Leaderboard

Popular Content

Showing content with the highest reputation on 07/11/19 in all areas

-

Yeah, no sleep till tonight. Had to pull everything out of the shop, paint it floor to ceiling, wait to it to dry enough, then put it all back. That was a long 24hrs... 90% tools, work bench, floor to ceiling shelving packed with more tools... I've been putting it off for 4 months. Yesterday morning I said screw it. It's getting done, now! And it all had to be done before others arrived that work in the building. Fast forward to this morning... Even the morning 2 cups of coffee ain't helping I'm so beat. Lol But it's done. Huge difference! Worth the work. So, I'll sleep good tonight!2 points

-

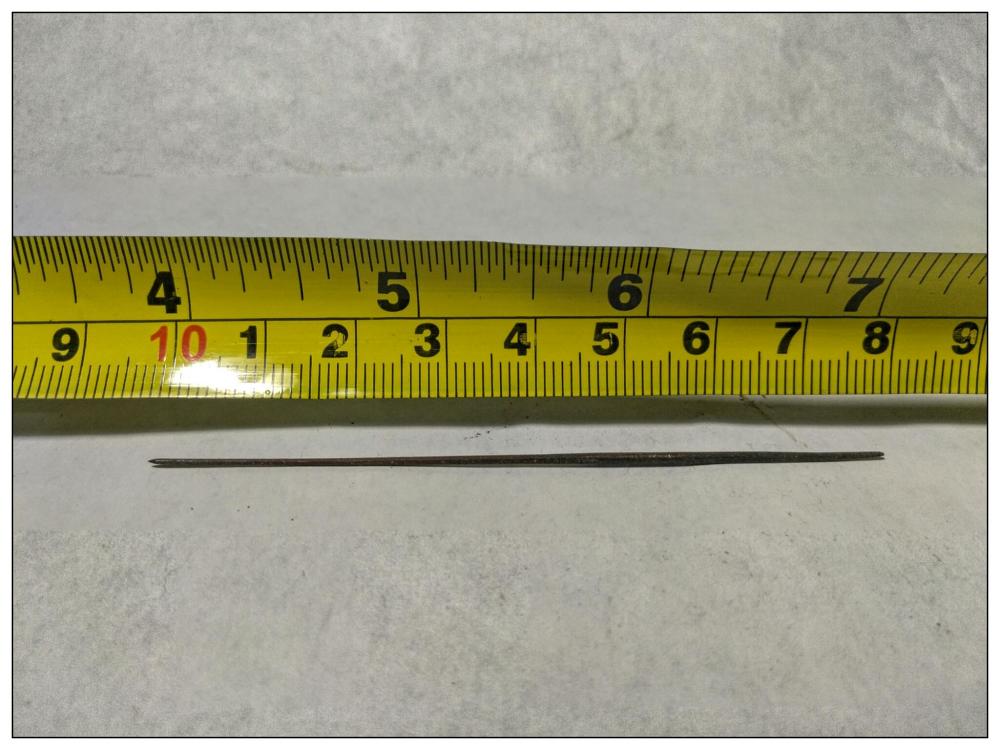

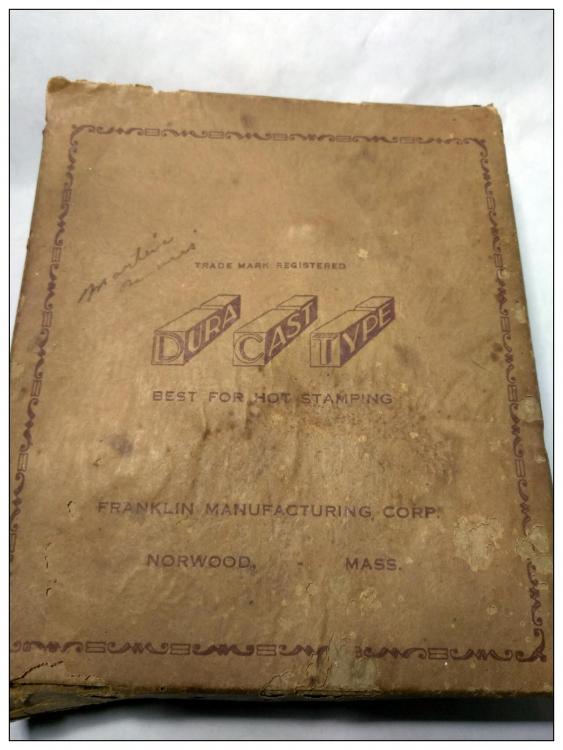

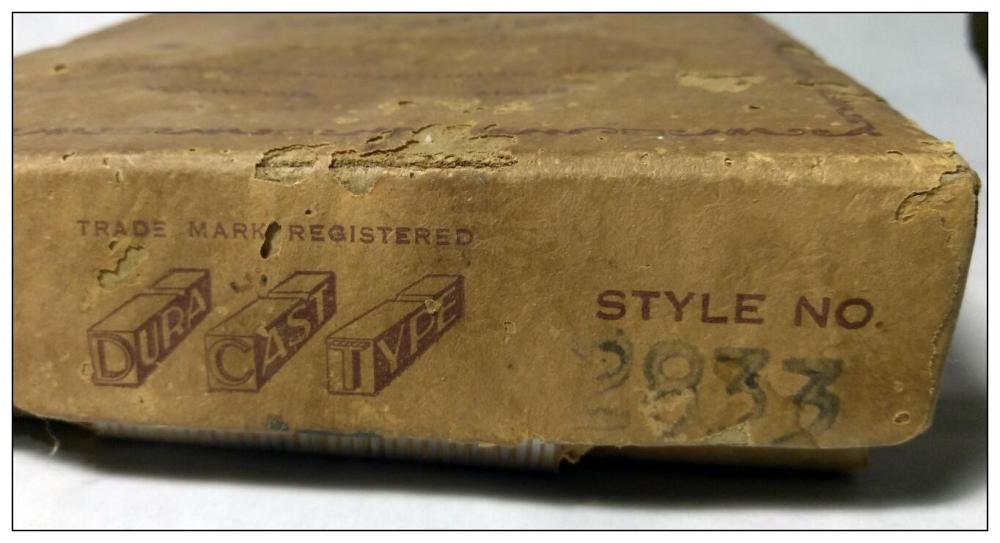

I have some tools I'm giving away. Nothing spectacular. All vintage or antique. All still in good condition, can be used today. These tools are all that's left of a life long watch repair/Jewelers man's business. Sadly he passed and well... This is the truth of what happens to your stuff after one does. It gets gone through, and most gets tossed if the family isn't interested in it. Or after they grab the gold and silver and valuables I should say. Same with those that go through it after... These trinkets are all that's left... But! I did salvage them, and thought I'd pass then on to someone that can use them. And please, I'd prefer these