Leaderboard

Popular Content

Showing content with the highest reputation on 10/17/19 in all areas

-

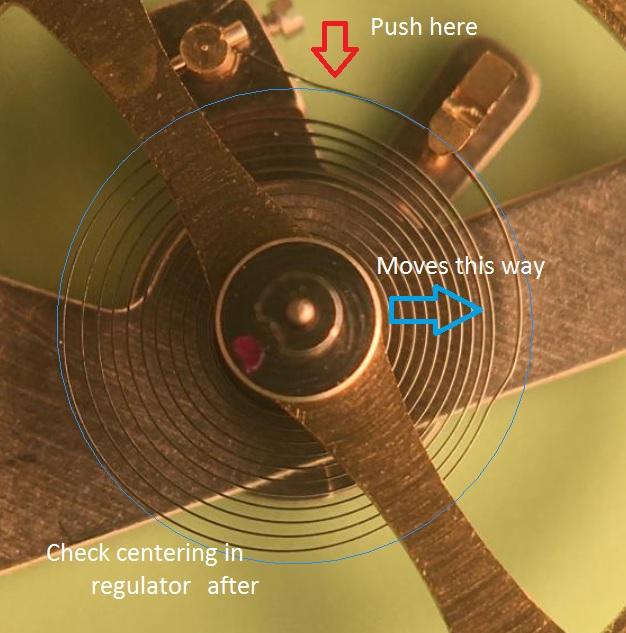

It's out of center, check pic for adjustment. The spring should be centered in the regulator when you're done, if it's not, push it right next to the stud to make it centered. The pins (pin and boot) should have a gap of about 1 hairspring thickness, and it should bounce from one to the other evenly when running.3 points

-

Just screw out the nut to the left, use tweezers or small pliers.3 points

-

You have an 8-day French carriage clock with a cylinder platform escapement. They must have been produced in there millions, this type is very common, the numbers are just case part numbers. It has an Arabic style dial with original hands. Cleaning Brass. All movement parts should be polished by hand. Brasso is what I used; some on here say Brasso is an abrasive and should not be used. Total rubbish, you will need old soft cloth and a soft brush to apply it. I would then clean in petrol and dry in soft sawdust. You will need a block of French chalk and a chalk soft brush (clean) you can buy this from any good supplier. Never use the chalk brush for any other work. You chalk brush every brass piece of the movement, this will prevent it from tarnishing, you will need a bench blower to blow away the excess chalk. Cleaning Steel Parts. All screws should be cleaned and polished, removing the burr, general tidying up of the screw heads. Best to use a lathe if you have one. You can do it by hand but you will not have such good results. You will need various emery sticks, start with a file, nothing too drastic and using various emery work down until you reach a nice shine. The same goes for all the platform screws. Clean off the arbor of any burr and use the emery sticks to finish, don’t forget the key end, the same goes for the handset. Polish the ratchet and the spring with emery. Cleaning the platform. Re-move the collet/hairspring from the balance; don’t forget to mark it so you know where to put it back in the same place. Put the hairspring in Ronsonol lighter fluid with the escape wheel; remove the regulator and its parts and leave. Clean all the brass parts in the same way as I have described above. Clean the regulator parts with emery and wash out in Ronsonol. You can clean the escape wheel with a glass fibre scratch brush. Cleaning the case. Polish in the same way, don’t French chalk it. You must make sure you have completely removed all access polish. You should lacquer the every part of the case with a clear lacquer, you will need a very soft artist brush for this so it doesn’t show brush strokes and brush in one way only, This dries very quick, so be careful. I have included a link for the lacquer. https://www.cousinsuk.com/product/lacquers-rapid-drying3 points

-

I have to drive to Virginia to get halo halo. Filipino bakery that is next to a Greek eatery..so I can have a really superbly greasy gyro and halo halo that must contain at least one quarter pound of sugar for dessert..2 points

-

2 points

-

Look at the spring position BETWEEN the regulator pins. If its central to both pins, I vote to leave it alone. The old guys (Fried and De Carle) often suggested using a slight bend in the hairspring to centralize the spring position between regulator pins. It does appear to be a little eccentric. At any rate, I doubt your slight kink would be a reason for low amplitude. Good luck, RMD2 points

