Leaderboard

Popular Content

Showing content with the highest reputation on 03/19/20 in all areas

-

1974 U.S. Military Benrus branded Eta 2750 A number of decades in a drawer with a bent lug and the wrong crown. Finally found a NOS case on ebay. Invested in a crystal claw, new MS from Cousins and a crown from stock. My first front loader and thank you Mark for the excellent video. I managed to rebuild it and get it back together without losing the lume from the hands so left the patina intact. Gains around 4 seconds a day or less. Finding a period correct one piece black nylon strap was as hard as finding the MS!3 points

-

Hi Cecking through my workshop laptop I came across these PDFs and thought they might be useful to the members new and old alike. I have several more and will post later. Cheers Witschi Training Course.pdf TZIllustratedGlossary (1).pdf handbook_of_watch_and_clock_repairsa.pdf Test and measuring technology mechanical watches.pdf1 point

-

Ha, I honestly don't know, but I think it is practically nothing. The date wheel takes a while to pull the date disc around. On some watches with instantaneous systems you might see 5-10 degrees drop while it's arming the system.1 point

-

Ok! To me it looks like there is quite little room between the wheels in the stack, and the wheels are quite thin; my first thought is that the discs may have a hair too much play on their tenons, and be tilting during a jump sometime, either causing a misjump or making one jump that shouldn't. Could we see what the underside of the discs look like? Another possibility is jumper tension; I think the discs are in engagement with the wheel stack in general, except when on a 'missing tooth' time, if the jumper tension is too light, or again if there is some play and the discs can come out of engagement with the jumper, then you'll go out of synch. Of course if the jumper tension is too high, you'll lose amplitude or stop the watch...1 point

-

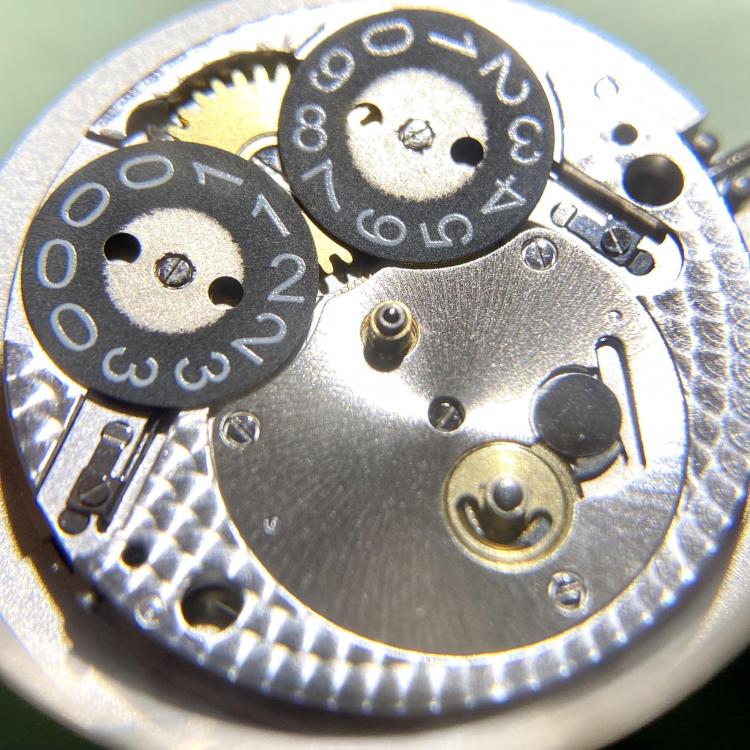

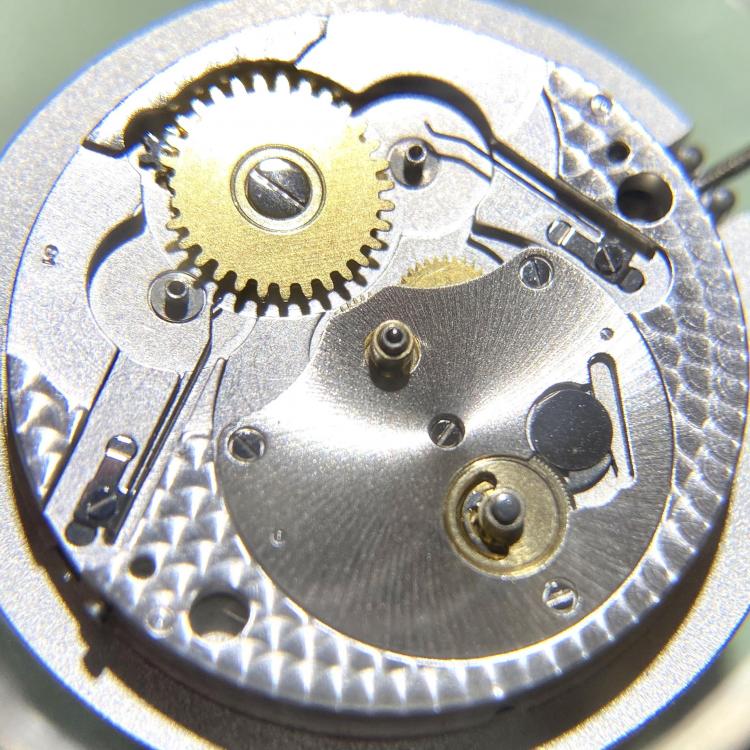

I had the same suspicion as you! But ended up doubting my instincts because I fixed this once (dates were out of sync). Checked it. Reassembled. And a month later the dates were out of sync. on closer inspection, this wheel is actually two wheels stacked. Both with appropriately missing teeth to allow either date disc to flip at the right time. So, in the end, I don’t think (right now) I need a new part. What I need to do is solve why this reoccurred. here’s the extra pictures.1 point

