Leaderboard

Popular Content

Showing content with the highest reputation on 05/13/20 in all areas

-

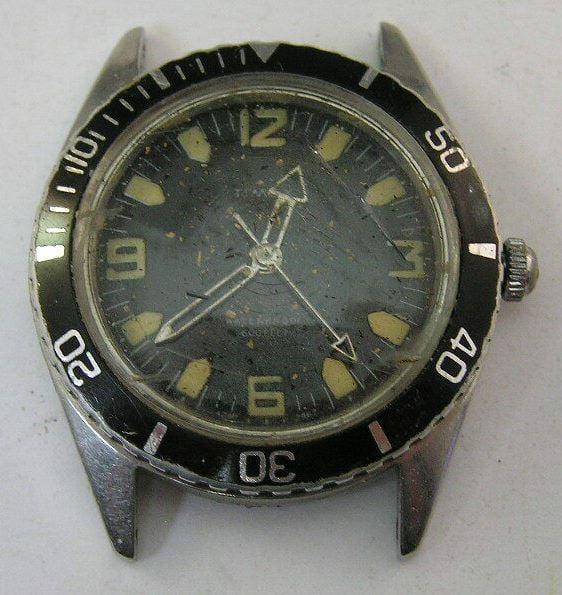

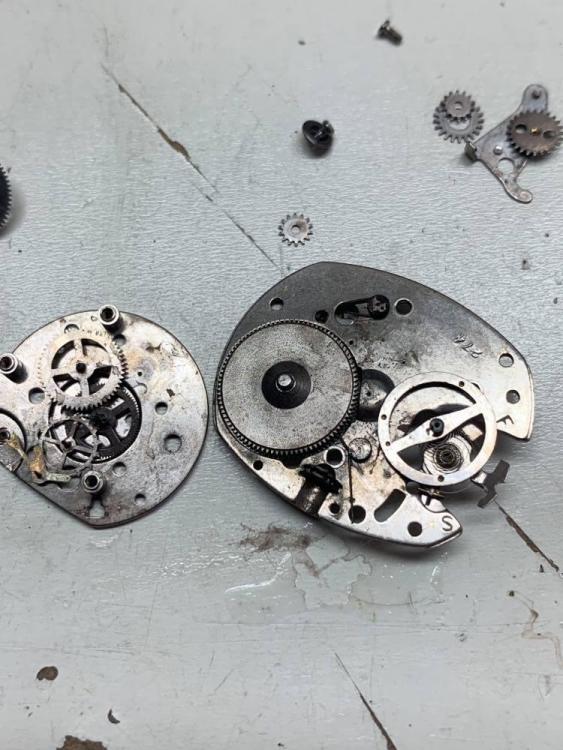

When I spotted this watch listed on eBay my first thought was what is going on with the crown. Its all wrong and I'm sure there is going to be signs of water damage inside. It did not disappoint there but the end result turned out great. That is just what I found and did end up replacing the movement . I began with a breakdown and inspection. Movement has seen better days and not worth the effort. So it gets replaced. Now the cosmetics - and there it is on the left along with the other 600 ft divers.4 points

-

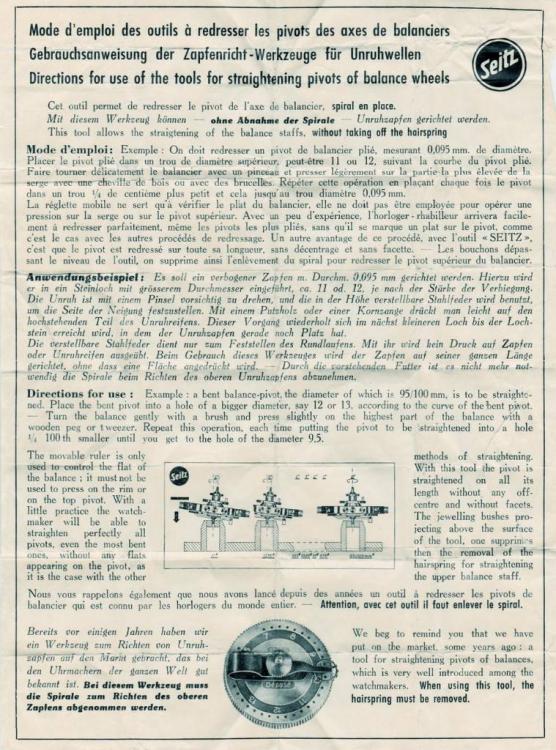

Here is a quick video I made with technique to reduce the thickness of a Seitz 30/200 jewel to fit into the 3rd upper jewel hole on an Elgin pocket watch. Sent from my iPhone using Tapatalk Pro2 points