-

1 point

-

1 point

-

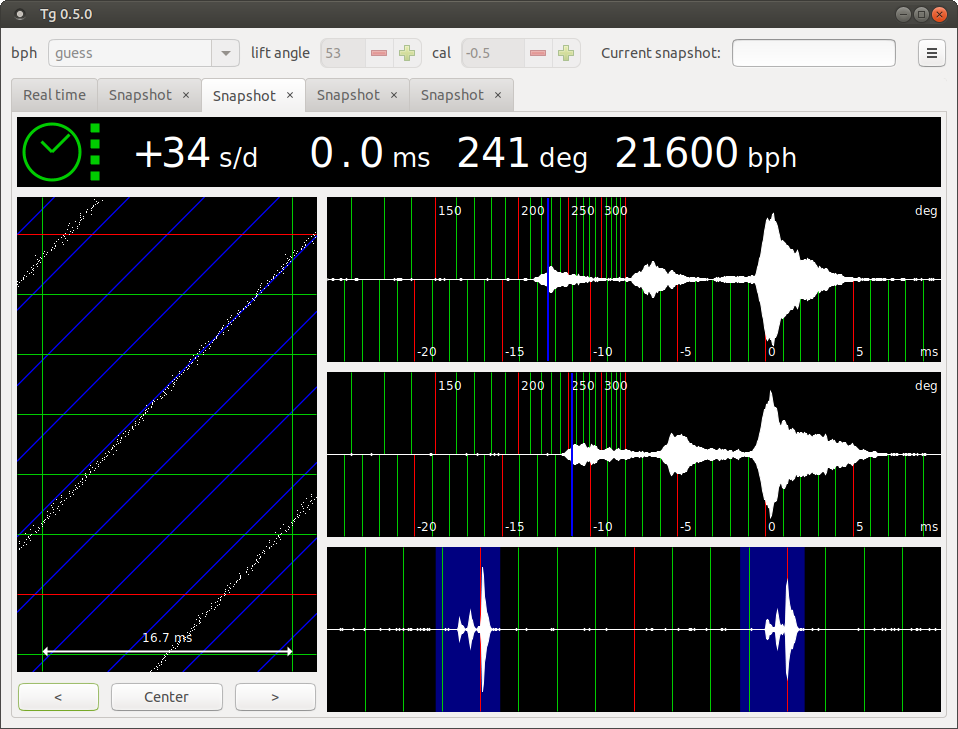

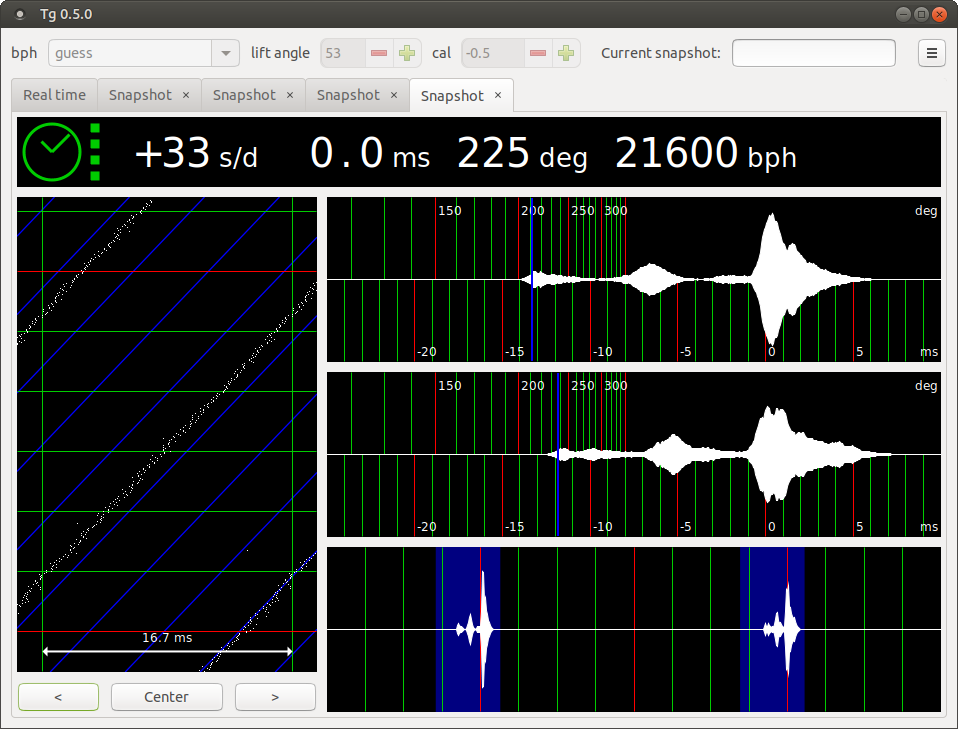

We need a clear picture looking in sideways at the hairspring and balance wheel in the watch. Then yes technically her out a center but it's minimal it shouldn't be the cause of amplitude problems. They hairspring not flat would be a cause of problems especially when it's touching something. Can we get timing machine results? And that includes the graphical display with the numbers.1 point

-

Is it level ? If level, all you need done is to push on the HS where Nickelsilver drew arrow, which is to be done when installed.1 point

-

I have noted a problem with Russian keyless works..As to whether it is the weakness of the metal or the strength of the wearers I have yet to determine. Of course it should also be politically incorrect of me to cast aspersions on ethnic cuisine.1 point

-

Continuing the Chinese theme, a "Winner" from the ever expanding pile of junk that comes with job lots of watches. This is a pretty standard Chinese Standard movement, all be it the skeletonized version. Most of the parts from this would therefore fit in the automatics from the previous post. It arrived in a completely gummed up condition, with the winder mechanism and keyless work jammed up with waxy crud, but responded well to a strip and clean. The case is "interesting" (i.e. in my opinion, pot ugly, and huge), and is held together with four screws that wouldn't look out of place securing the wires in a mains plug. It has the cheap feel of plated pot metal, and the plating is pretty thin, since the watch looks little used, but the "silver" plating on the reverse is starting to show signs of wearing down to the copper plated base layer on top of the frying pan alloy underneath. This may be a factory fitted feature however, the plating may have left the factory like this, and if so, it would compliment the free thumb prints that were generously added to the inside of the watch by the assembler. I am not however really in a position to comment, as when I was re-casing the thing after cleaning and servicing, I fumbled the top half