Leaderboard

Popular Content

Showing content with the highest reputation on 11/28/19 in all areas

-

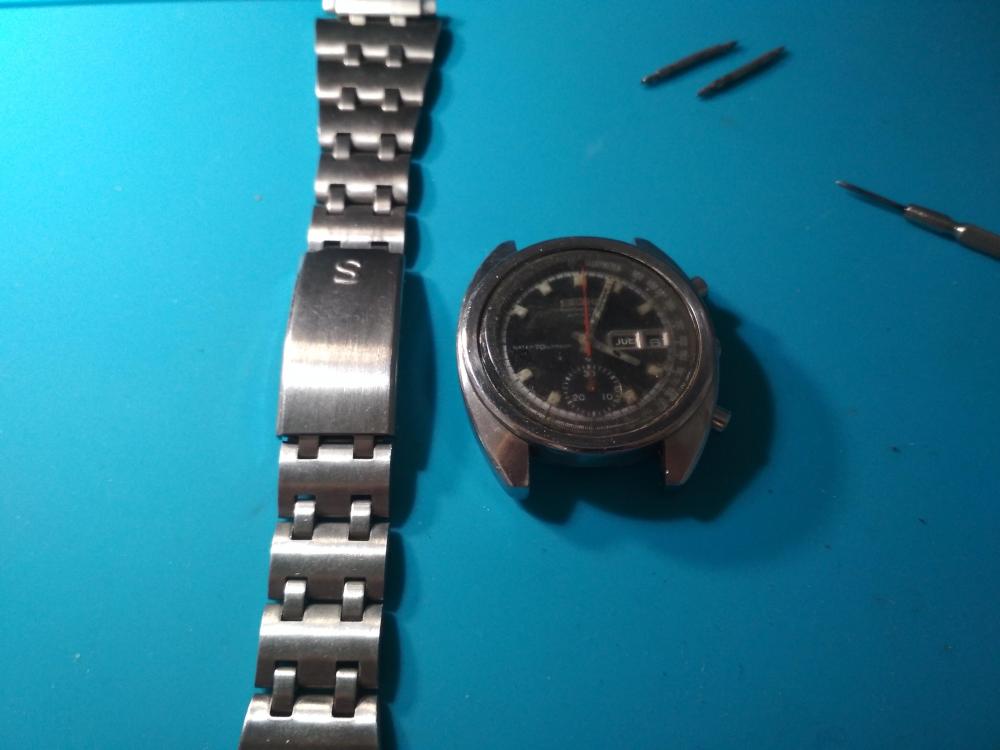

Hello guys. This is my last project – Seiko 6139-6010 aka Bruce Lee. Watch is from ‘69and it is based on the 6139A movement. Nice shot for the 50th Seiko anniversary of first automatic chronograph development. So please see the pictures below from all restoration proces. It took me 3-4 evenings. The watch came to me as non runner. Crystal was scratchy with many chips. Dial was dirty and dusty with signs of water damages. Hands lost their lume. Day calendar was loosen and didn’t work properly. Movement was complete but very dirty and dry – there weren’t any residues of old oil in the jewels. Somewhere were signs of water flood. I dissasembled movement and I gave it a bath in ultrasonic cleaner then i’ve assembled and oiled movement. Star disk od date wheel was repaird with small amouth of resin glue. Movement had tend to stop sometimes. Inspection showed that the tiny chip on the bottom pivot of the escape wheel. It was hard to see it. After replacment movement ran as a champ. I polished the hands cause there was rust and gave them new lume. Dial was cleaned. I didn’t touch the lume on the hours indexes. I was affraid to screw up it. I think now it is quite good despite the fact that the lume does not glow. Orginal crystal was polished but I decide that in the future I will replace it. Case and caseback got some polish works only with polishing paste, not too much cause I didn’t want to loose the sharpnes of orginal edges – as usual I did it. Bracelet was matted with abrasive wool. Everything was mix up and combined and there is the result. After measurments on timegrapher and adjustment it is a nice timekeeper. An amplitude satisfy me as well. Now I am enjoy to wear it. Please let me know what do you think of this restoration project and about my works on it. I appreciate your comment and your spend time. Cheers folks VID_20191016_170551.mp4 VID_20191017_195141.mp41 point

-

It want be far into future that anyone wearing a small vintage watch will be cool Sent from my iPad using Tapatalk Pro1 point

-

Thank you all for the replies, my wife wants to know why I am wearing a ladies watch, I had to explain the history of watch sizes ! Sent from my iPad using Tapatalk Pro1 point

-

Happy thanks giving to all who celebrate it and enjoy the festivities, From a Brit.1 point

-

Happy Thanksgiving to you and all! It's a great time for childhood memories of great feasts of freshly shot ducks and geese all baked to perfection along with the store bought turkey, pumpkin pie, candied yams, oyster dressing, oh my. What's left of my family will gather this weekend so the wife and I plan a smaller dinner this evening. It will still be good. Just her and I and the cats. One cat (the part British Short-hair) thinks he is a dog so we're a well rounded family down here in the woods. Enjoy!1 point

