Leaderboard

Popular Content

Showing content with the highest reputation on 09/14/19 in all areas

-

New watches? Either they are so hideous that an alligator wouldn't eat one,or they are electronic toys that happen to tell the time.2 points

-

Hi, i have been repairing watches for some forty years now, and still going strong, I have spares for watches in use before I was born, boy do i feel old !!2 points

-

Feel the side shake, grab the canon pinion( when installed) with tweezers, left & right with it, should not feel loose. ItproDad is right , tollorance betwwen ,Center wheel post OD and canon pinion ID is matter of micron.2 points

-

2 points

-

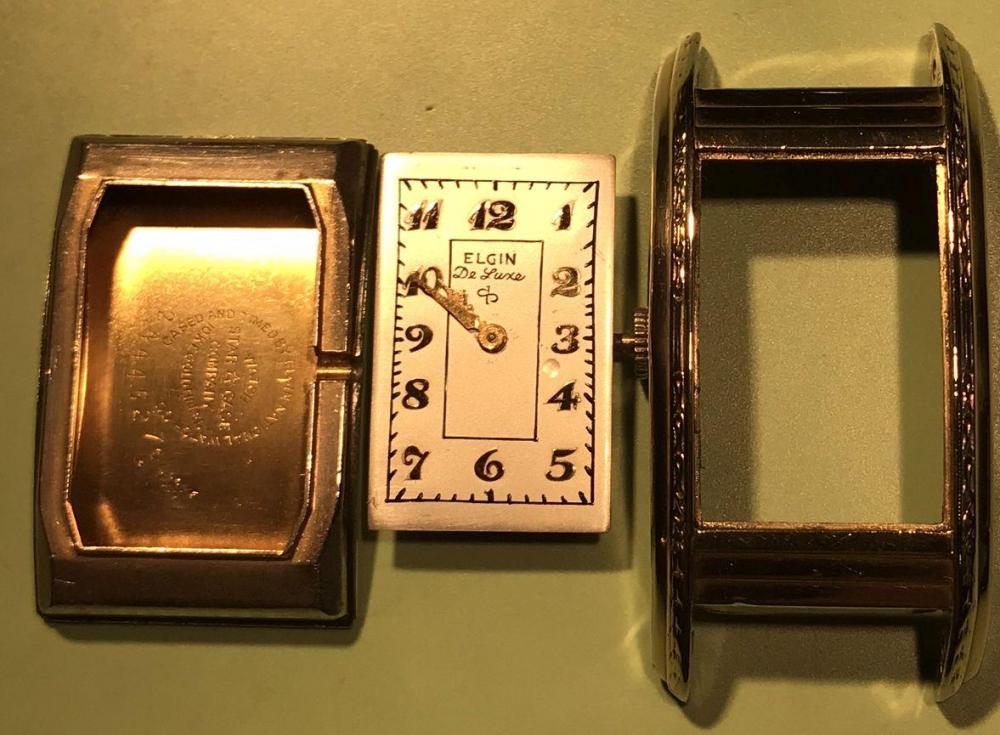

Vintage watches tell stories. They are written in the dents, dings, scratches and wear marks we see on them. I try not to alter the story anymore than necessary when I restore them. Sometimes it can't be helped. To wit: this old Wittnauer 73 Revue. The dial was just too far gone, so I stripped it and gave it a little polish and there was a beautiful gold dial hiding under the paint. The watch value wasn't sufficient to merit a dial restoration, so I just left it alone. Either you like it or you don't, but it stays. Sort of a "Stealth Gold". The other is a beautiful old Elgin 18/0 484 that I am restoring for my oldest son. Hopefully he will wear it occasionally instead of the electronic monstrosity he currently wears as a daily. Maybe for those special dress-up affairs. RMD1 point

