Leaderboard

Popular Content

Showing content with the highest reputation on 12/20/19 in all areas

-

Recently my dad gifted me his original Seiko Pogue and asked me if I could make it like when it was new. The original bezel insert was completely faded and had been previously replaced with another which had been scratched. The crystal was badly scratched and one of the original pushers was bent. Apparently the guy who worked on it previously lost the inner bezel gear as well. The watch was running well and I do not have the experience to work on the movement so I left it as it was, an outside inspection of the movement did not disclose any large faults and the watch keeps time well. I replaced the bezel, crystal, stem/gear, and the pushers and it turned out beautiful. The dial has the original patina which looks awesome. I know the aftermarket parts are not the original, but the new crystal and bezel insert bring new life to the watch. I do have all the original parts safely stored. I also added a canvas strap, I like the look (I do have the original stored safely too). Hope you guys like the result. Below are pictures of all the process and the finished watch. I sent pictures to my father and he was very emotional when he saw it. I plan to take the watch to him personally when I visit and have him enjoy it too.4 points

-

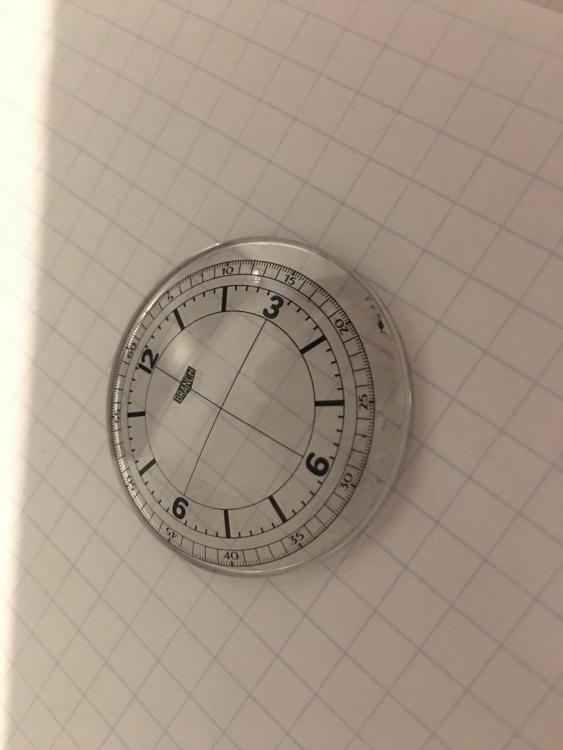

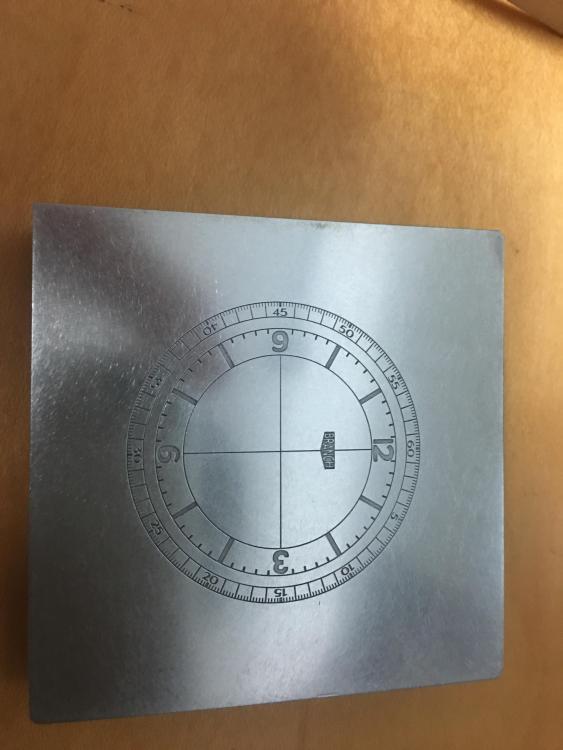

Hey guys, I have been working on a project to make my own watch dials over the past few months. I thought I would share my progress with you thus far. It has been an awfully expensive endeavour, and I have yet to reach a final dial but the work is well underway. I have purchased a pad printing machine, speciality inks and pads as well as a custom engraved cliche of my design. Now I’m putting it all together, I have been practing printing on plastic watch crystals, until I have my silver dials complete to print on. Let me know if you have any questions. Cheers3 points