-

The active ingredient for this purpose found in Coca Cola is phosphoric acid. It's the same active ingredient in a variety of rust removal products. On the one hand, it may be one of the least expensive and most readily available sources for phosphoric acid in relatively low concentrations, but there's a lot of not-phosphoric acid in there as well. If you can get your hands on a proper rust converter, it may be a better option. Not all rust converters are good for watches though. I like to use Evaporust when I restore cast iron tools and the like, but it will convert more types of iron oxide than just the red flavor, including and especially the critical blue... Turns everything black. Found that out the hard way.2 points

-

Heat is the last resort, since it can warp the plate, the least it may discolour the screw. I always soak the piece in coca cola for a day or two, have not broken a single screw yet, try it on a pratice piece, you be surprised.2 points

-

2 points

-

2 points

-

I think after all this is a watch repair forum not a watch appreciation forum. So if any watchmaker like their craftmanship and so be it. BTW I wouldnt agree that a justification of watch brand depends on how many rich men wear it.2 points

-

2 points

-

2 points

-

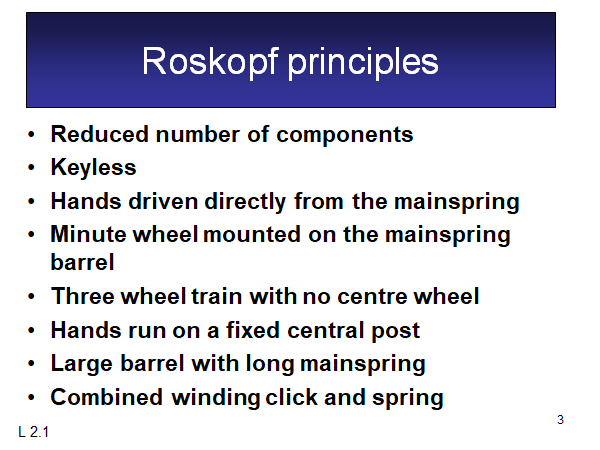

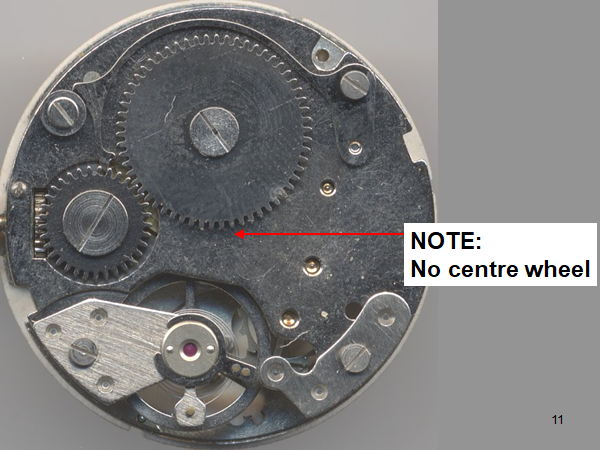

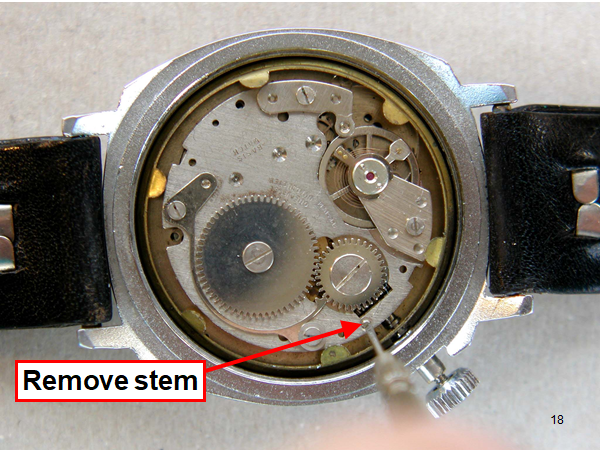

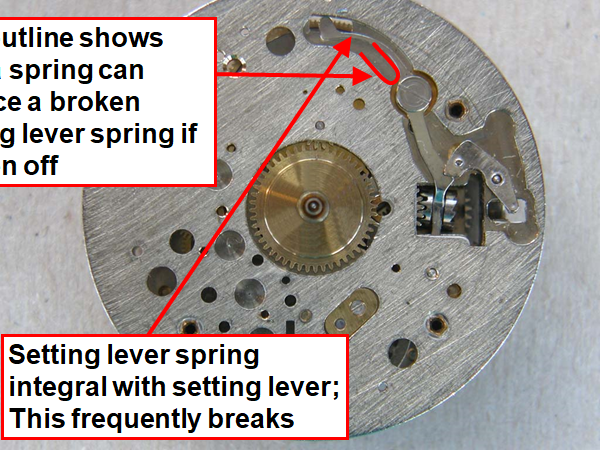

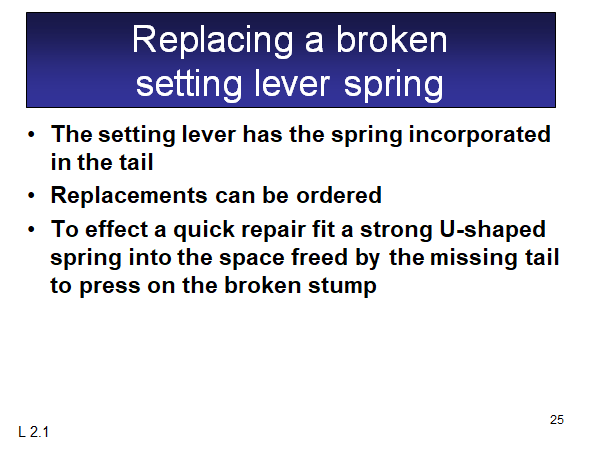

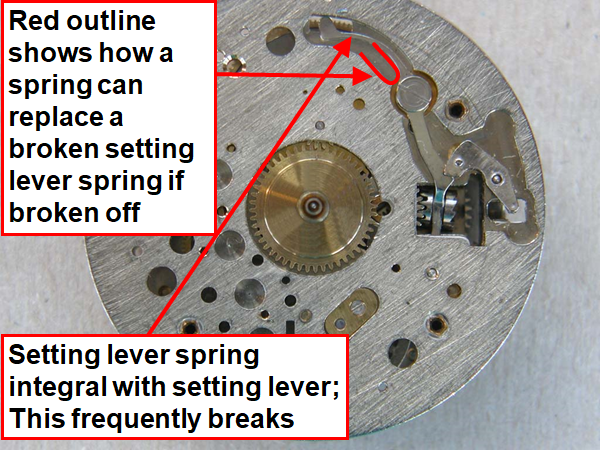

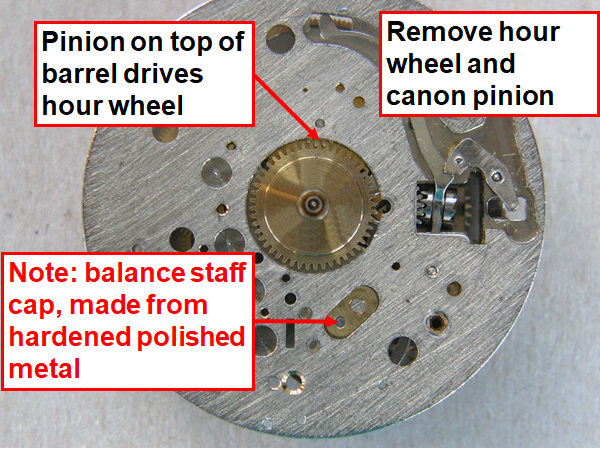

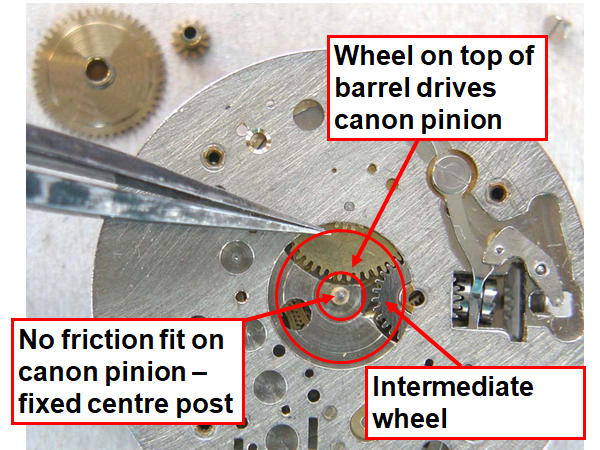

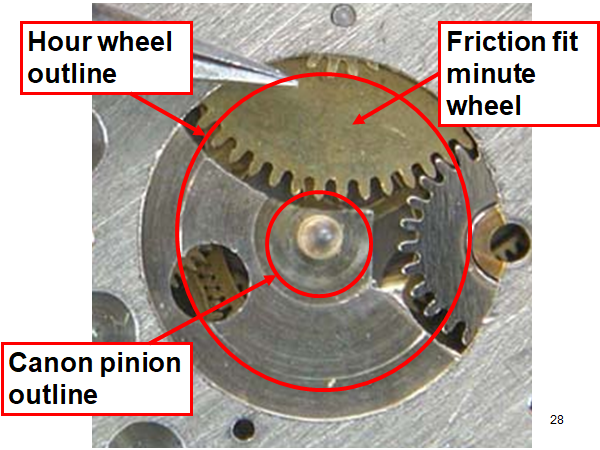

