Leaderboard

Popular Content

Showing content with the highest reputation on 09/17/19 in all areas

-

I’m not sure if it would be frowned upon by the watchmaking fraternity, but this has only happened once to me and it took about three days of soaking the screw (tiny amount on screw) in penetrating oil (e.g., WD40). It still needed gentle encouragement but it shifted it. However, I did then proceed to strip and clean the watch completely and needed to replace some heavily corroded keyless works components. I expect you’ll have the same. Good luck and hope that helps. Sent from my iPad using Tapatalk4 points

-

It works extremely well with movements that have seawater in them. Being a watchmaker not far from the seaside I used to get any amount of rusty watch movements to repair.3 points

-

Nothing wrong in that. I would have said the same thing. I expect you have rusty parts and that is why it won't release.3 points

-

My sister and her husband went to a yard sale last weekend. They told me they saw a bucket of what they thought were watch parts, but didn't buy. I was disappointed. My sister drove back to the sale site last Monday and ask if they still had the bucket and the lady said yes—she didn't know what it was and was about to throw out. My sister gave her $5.00 US for the bucket, and here it is. Each container is filled with watch movements and parts. Some appear to be new old stock that was never used. Many unusual items relating to small tools. I don't see anything newer than possibly mid 1950's. As I go though the bucket to inventory I will post updated pictures to this post for all to see. Regards...2 points

-

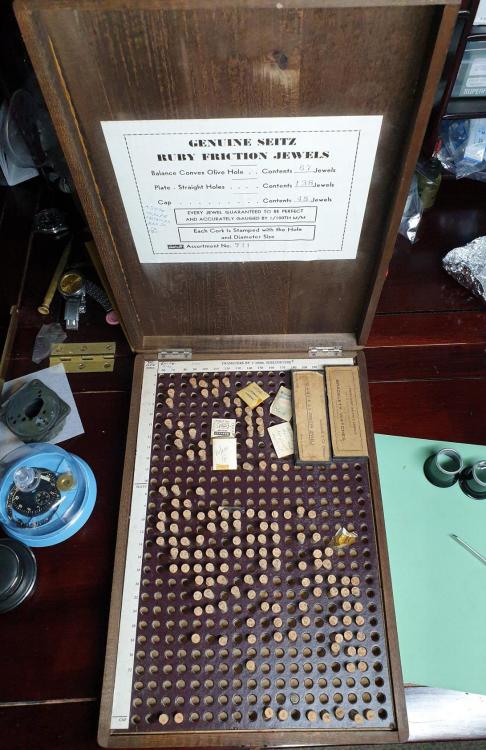

Yes I know its not a complete set of jewels, but it still has a large selection of sizes and has the endstone I need to replace the broken jewel on a German WWII aircraft clock I'm working on and best of all it only cost me $80 USD plus postage. Sometimes you get lucky and stumble across a real jewel (pun intended) with a too good BIN price to say no....2 points

-

Mark has a video showing how to get at the keyless works from the top plate side. Unwind the mainspring Remove the automatic winder Remove the ratchet wheel Remove the barrel bridge.the set lever screw may be tight in the bridge (oil it) but levering off the bridge should be possible. Then the keyless works will be exposed and you can more easily sort out the problem. This is the professional way forward.2 points

