Leaderboard

Popular Content

Showing content with the highest reputation on 04/06/20 in all areas

-

Eliminating process best start at canon pinion, next suspect is the barrel, check if lid is fully pressed in and sits level,it can rub on bridge. Check holes the arbor go in may be worn etc. Another common cause is fault in gear train.4 points

-

Always hard so make a guess... Anyway, I think the problem is on the dial side, i.e. the dial train (cannon pinion, minute wheel, hour wheel, intermediate wheel). Could it be that the clutch wheel doesn't disengage properly from the intermediate wheel that drives the minute wheel when you set the time? If so the intermediate wheel may bind up the minute wheel making things slow down and then stop. Well, just guessing. Anyway, I'd check the dial train (motion works) and the keyless works. I think your idea of removing the cannon pinion to see if it solves the problem is a good idea. If it doesn't help you'll know for sure the problem is with the train of wheels or the escapement. Good luck and let us know of any progress or any new observations.2 points

-

If the staff is friction fit then the staking set shown in the picture possibly has most of the tools you need. There's a bit of information online about friction fit staffs - identifying and cross sections to show how they go together. It's easy to think that switching the parts is simply a sequence of procedures which can be completed by having the tools. While that's an important part of it, there's gaining the feel for it, and knowing how to approach it - including stuff as simple as efficient manipulation of tweezers. In any case, I'd recommend watching plenty of videos on youtube - like the one shared earlier in this thread, and having a look at the Joseph Bulova School of Watchmaking book (which you may find in a digital form ). It has to be understood that if you follow instructions here or elsewhere, you may still have a broken or poor functioning watch. These things take practice and finesse which is difficult to convey in a forum - not to mention the watch you are asking about really deserves a pro.. although not something I'm seeking, I haven't been able to justify the cost of a 992. By now it may have been worked on a couple of times, which doesn't help things to go as smoothly as they might. Regardless whether it is a friction fit staff you'll need to remove the hairspring and roller before getting to the staff.. You can follow my text (below) at your own risk, it doesn't constitute official training, and is not comparable to having a pro by your side. I'm not sure how often I'll be online here either, so you may not get a quick response to any questions, and I'm also not a pro. I'll try and describe it as simply as possible, and not necessarily using all the official terms.. perhaps someone can double check it for me in case I've mis-typed or forgotten anything.. Remove the hairspring first, methods vary but essentially revolve around either using sharp and fairly fine couple of levers to lift it off (2 at 180 degrees apart). Or by inserting something lightly into the hairspring collet and twisting while pulling up. Some people use a screwdriver, or an oiler (I prefer to use an oiler). It is general practice to make a small mark on the balance wheel to indicate where the hairspring stud points in relation to the staff pivot - some people scribe a tiny scratch, nowadays you can get a fine marker pen which can later be removed. It wont take much force and realistically I'd suggest getting some practice with a couple of cheap parts broken watches. You'll also need to remove the roller.. the staking set possibly has an anvil and punch of the correct size. While you can use the seemingly friendly and approachable roller remover tool which is squeezed between your fingers, I wouldn't recommend it. A staking set or Platax tool (if you have the luxury of one) can do it so much more nicely. I have a staking set, and made the necessary anvils for this (and will make new sizes when needed). Basically use the anvil with a slit of the right width so the balance can go on it in a way which leaves it only supported on the roller (as the complete balance wheel minus the hairspring is upside down). The balance arms and rim, and staff need to be free of the anvil. Find an anvil which best supports the roller while not touching the rest of the balance wheel, sometimes the middle of the balance staff between the roller and balance arms may allow some more space between the balance and anvil so you can get more support under the roller - be careful the end of the roller jewel does not sit on a flat part of the anvil or it may get damaged or pushed out, usually there's a little groove/recess at 90 degrees to the slit. In the top of the staking tool you need a regular punch with a hole in the end, be sure to center the top punch on the anvil before going any further.. having a tiny cone in the end of the stake (as well as the tiny hole) would be ideal, if not then a flat end or riveting end will do. The hole in the end needs to be the right size to fit on the wider tapered part of the pivot on the end of the staff (you want to preserve the very end of the pivot for later comparison etc if needed and having it bent may stop the roller coming off easily). The punch should need minimal pressure from a watchmakers miniature hammer and the balance wheel and staff should drop free (maybe only half a mm into the anvil).. lift the roller off with tweezers. Removing the staff is another chapter, with the best method depending on the attachment of the staff in the wheel or wheel hub. A few people can probably describe that process, and it's also on youtube. Jonathan1 point