of the case, and grabbed it with my un-gloved hand as it shot rapidly across the bench in a failed attempt to smash itself on the floor. It was only once I had the mechanism back in place and the thing screwed shut that I realised that I too had autographed the thing by placing a nice big greasy splodge slap bang in the middle of the inside of the glass with my fat thumb. I did however take the time to strip it back down and remove the evidence. So what do you get for your not very much money, you may be wondering. Well, there are the lumed hands I suppose, but strangely, no lume on the dial, which would make reading it the dark a little bit hit and miss I suspect. You also get a 20mm "stainless" metal bracelet of similar quality to the case, which I have removed and substituted with a NOS white leather band, which hasn't really done much to improve the look of the thing I must admit. You do however get surprisingly good rock solid performance. I guess that is to be expected from a reasonably well finished Chinese standard movement. It 'aint exactly COSC, but I feel with a little more tinkering I might get close. Dial up. Dial down. Would I ever bee seen wearing the thing? Well I guess that depends on how much you paid me, but the fee would be a lot more than the cost of the watch. It does however make for a worthy addition to the 404 club. What I will say, is that you can pick up a Winner automatic, new, shipped from China for around £10.00, (search "winner" "automatic" for many others, for example these..) so if you want a new, cheap watch to tear apart and put back together, these are on a par with the HMTs in terms of cost, and are very easy to work on. Furthermore if you hunt through the junk lots on ebay, you can get them for next to nothing, so spare parts are extremely cheap, but quality is variable. What you learn from fixing one of these, you can apply to most other watches, and despite my reservations, the mechanisms actually look not too bad, or at least, not terrible, in terms of quality, and are reasonably attractive in terms of finish. Its just a shame, the same could not be said of the case.1 point