-

I'll just throw in here that naphtha is a sort of catch-all petroleum name that could be a mix of numerous levels of petroleum distillation. Here in Switzerland the really good drug stores have pretty much any chemical you want; I use Ronson lighter fluid to clean manky clock parts before actually running through the ultrasonic so thought I'd be smart and buy a liter of pure naphtha. The guy looked at me weird and asked why I wanted that and I said it's lighter fluid at a fraction off the cost. He said lighter fluid is benzine. I bought it anyway. This "pure" naphtha is super headache inducing stuff, I tried but it's actually scary. Back to lighter fluid for clocks. I use benzine frequently for various watch parts, generally precleaning muck before the cleaning machine. It's not particularly safe to breathe or stick your fingers in but not particularly bed either. If isopropyl alcohol will manage I use that as it's definitely safer. Side note- I needed fuel for my old Coleman camp stove and it's hard to find in Europe. Drugstore guy said "benzine, definitely", showed him the info I had and that it needs some specific mix of petroleum distillates and he held firm and danggit if my 40 year old stove doesn't run just perfectly on benzine, 5 years running. BUT- there are different types of benzine rectified, distilled, and what seems to be the good one here Benzine 60/95. No residue with that one. I bought distilled benzine once from a different source and it left visible traces. And if you google distilled benzine you get- naphtha.... The "pure" version of which is nothing like any benzine I've tried. French guy I worked with brought in benzine from France and it was different still hahahahaha. If anyone wants to go down a rabbit hole try to find out what's actually in Coleman fuel. Depending how you look its "26% naphtha, 34% naphtha 10% naphtha, 13% naphtha, 17% naphtha". Which could all be classified as benzine, depending on which definition you're using. CAS numbers get foggy here...3 points

-

Today I slipped on my Pam homage I made myself from eBay parts. I fell in love with the Panerai PAM00672. The classic shape of that case and the eye catching engraving caught my eye. I happened to see a "replica" of that case on the Bay and picked one up. I also grabbed a Sea-Gull 6498 movement and a sleek black California dial with matching hands. The strap came next and I chose one that looked the part. The correctly engraved clasp was ordered last to make it complete. I get compliments all the time on it.3 points

-

Watch papers are a sort of tissue paper. The big difference is they are not as fibrous as normal tissue. Used for drying off parts.2 points

-

I picked this vintage Timex Marlin up from a pawn shop for $10. It began ticking as soon as I wound it up which is always a good sign. The metallic brown dial and hidden lug case caught my eye, but the Crystal was quite rough, thankfully it wasn't cracked. Sadly it's wearing one of those atrocious expansion bracelets, so that will be ditched ASAP! This was my first time decoding the dial numbers, very useful information there. After a thorough sanding and polish the Crystal looks great! According to the catalog page, it looks like it originally came with a mesh band, I'll have to look for one.1 point

-

ETA Calibre 2772 Service Walkthrough Pictures – Disassembly (Please sort the pictures by name in ascending order) ETA Calibre 2772 Service Walkthrough Pictures – Assembly (Please sort the pictures by name in ascending order) For the disassembly sequence to make sense it is important that the pictures are sorted by name in ascending order. Generally, the sequence of pictures first shows the part to be removed in its position on the movement and the following picture shows the removed part along with any screws that held it in place. For the assembly sequence to make sense it is important that the pictures are sorted by name in ascending order. Generally, the sequence of pictures first shows the part to be assembled along with any screws holding it in place. If needed, the following picture shows the section of the movement where that part is to be assembled along with my lubrication suggestion, and the picture after that shows the part when assembled to the movement. Note that this is not a maintenance servicing tutorial. To be able to service a watch movement some basic tools are required as well as some basic skills. It’s not difficult but it requires a bit of practice and perseverance. I’ve used a lot of sources on the internet to learn about servicing and repairing but watchrepairlessons have so far not only been the best source but also the most affordable source I’ve come across. I am a patron of watchrepairlessons but I’m in no way affiliated with it. Prior to servicing this calibre 2772, I’ve serviced an ETA calibre 2472 and two ETA calibre 2824-2s and the kinship between these movement is obvious. The 2472 is from the mid-60s, the 2772 is from the mid-70s, and the 2824-2 is from the early 80s. They all have the same type of distinguishing train. The keyless works of the 2472 and the 2772 is of the more traditional type whereas the keyless works of the 2824-2 quite a bit more sophisticated. However, the calendar works of the older 2472 is by far the more complex with its instant flip over of the date. It has been very interesting to study the similarities and differences between these three related automatic ETA movements.1 point

-

Just lay a few down and place the wet parts on them. They will absorb faster than just sitting the parts in a tray Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

