Leaderboard

Popular Content

Showing content with the highest reputation on 09/03/19 in all areas

-

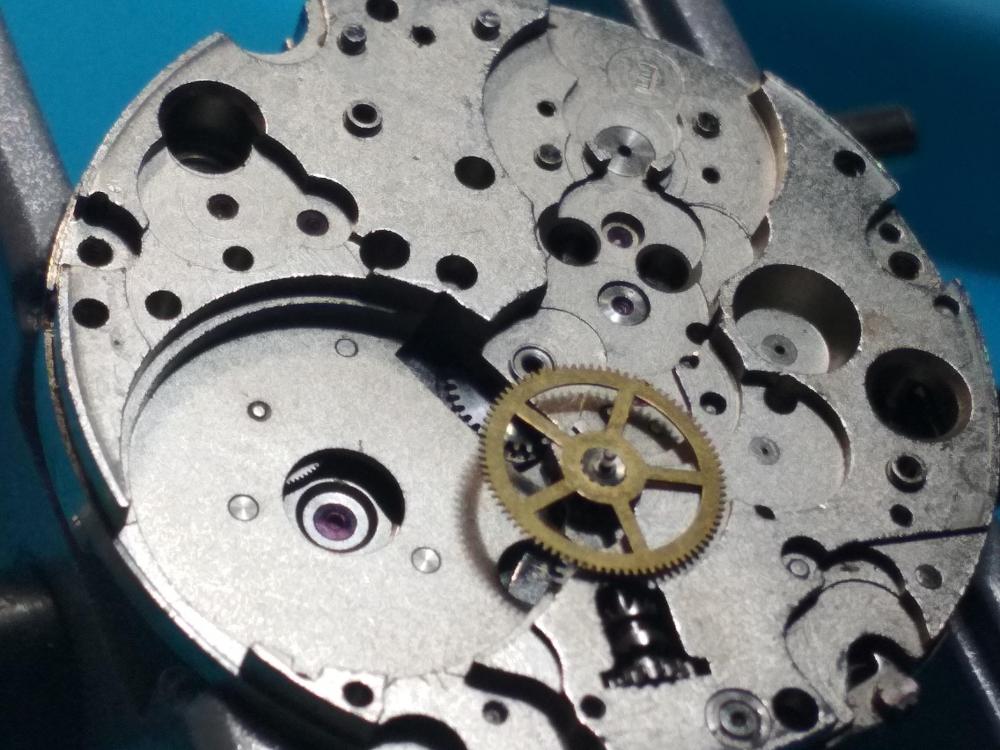

Hello, I started new project - Citizen 67-9119. It's seventies chronograph based on 8110A movement. Watch came to me as "fully working in great condition" As you can see there isn't crystal. The one which was here had chip and wasn't set properly in bezel so when i turned the watch it fall on the floor and broke. As you can see dial is in quite good condition, only it needs to be relumed. Hands needs to be repainted and relumed too. Movement works well but it is too speedy ( +3 min/24h). Chrono buttons work properly, only the hour counter stops at "3h" position so I must to take a look here. I striped down the watch and disassembled movement. There was some much oil everywhere so the cleaning is required.3 points

-

Today I've been giving my '96 Accurist some wrist time. Had this since new, its cost me £100 from argos. Its lasted well though the alarm has stopped working, which is nice! Daz. Sent from my SM-A405FN using Tapatalk3 points

