Leaderboard

Popular Content

Showing content with the highest reputation on 02/17/20 in all areas

-

When using a reamer always take your time and just a few turns and then test. That is the easiest way to go about such a task, If you do not have the type of tools to measure, then keep testing for size.2 points

-

I think that if you just watch the lessons, well you know how calm and demonstrative that Mark can be. I guess to get the most value you would have to be hands on and follow along. But the cost of tools and scrap movements, lubricants and a work area hmm. I suppose if you bought a $5000 motorcycle would a $250 community college course on how to ride the thing be worth it? You bet it would. But if you were determined half a kitchen table and a couple hundred dollars worth of ebay tools would allow you to find out for sure. Can you actually manipulate screws that are like specks of dust to the naked eye? and if you find out you like that sort of thing you could get miles ahead of those folks who are waiting till next summer. Super valuable I think.2 points

-

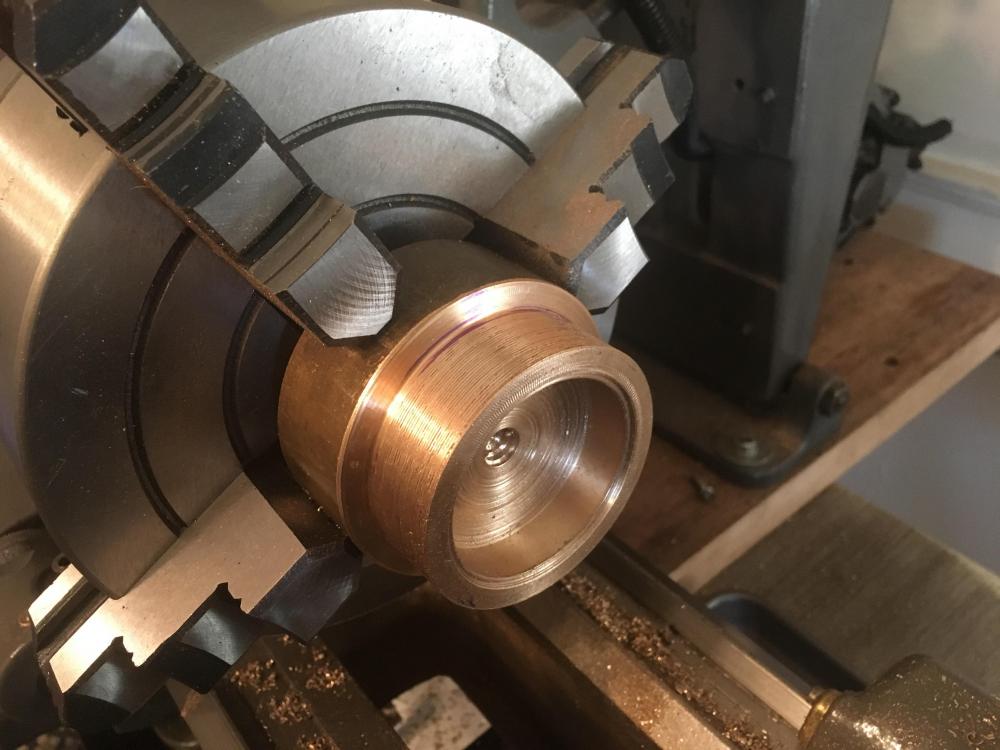

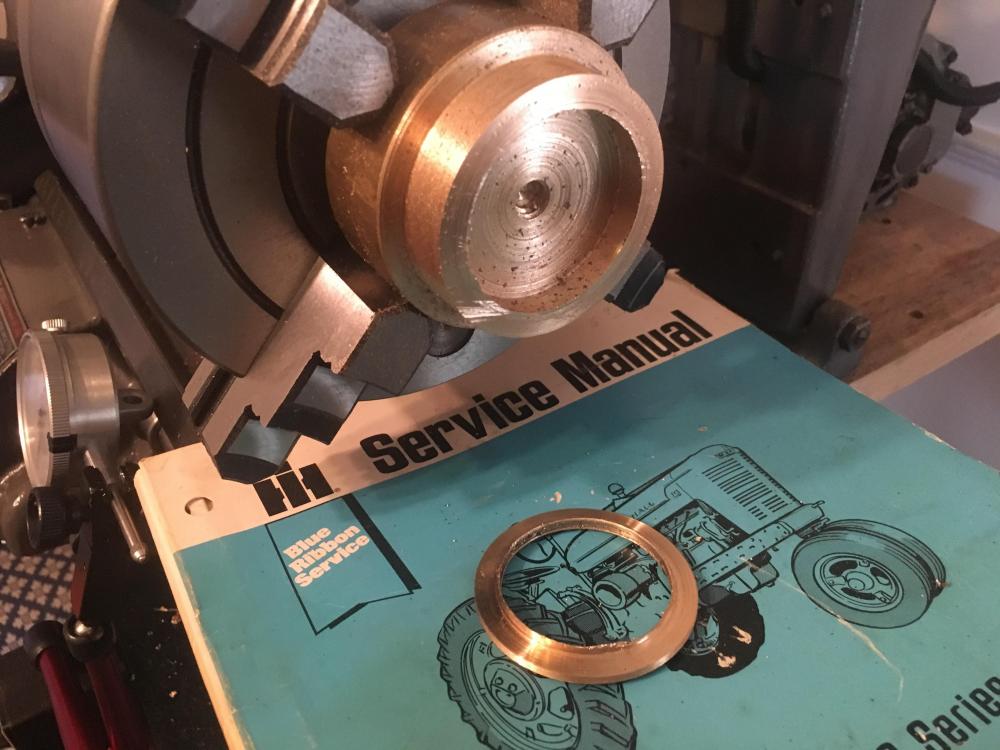

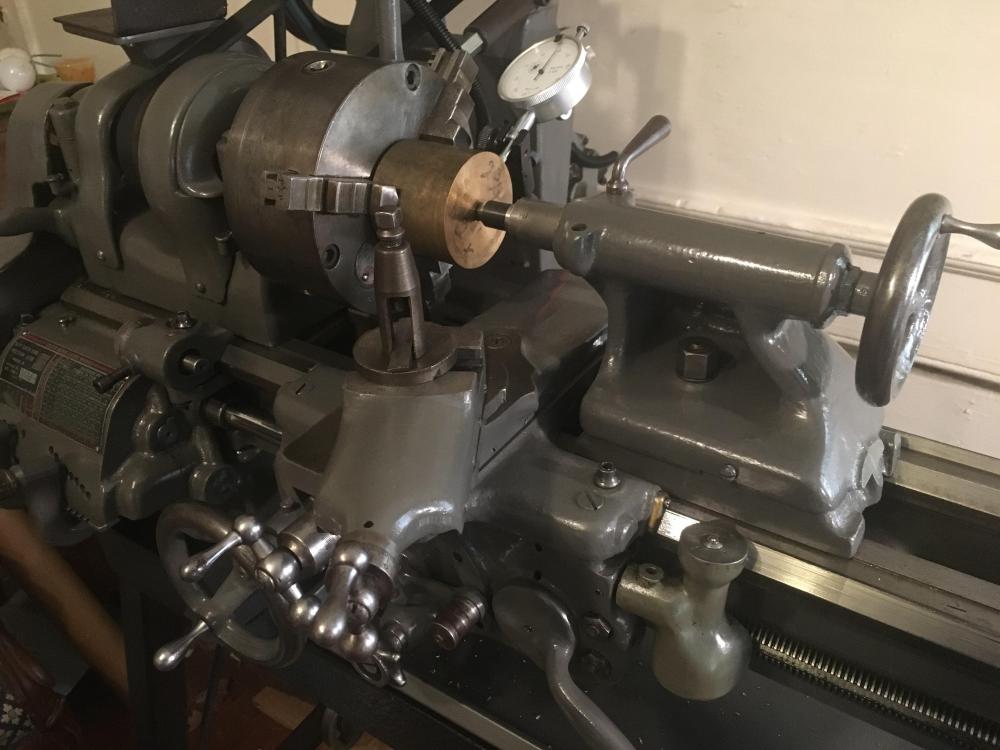

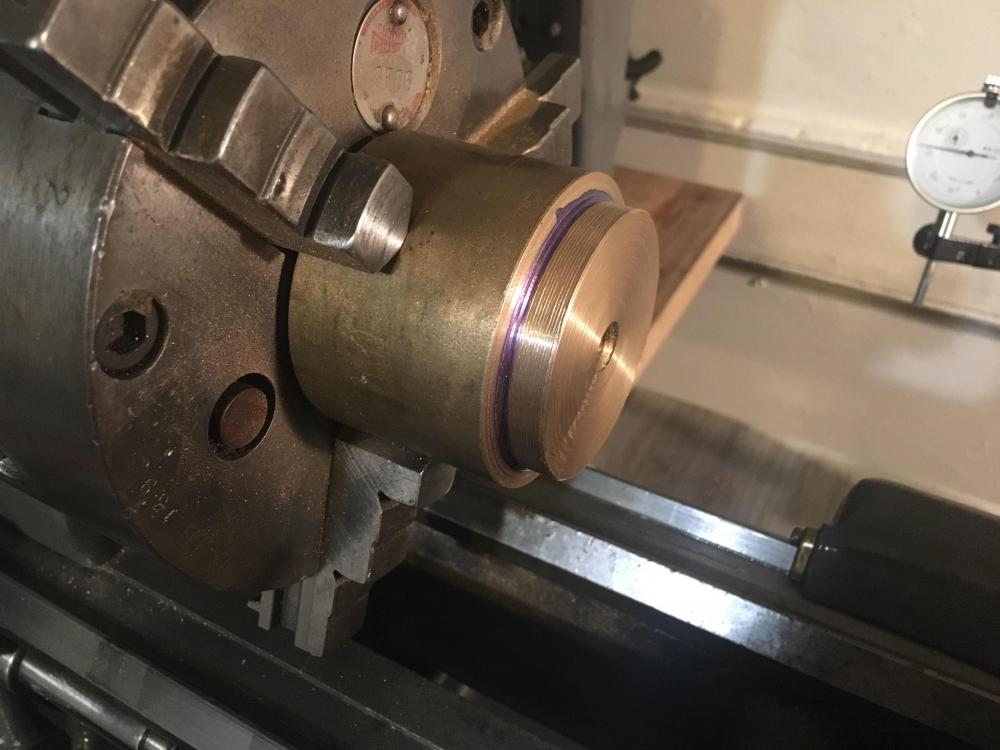

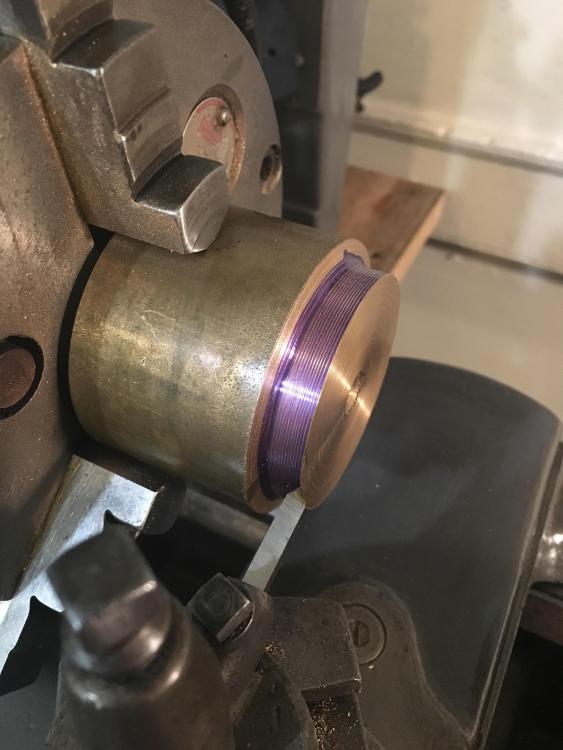

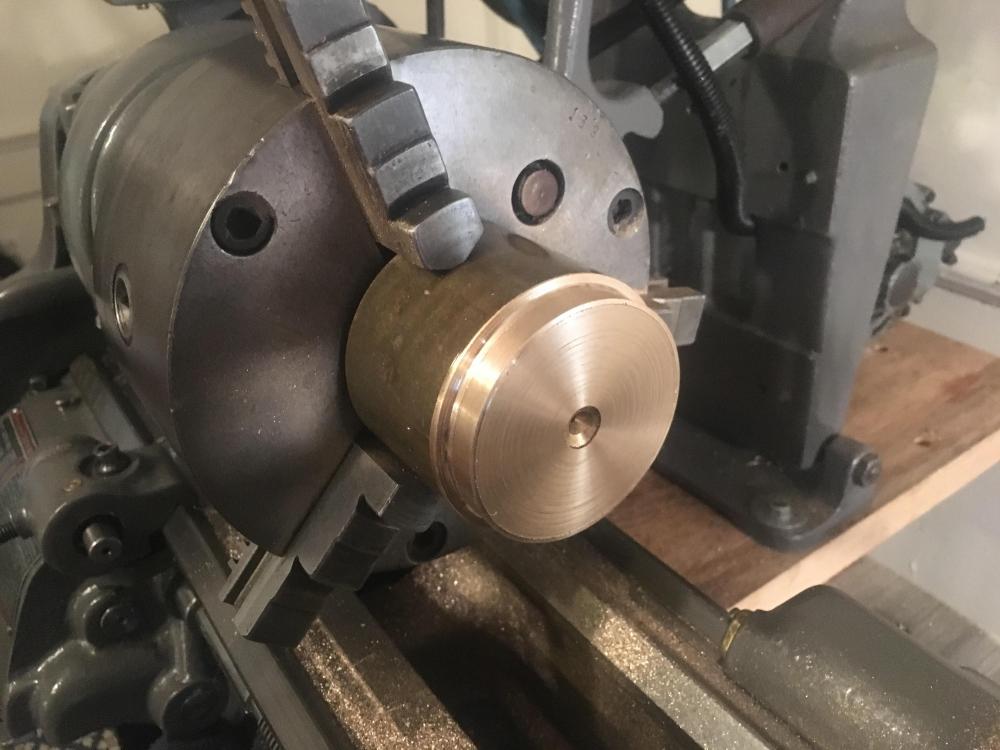

I thought some of you might want to watch me make this watch! You can follow on instagram but I will try to keep up here. It's a "unique" watch I would say so bear with me (New Bern pun!). Right now it involves making two brass rings that will seat in two hemispheres. I couldn't make the hemispheres yet so I cheated a bit and bought some until I can find a way to spin them myself (spinning metal is really hard on a lathe and I worry about my ancient (WW2 era) South Bend. I started with 2 3/4 brass (360 I think) and brought it down to size and threaded the outside and plan to cut the two rings from this but first I still need to open up the inside and create a groove along the interior rim. Center drill, 5/16 bit and will be moving to boring bars. Okay you are all caught up!1 point