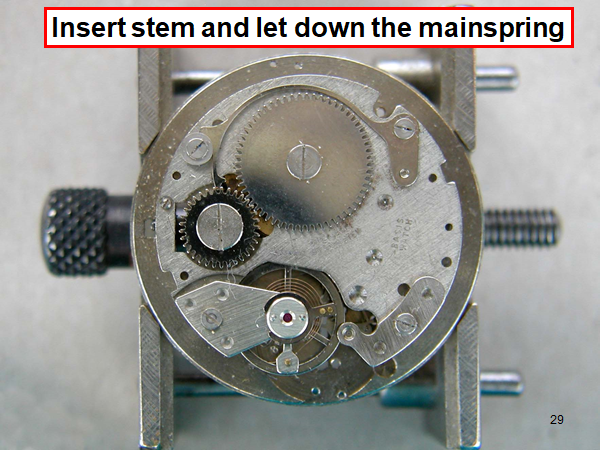

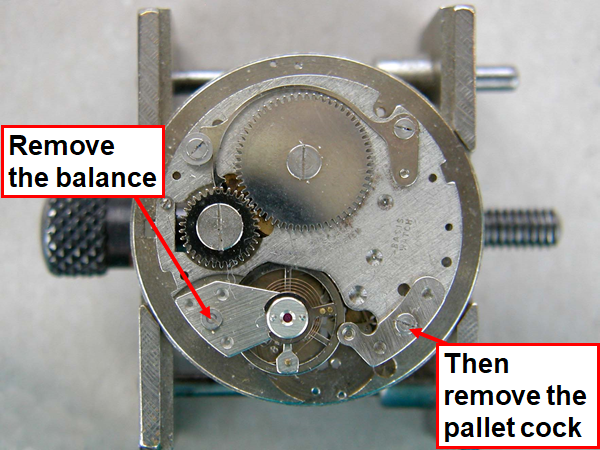

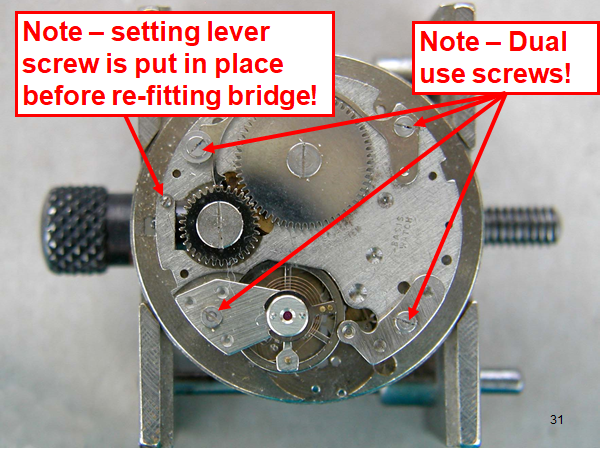

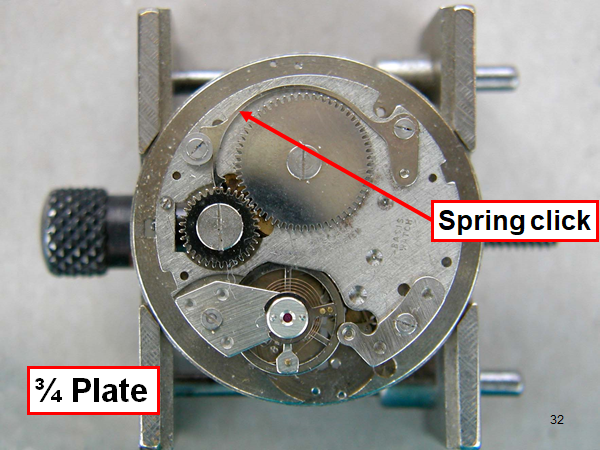

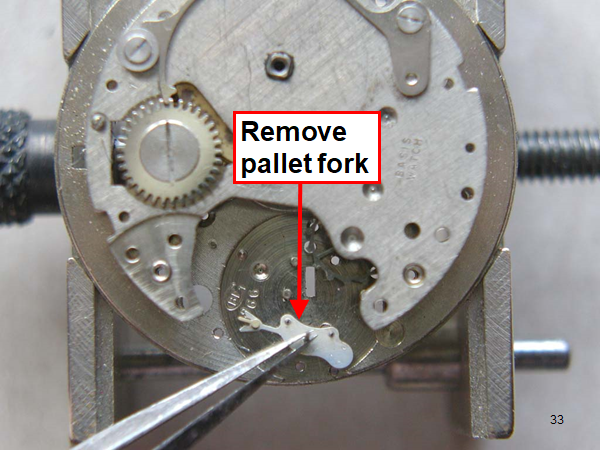

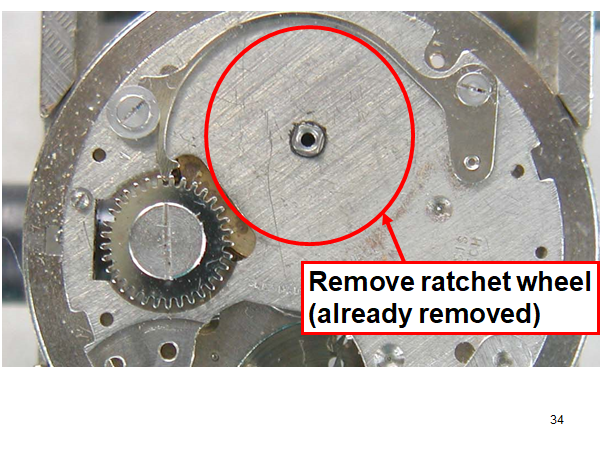

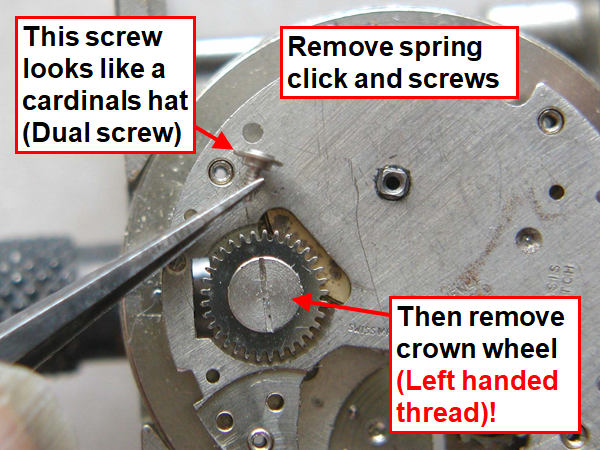

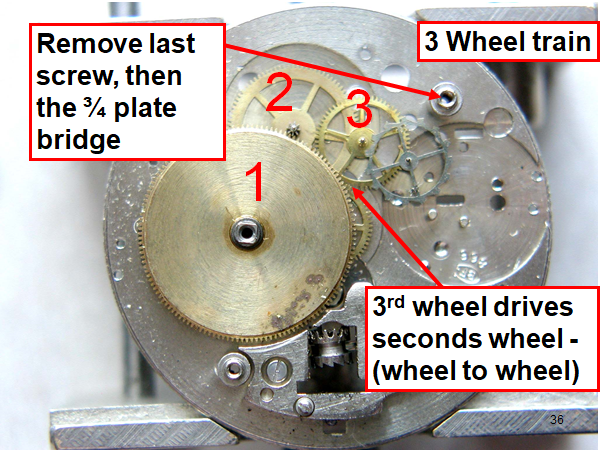

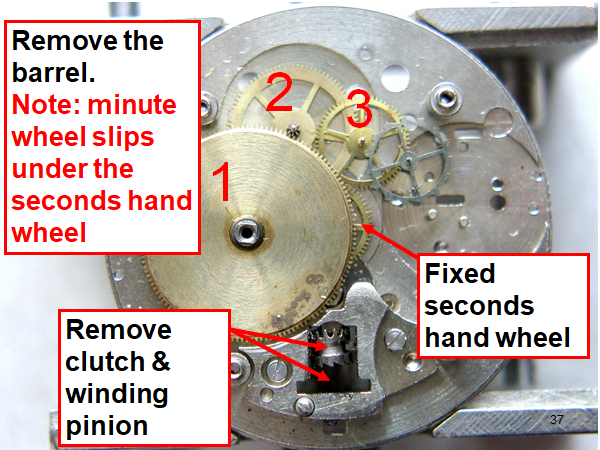

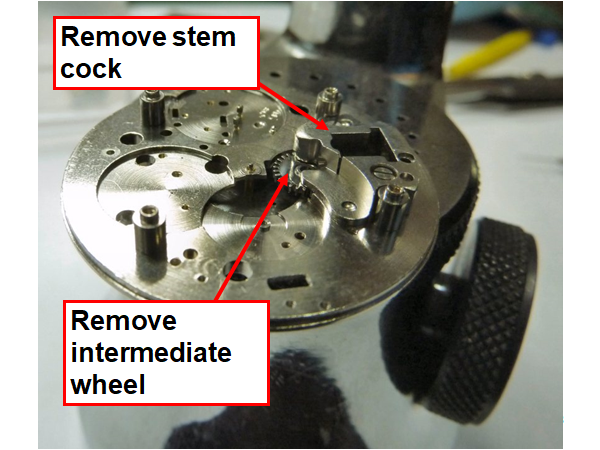

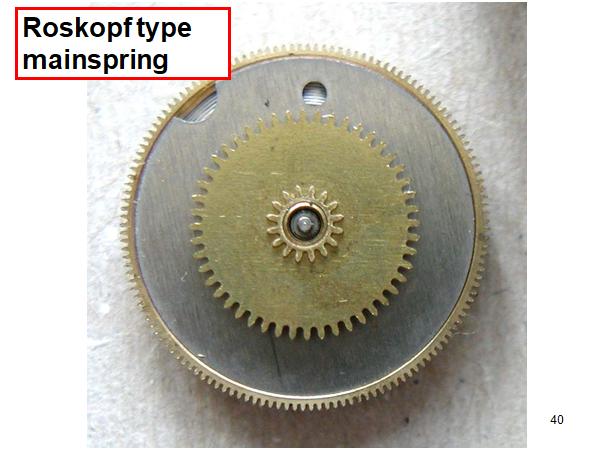

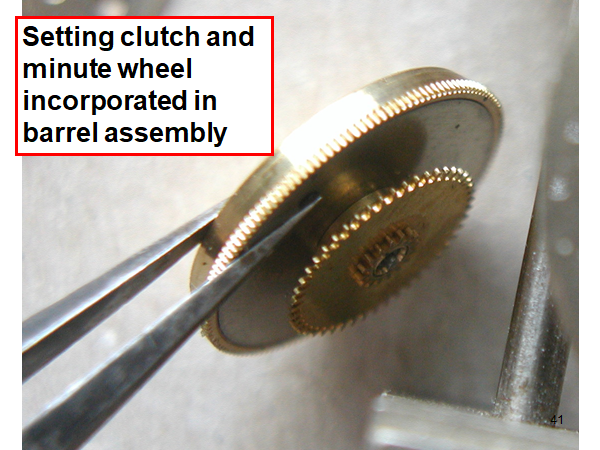

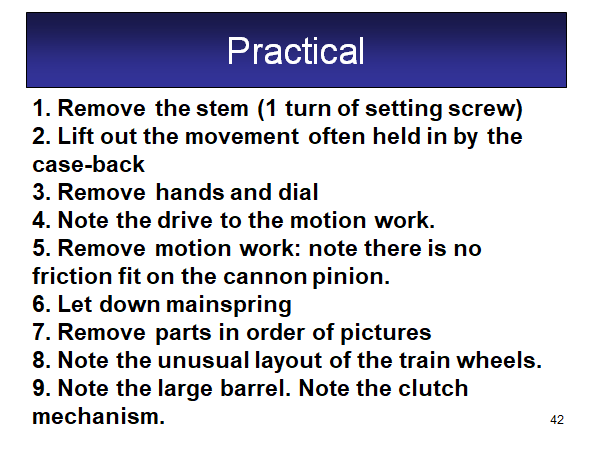

Hi, I teach watchmaking to complete beginners at Epping Forest Horology Centre, close to Epping and this is one of the lessons on the BFG 866. I wanted to show my class a classic pin pallet (Roskopf) movement and how to service it, as many watchmakers won't touch these watches as they hold no monetary