-

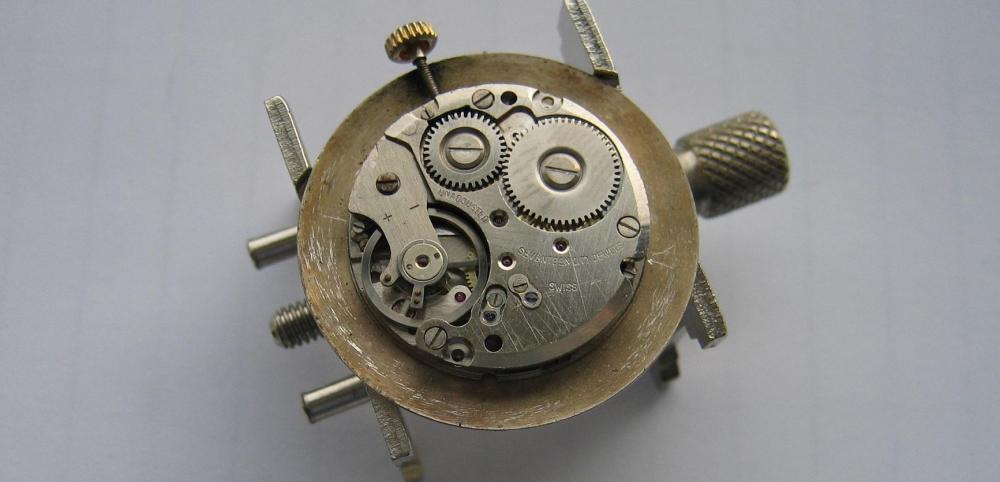

I agree with this, a good lighting makes wounders. Usually when I post here I take a quick picture with my phone and the 21Mp is quite fair and the files are small enough to upload. But a camera, correct lighting and a macro is what it takes to do some good movement por*. This pictures is just a part of a picture since I can't upload the complete one (Camera is a Sony A7R II 42,4 Mp so the files becomes large) but one gets what the difference in ligting do compared to my phone ones, this is just a part of the picture, it is just over 800k large! (or small).....3 points

-

If I had a penny for every tiny component I have pinged into some parallel dimension, I'd probably have an 18 liter bucket of pennies. They usually turn up again, after a long search, or more likely, when you go looking for the next thing you loose.2 points

-

I press the release gently and wiggle the stem slightly until it seats. Patience is the word for this process and you'll get it done.2 points

-

2 points

-

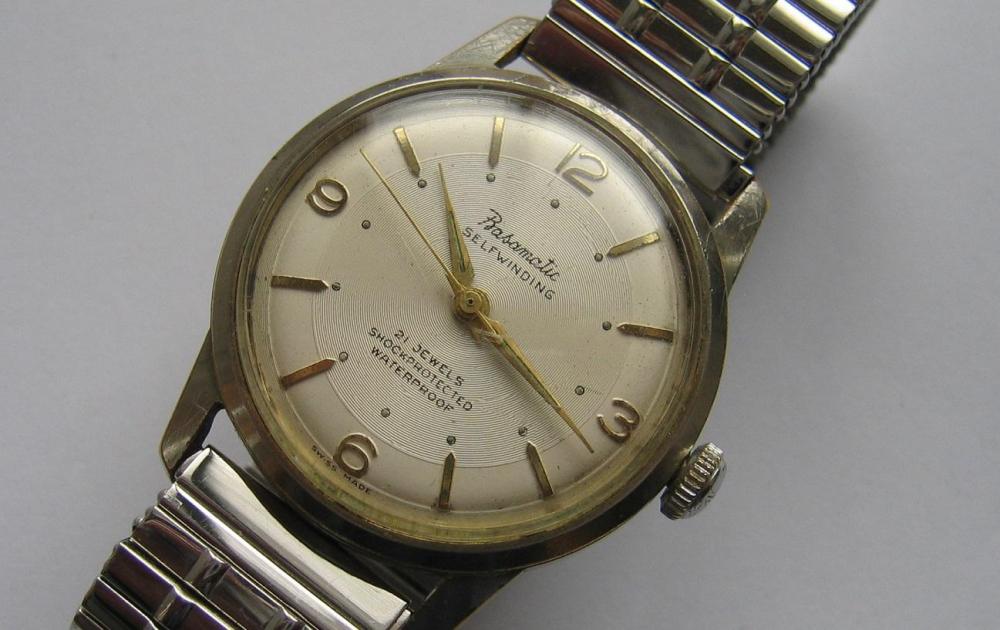

Before - and - After 107 Timex Automatic. This model orginated with a 31 automatic and was later made with the update 107. This watch insored designer Todd Synder to create a monern version. Actually quite a nice homage but saddly only a quartz https://www.toddsnyder.com/pages/the-military-watch-by-todd-snyder-timex1 point