-

Hi, two things to consider; Firslty, assuming that you have the real deal, we're talking here about a watch with a price tag in the high £10K's, if not the £100K's. Without wishing to sound disrespectful, if you don't know what you're doing then this really is something that should be left to someone who does unless you're happy to face the prospect of spending more £K's repairing the damage if (and more likely when) it all goes horribly wrong. And if you need to ask the question that you have asked it is unlikely that you have the requisite experience or understanding to carry out the necessary adjustment. If I'm wrong then I apologise, I don't mean to offend, simply to help save a huge expense. Secondly, this movement uses what is called a free sprung balance. The part that you have circled is an adjustable stud carrier which is used to get the balance in beat (equal length ticks and tocks). Don't touch it unles you have a timing machine that can display the beat error otherwise you will find it impossible to adjust out any errors that you may introduce. Timing, or rate, is adjusted by varying the moment of inertia of the balance, which is achieved by adjusting four (I think) small weights attached to the rim of the balance wheel. These need to be manipulated with extreme care in order not to damage anything, and by precisely the same amount so as not to impact on the poise of the balance. You need to have a timing machine to be able to properly assess the impact of any adjustment, and you probably have to use a proprietary tool which can only be obtained by an authorised service centre. Long story short; adjust the rim weights to increase the moment of inertia to slow the watch down, or decrease the moment of inertia to speed it up. If that makes no sense to you then please take the problem to a competent watchmaker to be adjusted. Out of interest, what exactly is problematic about the watch?1 point

-

Depends what type you intend to get. I use the screw down type like the pic. Seems to give you more control but the princible is the same. The smaller die presses down on the inside of the crystal and contracts the outer rim. The watch front is then pressed down onto the crystal. Hold down while undoing the the large wheel. Hopefully the crystal will then be in place. Takes a bit of practise. A small circle of linen will prevent the top die marking the crystal.1 point

-

That is certainly a plastic crystal and can be polished perfectly as a matter of general maintenance, if it's original it would be a travesty to change it out. Gorgeous watch and yes some models were luminous and some were yellow painted. Don't change it, they're different models and all original configurations are relatively rare. I'd rather have that one with a nicely polished orig crystal than with an nos crystal that's two weeks away from looking like the one you just polished anyway. :)1 point

-

Sorry to hear about your disaster, maybe you could help me avoid the same result. As a nubee I'll purchase a crystal press in the near future. Can you please describe the technique for using it for me?1 point

-

1 point

-

I'm intrigued to see which mechanism is in this one. For less than the cost of a latté I'm about to find out.1 point

-

it looks to me that if you loosen the two screws A & B then move the micrometer away from the table, move shaft C, which is now loose to the middle of the table E. Tighten the two screws A & B You should the have the meeting point of the two shafts in the middle of the table and both point will be able to meet each other.1 point

-

1 point

-

i don't use mineral oil. it is antique. i use synthetic and muti viscosity oils. hydraulic in a press. i have delt with " oil engineers" AND i don't intend to argue further. vin1 point

-

usually with American pocket watches even if you have a part number you absolutely still have to measure the staff to verify its dimensions match the one that the part number has. For instance I'm attaching an image you'll notice that even if you have a part number for some staffs they have a lot of variations. Variations lead to frustrations for people that don't grasp that there are variations. Fortunately it appears to be your staff doesn't have variations. Although the parts book I looked in listed the number is 5317 and the image I'm attaching ads the C which conceivably means there's a variation even though it's not shown in the listing. than the eBay listing above has staff number 4191C which is an entirely different staff than the one that I came up with by looking in the Elgin parts catalog of the 50s. I'm also attaching it the images from the 50s catalog. They can see your serial number range comes up with a number. Then with that number you can look up the part number.1 point

-

Balance staffs are usually identified by 'Ronda number' and it is this number you ideally need. Probably like your watch repairer I've had trouble tracking down a parts list for your calibre that includes this but let's see if we can do a bit of detective work ... It's the calibre information we're interested in here and it's an Elgin 495 confirmed from the information you've found. Here's data on that calibre: http://www.ranfft.de/cgi-bin/bidfun-db.cgi?10&ranfft&0&2uswk&Elgin_495 What's helpful from this data is that your movement belongs to the family of calibre IDs shown on the right hand side i.e. a balance staff from one calibre in the family will fit another. I had a look in the various info I have and a quick search around the web but I couldn't find these calibres (but I do mainly deal with Swiss watches). However a look on ebay finds this: https://www.ebay.com/itm/Elgin-balance-staff-12s-4191C-DR-448-450-451-ht-365-axe-balancier-Unruhwelle/202717852076 This ebay listing cites calibres 450 and 451 ... in the same family as your 495 and confirms for a calibre with (American) size 12. Helpfully the staff dimensions are also included. My recommendation is for your watch repairer to confirm dimensions tie up with your movement before ordering. If these dimensions don't pan out for some reason then your watch repairer should be able to identify a correctly dimensioned staff and order by appropriate Ronda number from their usual supplier. imho they should have really gone this route to start with rather than getting you, the customer, to try and find things out. It's probably worth waiting first for any replies from other forum members who may be more familiar with Elgin movements in case they can come straight up with a specific Ronda number for you.1 point

-

1 point

-

Start with an old pocket watch many are very much alike to a watch movement just bigger. Learn what the parts are called, strip it right down and put it all back together, do this many times so you can do it in your sleep. This will help you in using you eyeglass, tweezers and watchmakers screwdrivers. Don’t get hold of any fusee pocket watch movements they are completely different. When you have achieved all with your pocket watch move to a simple Gents watch, just the movement, no calendar and certainly not an automatic.1 point

-

Hi You might find this interesting reading regarding citizen watches 0-Basic-Technical-Manual.pdf 1971 Citizen Technical Information - 05 Gents Movement.pdf1 point

-

One option could be to put a military style backpad leather band with a 10mm strap. Another option would be to order a 18 mm leather strap (looking I your pic I suppose it could fit but of course you must check) and cut the ends to 10 mm large with an X-Acto. Then you'll get something close to an oris leather strap. Just select a strap thick enough so that the leather will resist but thin enough so that it could match with your Seiko.1 point