-

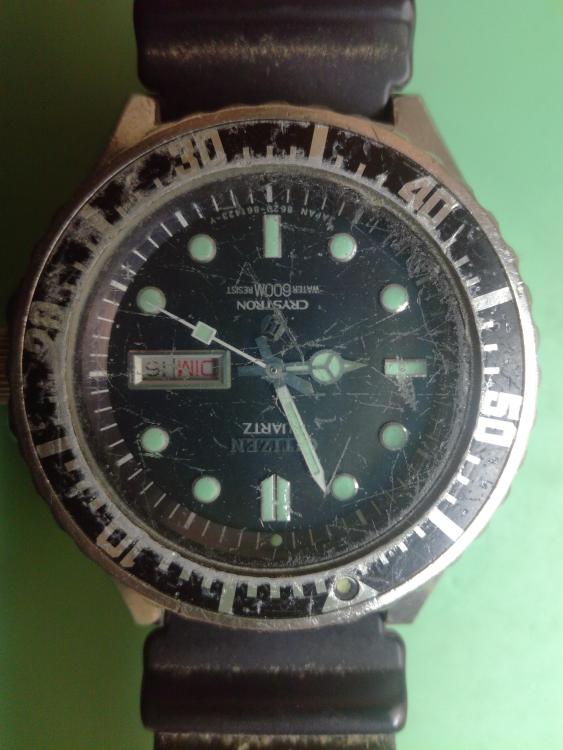

Hi everyone I have been left with a citizen crystron. It appears to be a one piece case indeed im certain theres no seem between the "case back" and case. Ive done many one piece watches however this being a bit rare and a 600m water resistant watch (im thinking the glass will be near impossible to blow out withof air pressure) id really like to see if anyone had any experience or insights with these before I commit to trying to open it.1 point

-

I also agree, old watches or pocket watches, had that charm and look. Plain but elegant. And the skill gone into making them requires as it gets older.1 point

-

Hi I agree with Yankeedog the elegance has gone from watches these days for the sake of great chunky things, no longer the clean and simple lines of old.1 point

-

Hi No what I remember is the cannon is free running driven from the large periphery of the minute wheel and the hour wheel is driven from the smaller gear on the minute wheel. what I would do is to assemble the watch with the top plate fit the hands and put a turn or two on the mainspring then let it run, If all ok and the hands drive ok then fit the dial and re-run the watch uncased under a glass/plastic cover and see how that goes, do not at this stage maul the cannon pinion. The time loss could be down to a dirty movement /old oil, there are a number of reasons. Have you dismantled and cleaned the watch or is it as it was purchased, It the best bet is to service the watch and check the rate then lets just see where we go from there before altering anything. These Omega's are fine movements so be careful.1 point

-

Hi I think we are missing something here, the cannon pinion is driven from the adjacent wheel and once fitted the HOUR WHEEL fits over the cannon pinion and engages the smaller gear on the same gear onto which the canon pinion engages. The cannon is free fitting on the 4th wheel shaft which carries the center seconds shaft and is driven by the gear. cannon number depending on height is 1218 to 1220. hour wheel number is again depending on height 1231 to 1233. So in short just fit the cannon and fit hour wheel over it. The min hand fits the cannon the hour hand fits the hour wheel. On a lot of older watches the cannon is indented and friction fits to the center wheel shaft and is driven by the same. Do you have the hour wheel for this movement.1 point

-

That means i'm learning allready! Thank you, I will try it tonight. I've bought a pair of nailclippers and are going to file away a gap.1 point

-

1 point

-

1 point

-

I will do that, I hope I learned a lot from my first attempt . By the way, thank you guys so much for helping me with this.1 point

-

Gently and small steps. Sent from my iPad using Tapatalk1 point

-

Depends on if there is a center sweep second hand. If not, yes. The minute hand mounts to the center wheel staff. Sent from my iPad using Tapatalk1 point

-

It doesn't feel like its moving at all when I perform a side shake, its not loose on the sides but it does fall in place without force. Silly question: The minute hand is mounted to the cannon pinion, right, and not to the center wheel staff.1 point

