Leaderboard

Popular Content

Showing content with the highest reputation on 10/05/19 in all areas

-

When I get a boot that doesn't want to move I put some oil, thin like 9010, on its mounting point. Turn back and forth with (well fitting) screwdriver and they go free. Only recall one in 20 years that didn't work, old Lecoultre from the 20's. WWsol is right about the pin, need to be really careful, the gap should be roughly equivalent to a hairspring thickness when you're done.5 points

-

Hi the regulator pins are not meant to be bent as this will effect the rating of the watch as the gap in which the balance spring operates will be incorrect. In your case the boot shaped leg has to turn thro 90 deg to release the spring. Some of these legs are tight, Use a screwdriver which fits the slot and place the balance cock on a firm surface and with firm pressure attempt to turn the leg. If you manage this there is just a chance you will be able to stroke the fine pin upright with fine tweezers, stroke it along its lenght carefully do not attempt to bend it straight or it will break off.2 points

-

Hi Working on a seiko 7009A today, a bit of a wreck. Dial loose intermediate date wheel u/s, all back up and running but had to sort out the dial so I dug out the dial foot machine build a couple of years ago, as you can see by the pics it still works and no marking on the dial. It was build from readily available parts. The power source is a car battery charger which plugs into the unit. the probe is the carbon center core from a battery. I belive it goes under the heading of cold soldering, basicaly it provides an arc at the bottom of the dial foot wire where you place some flux and bits of solder. the resulting arc melts the solder and attaches the foot wire. Any body interested can find the details on the net. The origionator of this particular design was one Dirk Fassbender the details he put on the net are still there or alternativly there is a book, Quartz watch retro fitting by Wesley R Door, available in America but not so easy over here in the uk. I have some pictures I copied from the net that give the basics. All it is is a transformer providing the Arc not hard to build and a very hand tool to have in your collection..1 point

-

Keeping with the Timex Dundee theme a 1978 Marlin(?) (24560 02578). This was a junk lot watch. I could see in the ebay advert that the date ring was missing, and as I discovered when I opened it, so too was the movement holder, but fortunately I had both in my stash. Here it is just prior to putting the lid back on, after cleaning and servicing. The crystal was heavily scratched with some paint marks for good measure. Advertised as not running, how could I resist? It looked a perfect candidate for the 404 club. This was the starting point. The dial and hands look fine, but the rest was a bit of a mess.1 point

-

1 point

-

I just came back to report that this was indeed the case. Our central workshop returned it to us undone , so I decided to remove the bezel and take a look, I was pretty overjoyed to see the notch and realised what I was looking at. Im glad I shared your other suspicion early on regarding the stem lever, a lesser technician might have forced it and damaged it. I now having it ticking and awaiting collection, thanks everyone.1 point

-

Hi The object of the exercise is to decrease the shake, Then removing metal as suggested will do that. The medodology does not matter as long as it does the job. Reaming the tube to lower the weight will do as long as after every turn of the reamer you check the fit untlill you achieve the desired result. An ordinary chuck is like the one on a dremel to hold the bit. I would not use a power tool as the chance of removing too much metal is too high better to use hand tools for such an operation and take great care and check regularly.1 point

-

Success! A drop of oil on the base boot and the head of the rivet then letting it soak for a while worked wonders! Didn't even need working loose, just turned like there'd never been a problem. I also managed to straighten the pin to a reasonable degree by placing the tip of an oiler between pin and boot, then squeezing with tweezers. The final adjustment of the gap I will do when fitting everything back together. I don't see how I can get the gap small enough and parallel, without putting a severe dog-leg in the pin right at the bottom, but I might not have to. We'll see. Thanks very much once again. Amazing how just having the confidence you are doing the right thing helps you do it right.1 point

-

1 point

-

Out of round balance wheel would cause variation in PU & PD positions. Poise issue is of the same nature. If balance wheels weigh the same, the good HS + good balance wheel would work (simply interchangable). In case of different weight, there is still a chance to vibrate the two. Have you checked the upper jewel assembly? Combine with excess endshake, they exacrebate the problem. Best1 point

-

This is a very solid movement, so 99.999% sure nothing shifted. If all's free up to the escape wheel good chance theres a hair or whatever under the cock causing it to tilt and clamp down. Or maybe an escape wheel pivot is bent/rusted/damaged.1 point