-

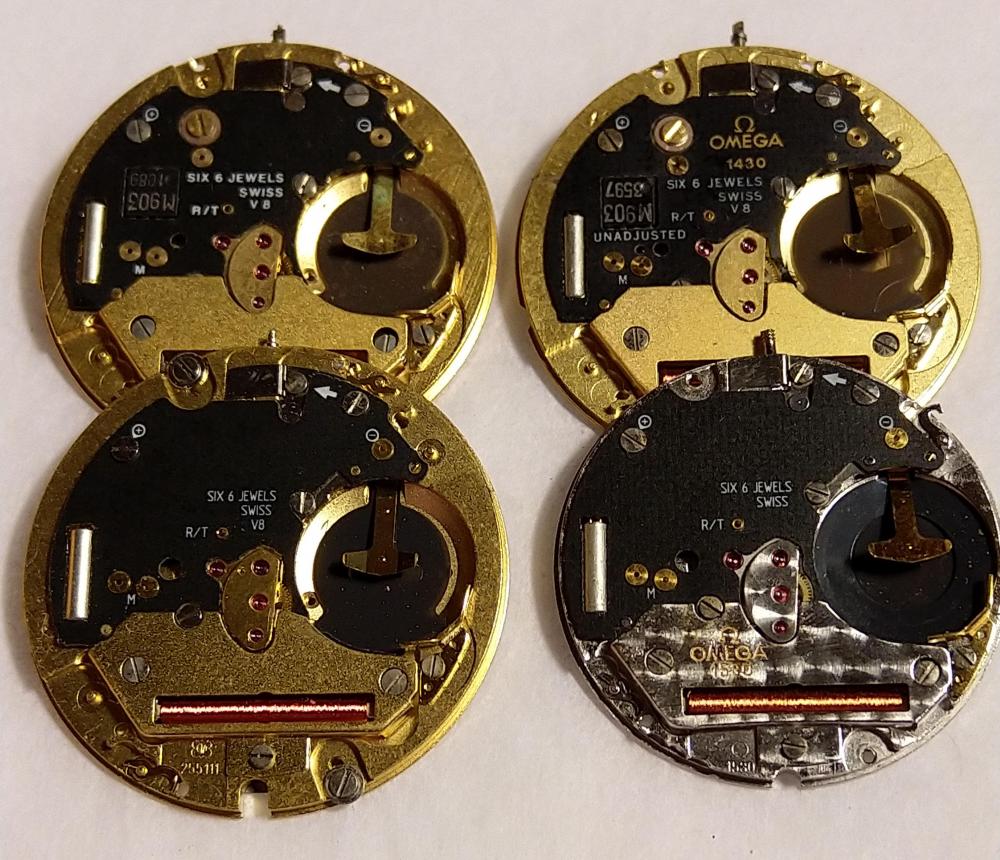

Now it is time for me to look at the ETA 255.111, a movement found in a large amount of mid-priced quarts watches from Certina, Tissot, Omega, ETERNA, Longines, Tudor and many others. Though it goes by many names the original movement can be used as a guide when servicing others in this family. To save space and not make the thread a mile long I as usual made two PDF files of the Disassembly and Assembly of the movement. And as usual I urge you to look at the oiling and greasing scheme in the original documents from ETA. Enjoy! ETA_255_111_Disassemble.pdf ETA_255_111_Assemble.pdf1 point

-

First a nice Elgin driver, a "Parkton" I believe. Its been sitting finished so long I can't remember the movement details, but a 670 inside I "think". Next a 1928 Elgin in a "jobbers" case with a 6/0s, Grade 430, seven jewel movement. Finally, a lovely Elgin "Capricorn" with a 714 Shockmaster movement. Michael was a lucky kid in 1962. The movement dates to 1958. RMD1 point

-

Well done, one doesn't advocate putting wd 40 on watches, even quartz ones. Its better to remove battery hands and dial and cltane in Naptha (lighterfuel) or ISO propyl alchohol or even carburetter cleaner thyen when dry touch the pivots with quartz oil then a quick turn on the line release and in with battery usually they start up again. But full marks for getting it going again Please dont do this on mechanical watches as wd 40 gumms the works up eventually and attracts dirt.1 point

-

1 point

-

1 point

-

use plastic tweezers and a tooth pick around batterys. remember or note the + side. check new and old batterys with a volt meter. good luck vin1 point

-

Agreed generic China movement.as previously mentioned you may need to momentarily touch one point to another to start the watch.with the battery out you will notice a central contact which touches the positive side of the battery.follow the metal,see where it goes.look for a spot that would be exposed when the battery is reinserted. After you put the battery back in.Touch that spot using a pin or tweezers or anything conductive to the metal on the back of the movement . Additionally be aware that the watch stem is a switch.it must be pushed in.good luck mom.keep us posted.1 point