-

Lots of dirt on pivots, teeth, hairspring? Possibly, worn pivots and jewels. Tired, gummed-up mainspring? Basically, no way to be sure without disassembly, cleaning and close inspection.1 point

-

The impulse jewel on the balance is usually fixed with shellac too. One way to clean on a budget is to soak / brush / ultrasonic with lighter fuel, then a quick rinse in ipa to get rid of any residues and dry with a blower. Some people on here will not take the risk of getting alcohol on shellac, because it will soften it and dissolve it eventually, but the general consensus is that a few minutes contact don't hurt. Also, ammonia-based cleaners work well and are not too expensive. Then a rinse in alcohol is a good way to finish, because it drives off the water then evaporates without trace.1 point

-

Well it should be simple enough to get it to 0~+5 on the wrist. You sync the time to a reference and wear the watch for something like a week. Then you calculate average seconds gained/lost per day for the period you wore it. If the watch gained/lost you subtract/add the average gained/lost per day from whatever the timegraph displays and that would be your target rate to regulate to. For example I wear the watch and at the end of the week I find that it had gained 35 seconds. I divide 35 by 7 and get 5 which means it gained on average 5 seconds a day. I wind it up fully and put it on the timegraph dial down and it reads +2. I subtract 5 from 2 which gets me -3. Now I regulate it so that it reads -3 dial down on timegraph and see where that gets me. Unless your wearing habits change significantly from week to week too much consideration need not be placed on wearing habits because all that would already be factored in.1 point

-

No you have two weak springs instead of one strong one. Like many Russian watch of that period it was a gimmick. I have repaired some that are day/date, on the dial it says something like 30 jewel movement, remove the dial and you have a plate with jewels pressed in and there just for show, they do nothing.1 point

-

That is a chronometer certified movement if I'm not mistaken, and should be an absolute piece of cake to regulate to that level. It should also maintain that rate or darn close to it after 24 hours, which would be a hair over 50% of the reserve total. If it was serviced recently the watchmaker should definitely have a look.1 point

-

No pictures inside thee two electronic watches, but the two Russian numbers look reasonable. The first one is a rather fine Raketa 2628.h. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Raketa_2628_H The other is a Slava 2414 twin barrel. http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&&2uswk&Slava_24141 point

-

Wait you mentioned that the rate suddenly increased? How are we forgetting the most obvious approach to this problem? Try hitting it with the demagnetizer!1 point

-

Those take me back! You might like this, which appeared in my youtube's suggested vids recently. BTW I've not been fixing many clocks while on holiday, but I did a quick fix on this camera. It belonged to my late father in law, who is in the picture, and which picture may have been taken with this very camera Sadly I never met him as he passed away a good few years before I met my wife. I cleaned things up as best I could given the lack of proper tools, and re- seated the mirror, which was lying loose inside. It would need a little more work to clean up and lubricate the self timer, shutter etc. before it could take pictures, but for that I would need access to my normal array of tools, but at least now you can look through the viewfinder and see the "view" once more. The mirror has suffered a bit over the years, but the lenses look clean.1 point

-

I assume you're using the seitz tool? I have a picture from the manual showing how you supposedly use the reamer. As already pointed out by oldhippie and my own personal experience do not follow the example shown in the manual. It is so easy to go past the hole size if you're not careful and end up with a hole that is too big. If you have a complete seitz set it should have the hole closing punches. Then worst-case they also make brass bushings that can be inserted in and then you put the jewel into the bushing.1 point

-

As mentioned in similar topics before one can't, in practice, do any manipulation 7S26 hairspring collet. It is set at the factory and meant to stay like that for life. So in case of any problem the balance complete must be replaced.1 point

-

Possibly because it didn't needed to be replaced. I think you should bring it back to the repairer explaining the problem to give him a chance to use his professionalism in regulating it the best possible. In any case not letting the watch stay more than, say a night, without wearing or otherwise winding it should help in getting at a more constant rate.1 point

