Leaderboard

Popular Content

Showing content with the highest reputation on 08/29/19 in all areas

-

There are several different types of Journeyman machinists in which I am the millwright / maintenance type. I repair and maintain a fleet of specialized heavy equipment that repairs and maintains railroad tracks. I repair everything on the machines from front to back. Anything from mechanical systems to hydraulic, pneumatic, electrical and computers. I mentioned jet engines in my post because I maintain two machines that have Vietnam era Pratt and Whitney J57 jet engines on them. They are used to blow and melt snow off of the track switches. I do have a horizontal mill and a small lathe that I use sometimes but by no means am a master at using them.2 points

-

+1 to that, assuming the watch is not under any kind of current Breitling warranty.2 points

-

Has this watch been cleaned and serviced? If not then it should be and a new mainspring included. Anilv2 points

-

I suspect this is part of the story. The fact that it lasts 15 hours suggests that the mainspring may be the issue, as it reaches a certain point of its expansion within the barrel, it may be catching (possibly on some dirt, or possibly on a wear mark within the barrel or barrel lid), once it sticks in this way, it then has far less torque, and acts as described in the previous post. I would start by cleaning and inspecting the mainspring.2 points

-

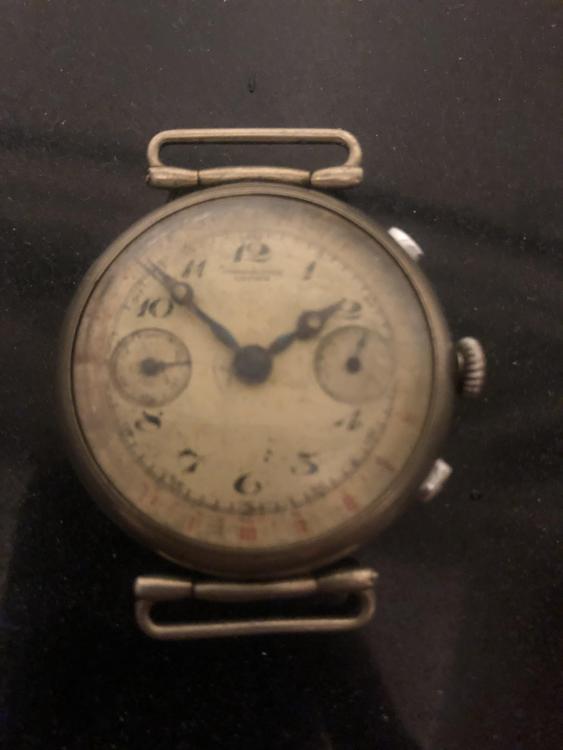

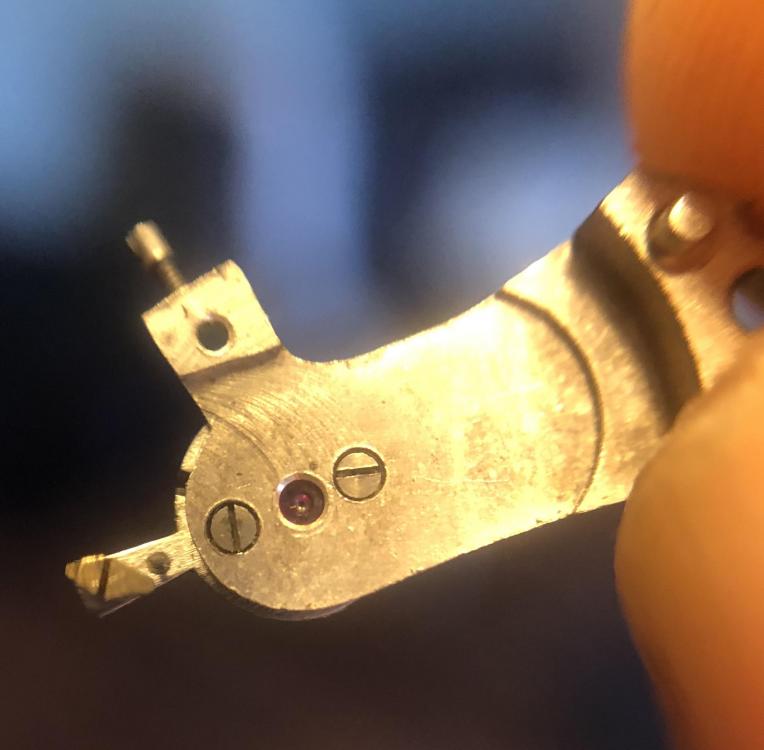

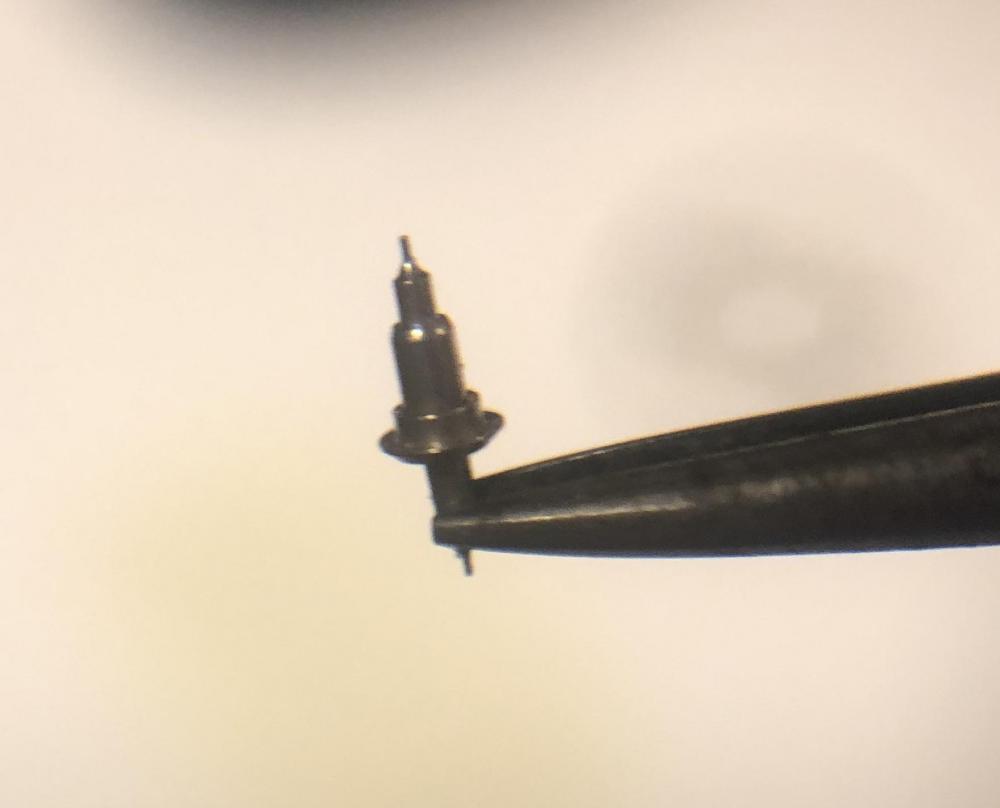

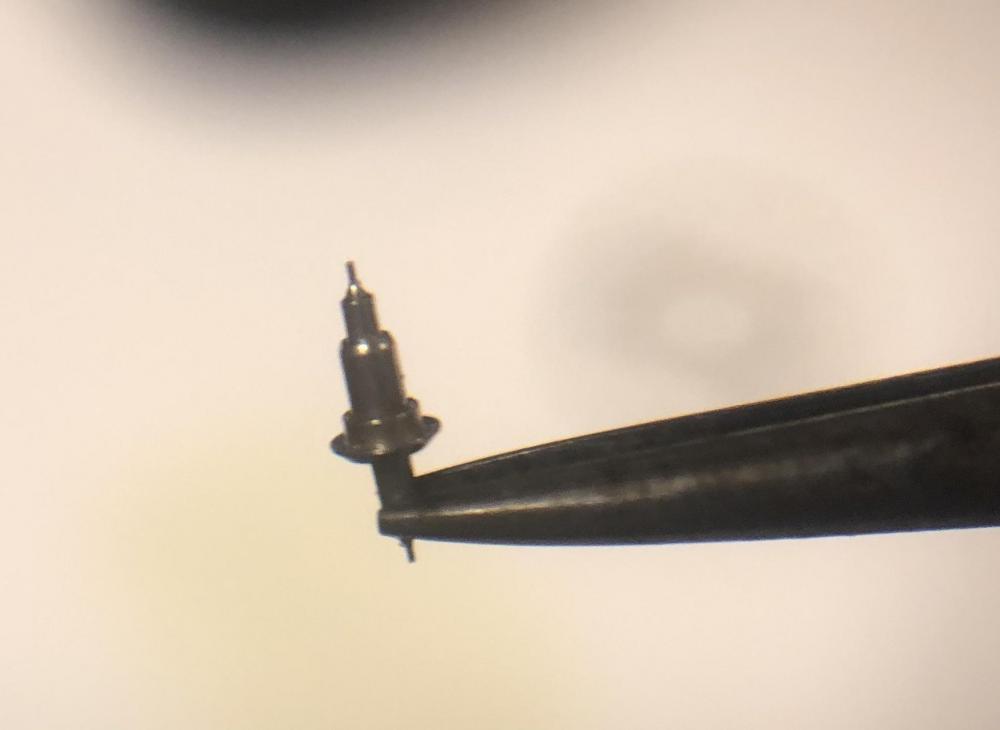

Sourced on ebay some relatively inexpensive Landeron 3 watch. Looks like 30ties, all original. 40mm diameter without crown. Watch was sold for parts or repairs. This is all info what I got from seller: Watch looks very dirty (I will not wonder if that dirt is still from war)... Balance completely disassembled, but all parts present (in the same box as watch, at least hairspring was in container). One of the pusher levers is broken (but broken piece is there). Other pusher was not properly installed (fixed that already). Foil disc from under dial is also there inside the box. Dial was not tightened enough, so small register seconds hand was hanging around under scratched glass. Mainspring was fully wounded. I don't know what to think about that... I mean, I am a beginner, but at least I wouldn't left wounded mainspring, and probably disassembled balance parts I wouldn't just throw in a box with the watch. When I look at the balance staff, it doesn't look so bad to me (see the pics and comment please, I might be wrong), so I wonder, why it's disassembled. Could it be, that watch stopped working because of dirt/old oil, and someone unexperienced decided that balance needs to be disassembled? Any ideas where to start? I was thinking about bringing it to watchmaker to check/assemble the balance, and see if it swings more or less fine, and after that start with cleaning/oiling. P.S. Does anyone has spare pusher levers for this movement? Or could some laser welding work to fix broken one, or that will not be strong enough? And any suggestions about hands - should I restore them (blue layer is coming off at some parts) or keep them "patinated" as they are?1 point

-

A ring. The best way and cheapest is to clean it in warm soapy water., using an old tooth brush. Providing it doesn't have any stones you can use jewelers rouge on a rotating mop, then in the soapy water.1 point

-

Valjoux 724 was produced for a short time and was replaced with 729 . Manual of which would do, If you can find one. Ni1 point