-

A couple of other tricks Re-nsert the stem as soon as possible after removing it, and try not to tap or invert the movement till it is back in. The longer the stem is out of the movement, the more likely you are to disturb things. Keep the stem completely flat, or angled very slightly towards the mischievous spring as you insert it. Insert it very gently so you can feel the edges of the clutch parts as it works its way in. Poking it in hard will almost certainly move stuff about. Go in to the operation with the attitude that there is every possibility that you are going to have to remove the dial so it is a bonus if you don't. This issue also affects a bunch of other movements, so the techniques apply with those too. I was working on an old Poljot 2609H based USSR era watch last night, that arrived with the spring already sprung as it were, and thus it didn't wind or set. I also have an HMT 0231 based Janata sitting here with the same symptoms, that most likely has the same issue.1 point

-

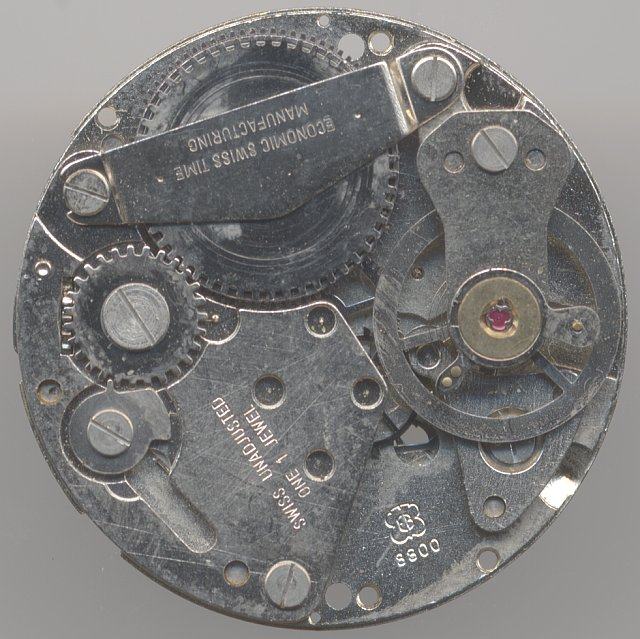

Looks like an EB8805 -> https://17jewels.info/movements/e/eb/eb-8805/ It should be relatively easy to find a donor movement, as they were produced in large numbers. I may in fact have one somewhere, but I'm at work, so I can't check at the moment. What does the broken part actually do? Do you have access to a 3d printer to print some sort of movementretaining ring? If not you may be able to modify one from a modern quartz watch to fit.1 point

-

Depressing the release is not the expertise of solely newbee'e. Where the release botton is place in a circulare hole combined with an oval hole. The oval hole presets a depth limit to press the release button. Consider the larger oval diameter, insert the widest blade screwdiver it can accomodate in. You can,t go wrong.1 point

-

1 point

-

Since you know that having the stem in the hand-set position when removing I would imagine you know that the stem release only needs to be depressed a little bit.. ie to the depth of the slot using a suitable screwdriver. You mentioned that you've tried to insert the stem without pressing the release.. I have not much success with this... you need to press the release button slightly and insert stem. The other thing I would check is if the set-lever components are totally flat.. even if they are slightly bent they can cause problems. Good luck. Anilv1 point

-

Today's bench time journey began with the exploration of a stash of non runners from what I have dubbed "The FS Collection". I found that the coil had come off the balance so I went to my parts bins. Knowing this is a model 85 I was at first a bit unsure because the repalcment part I found looked different. But, "FS" aka Fred Smythe was a quality control engineer at Timex so I just figured this was another one of his expermiental movments. So cut to the chase, I swapped in the NOS part popped in a battery and off it went. Still under bench test for now.1 point

-

Could well be the case. Watch oils normally also need certain additives such as anti-wear, anti-oxidant, even extreme pressure, and sometimes metal pacifiers (anti corrosion/staining). Also baby oils tend to be quite high viscosity so would not be suitable for balance etc which requires a relatively thin oil for minimum friction in the oil. Thinner are available but maybe not readily in small quantities. Simple way of comparing with a known oil is let the oils equalise for temperature then put a drop of each on a flat clean glass slide then tip it up to about 45-60 deg and see which oil wins the race to the bottom. The thinner oil will win! The first thing to select when choosing an oil is the correct viscosity for the application then decide if any additional properties are needed via additives. Generally slow moving means thick (high viscosity) and fast moving means thin (low viscosity). WD40 is designed to Displace Water and leave waxy type protective film to prevent further water ingress. NOT what is wanted in a watch lubricant!1 point

