Leaderboard

Popular Content

Showing content with the highest reputation on 02/19/20 in all areas

-

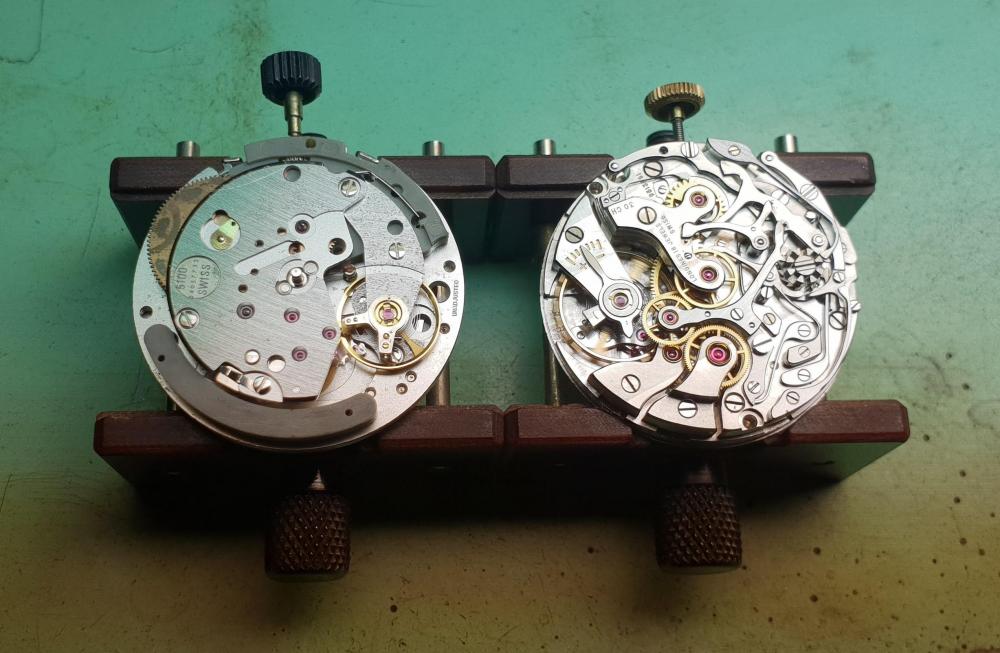

Have these two on the bench this week, thought it was a funny contrast. The left is the Lemania 5100, perhaps the epitome of industrialization and use of injection molded plastic in a mechanical chronograph; almost the whole chrono mechanism is on the dial side, under an acrylic plate that supports the date rings. Vertical clutch with nylon gearing in it, plastic all over. Extremely reliable however! This one had suffered some sort of chemical exposure in the past, with pock marks in the rhodium plating and harsh staining on the barrel great wheel. Ended up running fine with 11 second delta in 6 positions. The right hand one is a Longines 30CH, one of the most beautiful chronos ever made in my opinion. This one was in fine shape other than a non-original, ugly, and nonfunctional minute counter jumper. The one present in the photo is the replacement I made. This beauty had a whopping 16 second delta, and still hit near 270 degrees amp at 24 hours. Amazing.7 points

-

Hi attached is a lot of files apertaining to the seiko casing guide information. 03. Casing Guide seiko.pdf Seiko Casing Parts List (1977) IV. Cal. 3302 to 5245-6010.pdf Seiko Casing Parts List (1977) V. Cal. 5245-7000 to 5740-8010.pdf Seiko Casing Parts List (1977) VI. Cal. 6100-8000 to 6245-9001.pdf Seiko Casing Parts List (1977) VII. Cal. 6306-5000 to 8346-9020.pdf Seiko Casing Parts List (1977) I. Notes & Index.pdf Seiko Casing Parts List (1977) II. Watches Japan Market Only (1).pdf Seiko Casing Parts List (1977) III. Cal. 0702-0723.pdf2 points

-

Another 'job lot' here, coming soon. Bought primarily for the Timex M84 Electric... Never seen one with so little written on the stainless back, or with a knurled battery hatch before...? The Avia might be interesting as well........2 points