-

A Citizen 0200 based piece from 1967. Similar in size to a Timex Mercury, but fully jewelled. The dial is marked with "Water Protected" and "Japan" below the 6 O'clock position, and the case serial number starts with 707, so since it is an 0200 based watch, this gives a date of manufacture of July '67. This was in a pretty bad shape. The barrel bridge was damaged, and the screw from the barrel had been swapped with the one from the winder gear, as a result, the longer screw was sticking out of the bottom of the barrel plate, and was fouling the clutch, causing someone to break the clutch spring. It was also missing its balance cock jewels and shock spring. The slightly Frankenstein finished watch. On the plus side, it is a Citizen 0200 and I have pretty much every spare you could possible need for these in the form of some donor HMT 200 movements, so I set about harvesting the necessary parts, and transplanted them into this little fellow. It now runs fine. Was it worth it? From a financial perspective, not at all. The watch appears to be relatively rare, but not particularly valuable. From a learning perspective though, it certainly was. I now know that all of the major parts of the HMT and Citizen movements are completely interchangeable, including things like the balance jewels, clutch, barrel, barrel bridge, screws, springs and so forth.1 point

-

Don’t worry I won’t mate, just had a bad graver day today, they kept dulling in double time, Friday they stayed good for ages.1 point

-

Welcome here! 17, 47, or 87 is a great age to learn watch repairing. If other members weren't timely in greetings it's just because they were too busy doing repairs or the opposite.1 point

-

I don't have that tool. We have many topics running about Chinese tools in general, about this here we would be just guessing. It's really up to each one to decide if to spend $60, $190, or almost nothing to remove a broken tube.1 point

-

Oh as you are looking at doing forming or plating over brass, there is the lead issue. You may need to do a strike or activation step first to get a good plate. While plating over copper is quite simple.1 point

-

Ok had another go today and I’m going to wait until the other collets arrive. I managed to find 3 in France that I bought yesterday and are currently in the postage system. I got a good pivot on the one I did this morning but there’s no way I can do the other pivot until I can turn the job around and hold it in the smaller sized collet. So it’s a waiting game now, so I’ve a few Balance staffs that need changing so I’m going to get on with them for now until I can carry on with this job.1 point