-

Also try pulling out the crown and resetting the hands to say 12 O'clock and pressing the crown home again, just to ensure everything actually turns, in case pushing the battery in has squished something. Push and hold both buttons in together for 10 seconds and release. If that doesn't work, try the same thing with each button in turn. Also check the voltage on the new battery with a multimeter as it may have been stored so long that has died of self discharge. A new cell will be around 1.5V, or a little higher, and a dead one, probably under 1V.1 point

-

Hi BS By the look of the backplate which is featureless with only SL70 on it would look like an Hattori or a Chinese movment, also the fact that the plates are rivited to the frame, most likely plastic and there fore not for disassembly and is in fact a throw away movement, But having said all that if it was working before the battery change and has failed since I would check that you have not disturbed anything during the change. On some wartches i.e. the seiko 732T it requires you to start the movment by shorting the ac point to the +ve terminal on the battery. There is nothing obvious in the pictures. Perhaps a clearer picture of the back plate and dial will render some clue. What name has it on the dial. removing the dial and hands might reveal a makers calibe number.1 point

-

Here's the watch with its new look I hope it stays there for a long time.1 point

-

1 point

-

Not a great picture. Taken at the bench with the lights and cellphone. Elgin Grade 430 3/0s in a jobber's case, Elgin 714 Shockmaster, and Wittnauer Revue 73. The Witt dial was shot so I just stripped it down to metal and did barely enough polishing the make it un-ugly. I didn't think it was valuable enough to justify restoration. Probably all will go to the auction site now that I am done with them. RMD1 point

-

......and here by, ahem, popular demand, are some multi-jewelled pin-levers, excluding the usual suspects of BFG, EB and Ronda, as well as any with less than 17 jewels. Each movement is preceded by the watch wherein it lurks and the images can be expanded for anyone interested. Not sure how to text - photo - text, so in order of appearance they are: Lorsa 655G.3, Lorsa 652, Lorsa 651, Brac 117, Brac 2002, Brac 118, Brac 903, 17j Ebosa 65, 21j Ebosa 65, 21j Oberon, 17j Oberon. Regards. EDIT. Image No.3 should have been at the top and image No.4 should be in third place. The joys of being tech-unsavvy.1 point

-

The old iron disease has got me in a death grip. I just can't go past a nice old machine and leave well enough alone. Anyway, great fun and lots of new projects added to the list to spruce these up. I was out of the house at 5:30 last weekend on a mission, got a Levin lathe, Hauser pivot polisher and a baby Jones Shipman cylindrical grinder. Some need a bit of work and cleaning, but most of the major bits are there. Snagged a nice 10mm Levin, don't really need another lathe, but this thing was so nicely accessorized I couldn't pass it up. Two Variable speed Levin drives, spindle and accessories, coolant, collect closer, tons of collets, 4 jaw, 3 jaw, faceplate, steady, milling attachment, turret tailstock, 2nd op double crosslide and the pièce de résistance, the drilling tailstock. This has its own drive and fine adjustment in two planes so you can perfectly centre it to the lathe's spindle. Its also got the threading attachment but no gears. The power pack is mess, as is the motor. Insulation in and out of the motor has crumbled, something shorted. I think I will scrap it and use a new 3Pp motor and vfd, but bury the vfd in the OEM control and use all the OEM controls so it look correct. Next is a Hauser pivot burnisher. You put a clock or watch wheel and shaft (takes 8mm collets), it spins it in collet at one end and jacot at the other and floods with with oil while you bring down a spinning carbide wheel to burnish the pivot (bearing journal). There's a very precise depth stop on the carbide wheel so you can control diameter. With an inverter and motor connected as delta this should be easy to get running King of the cool is the grinder. This is a Jones Shipman 520, a table top cylindrical grinder. Beautifully made piece, cross feed is graduated in tenths. It came with internal and external quils and holders, both centres and the workhead as well as an adapter so it'll take 8mm collets. It has flood and both the regular and internal attachments. The external is mounted and internal is on the bench will the quill is on the wood box. There's a busted oil cup I have to make parts for and figure the drive There is a huge overhead drive for this shown in my driveway, I can barely lift it. The drive is upside down, not shown are the uprights the drive mounts on so it sort of hovers over the machine. The idea is the motor is separated from the grinder and you can spin both the spindle and work. Not sure what I'll do here, store the drive and hook up something modern - fractional ho 3p with vfd and small countershaft (grinding spindle and work get drive in opposite directions) Last photo is it sitting on top of my horizontal mill to show how small it is - a cylindrical grinder you can pick up and carry!1 point