-

2 points

-

I believe that both evaporate very quickly. As far as I understand it (I don't use either), they are both either dry lubricants in a highly volatile carrier, or the lubricant portion of it is extremely small so it has to be applied using a carrier to bulk it out for handling purposes. Either way the carrier solvent is designed to be very volatile so that it quickly dries after application, leaving just a very light coating of the actual lubricant behind. Pretty much the same as the old school "couple of drops of 9020 in 10ml of benzine" trick that @nickelsilver alluded to above; the benzine evaporates leaving behind just the lightest application of 9020 residue.2 points

-

Bierina ? Sounds like a franco english word telling me the the designer had one too many. Either that or it is a funerary device.2 points

-

Just received my original 1978 Timex Falcon Eye. This blue dial is hypnotic. The battery had indeed leaked, but the corrosion was confined to the battery itself. I carefully removed the battery and cleaned the muck left behind. I carefully brushed out the rest of the crumbs and the dial with a clean dry paint brush. Absolutely nothing was corroded other than the battery itself. I popped a fresh battery in, gave it a wiggle and the balance took off running. It's been running since and keeping great time. The movement, I believe, is a M63 quartz regulated electro-mechanical model. I'll polish the crystal next week and clean up the rest. Considering how pricey the vintage models are going for, I did pretty food on this one, less than $30. Miraculously, the band fits PERFECTLY! I guess now that I own one, Timex says it can help me to carve stone horses, SWEET! Just what I always wanted!1 point

-

Just got this Sprite the other day had to service movement and give it a new crystal came out pretty good. Sent from my SM-G975F using Tapatalk1 point

-

1 point

-

The minute jumper looks fantastic- I think you're a bit had on yourself there! The Longines chronograph movement is gorgeous. They are rare thing today and I can only hope one crosses my bench eventually. Lemania's 5100 is well loved because of it's bullet-proof nature. I've worked on one and was amazed at how easy it was to assemble and also that it required no tuning to get the chronograph function working properly. It's sad they don't produce them anymore. The C01.211 is just a shadow of the 5100.1 point