-

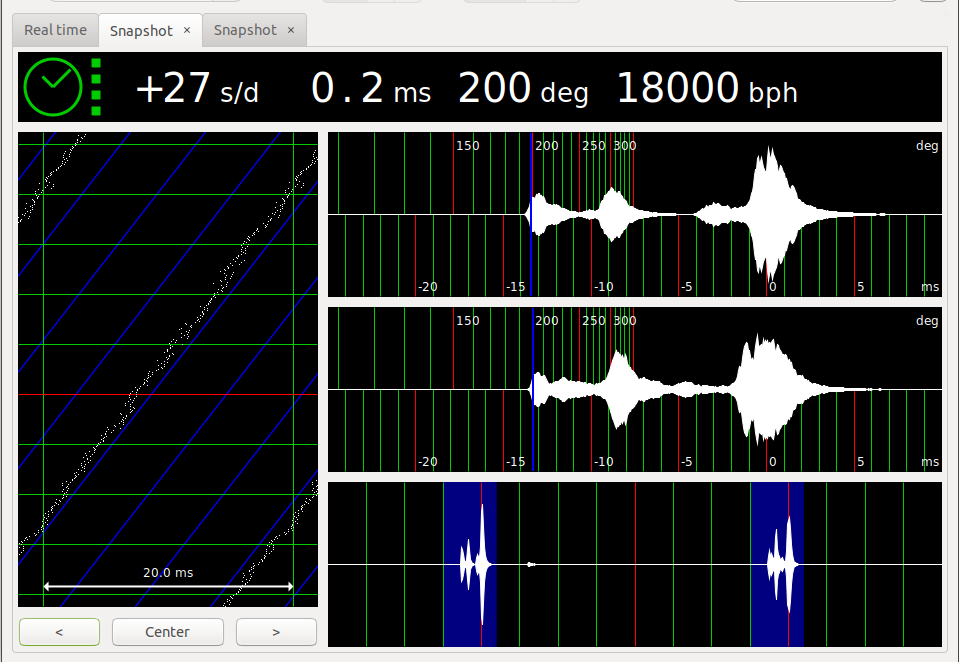

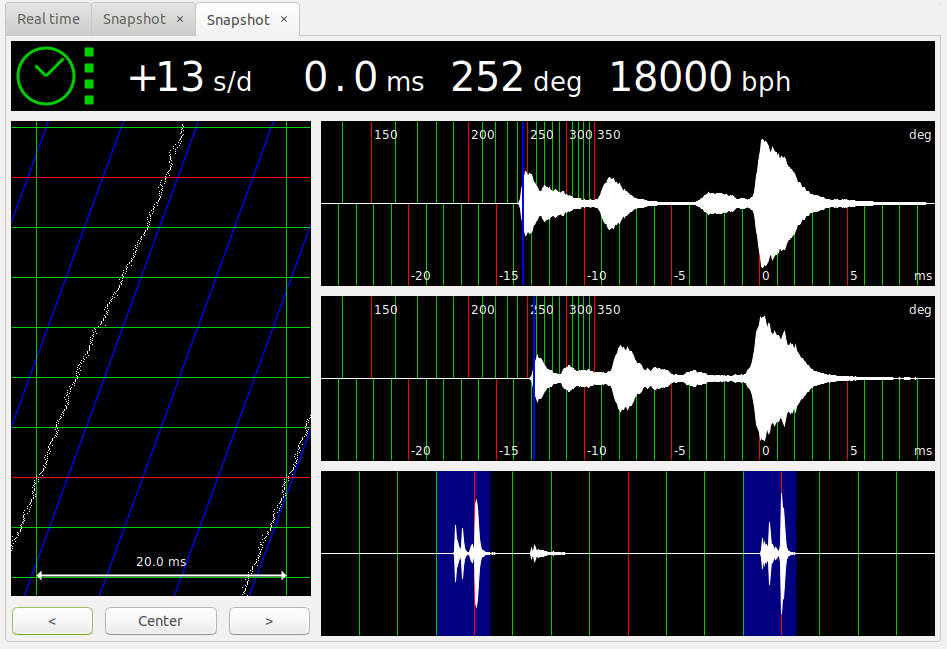

Continuing this theme, here is a Raketa 2609.HA from the mid 1970s immediately post-op, and the same watch some 12 hours later, both dial up. The big balances in these 1800bph movements make for some nice stable traces, and allowing everything to bed in has improved the picture immensely. Nothing has been done to the watch between the first graph and the second, other than wearing it on my wrist for a few hours, and letting it sit overnight. The improvement is entirely down to the fresh lubrication doing its work.1 point

-

You mean from the outside pressing in? A men watch doesn't even fit vertically under the stake. Then, some tubes have a step and won't leave in that direction. https://www.cousinsuk.com/product/box-sets-of-tube1 point

-

check if it is screwed in or press fitted as watchweasol said, probably pressed. If you have a staking set, you can use that to get the remaining piece of tube out. if it comes out in one piece, measure the diameter and look on ebay for Clark watch parts, they might have a good solution, or some chinese sellers offer a variety of different tubes and stems assortment1 point

-

Changing a balance staff is not for the faint hearted. If you are going to do this I recommend you watch a few vids first. The key is to remove the old without distorting the balance in any way. When riveting in the new it must be flush and straight. Finally once fitted checking the poise of the balance with the new staff is also important for a pro job.1 point