-

An escapee from my watchmaker’s bag of Horrible Dead Things, the only polite description for his parts stash of old broken pin-levers which he’d hoped never to need again until, to his undisguised horror, I introduced him to my old nonsenses some years ago. I always tell him that instead of just sitting there changing batteries and re-sizing bracelets on fashion watches all day, he should be grateful for my helping him maintain his traditional skills. By way of witty riposte, he tells me to “@&*# off”. So, a forlorn Ostara which, although having lost the jaunty looks of its youth long ago, was willing to run with a little encouragement. The display back looked as time-worn as the rest of the watch so may well be original as I somehow can’t imagine anyone retro-fitting it to proudly exhibit its 15j EB 1344. The case and bezel topsides had lost their plating but have now been brightened up a little. With that and new crystals fore and aft, new crown and the missing seconds hand replaced, it now looks almost presentable. Oh, and it’s also had a new balance staff, because when it fell from Mr Grumpy the Watchmaker’s grasp, he expertly managed to dropkick it the length of his workspace whilst attempting to cushion its fall with his foot. Cue Mr Even Grumpier the Watchmaker. The watch was by Walter Ris of Grenchen, founded in 1945, with the Ostara brand following in 1950. They were making watches certainly into the ‘70s before liquidation in 1997 and eventual dissolution in 1998. Regards.1 point