-

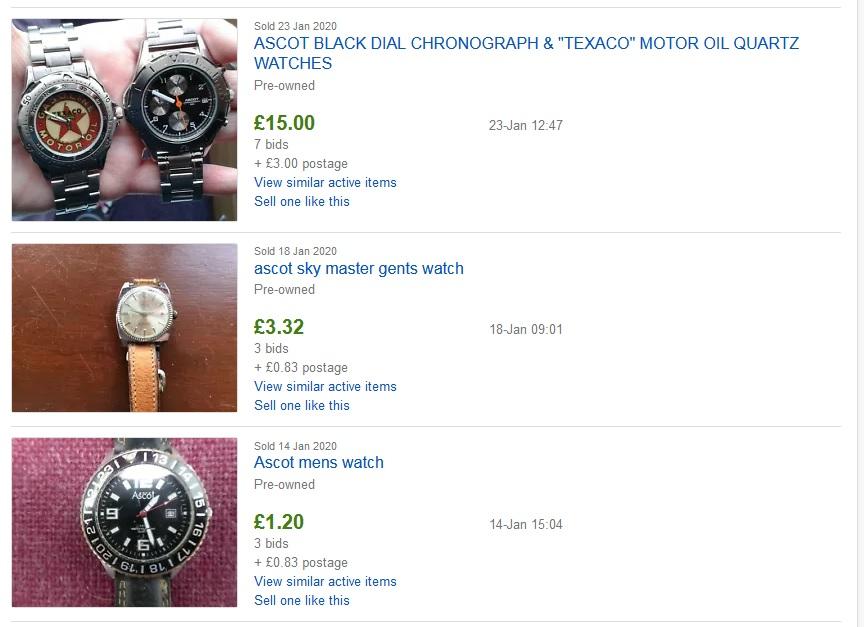

The twin of my COSC accurate USSR 2628 H 19 jewel TV dialed manual wind day date appeared on ebay, so I placed my usual humble bid and it is on its way. I picked this up for even less. A similar era USSR Sekonda twin barreled square face with date. And the final bit of madness was an LED Timex and an early LCD Trafalgar as a job lot. I really only wanted the LED, but since they came in averaging £3.85 each, I figured what the heck. I'm curious to know why the Trafalgar has the "T British Made T" logo, perhaps it has a tritium "backlight". I'm sure a little more mild radioactivity around the place is not going to make much difference.1 point

-

the dial has changed color over time. It was originally a pale cream color.1 point

-

1 point

-

How big was the original rubbed in jewel? The material there is minimal, generally you'd ream well oversize to get outside the "rub in" area so there's some substance for the friction fit, unless you have a jewel that's just a hair over original. The reamers can go oversized, we're talking 0.01mm friction fit, best to have plug gages to check (I know nobody has them) or go almost all the way and test.1 point

-

1 point

-

1 point

-

Varnishes will yellow with time. Moreso depending on environmental issues. It is legitimately possible yours is a victim of all of those.1 point

-

As the trimmer on this is a tiny low value variable capacitance it is probable that some contaminant has bridged between the two capacitor plates, at an edge, and dramatically changed the value of the trimmer, preventing the quartz oscillator from running. Turning the trimmer would break any bridging at the edge. 'All' you need now is to reset the trimmer for accurate time keeping , fortunately something I can now do on these, since I realised that if I set the gate time on my Seiko QT-99 Quartztester to 120seconds it reads these and allows you to adjust them accurately. My M58 jump minute watch now runs to +0.5 secs/day1 point

-

2 More Timex quartz watches on their way to me. The first is slightly more modern and I believe has a more conventional stepper movement. There is a recessed pusher on this model, I assume it's to advance the date? The second has a quartz regulated electronic balance with a Day/Date feature similar to my Falcon Eye. here is that recessed date(?) pusher. Day/Date Quartz regulated electronic balance model I also purchased this vintage watch. It is made by the Pierce watch company. I got this one for 2 reasons, the first and most important, my youngest son is named Pierce. That alone is reason enough for me. Second reason is, I like the simple style of it. Pierce made a very nice Chronograph as well, If I can find one at a reasonable price, I'll grab one as well.1 point