-

1 point

-

Another Swiss pin lever joins the 404 crowd today. The style suggests early sixties, but the fact that the lume kinda works, suggests it might be a little later. It has 17mm lugs, and I have no 17mm straps at the moment, so it is flapping around on a 16mm. It got a service and clean, and is now clanking away at around +30 sec/day. Not bad, but I think we can do better.1 point

-

I grew up next to a clock maker and repair man who's business was the largest in Chicagoland area. Seeing the movements and tools and the time consuming precise work amazed me as a child, my love for clocks turned to watches in High School when after saving what seemed forever to buy an Oris TT1 Chronograph because it "looked cool" my horologist neighbor took the ETA/Valjoux 7750 movement out to clean and oil 6 years afterwards, showing me how things worked and that was it. Hooked. Funny how this watch is the least impressive brand wise, movement wise in my collection years later and yet there's not a timepiece on earth I'd trade it for, to me there isn't anything more interesting than time movements and the folks who enjoy viewing them or collecting them.1 point

-

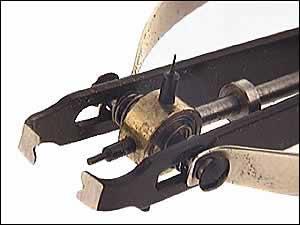

Balance staffs for Elgin watches are always a challenge, pivots are not necessarily a prime problem right now? Elgin balance staff numbers are interesting in that one number can refer to a whole bunch of different staffs not just pivots size variation. So for instance is This a old-style or a new style I'm going to attach snippets out of various PDFs. So first problem I'm having is from the normal source I look at its indicating it's a single roller but yet your picture is showing a double roller? This then requires going to a different book to find out it could be both? So I'm attached additional images it looks like it's not a problem it's listed as a single roller staff but it can have a double roller. The first step with replacing a balance staff is measuring the old staff. This will avoid any unnecessary complication of problems later on or surprises. So remove the hairspring and the rollers. Then also depends on how you're going to remove the staff? If you're going to cut the staff out before you do so you need to take all of your measurements. Otherwise you can attempt to knock the staff out and take your measurements after. There are two purposes of measuring the staff first to verify what which staff that is second to measure the new staff to verify it has all the same dimensions. So differentiate between the two staffs it appears to be the total length and the hub size. You'll have to guess on the total length which is problematic without pivots if you're lucky the hub size will give you a clue. Then as you can see four different pivots sizes. This is where having a watchmaker's lathe is really nice in that if you're lucky you'll get the biggest size you can shrink to the smaller size if necessary. But as a guess because this is a seven jewel watch it probably has larger pivots. Then if you think this is complicated celebrate that you don't have the 18 size staff number 857. It comes in four different variations with some of those having up to five different pivots sizes. Most of the watch companies have unique numbers for each of their staffs not Elgin unfortunately.1 point

-

In a lot of cases re-staking is possible. If you don't have a staking set a crude method with thumbtack I've tried before worked for me: Fit the tube back into the hole and have it stand upright, and then tap the tip of the thumbtack into the hole. Make sure to start with light taps and check progress under magnification as to ensure you don't split the tube. You just want a bit of expansion of the tube where it fits into the hand. Also make sure to do it on a hard surface so it doesn't absorb any of the impact and have the tube driven into it. Also consider filing the tip of the thumbtack to put some facets to it. This will make the rivet irregular and stands to have less of a chance of slippage at reset than a perfectly round rivet. Although the one time I tried the thumbtack I didn't bother with this and the subject watch hasn't given me any problems yet.1 point

-

1 point

-

Thank you for your introduction and welcome to this friendly forum. I always recommend you start with a pocket watch. Just practice taking it apart and putting it together. Most are like a watch movement. Get to know the names of the parts as well. Don't touch the fusee pocket watches as those are completely different. Some thing like this is a good start.1 point

-

1 point

-

Hi there ,here's some reading for you ,hope this helps some of it is a bit deep but with your background you should find it interesting .If you type pdf into search bar then click on the discussions there .Should be some pdf's to download. You could also watch videos on youtube heaps there ,even have a look at Mark Lovic's watch repair course you will soon learn the ins and outs.https://www.watchrepairlessons.com/ Q&A Student Watchmaker.pdf 302909542_practicalspringing.pdf Practical watchmaking.pdf Fundementals of oiling.pdf1 point

-

1 point

-

1 point