-

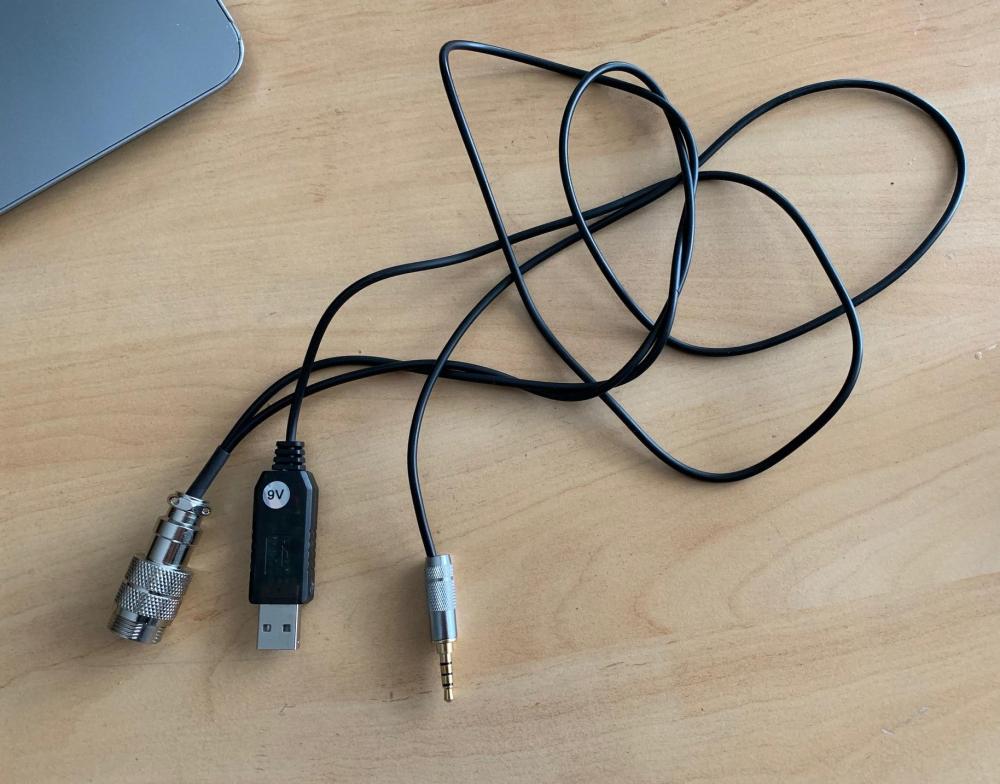

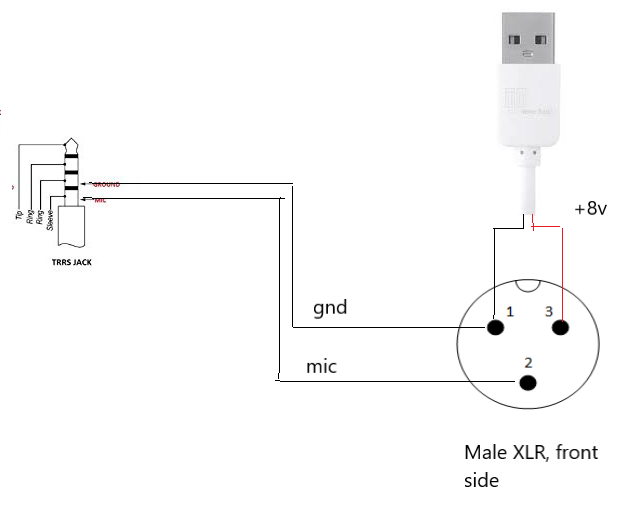

On my Weishi No 1000 timegrapher, the preamp uses a Ti 2272C, wich is powered by +8V. I bought a DIY adapter for Weishi microphone and PC, in order to have the benefits of Weishi microphone stand and graphic display of TG software. -With Weishi microphone stand, I like to test the watch or the movement in all positions, safely. -With TG software, I like the details provided by the PC screen, and to "see" the sound from tic toc The adapter has an USB powered 8v power supply, a TRRS microphone jack and an XLR connector for the microphone.1 point

-

1 point

-

1 point

-

1 point

-

I use mostly Eco Flo products from Tandy Leather but there are others like Fiebings. The accompanying picture has some of the things used in making a watch strap and also in the pic are some of the earlier straps I made which are quite simple. You start with a fairly thin piece of leather and cut it to shape, make sure the edge is straight then you skive the edge down so it will bend to fit over the pin. You would then use an edge beveler (the thing with the mahogany colored handle in the pic) to bevel the edge so as to make it rounded on both sides, top and bottom. Then you would slick the edges with an edge slicker (the 3 wood things in the pic). You would use the groove that best fits the leather you're slicking. Just dip your finger in some water or gum tragacanth and run it along the edge and rub the slicker vigorously back and forth until the edge is slicked and smooth. Let it dry and then apply stain with a damp sponge. Let dry then fold over the ends you're going to sew, apply some glue, then mark your stitching line with wing dividers then use the stitching chisels to make the holes. There are 4 stitching chisels in the pic, the one with the most prongs is used for long straight lines and the 2 prong for curves. You would then get needle and thread and sew her up using a saddle stitch, backstitch 1 hole, cut your thread and burn the ends to melt it. When stitching along the length of the strap, it is helpful to get a stitching pony, that is the gizmo on the right of the pic. You sit on it and place the work in the jaws and clamp it down in such a way that the row of holes are about 1/2" above the jaw and then to make sure the hole is clear, you would use a sewing awl. It is the awl with the short tip and you push it through the first hole you made then you start stitching. This was probably the hardest part of leatherwork for me to master.1 point

-

and here is the after - NOS case, crown\stem and movement. Crystal buffed out, dial has signs of the damage that occurred but she is running again. Now this is not a sort after vintage Timex but since I had the parts a figured what the heck. The kicker even though I did give the movement a quick test before installing it did fail latter on. I tried several times to clear it out with cleaner spay and followed with lube. But it just would not go. Than yesterday I popped the battery back in and off she went running right on time. Could have been some of the cleaner did not flush out and was shorting somewhere. Well she is running now!1 point

-

I have been ‘tinkering’ with this ‘Aviation’ watch on and off for about 6 months. As ever, those beryllium copper hair springs are my nemesis. The problem with vintage watches is you never know if someone has fitted incorrect parts before you get to look at it. I just couldn’t get this watch to regulate - always running way too fast. It turned out the spring was too short so I had to sit tight and wait for a similar movement to come up on fleabay. Anyway, with the case polished, a new crystal fitted and sporting a brown leather bund from Germany, I’m rather pleased with this little Pin Pallet ticker. Sent from my iPhone using Tapatalk1 point

-

Welcome to WRT My watch cleaning machine works perfectly every time. That's because it's me. Part of the "fun, challenge,learning " comes with doing it by hand. But that's just me. If I had a business where I had a bunch in the " Q " I would want a machine.1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)