-

1 point

-

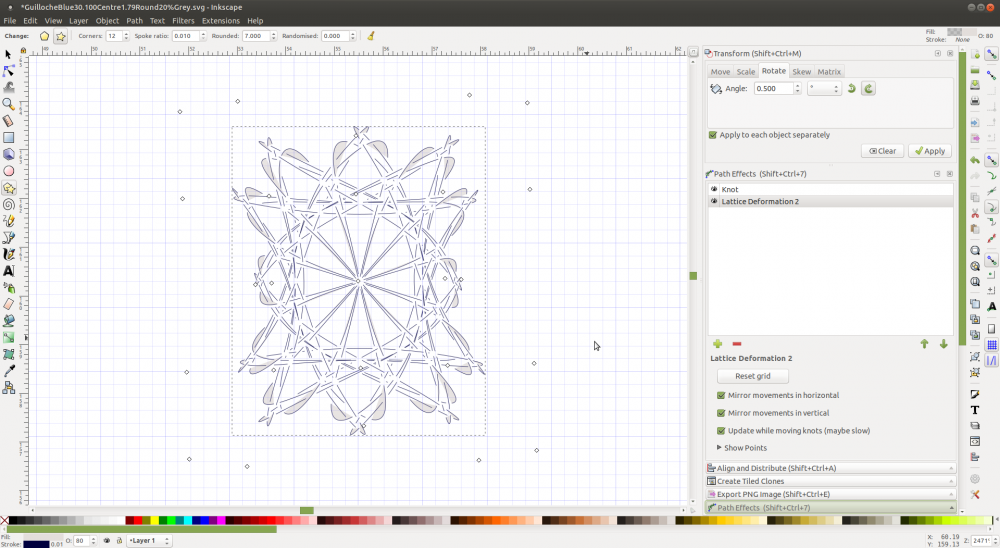

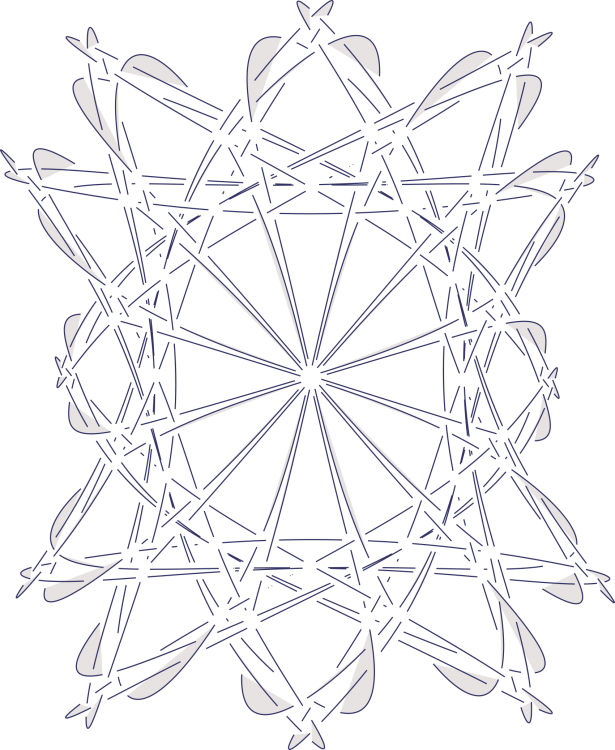

Most of the patterns I have experimented with so far have been circular, but not all dials are round, so what can you do if you wand to fit a round peg into a square hole? This is where "Path Effects", and in particular, "Lattice Deformations" come in to play. The Lattice Deformation allows you to constrain a pattern within another shape. There are other ways to do this, but this is probably the easiest. If we take a 12 sided "curved polygon" similar to the ones in the previous examples, and add a couple of path effects to it, we can create some interesting designs. The first effect adds the "knot" to our simple shape, and careful tweaking of the line properties (the fill and stoke widths, colours, textures and graidients) give a softness to the edges. If we then add the "Lattice Deformation 2" path effect, we can constrain our design to more rectangular shape. Note the use of the tick-boxes to keep the effect symmetrical about both the horizontal and vertical axis. We simply pull the "handles" around till we get the effect that we want. Rectangular1.svg1 point

-

1 point

-

Update - Basically redid all previous steps (turn, thread, hollow) and back to cutoff. So reground the cutoff tool a bit and went really slowly till it just starts the deform (once the brass gets so thin it can't hold itself steady) then cut it off with a hack saw. Both came out without issue and will of course need cleanup later but I am satisfied with it - Now on to some pillar plates.1 point