-

1 point

-

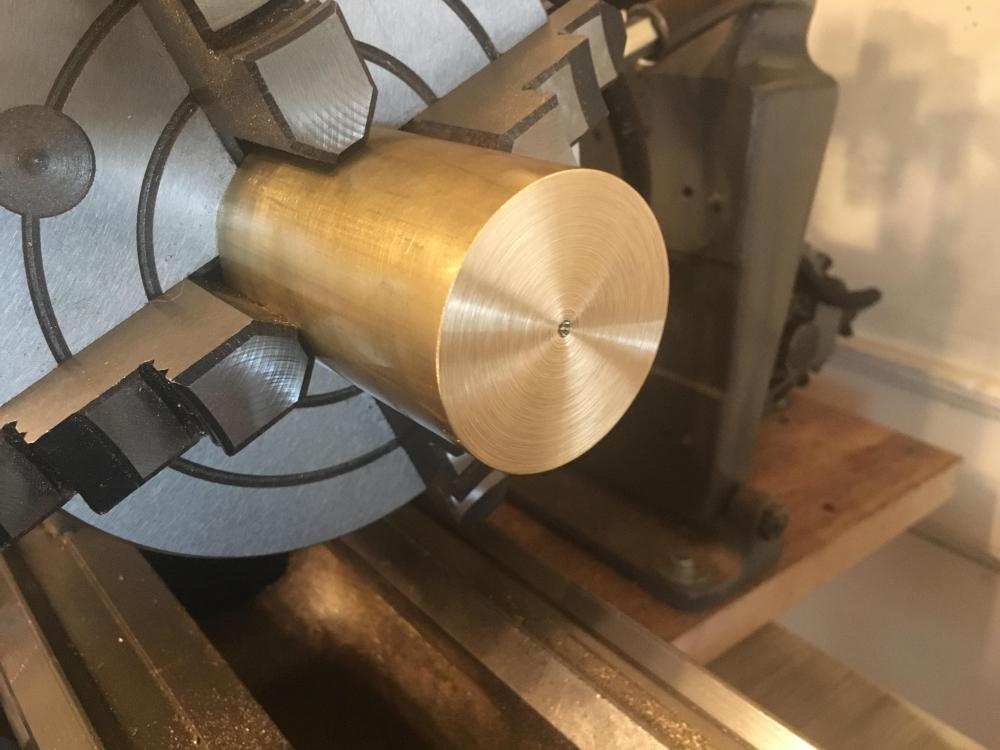

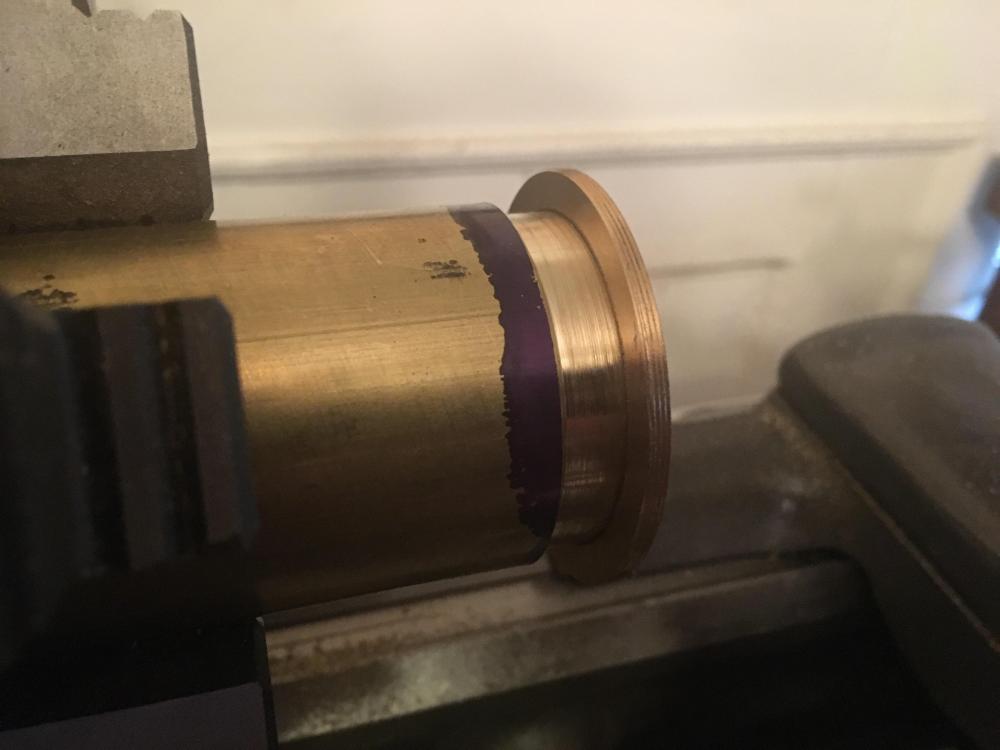

A bit early in the week for an update but here it is... Turning down 2" stock (definitely 360) to fit the lip created in the rings (they aren't both the same which will have to be remedied (I cut them shallow just as guides so I am not very concerned). You can see the brass is actually of two varieties with the smaller 360 and the ring 836 which is why it is a more red color. 836 Brass is 85% copper while 360 is about 65%. The 836 was used only because it is what I found in a size large enough for it but I think in the future I will try to find larger diameter 360. The outside being turned to size, now the inside will be turned to fit the ID of the ring. I need a final size in order to do that so I will need to clean up the ring.1 point