-

Hi One would suppose that if the balance came from a donor unit of the same caliber that wold be the case. But the watch was working ok untill the balance was changed which points to the balance being off key.1 point

-

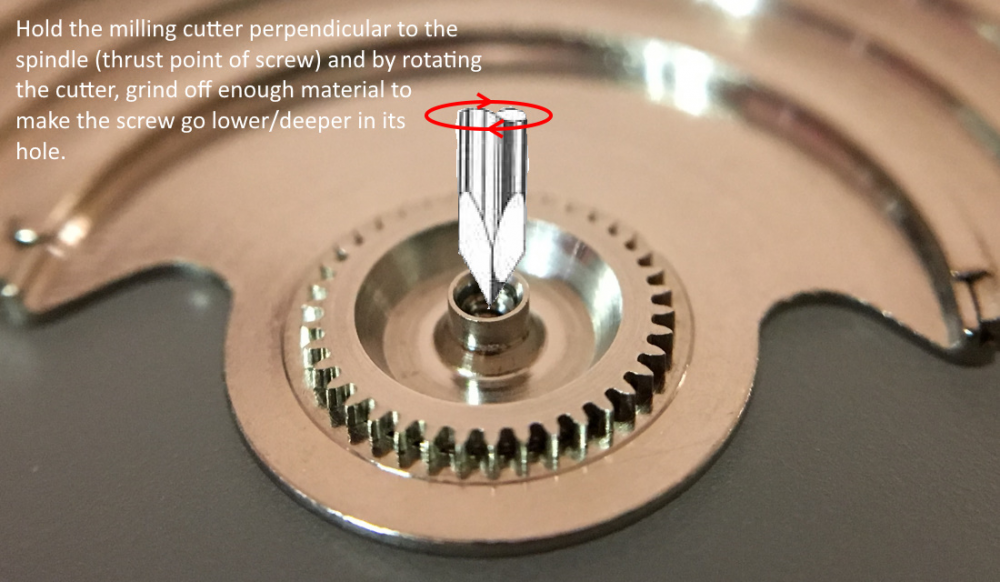

Thank you for your posts, very much appreciated! I just realized there was an image (see above) of the 60° milling cutter tool suggested by ETA to adjust the oscillating weight end-shake in ETAs tech sheet for calibre 2472 (apologies, silly me!) So, in both cases (too much/too little end-shake) what ETA tells us to do is to: “remove material from cone inside…”, either “tube” to increase end-shake, or “spindle (thrust point of screw)” to reduce end-shake. (I forgot to quote the “thrust point of screw” in my previous post, sorry!). So, what’s the difference between a “tube” and a “spindle” and where are they located? Well, I can’t figure it out! Getting new parts from Cousins does unfortunately not seem to be an option as these parts are “Obsolete”. Anyway, based on what I’ve read so far in this thread, the above is my guess of what I can try to do to reduce the end-shake. Let me know what you think (please verify!) I suppose it would be critical to get the cutter dead centre (90° angle) to the hole?1 point

-

There she is! The first bath is the cleaner, it's circulated through a filter which also has a magnet, and is ultrasonic of course. The second bath is the alcohol. The reservoir is in the case at the bottom right, it's a bit over 1 liter capacity. The condenser is behind the 1st bath, the vent at the top left is where the hot air (it's air cooled) escapes, and is also the dryer for the parts (clever!). The rightmost section is the eplilame treatment. There is stearic acid in the bottom, which gets heated to its melting point; the parts sit above that and with the lid closed sit for about a minute. This deposits a microscopic layer of the stearic acid vapor, which is the original epilame (Moebius used to sell it in liquid form as Aretol). I don't know what I'll do when the old girl dies...1 point

-

If it’s anything like the newer citizen monocoque cases you pry off the rotating bezel and can see the crystal is pressed into a crystal holding ring which is then pressed into the case. Pry out the crystal and ring as a unit and you will see a lever to release the stem. Sent from my iPad using Tapatalk1 point

-

Welcome Jason. I’m also in the US. A bit further south, in Texas. I had the same problem finding a genuine watch maker to service my first vintage purchase. So I did what any sensible person would do in that case. Instead of looking outside of my local, I spent thousands of dollars and years of my time learning to do most things myself. Still learning and making mistakes. Don’t regret a cent or a moment!! welcome, and enjoy!! regards1 point