-

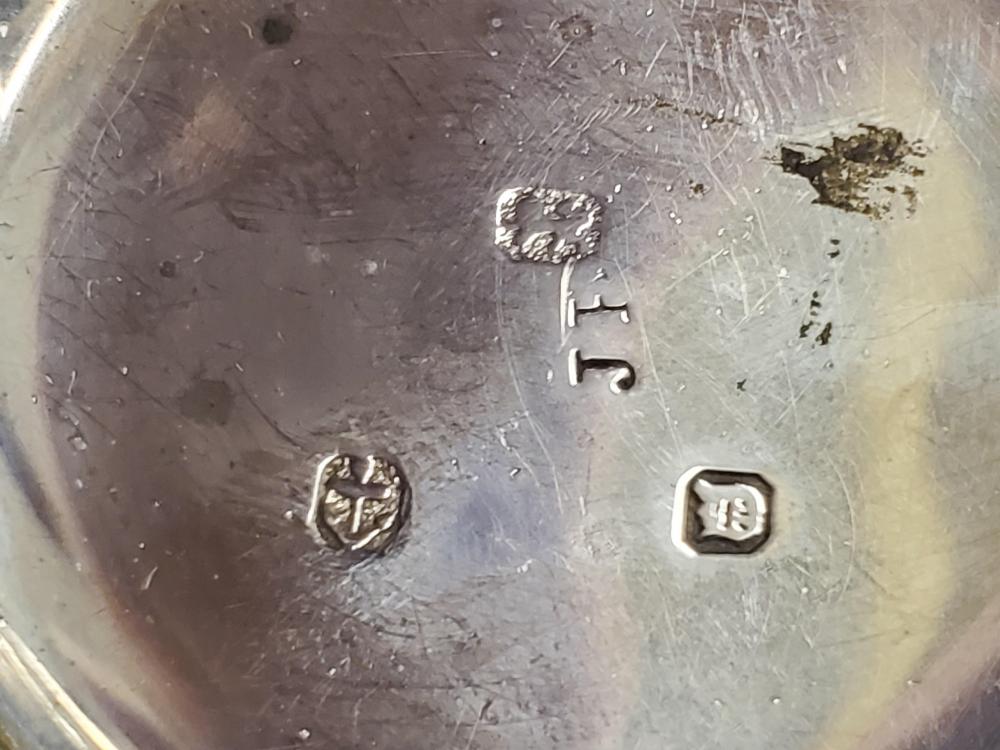

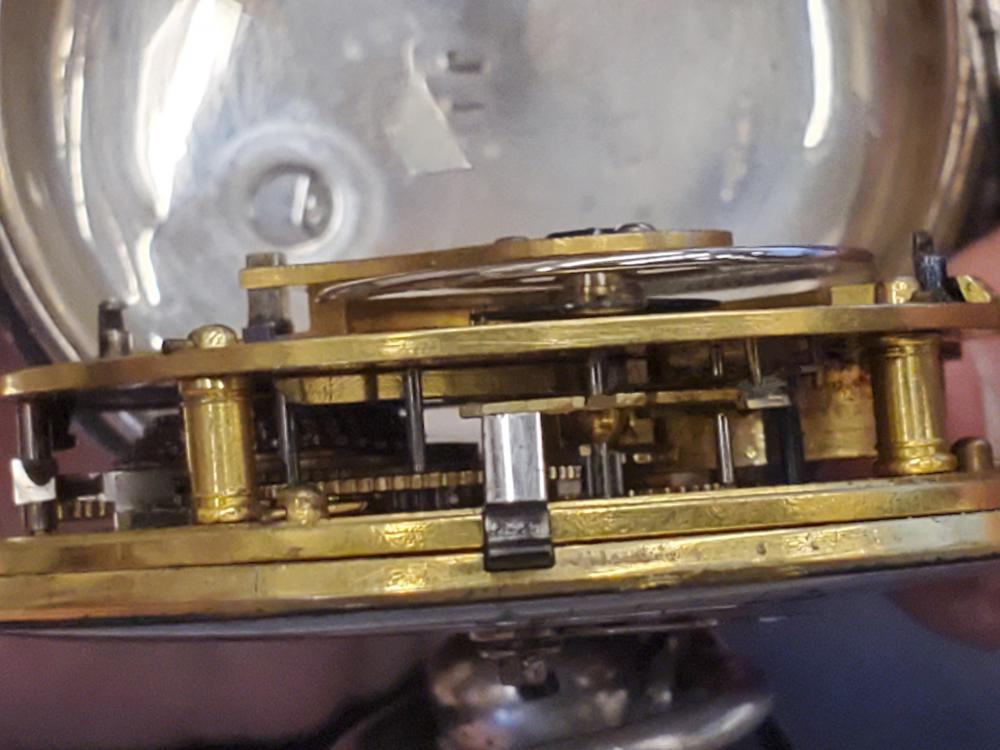

As a coincidence, I happened to be carrying my oldest English pocket watch. It is from 1827. It was made by John Nichols. I was able to confirm this by the silver hallmarks on the case and research I did on the maker and the design of the watch, though thiese watches were often re-cased and it doesn't always apply. Other methods to roughly date these watches is by the type of escapement. The watch above has a Verge escapement, as did nearly every single watch from the 1500's until the very early 1800's. My watch has an early English lever escapement invented by a watchmaker named Edward Massey, mine being the third and more common revision. The Massey lever was used from 1820-1845. Fusee watches were the dominant portable watch mechanisms for nearly 300 years until the Americans perfected the "Going barrel" gear train in the 1850's. Fusee movements are more delicate and were subject to catastrophic failures if the mainspring or fusee chain broke. The Americans mitigated spring breakage by inventing the "Safety Pinion". A pinion attached to the center wheel that would intentionally unscrew itself to absorb the shock and prevent it from transmitting into the gear train. This pinion could be easily reset by the watchmaker when he replaced the mainspring. Among the ways to narrow down the age of English fusee watches include, but are not limited to: the design and shape of the balance cock, the type and quantity of engravings, the type of regulator, the type of escapement, whether or not it has a sub-seconds dial, whether or not it has a jeweled gear train, if it has a compensated or uncompensated balance, support pillar shape and the silver case hallmarks. By the late 1800's, American watchmakers had become so successful the English had abandoned Fusee movements for going barrel movements. In fact, there was a whole industry dedicated to copying american watches. Today, some people collect just the ornate balance cocks because they are so beautifully engraved, each one telling a different story, with faces, animals and flowers being common motifs. @Frankm, you have a very handsome watch, hopefully you have enough parts to get it running again. Would be awesome to get a 200 year old watch running. Below is my 1827 Fusee, can you spot some of the date specific features of it? Date hint #1 No sub-seconds dial Date Hint #2, Silver Hallmarks Date hint #3 Dust cover and balance cock shape Date hint #4 and #5, uncompensated balance and watchmakers name and location Date hint #6 and #7 Escapement type and pillar shape Here is a view of the Fusee chain wrapped around the Fusee cone1 point