-

In my experience the most likely cause is dirt, and most likely dirt that has migrated from the keyless work. Next most likely is dried oil. Both would respond to a good soak in naptha, but you will need to re-oil afterwards as naptha will tend to remove any lubrication. Running without oiling will cause more problems.1 point

-

If you are all in the mood for a little bit of Soviet era horology, then I'd like to introduce today's 404 club fixer upper. A Raketa 2609.HA based Sekonda, complete with the obligatory USSR marking on the bottom of the dial. The gold plated case (stamped AU9) and the near indestructible Raketa movement make these little Sekondas rather pleasing and rewarding pieces to resurrect. I think it too enjoyed its well earned service and good scrub down, as it is now sitting at >270 degrees, beat error around 0.1ms and somewhere around +30 sec per day without me adjusting anything. It is still sporting the original high dome crystal, which took a good polish and save for a few tiny blemishes looks almost new One other great thing about these (I have a couple of similar examples) is the dial. It is both easily readable, and classically elegant at the same time. A station clock for the wrist. Maybe the 1970s weren't completely devoid of taste after all.1 point

-

Hi The difficult bit is removing the staff without bending the balance rim hence the use of the Platax tool and the K&D tools to hold the balance flat. Some watch makers put the broken balance in a lathe and cut the rivit off, which is a skilled job so as not to mess up the balance hub. I have in the past done it using a stake and a set of punches and was succesfull. The K&D tools come up on the bay from time to time as do Platax tools who command a price greater than £250 the K&K s go for arround the £50 mark. I would reccomend that before embarking on this journey that you watch Mark our Hosts videos on UTube and then decide on the course of action to take. Hope all this is useful for you. cheers1 point

-

HI tech sheet for raketa attached might be usefull some time Raketa 2628 (1).pdf1 point

-

Hi and welcome to the forum. When it next stops try to remove the balance assy and take a look at the pallet/fork and check it moves smartly from banking pin to pin, If not you still may have a problem with the mainspring sticking in the barrel, worth checking pivots and jewels for wear and or cracks. When you cleaned it what was it with ?1 point

-

"3 Russians and an American enter a bar." Sounds like something is about to go down if that were true! But in this case I acquired 4 new watches including 2 Russian made electronics and 1 Russian made, early mecha-quartz and 1 Timex Electronic. Yes, I know I have an issue with blue watches, That's why I started my post about them here, lol. I'm not sure about the canary yellow Luch, maybe it will grow on me when I get it in hand. I fell in love with this Chayka mecha-quartz. The model 3050, stepper is enormous! Plus, that blue sucks me in every time! I've wanted one of these Luch electronic watches for some time, the seller had two and offered a great price for them. Hoping the yellow isn't as intense in hand. I've heard good things about the 3055 movements, hopefully it's true. Ever since @JohnD Shared his copy of this watch, I knew I had to have one. I'm sorry folks if I'm not acquiring wholly unique pieces, But I collect what I like, as I hope we all do. I'm a bit nervous for the Russians as I'm not certain about the reliability of the various movements. Hopefully the rugged simplicity that are the hallmarks of the Russian engineering ethos will win through.1 point

-

1 point

-

Thanks, attached to the barrel is the driving wheel, its attached by a rivet , this is moved by friction to move the hands , I stupidly lost the part that holds the wheel to the barrel, see the PIC below The piece is the bit on the left of the second picture, it will be easier to find the whole barrel with the wheel already attached. Any help will be appreciated Thanks Thanks Sent from my Nexus 5 using Tapatalk1 point

.thumb.jpg.9ce273e0cd26d7f4ce61a38fa37bbb54.jpg)

.thumb.jpg.20baf3afeb397643e310ef6b73f1cd69.jpg)

.thumb.jpg.9a6368003a70cfa0e1675e67f8a3d123.jpg)

.thumb.jpg.70f7b4616cf881b4b4373dc2fe1415f8.jpg)

.thumb.jpg.4d54940ef1d9e0d80ecbc53e24632dfd.jpg)