value. Turn the setting lever screw 1 to 1 and a half turns to release the winding stem A piece of watch paper or small plastic jiffy bag to protect the dial, whilst removing the hands The driving pinion is part of the friction fitted minute wheel on top of the barrel. This work in a similar way to a friction fitted canon pinion to set the watch hands Remove the keyless work: setting lever, held in place by the setting lever screw, screwed from the other side of the mainplate, then the yoke, which sits on top of the clutch (castle) and also the winding pinion. I have three other lessons on this movement that cover bringing the watch 'into beat' as well as taking apart the friction fitted minute wheel from the barrel, lubricating and staking back on to achieve the correct friction setting and finally how to remove the centre seconds wheel safely and refit using a staking set. Many people leave the friction fitted minute wheel on top of the barrel, not realising the amount of old grease that can't be cleaned out from it, as well as not removing the wheel of the centre seconds arbor and again not cleaning out the pipe which has old grease inside. Hope you enjoyed the tutorial? More to come....1 point

-

Hi everyone! I made log of my activities with photos of my practical exercises for WR Course level 2. It's in the PDF file attached. I had some scary moments doing this. One of them was the balance cock that slid off the movement onto the table while dangling by the hairspring. Furthermore, I discovered that end stone jewels and shock springs also like to fly, causing lengthy search parties Cheers, Mark Watch Repair Course L2 v2.pdf1 point