-

1 point

-

1 point

-

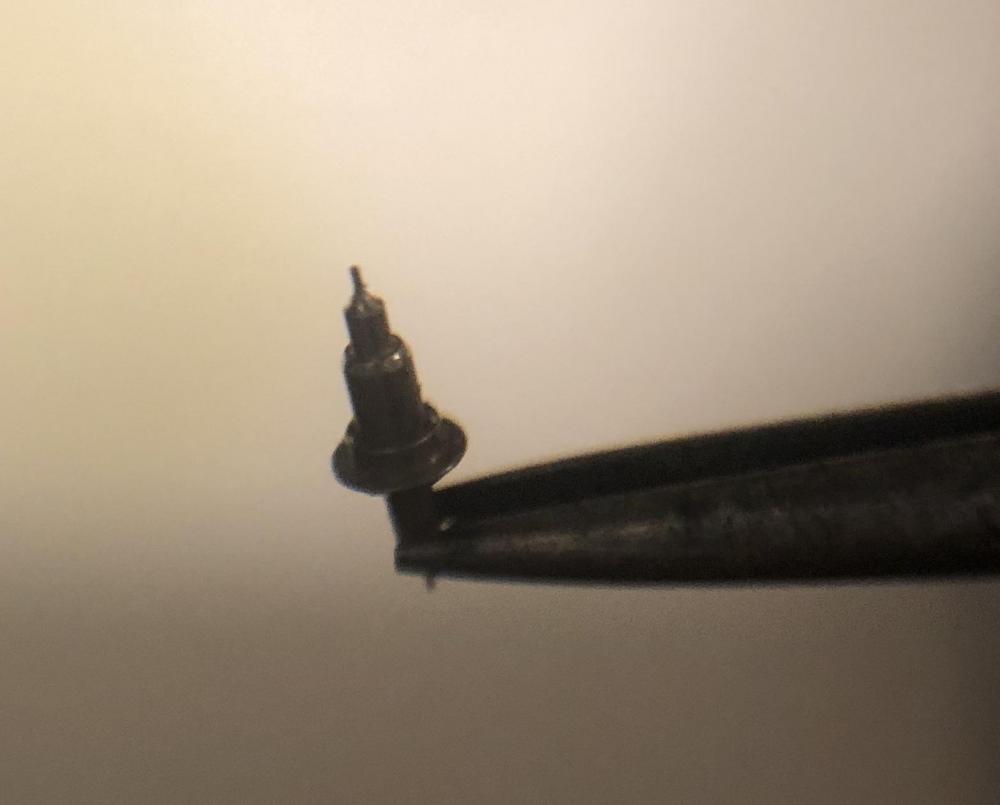

Tools for rubbed in jewels are not made anymore. Your best bet is just to keep an eye on ebay, but don't bid unless they show good photos of the tips of the tools as they can be rusted or damaged and then they will be useless. Remember you need both sets of tools, the openers and closers. I've got a great set of openers, but still haven't got myself a good set of closers, you can get away without them if you have a watchmakers lathe, but that does get more compicated. Good luck in your search.1 point

-

Attached. Need to use a desktop to download from ETA. _c_t_ct_7750_esi_465853_16.pdf _c_t_ct_7750_fde_465595_16.pdf1 point

-

Is this a possible explanation? A fully wound watch generates maximum torque through the gear train and pallet fork against the impulse jewel causing the balance wheel to swing with maximum amplitude. However, as the mainspring winds down the torque may be decreasing, so there is less energy applied to the impulse jewel which creates a smaller amplitude. A lower amplitude means the balance wheel swings in a shorter arc so the hairspring is oscillating faster producing a faster rate.1 point

-

John, I take it you are a Soldier.Although you may be officially retired,It is something you always are.I wore the camouflage of Uncle Sam's Misguided Children for six years.I found that although that uniform hides you in the forest,In the civilian world it makes you stick out like a sore thumb.would you care to comment?1 point

-

Just drag and drop pictures into a post. No need for photobucket etc1 point

-

Part list found via Google attached. When service sheet isn't available just proceed as with a similar mov't, take plenty pics, separate different screws and it won't be a big deal as long one know why he's doing. 2451,6601A.pdf1 point

-

After receiving a watch from a WWII Veteran Uncle, I sent it out for a repair estimate.. I was shocked the price and decided I need to learn to do it myself. I didn't dare just jump in, so after watching dozens of Mark's videos I purchased a similar watch from eBay for practice.... it was a real learning exercise.. I learned what tools were good, best, and better. Which vendors to call for parts, and what was really needed to do a proper service and repair... Needless to say, I got my Uncle's watch running and wear it with pride. It was a long cold winter and I kept myself busy with all of that new gained knowledge and growing experience... I have attached a few photos of where I have gotten... I have cleaned, oiled and timed every single one... taken off the old straps and found original new old stock, or period correct straps to make them authentic. Some I left with patina, other cleaned up to near minty condition. Out of the 50-odd watches all but 3 or 4 keep time with a few seconds a day. I had so much fun learning that I started looking for more projects by cleaning out the local swap meets and pawn shops of their WWII watches (mostly Elgin, Waltham, Bulova, and Hamilton).. now I have a few extras and I owe it all to Mark. Thanks Mark! Now if I can get my work bench cleaned off I can get started working on my Willys Jeep transmission rebuild....1 point

-

Does anybody know if I can use the Watch cleaning machine and these solutions to clean 18K gold jewellery?0 points