Leaderboard

Popular Content

Showing content with the highest reputation on 11/24/19 in all areas

-

2 points

-

This guy always gives good explanations: My own documentation is BHI material and is copyrighted, so I will not share it, but that video gives a good description. It's important to realise what happens at the different phases of the escapement motion. If it's too much to take in at once, then start with the anchor escapement and advance from there. That is how escapements are traditionally taught, starting with the simplest.2 points

-

Hi, I have a lecoultre inline banjo type 8 day clock cal.250 that needs a new jewel fitting. What tool do I need to measure the diameter of the jewel hole ? Or can I just measure the pivot on the wheel and use that measurement ? Wayne1 point

-

Hi all, New to the forum today! I have been interested in watches for some time now but have only just delved into the realms of watchmaking as a hobby, so far I have stripped down and stuffed up 3 movements, a DG2813 and two Citizen Miyotas, I have however successfully put together two vintage eta's which are decidedly easier to put together. I signed up to Marks Watch Repair Course this weekend and have passed part one today and looking forward to completing the following two courses (which I have already committed to). I am currently in the process of cleaning a WWII pocket watch that is filithy and not working and am hopeful that I can at least get it back to ticking. Nice to be here and I look forward to interacting!1 point

-

Excellent advice above, particularly about dressing your screwdriver blades correctly. I started with a £5 set of drivers from Maplin which were fine as long as I looked after the tips. I would only add that I found modest magnification to be a great help when handling those little screws. I always use a 2.5x Binomag for all general watch work with higher mag devices for the trickier jobs. Get some magnification and stick at it, you will improve in no time.1 point

-

You are going to have to take that back plate off but you've done the right thing stopping when you were unsure. We need to try and find the movement reference. This is probably around the area I have marked in your picture - I just just about mae out Citizen and Japan but there's too much shine on it to see a number reference. When replying also include a copy of the case back as that can sometimes have useful information stamped on it.1 point

-

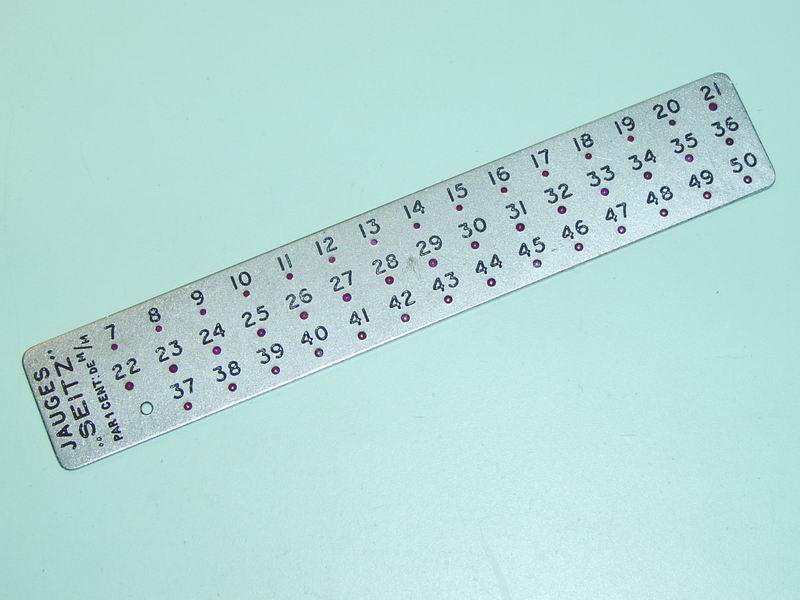

If you've just got to see that link here's an archived version: https://web.archive.org/web/20160423192340/http://www.tp178.com/jd/watch-school/3/ws3a.html ! If you've got a decent micrometer gauge then you can measure the pivot width. You then need to get the nearest jewel hole size up from that so the pivot moves freely. If you think you'll be replacing jewels often then a gauge is useful thing to have since, as @watchweasol says, it just make measuring quicker and easier. Since any hole gauge is just a bunch of super accurate holes then sure you could go for the non-jewelled version. Another way of looking at this however is that if you primarily deal with wristwatches of a limited ligne range (certainly most of what I deal with seem to be 11.5 ligne!) then you'll be dealing with a finite range of pivot/hole sizes. You could then just buy a small range of 'reference jewels' of known hole sizes (but around the size you've measured with a micrometer on a 'typical' movement) to make your own jewelled gauge.1 point

-

Only things is to get the drill and file out and make one . I have made a few setting lever springs when i can't find one. Use the steel from a feeler gauge . I have some old pierce movements but none of them have a setting lever. All broken or missing.1 point

-

Hi Watchie I would guess that a precise Micrometer would suffice. the complete gauges just make the job easier in the long run and quicker, hence the price for a labour saving gauge.1 point