-

+1 on Kroil. I have used this stuff on rust-siezed automotive bolts that after a few minutes turn easily. It's really freaky.1 point

-

in modern watch repair shops is where you're going to find pre-cleaning. the pre-cleaning procedure is to remove the watch from the case remove the dial and calendar parts for the most part. I know someone who does Rolex repair and claims at least one Rolex watch you can leave the calendar parts on because they're not affected but to be safe everything with paint the dial etc. has to come off. then the entire watch is run through the pre-clean cleaning machine. Yes they usually are separate cleaning machines. It's usually set to a shorter cycle than you normally would run all the pieces through. The reason for doing this is it gives you a nice clean watch allows you to evaluate everything. then out of curiosity how was your escapement class? then you want to be careful with your rodico is really amazing for cleaning but it can leave a residue behind that interferes with things.1 point

-

I don't suppose that the click physically is still functional? Because of it is I would just leave it alone. then as nice as WD-40 is for some people they actually make penetrating oil for screws. Conveniently I can't find the stuff that we have at work comes in a white syringe. The stuff at the link below should be equivalent. http://www.julesborel.com/products/tools-lubricating-oils/Kroil-Penetration-Oil1 point

-

I suspect there is something restricting the minute wheel from turning freely. Even if the canon pinion was so tight it was hard or impossible to set the watch it wouldn't stop it from running normally.1 point

-

That sounds really odd! Would you be able to post some pictures showing how the crown holds everything together? I am really struggling to imagine how that works.1 point

-

probably too tight, excessive tightening in effect integrates canon and the arbour into one piece. Canon pinion is suppose to turn on the arbour it is mounted on, to set the time. first thing to do in case you haven't already is to put some oil in the canon and turn . If no good you would need to broach it.1 point

-

Would it not be better to heat up the plate around the screw so that it expands around the screw rather than the screw expanding into the plate? That's what I'd do with most other machines, but I can imagine issues with the much tighter tolerances... Heat application with a soldering iron tip is also more precise than a torch....1 point

-

You may have to give the pentrating oil 48 hrs, soak for longer period nearly gurantees success. If the jewels have no chaton, you can just drop the bridge in some Coca cola, that two needs a good soak 48hrs, attack with a well dressed screwdriver, you will be surprised how easy it unscrews after a long soak.1 point

-

Hi Tom find attached the tech sheet fir the Miyota just in case you need. Cheers 8691_276584548-Spare-parts-reference-for-the-Miyota-8205-8215-movement.pdf1 point

-

Hi Vwatchie I think you did well on the price and if used sucessfully a few time will have paid for its self, good luck. keep safe Cheers1 point

-

Hi Adam I suppose you have tried the counter clock, Therefore we assume its just seized. Two methods which are not invasive are heat and the penetration oil, Probably the only time WD40 can be used on a watch. The heat method is to ude a soldering iron with a broad to heat up the screw so a to break any rust/corrosion which may have occured or alternativly a bit of WD40 on a blade and put round the screw and left to soak, or make a reservior with rodico round the screw and fill with WD40/penetration oil and again leave to soak at least 24hrs.1 point

-

1 point

-

Thank you for the video, that will prove invaluable. Maybe I could do all my work in a well lit one man tent to increase the chances of finding springs that like to sprung! The current plan is to finish the automatic watch for everyday wearing, and the quartz watch I want to use at work. As soon as that's done, I "look forward" to stripping down the mishandled movement. It also just occurred to me that I read your introduction thread before signing up. The 404 club is an inspiring collection, being able to service and refurbish watches half as well as some of yours would be a huge achievement.1 point

-

1 point

-

The first few minutes might be where your issue lies. I'm not advocating stripping the movement down unless you are comfortable doing that and have the tools, but it will give you some idea of what is involved. Whatever the issue is, the keyless work is likely to be what has popped out of alignment. EDIT: If you do attempt to strip it down, be aware that there are a couple of springs that like to become airborne, when you remove the three screws in that top plate. Don't say i didn't warn you.1 point

-

1 point

-

I'm pretty sure we have all broken a few over the years, its all part of the learning process. I seem to still be capable of breaking the occasional victim in "new and interesting ways" from time to time. The skill lies in fixing more than you break, and "unbreaking" the ones you broke while trying to fix them. Hairsprings are a particular favourite on the "ooops what happened there part" of this journey, followed by balance pivots. Unless you ran it over with a tank, I'm pretty sure your broken movement can be fixed. What exactly went wrong?1 point