-

1 point

-

Hi all , Just thought I would share with you guys and gals a video of a Seiko Pressure tester purchased some time ago .Its part of the traveling tool kit that I take to service friends and relatives watches on the go . Anyway it's a Seiko S-451 pressure tester and it is probably from the 80s or early 90s and very useful for vintage water resistant watches and quarts . I had to upload it to youtube so I could paste on the forum .I restored the Tissot Seastar that you will see as it was a complete no runner with numerous problems .Anyway check it out and enjoy a cigar and a vino rosso https://youtu.be/n8dbQLwsHbg1 point

-

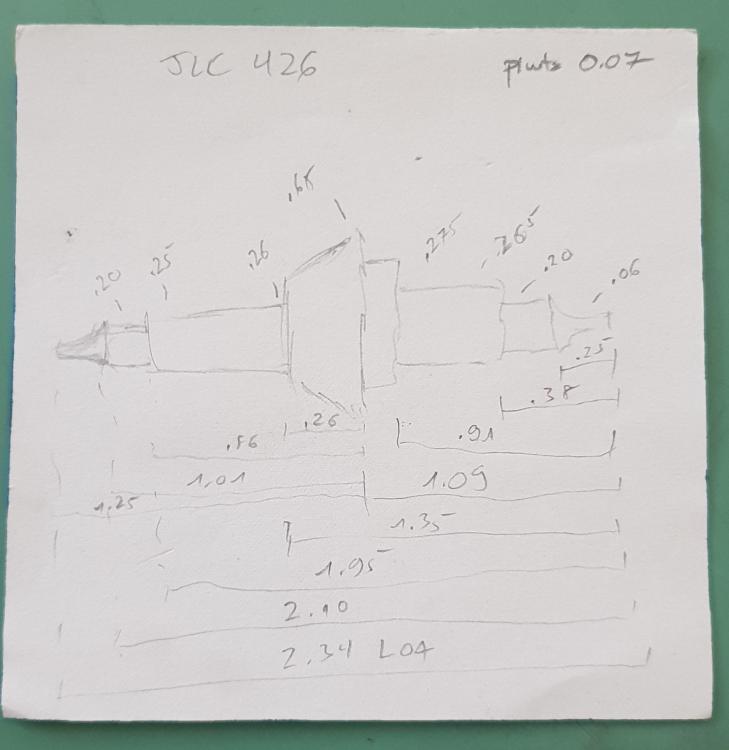

I do about a staff per week and have honed things a bit in a couple of decades. One thing I'd modify on the drawing above is how the measurements are referenced for the lengths. I find it's good to have a start point, and work from there as much as possible. In the little sketch below the tip of the pivot is "zero" and all the lengths are referenced from there. This helps avoid stacking up errors, where if you were individually measuring the length of the balance seat, hairspring collet diameter, pivot etc. even if being very careful you can end up surprisingly far off on the total. In my case I rough them out with a cross slide so while I have lengths referenced from right to left for everything, there is a second set of lengths starting from the hub for the lower half. If I was flipping the staff to work the bottom I'd do new lengths referenced from the lower pivot.1 point

-

If the clip fails to grip the hairspring and it drops onto the plexyglass you could end up with a broken balance staff. That clip looks as if it might bend the hairspring so it could be out of shape. Nice try but I think you need to modify it. Why do you need such a device? Are you intending to make your own balance?1 point

-

platinum is expensive one thing i wonder about is that you could twist above the class that " line " or what it is called ? you can twist it around and round how many times you want, why can i even rub this thing around the clock.0 points

-

probably we will se where Ebay will take me dont know how many thounsand of euro/gulden they paid for it baack in the time but atleast a couple, think it whas 1994 or close to that when i got this 2 beatiful ones0 points

.thumb.jpg.2d108cdd15cca46d4a51264e1f21ce18.jpg)

.thumb.jpg.36112c194776e23424d654c66793a86b.jpg)

.thumb.jpg.03602a3cd0762e78c46c959fab4e3ff5.jpg)

.thumb.jpg.8d2e575bfaac3bf3ec8cd44e03598d6d.jpg)