-

I'm looking at this set on ebay. I was wondering if it's a good set. And how complete it appears. Does it have the main tools needed for most common repairs? Would this be equal to the K&D inverto's? And are other brand stumps and punches able to be used? I'm currently high bidder at $50+shipping. Seems like a good deal to me. But maybe not? LMK what you all think. Thanks1 point

-

You can get specific jewels from Cousins. Look here: https://www.cousinsuk.com/category/jewels-seitz Good topic here on gauges: https://www.watchrepairtalk.com/topic/4765-what-tool-for-measuring-jewel-holes/ And now for my search tip of the day. Go to google and type in... "jewel types" site:watchrepairtalk.com This will get any topic on this forum that has the phrase 'jewel types' in; hopefully you can spot the topic you were thinking of! [I realise the forum has its own search facility but sometimes a search is easier with a browser's search engine].1 point

-

Not bad for the price. I would clean it all up before the rust and gunk get's worse. Make sure the holes are not blocked in those stakes.1 point

-

Mov't ring, tabs and screws. Sometime one struggles placing back springbars, mind you. With time you will acquire handiness that is just the understanding how tiny parts behave, what is the best way to handle them, and controlling your movements and techniques. Sometime it helps using small tricks, e.g. using, rodico etc. Don't be too quick in blaming tools. is use now a $15 drivers set, it was a $10 one before, and have noting to complain about either, but you MUST make sure that the tip is dressed in the right shape to wedge in, otherwise the poor grip will just make you go crazy.1 point

-

Ive written about this numerous times. Be careful....the tag and Oris lovers will pounce on you when you compare their $3000 diver watch to an invicta......they dont like being made out to be a fool. They will regurgitate the koolaid in a hearbeat. Stand by. As far as Omega....at least they do some secondary work. Ive seen the void on a 7750 between low to high be as much as 10 grand. Its nuuuuuuuts. Sent from my SM-G950U using Tapatalk1 point

-

The Bellmatic arrived today and it looks and runs great. It's clean and rings perfectly. I had trouble setting the day/date function at first.. But the Google of everything solved that problem. The only hiccup is the bracelet. Like @ro63rto said, it's a replacement. Someone grafted an old Seiko quartz clasp that was once gold but someone scrubbed the plating off. I'm on the hunt for a proper Seiko coffin link bracelet now.1 point

-

Unscrew the bezel. The bezel and crystal will come away and the rest of the clock will come out the back.1 point

-

1 point

-

1 point

-

Great results on your efforts @eccentric59. IMO, New York Standard had some of the most visually appealing movements during the hey day of pocket watches.1 point

-

Interesting question and now that you mention it there's a story to tell which could possibly be, or be part of the problem! I always replace the mainspring with a new mainspring if I can find one. In this case however the cousinsuk.com search function did not yield a result for calibre 6380, but I noticed that ranfft.de listed the same mainspring dimensions for calibre 6325 which was available (Generale ressorts GR5171). However, the diameter of the inner coil was too wide to fit the barrel arbor so I had to adjust the inner coil by pressing on it with the wide section of my brass tweezers. However, I only noticed that the inner coil was too wide after I had pressed it into the mainspring barrel, and at that point I couldn't reach the inner coil sufficiently with my tweezers. So, I had to take it out, put it on a mainspring winder (K&D), adjust it (while in the winder barrel) and press it back in to the mainspring barrel. In the process I slightly deformed the inner coil but didn't think much of it. Now that you mention it, I wonder if that could be part of the problem?1 point

-

What about the strength of the mainspring? Sent from my GT-N5110 using Tapatalk1 point

-

Good job! I would be very nervous getting that broken screw out. For me concentration goes into overdrive when working around coils. Thanks for posting.1 point

-

I think I may opt for saving and buying the gauges, I have the outlook that if I don't use them enough I can always resell them later. I bought the jeweling set for £40.00 thinking, that it may be useful one day so I now have a project to use it on, I have been practicing on old movements pushing jewels out and resetting so think I will be able to manage the job( famous last words). I shall keep my eyes peeled and hopefully I can source them at reasonable prices, Many thanks for your help, Wayne1 point

-

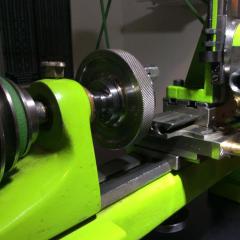

I have a jewel hole gauge and a pivot gauge similar to these: The problem is that these are VERY expensive tools. You can also measure the pivot using a micrometer. You will need a jewel with a hole slightly larger than the pivot. Of course you also need to know the measurement of the outside diameter of the jewel in order to make sure it can be fit into the plate or chaton. You may need to ream the hole to a larger size. You will need a jeweling set for reaming and pushing in the new jewel. Are you certain that the jewel is friction fit??1 point

-

I agree totally, ebay seller thewatchcollector has a couple of ETA 2846 which are a little older but quite similar in many aspects. The beauty of having a couple of those (cheap) is that maybe you can get one donor to make/rebuild a real good watch out of the other. I did with a couple of seikos I bought from him. At least it was fun. Robert1 point