Can be used to soak up excess moisture from cleaned parts, thats one use at least.1 point

-

As reported in jdm's 6R15 Service Walk Through thread, on disassembling the 3rd wheel and escape wheel jewel assemblies, I did find some dirt in one of the holes. As I am stull struggling to get pegwood to a fine enough point to get into holes like this, I used a hair from my dog. Maybe not haute horologie, but it got the muck out. I cleaned the fast end of the train and the escapement a second time in lighter fuel in the ultrasonic machine, then rinsed everything in pure isopropyl alcohol. I checked every moving part under the microscope (not a stereo microscope, but I have a Chinese digital one which serves my requirements well) and found otherwise only clean surfaces with no wear. Well, that is apart from another dimple in the centre of the escape wheel cap stone. I took particular care to use the correct oils and not to over-oil. In the end, I'm not sure that the dirt I found was the only cause of the low amplitude, but it was probably a significant factor. In any case, the watch is working well now. I'm not getting more than 260 degrees of amplitude, but the traces are clean and consistent. Thanks to everyone who took the time to reply.1 point

-

JDM, I was thinking that exact thing about this ETA movement but failed to convey it. These are very rebuildable and based on the existence of a technical guide, they are expected to be serviced. Quartz doesn't excite me like automatics. Early on, my exposure to quartz was cheap throw away movements. I discovered older Seiko quartz and they are loaded with interesting stuff that makes them worth maintaining. My comments about watch makers was based on what I experienced locally. This is likely the situation most face if they stay local. I know there are watchmakers that willingly work on everything. Finding them is the hard part. I like this site because there is help available for anything that keeps time. No judgment zone.1 point

-

Here is a video I made on watchmakers tools Sent from my iPhone using Tapatalk Pro1 point

-

You're on the point as always, Normally at this point of discussion some Anglophone comes in a very serious tone to remember everyone that benzene (https://en.wikipedia.org/wiki/Benzene) is toxic. No surprise, as 'E' and 'I' are often mixed since the time Britons began using the Latin script. Another guy was worried that Petroleoum ether was in fact Diethyl ether and we all would get high .1 point

-

To further complicate things, the watch case posted does not correspond to most google pictures of a 6309-8840. It has a 3 o'clock crown and google pictures are mostly 4 o'clock crowns. There really is no way to know what case that really is. That case number shows up on several other case shapes and sizes. Mostly on one case shape with several dial colors. Seiko does not use the same number for different shapes. The case backs size is very consistent though. My guess is the watch came from an Indian seller on eBay. At a minimum, the case back has been swapped.1 point

-

FLwatchguy73's device was good except I would avoid as a beginner 18 size movements if their American. Typically they are full plate watches and getting them together can be a challenge for beginners. Then as they are before the 16 size watches where designs hadn't quite stabilized there is more variation of things like the setting and winding. The good choice would be 16 size American pocket watches namebrand as they made a lot of them. then the link below is to the pocket watch database you can enter and serial numbers company name for American watches you come up with technical information and sometimes parts lists. https://pocketwatchdatabase.com/1 point

-

Place parts at eye level. Place the bezel as level as possible, positioned like 10 minutes before the threads mesh. Use case opening ball to press down a bit while rotating. Be reassured, it's just a matter of patience some time.1 point

-

in the past you to purchase the cylinders all assembled or the plugs and cylinder separate. As at one time this was a relatively common escapement. Occasionally though come up on eBay Or if you type in the right search term you can find pictures I was looking for pictures of the components but I think you'll find these pictures useful https://timepieceshoppe.com/cylinder-watch-mechanical-restoration/1 point

-

1 point

-

1 point

-

A lot of crown wheels have a bushing fitted here..is yours missing? Anilv1 point

-

That's the perfect way to do it JD! You could even turn down a large clock bush to suit and then open up the hole to fit over the newly shaped post. A bit of loctite and the jobs a good un1 point

-

Do what you can within your budget, lots of people on this forum do quite a bit without a lot of expensive tools. It's worth investing in the basics like good screwdrivers & tweezers, and leave the rest for the future. Most of the skills you need to learn at the start don't require the most expensive tools. For example, I still don't have a lathe, although I really should. Good luck!1 point

-

If the cap jewels are seated correctly and you have not transposed them then the balance is not aligned correctly. Rule of thumb DON'T FALSE ANYTHING. By any chance when you removed the balance cock for cleaning was there a shim between the cock bridge and plate. Sometimes if a new balance staff is changed and it is bit tight a cheats way is to put a thin shim under the cock.1 point