-

Something from Germany not far from the Swiss border on its way today. Slightly scruffy, and in need of some TLC, this has one of Kienzle's pin lever movements in it, maybe this one. The missing lume and slight deformation on the hour hand suggests this has been taken a part and worked on at some stage. Exactly which pin lever is in it is not clear from the sellers pictures, so I'll have to wait and see. The hammer fell at the 404 mark, so it just squeezed into the club.1 point

-

1 point

-

Hi There is a compete guide on how to maintain your screwdrivers on https://blog.esslinger.com/ web site with easy to understand notes, cheers1 point

-

Hello and welcome Tom to the forum, At least you can put it down and have a pint and start again in a better light, as far as that goes ther is no pressure. two attachments that might be of use to you. Cheers TZIllustratedGlossary.pdf TimeZone Watch School Home.html1 point

-

1 point

-

the problem is not all browsers know what to do with HEIC files JPEG would be a better option.1 point

-

I do have a grand seiko, a spring drive, that is as proud as seiko ever got, it simply lacks elegance, glory,its heavy, looks nothing like a jewel. some who have a only a couple of hundered box to pay, wouldn,t even think of getting an IWC so they just settle for a Seiko. g Gosh, are you saying seiko can measure up to a jaeger Lecoultre, in any way, shape, manner. I wouldn't trade just the paint on dial of JLC for a brand new Seiko. Haven't seen a rich man wear a Seiko, have you?1 point

-

1 point

-

maybe be best to go back to the beginning like where did the staff come from? Did you compare the new staff to the old staff preferably with a measuring device not just your eyes? then what was the perceived problem that required filing the pivots by hand? I looked up the staff cross references back to the base model of 1553. I have a complete list of all the watches that use this staff. Also website below they sell balance staffs but more important they give dimensions. Also the bestfit book has dimensions I snipped out that image the numbers all agree so that should be the size of your staff. 100/1659 Factory Number:STAFF/BET 1553 BET 1553 BET 1554 BET 1579 BET 1605 BET 8020 BET 8020N BET 8021 BET 8021-68 BET 8022 BET 8022N BET 8023 BET 8024 BET 8025 BET 8027 BET 802IN https://www.balancestaffs.com/eb.php1 point

-

And if I ever find a more correct solution - I can always upgrade. -Paul1 point

-

Hmm. Maybe stick to Horology my friend [emoji6] Sent from my iPhone using Tapatalk1 point

-

You can take the fork out and test the balance wheel inside the watch for wobble.1 point

-

Hello, Here is my watchmaker's workbench that I made with my father today : Dimensions: 1m in length 50cm wide 33cm tall Here is some picture without my tools and my lamp : The cuttings arent clean and smooth because we went quick as I needed (and wanted )the workbench quick, but if do an another one in the future, I will do a cleaner version for sure ! Does anyone have any recommandations for the workmat ? (excepted Bergeon) Thank you ! A. Nogues, a french watchmaking student.1 point

-

The glass in the LeCoultre looks curved in both directions, or is it just the reflection? It looks to be glued in, and if so you will get good results with the replacement using the cement you have bought. If you can't get an exact fit, you will have to buy oversize and grind down the edges. Luckily for me, my wife used to be into stained-glass craftworking, so we have a diamond wheel with water circulation. I used it to do something similar a while ago, and that worked really well. As you say, a lot of work though.1 point

-

RMD, Thanks for the post. That sounds like a good technique on the acrylic. I have ordered some GS Hypo that I plan to use on the ladies Girard-Perregaux. Not sure if that crystal is original, but it's nice and will be great once it's re-glued. Here's a pic of that one... I think this is a great piece. It even came on a brand new unworn Girard-Perregaux lizard strap. It could use a service and a little adjusting - but running pretty well as-is. I also ordered a (small) blank sheet of acrylic to cut a replacement for the LeCoultre. I could probably live with mineral crystal on that watch (since I wouldn't expose it to any abuse) but I think acrylic is a much better choice for replacement. I expect cutting and fitting mineral crystal requires some tooling that I don't care to invest in. I'll post some pics of the finished work. Thanks again! -Paul1 point

-

Nickelsilver, I specifically found an FP1 for that reason.. though a standalone drill press is handy.. shall probably get rid of the drill. JDM, I wouldn't swap it for a different type of machine.. it's small enough to just wheel through a normal doorway when the table handwheels are removed, and maybe 5' tall without a vertical head, yet rigid. There are some industrial duty swiveling castors which can be lowered onto inbuilt feet, I wonder if anyone here has used those to make the most of limited space.1 point

-

1 point

-

1 point

-

1 point

-

Great video! I just picked up one of these today and incidentally came across your thread. Still slightly outside of my skill set for the time being. Random question but are you a Canadian Engineer? I noticed the ring on your hand and I have the same one.1 point