-

Then back to cleaning pivots and for that matter the entire watch. Maybe another solution would be purchasing proper solutions designed specifically for this. So rather than looking at the usual sources for these things I looked at Amazon and eBay. I'm giving the Amazon links of a couple below there is probably more I just didn't go looking for them. I noticed eBay had at least one of these listed below. Then fourth link PDF description of these. So you will note with the cleaning product you need a associated rinse product. Then minor caution when you're using professional fluids that clean extremely well be careful not to leave your watch in there all day or you'll find it goes beyond cleaning and starts to etch. You can usually recognize this the solution will turn blue that's the copper that used to be in your watch plate now in solution. Worse case was a watchmaker told the story of going on vacation forgot to take the watch out the cleaner and now needed a new movement. Then unfortunately depending upon the temperature the fluid a variety of unknown conditions I wouldn't go over 10 minutes with any of the cleaning solutions I typically aim for five minutes. The rinse itself shouldn't be an issue but just to avoid any unpleasant surprises probably best not To leave your watch in any fluids for any length of time. https://www.amazon.com/Ultrasonic-Ammoniated-Watch-Cleaning-Solution/dp/B06X9CC2RM https://www.amazon.com/Watch-Rinsing-Solution-Chlorinated-Solvents/dp/B06WWH9Q3Z https://www.amazon.com/Ultrasonic-Non-Ammoniated-Watch-Cleaning-Solution/dp/B01LQYMRRC http://www.lrultrasonics.com/pdf/Jwlry.WatchSolutionsGuide.pdf1 point

-

Helpful to have the background history? What was the watch doing before you service the watch? Then timing machine results dial up, dial down and at least one crown position crown down would be fine more would be better. Not just numeric results we need the graphical display. Then the following a proper timing machine protocol is to wind the watch fully up let it run for 15 to 30 minutes typically. Time for 30 seconds in each position and allow 30 seconds in between shifting positions to settle down. A lot of this will depend on the type of watch some will settle down faster than others.1 point

-

Balloon Chucks I've attached a picture of the common type ones that you will find. The older style ones can have a lid that unscrews. The newer style tend to be the two that are on the bottom. The most important thing though is that when it's holding the balance and the pivot is sticking out that the Pivot is not wobbling. Then you have a variety of things that you can use with your pivots. Sometimes referred to diamond lapping the film that's the colored strips on the left-hand side. Note there is no diamond it is aluminum oxide they come in a variety of micron finishes. Depending upon how aggressive you want to be there things like hard Arkansas stone, steel burnishers, Stone and sapphire burnishers Etc.1 point

-

As we appear to be somewhat going off subject I will continue with that. The jacot tool mentioned above is an interesting tool. As a young watch student one of the older watchmakers showed me how to use it. So this is what I got out of it to be good you need to practice every day. If you know how to use the tool like he did the polish produced is outstanding and that's a gross understatement. In the absence of that tool and the practice of every day a balloon Chuck works fine.1 point

-

I should've extracted out each section of your reply like this it might make it easier to read. Polishing in general does not change the shape I have no objection to the method only polishing usually doesn't remove crusty stuff and is a final step not the only step. Then the reference to the Balloon chock and heavy burnishing? That is in reference to the video in the video the burnishing tool appears to be a clock pivot burnishing tool. A clock burnishing tool is in general way too aggressive on a watch pivot.1 point

-

First off to avoid any complications I've seen his website I like his website I just have problems with this particular page and in relationship to this particular discussion. Then quoting your text above is a problem in that you're commenting about a whole bunch of things at the same time which is going to make for a very confusing answer possibly and hopefully no one will quote this mess as it will be super complicated it be better to break this up into simple questions and answers. So this discussion is on "Cleaning balance pivots" .The website is on "Cleaning Balance Staff Pivots" Then quoting again from his website "But sometimes we need to kick it up a notch. Crusty pivots, like crusty jewels, need a thorough scrubbing. In The Watch Repairer’s Manual (4th ed., 156-157), Fried describes a useful method for scrubbing pivots to a clean and shiny polish without removing metal or changing a pivot’s shape." Then minor nitpicky complaints when quoting from a book that was printed in multiple additions giving the title of the chapter would be helpful for us that have a different addition of the book. Let's see if I can summarize crusty pivots could someone give me a definition of that? What he is described in your quote on the webpage and Henry's book is a wonderful method of polishing a pivot. My objection is crusty and polishing does not usually turn out well. Polishing is more of a final step when you have a clean pivot. Then I see I need to improve my reading skills? I see at the very end he does comment you can freehand doing and if he says you can I'm not going to object that he can but I wouldn't. Then it would be really nice if he had shown a picture of the blue and Chuck and the pivot polisher because most people probably have never seen these before. Then this answer is too long and I don't think I covered everything in your huge quote so I'm going to start another answer1 point