-

2 points

-

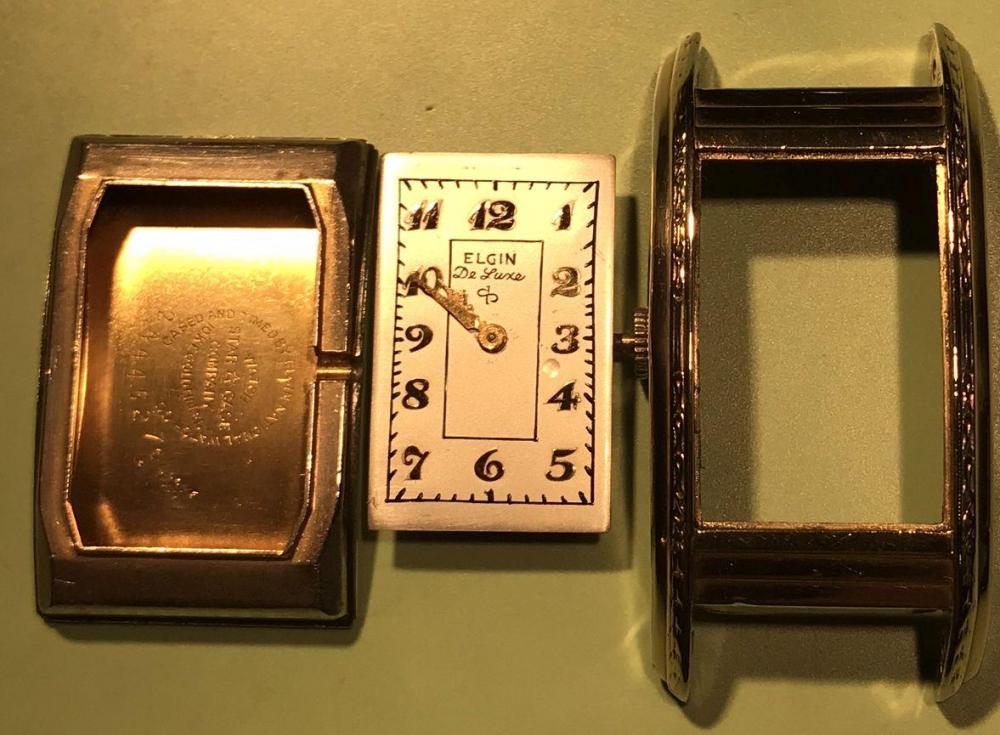

Vintage watches tell stories. They are written in the dents, dings, scratches and wear marks we see on them. I try not to alter the story anymore than necessary when I restore them. Sometimes it can't be helped. To wit: this old Wittnauer 73 Revue. The dial was just too far gone, so I stripped it and gave it a little polish and there was a beautiful gold dial hiding under the paint. The watch value wasn't sufficient to merit a dial restoration, so I just left it alone. Either you like it or you don't, but it stays. Sort of a "Stealth Gold". The other is a beautiful old Elgin 18/0 484 that I am restoring for my oldest son. Hopefully he will wear it occasionally instead of the electronic monstrosity he currently wears as a daily. Maybe for those special dress-up affairs. RMD1 point

-

Cut another balance staff for an old British Pocket watch. Again used a piece of blued steel and cut 90% of the staff before breaking it off and flipping it around to finish the rolled table end and the lower pivot.Measuring the upper jewel hole with a pivot gauge. Sent from my iPhone using Tapatalk Pro1 point

-

Hi Rogart, I hope you'll see this! I am in dire need of dial feet screws for the 8215, do you still have some? I am building a watch for my friend and I lost one...1 point

-

1 point

-

Not that easy. You need to know a bit about them, other wise you could waste you're money and end up with a real turkey.1 point

-

Thank you for the suggestions! I'll try penetrating oil out tonight and let you know how it goes. I hope it's not too Rusty under there. Thank you!1 point

-

Yes, excessive battery usage is a sign of dried lubrication. Current draw can also be measure with analog multi-meter, to compare with manufacturer specifications. Many quartz modules are more practical and economical to replace than to service.1 point

-

Postage is way too high sometimes. Good buy though, and good luck in repair. If new, photo stages, so you know where that spare piece came from lol. Also careful of low flying parts, if not gentle1 point

-

Excellent, I'm jealous!. Would love to try myself, but a few problems, got no lathe, and probably not steady enough.1 point

-

This approach is unconventional. I would apply penetrating oil, let soak over night and; Release the power at the click. Remove rotor and winder module. Remove the ratchet and crown wheel. You would get somewhat better access to apply penetrating oil to the set lever screw, let soak for a night or two, attack the screw. Avoid excessive oiling. You would expectedly discover rusted parts underneath, best to be prepared for complete overhaul. Good luck.1 point

-

1 point

-

1 point

-

This is x20 magnification. I can get up to x270 mag with an optional eye piece. X70 in current configuration which is great for looking at wheel teeth, jewels and hairsprings. Plus progressive linear zoom from x20 to x70. I love the well made piece of equipment. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

I would use a fine sanding block, sponge type or paper on wood. A so small difference is done easily, check often the bezel fitting to not remove too much.1 point

-

To calculate, you need teeth numbers of wheels and pinions and known revolution times (e.g. 2nd wheel, 4th wheel). Once I calculated these times for a calibre that I often work on (18000, small second): 1 tooth of the barrel (=2nd wheel pinion tooth) = 5 minutes 1 revolution 3rd wheel = 7.5 minutes I found that most often the tooth is to consider, less often the wheel. Frank1 point

-

Funny because I’m on my patio smoking a 5 cent cigar sorting out parts. Perfect combo.1 point

-

1 point

-

Hi guys, Managed to snag a watch that's been on my wish list for the last few years.... a Zodiac Astrographic, It has the original band but a few mismatched links have been added. The band reminds me of the ones found on Rado watches of the period (NSA) down to the sprung clasp. The crystal has been polished... but its still a bit dull... looks like the did the coarse polish but forgot the finee grades. Will need to work on that and see if I can improve it, these crystals are not easy to get hold of and cost a bomb when they do come up for sale. The case has also been polished and has lost the radial brushing which is a big part of the attractiveness of these watches..I am not able to replicate that so it has to stay polished! The watch keeps time well.. (+4 secs/day) but I may open it up and give it a service anyway, these hi-beat movements need to be kept clean with fresh oil or they will wear out pretty fast. Not so much because of the high frequency but more because the mainspring is stronger than normal and this puts a lot of stress on the train. Here's some pictures. Anilv1 point

-

1 point

-

A glove box about a foot wide with gloves on each side, not suppose to accomodate the watchmaker himself just his hands, no sweat. I got a cheap LED telescope seeing the piece on a 50 inch screen is a treat. One disadvantage though is, mosquito looks as big as a parrot. Another disadvantage is I often find myself looking at the piece but details are to be seen on the screen. No cabinet neither just nylon compartment.1 point

-

Hi oldhippy, I have just finished the Everite watch and your comments about oiling the pallet pivots were Spot On!. I cleaned them with Acetone, dried and then re-assembled the balance. The balance now has a steady 220 deg. Amplitude. I have timed it to +30 Secs per day. It is much better now. Thank you so much for your correct diagnosis and perhaps 9010 is a little stickier than I thought. I have learnt something from your years of experience and am most grateful to you. Thinking about it there would no real need to oil the pallet bearings as the rotational moment is so small, I realise this now that you pointed it out. Thanking you again, Best regards, the old Jobber Mike. spot on !.1 point

-

Did you check the impulse jewel to see if it was chipped or loose? What type of oil did you use on the ecsapement. You know pallet pivots should not be oiled as it can and will cause drag.1 point

.thumb.jpg.af6a696998eda8ffc2d5b60498647bf7.jpg)