-

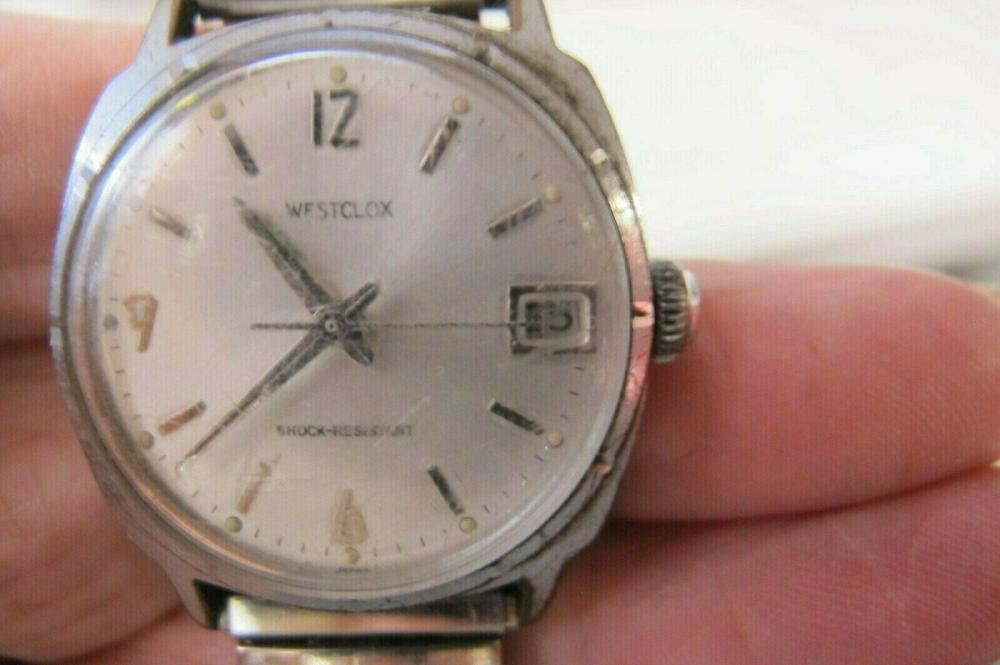

Update: Got a donor Junghans pocket watch and also some more tools recommended by Deggsie. Going to be trying to rebuild this pocket watch soon. Also I’ve recently been able to mess around with a cheap Timex I bought. I can see why there’s not much demand to restore these, but it was still fun to see how it all worked. The watch was sticking due to a lot of rust and I followed marks watch repair Breitling video where he used baking soda to scrub the rust off. Did the best I could and now it runs, just need to regulate it now1 point

-

1 point

-

Hi Mick If its not hall marked on every gold link the yellow metal will be plated gold have a look at the wear points to see if there is any base metal showing like copper colour.1 point

-

From the position of the balance etc., It looks like a variant of the skeletonized "Chinese Standard movement", and as such is not really worth much. There are several different versions of these movements, but they tend to have a similar layout, but different bridge configurations. Does the movement have any numbers stamped anywhere on it perhaps under the balance, or on the bridges that might help to identify it? Does it claim anywhere on the watch that it is Swiss Made? Franklin Mint -> https://en.wikipedia.org/wiki/The_Franklin_Mint In my limited experience of their stuff, I would tactfully describe as perhaps slightly higher quality than Gerald Ratner might have been selling... maybe. Check for hallmarks, if there are none, then treat it as a good piece to improve your watch cleaning skills on, but little more.1 point

-

You should hold the barrel in one hand, the other on the teeth and turn it back to open.1 point

-

Hello Rogart, and thank you for the generous offer. After a quick look on ranfft it does appear that 12.68N does have a quite a bit larger pivot, as the dimensions listed are "1.6 x 1.00 x 0.22mm", while the 12.68Z has "1.32 x 0.75 x 0.22mm". So unless I am missing something, I'm assuming they wouldn't fit very well. I did measure the lenght of my hands, 10.9mm on the hour, and 14.75mm on the minute, roughly as the metal looks quite brittle, and I didn't want to mash it in my caliper. I am curious if the lenghts are similar to the 12.68N.1 point

-

The Tudor with the ETA base would use ETA or "normal"; Rolex reversers are fairly unique in design.1 point