-

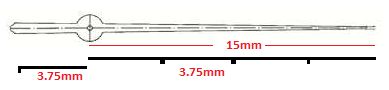

In lieu of someone coming up with the hand you need, or a source to buy from, I've got something that probably fits into your category of an idea! You can pick up generic second hands relatively inexpensively from a source like Cousins: https://www.cousinsuk.com/product/centre-seconds-by-size; they do the 0.25mm you need. Now whilst it looks like the longest they do is only 15mm note this is from the centre hole to the end; not the entire length. How long is the entire hand? I'm not sure but if I take their scale diagram and do a very simplistic split-the-15mm-into-four I get 3.75mm per quarter. If I then transpose that quarter to the remaining length I can see the entire length will be over the 18.5mm you need: But you require a squared off end ... so you could carefully file to the length and profile you need. Bingo! Ah ... but it's not blue. Well that's now over to your requirements and skills. Painting (e.g. airbrushing) is straightforward or you could look at any of the helpful online resources videos on how to hot blue (stainless) steel.1 point

-

1 point

-

1 point

-

1 point

-

Most balance pivots I've worked on are usually clean and since I don't usually dismount the balance from its cock I just install it back in the movement after cleaning. Just before installing the balance jewels I give them a dab with Rodico to remove any dust and any other stuff and then install the balance jewels. Inspection is very important, any score marks or deformation will require further action. Anilv1 point

-

I presume by that, you mean that they would survive a nuclear apocalypse, rather than that they are tasty when fried in a wok. EDIT: I forgot to mention it also needed the winding pinion replaced as there were teeth missing. I also shortened the stem to the correct length, and re-polished the crystal, so it now looks a whole lot better. I'll finish adjusting and regulating it tomorrow. The Eden-matic (from the same job-lot) is also going nicely. The pair of them can then join the 404 club.1 point

-

I don't know the answer but may I ask you a question also, my sincere curiosity, have you done any pivot work before (Jacot tool)? I never did but hope to get at that point of excellence in the future. With or without rouge and wood.1 point

-

Good point, now to keep things in perspective let's look at the prices of some new horological collets. 20 pcs set Sincere, $262. https://docs.google.com/spreadsheets/d/1d-eiO04y72L-BtWxkXPAySAazyTfYFGE_6A73yMo2KI 20 pcs Cowell, you have to buy individually http://www.cowells.com/pricelist.htm (1 x £179) + (2 x £169) + (2 x £105) + (15 x £92) = £2,286 + 20% VAT = £2.743 = $3,5191 point

-

Mark's experience of having to open up the bore the fit the collet is about the most negative testimony you could give, imo. Mark's a positive guy so was very kind to them overall, but that is an fail.... I mean whats more important than bearing and collet fit? They should be done properly to very fine tolerances to get a passing grade. I've not owned that make but have owned a dozen other lathes and the collets always fit perfectly1 point

-

Take a good picture in the current conditions, apply the miraculous product, then picture again. We'll talk then.1 point

-

Flammble or posioneous gases are mixed with bad smelling gases mostly to stink, an effective warning and copied from nature. A life saver.1 point

-

1 point

-

Very true JDM.....Probably going back to my childhood..It has the feeling of a small pedal car....1 point

-

It is positive opinions anywhere you look. Here we have a(t least) David and our Host Mark having one. Other forum says the same. I researched and posted a listing summary of all the variants, bundle options and accessories. However just like with any tools what can be done with it depends more from the person using it than the bare metal.1 point

-

Still scarred. I used to use this stuff to clean my guns when I was in the army. No gloves either, naphtha bath they called it. Sent from my iPhone using Tapatalk Pro1 point

-

A toothpick could bend the pivot. Pith Wood is the best. Sent from my iPhone using Tapatalk Pro1 point

-

Wood cleans pivots real well. You can also put some avgas, lighter fluid or paint thinner on pivots, stick the pivot into a toothpick( embed the pivot inside the toothpick) turn the toothpick, repeat, ready for the ultrasonic bath.1 point

-

Definitely no accuracy certificate but others have done everything watchmaking needs with it. Also this lathe is cleaned up and sold as vector Lathes, vector Lathes are apparently used in watchmaking school... That's good enough for me Sent from my Nexus 5 using Tapatalk1 point