-

Purrs, from the s it looks like the center wheel staff is much smaller than the cannon pinion. Is ther visible space between the staff and the cannon pinion? If so, perhaps the center wheel post is worn or not original? To tighten the cannon pinion to fit the staff should be an imperceptible adjustment measured in microns. If you have to tighten a visible amount, I think something else is afoot. Sent from my iPad using Tapatalk1 point

-

Have a close look at the new cannon pinion to see if there is a small indent in its surface if so this is the friction point you need to increase if not check again you have the right one check the part number against the attached tech sheet. 4038_Omega 611 New.pdf1 point

-

good show. i would use a stone or file to Dub the sharp edge. put a drill rod in the tube before making the crush. you can very the crush via the drill rod size. vin1 point

-

This is often asked. In your case the name on the watch means nothing. You can search internet base on the mode type which often carries in evidence, or measure the recess diameter and depth, then refer to any battery size table, again immediately found with a search.1 point

-

1 point

-

A close up of the center hole/ jewel helps. Perhaps the center arbor is worn out.1 point

-

Many people will disagree, but I find that it is ok to fit mainsprings by hand if you are careful. I still use a winder when it's easier though.1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

Following on from yesterday’s effort, today it’s the turn of this 1950s Oberon from Erwin Rudolf’s now largely forgotten Oberon Watch Co. It has absolutely no connection to the modern day “Oberon” brand and came as something of a cosmetic and mechanical basket-case, needing a strap, new crystal, replacement sweep seconds hand, new crown & stem, new mainspring and a service. Instead of using their own Oberon calibre, this one runs on a similarly obscure 17j Brac 903, unfortunately absent from the usual archives although it is referenced in Bestfit. An interesting little company and one who, probably on the grounds of cost, initially used their own solitary movement before sourcing from other, more established, makers. Regards.1 point

-

1 point

-

Here are some pics I took on a 7734 (7733 is the same just without date). And I agree that the start stop lever is really tricky. Before disassembly have a close look from the side, keep the layering in mind and take some photos.1 point

-

1 point

-

I have a link below to the website talking about lubrication of Rolex. Then I'm attaching a file that also talks about lubrication. So if it was a real Rolex you're supposed to use something called MR-1 that were never going to see in the real world. If you look at both references the mainspring itself is considered prelubricated only the barrel wall is lubricated with this strange substance. I think if you do a search we've discussed barrel wall lubrication somewhere else in the message board. Another recommendation Is Kluber P125. But if you use this yet be really careful a is just a real tiny bit because it is super sticky http://www.horologist.com/rolex_lubrication.htm https://www.youtube.com/watch?v=7KNTrHVD088 https://www.cousinsuk.com/product/kluber-chronogrease-p125 Rolex-3135-tech.pdf1 point

-

I think you'll find the link below interesting. As mentioned above it used to be 9010 was recommended on pallet stones even Seiko up until relatively recently was using it. Then 941 came into existence interestingly enough it's slightly lighter in viscosity than 9010. Then much later on 9415 classified as a grease for higher frequency Escapement's. 9415 has interesting properties it's a grease so it stays in place but on the impact it becomes fluid. Then if you look at current tech sheets they probably grasp that watchmakers are cheap and it's basically either or for 941 or 9415. Then I'm attaching a PDF Starting on page 13 is lubrication of a lever escapement. This is where things get really complicated 9415 has a problem if it is applied too heavy. So they explain how it has to be applied very very thinly. You'll also notice another term Lubrifar which is really just Molybdenum disulfide ETA And probably others have been using it for quite a number of years on the escape wheels. http://www.moebius-lubricants.ch/en/products/oils 8645_WI_40_rules for lubrication.pdf1 point

.thumb.jpg.af6a696998eda8ffc2d5b60498647bf7.jpg)