-

Thank you for your introduction and welcome to this friendly forum. Lovely country Norway.1 point

-

1 point

-

1 point

-

1 point

-

Minus the obvious "SEIKO" text, I would have thought this was a swatch given the styling.1 point

-

I am wearing a Seiko Arctura Kinetic. It's from the 90' of last century. I repalced the capacitor in it, as well as the crystal and made my own leather band. Love this thing!1 point

-

1 point

-

1 point

-

Worth to remind that even without bothering to set lift angle, or having a "large" discrepancy of 5°, the amplitude value is not greatly affected and will be accurate enough for making a go/no to call.1 point

-

1 point

-

Hi here is a bit of Gruen info for you I have quite a bit more if you are interested like their catalogue of movements etc. Gruen Movement Catalog - Caliber Date Table V1.1 (1).pdf1 point

-

1 point

-

Ok, and don't want to be a downer, but you've picked two of the most difficult complications to do there. A tourbillon is a cakewalk in comparison. Just for a little perspective, I used to put together repeaters from kits, all parts made, beveled decorated already, the manufacturer expected their watchmakers to do 10/year. That's just assembling and making the strike work correctly, filing a few hundredths off here and there, thinning springs, a bit of flat polishing. Also did a bunch of perpetual calendars... I'm only suggesting a simpler first piece because I've seen many trained watchmakers set out to do that, only to give up in despair a couple of years later. Just making a simple watch not including the escapement or winding parts (surprisingly tricky to get right) is a major accomplishment. I'd hate to see you get discouraged and end up like others I've known.1 point

-

1 point

-

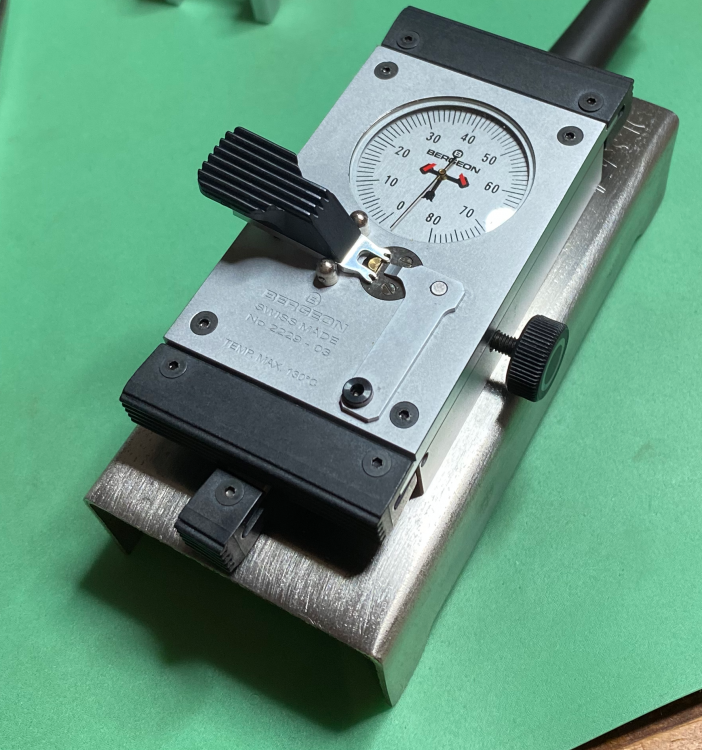

Excuse the sideways picture before. It's called an escapement tester. But I'm not really sure why. It should be called a pallet stone adjuster. You can use it to very precisely move pallet stones in or out. You heat the entire thing up to 130 degrees. The pallet fork is secured in one of the lobster claws. The hammer shaped thing on the right is pushed up against the pallet fork. The stone is touching the brass half moon shaped bit in the middle. Tiny adjustments, 0.01mm, can be seen on the dial as you move the stone. It's really quite ingenious.1 point

-

what would a "flat ground" look like? it might make the tip too long and weak. have you ever twisted the tip off a tight screw? a compromise is hollow grind. vin1 point