in many respects at least comparable in engineering and build quality to the Swiss. The Swiss however mastered the promotion of their product, by pushing Swiss engineering quality as its most important feature. Having said that, a low cost, basically engineered EB8800 pin lever could hardly be said to be as high quality as a Seiko, Citizen, HMT, Luch, Seagull or even Kienzle jewelled movement.1 point

-

Having watched ML's strip down and rebuild of the Seiko Bellmatic I was intrigued so much so that I just had to get one. Well I won one on Ebay for £103 plus postage. The description infers its not keeping time but it looks in reasonable condition in the pictures. It does have a strap. Soon as I get it I will post photos.1 point

-

Ofrie has the jewels and they are on sale at the moment, might compensate the shipping costs. http://www.ofrei.com/page942.html The might be closer to 0.30mm high, not sure if that will be too much.1 point

-

1 point

-

Also, an obvious point, but make sure you use a screwdriver with a blade as wide as the screw head.1 point

-

You could try cross drilling the arbor and inserting a brass pin, shaped to form a hook.1 point

-

Hi try applying the tip of a soldering iron to the two stuck screw heads for a wee while to warm up the screws If they are just stuck the heat will expand the screw hopefully breaking its hold be it loctite or rust. As mentioned the crown wheel screw will be a left hand thread and will undo clockwise, use a little wd40 on the screw but be sure to clean everything. and re lubricate.1 point

-

N8 is not the caliber it's the date code (N for the decade, 1970's, and 8 for the year number, so 1978). Are there any marks in the main plate underneath the balance wheel? This is a french made movement so I suspect it's an FE, possibly a 140-C1 point

-

Yeah that's what I have and indeed is weak so to suggest that faith is also required for it to hold.1 point

-

These pieces with the year at the 10 a clock position has been around for a while, I noted they still are for sale at a reduced price. Now at a 30% sale.. but still with the 750 (18k gold mark). http://www.ukwatches.cn/zenith-zn-002-white-dial-stainless-steel-case-auto-black-leather_22033.html1 point

-

I think this autowinder has been up here a couple of times, here you can see one thread and some shots I took of how to assemble it again. as you can see your click spring is not corretly assembled.1 point

-

I have a couple of the early electric versions of those Timex ladies watches......1 point