go to an end user. Not a reseller. Pick what you want, send me a PM indicating which item you want and a mailing address. I'll get them in the mail to you as soon as I can. 1) 4 Oilers and old bottle of clock oil with a little left in it. Bottle label reads "W. F. NYE Inc., Electric Clock Oil, New Bedford Mass. USA" and something on the other side I can't make out. 2) Tiny micro something. I don't know what it is. It's squared and comes to a point. I thought it was a file at first but it's not. Almost like a really long needle only out of hardened metal. 3) Mixed set of vintage mini screwdrivers. They need to be cleaned up, but they're all good. I'd keep them but I have 5 or 6 sets already. 4) Dura Cast Type Set in original box. Style 2833. For hot stamping. Missing one or two letters. 5) I'm not sure what this tool is. I have another post asking if anyone recognizes it. But it's up for grabs as well. If you can make out what that writing says on the box, please let me know. It'll satisfy my curiosity. I have one more thing I'm giving away as well, I'll add to this post later. I found out what it was a while back but forgot. I have to take a pic of it before adding it. As mentioned, nothing spectacular, but maybe someone could use these tools even though their old. I'll ship to wherever in USA, sorry, I'm not willing to pay shipping overseas. Cheers...1 point

-

Here’s a tip for those of you who shop from CousinsUK.com! Cousins have a strict policy when it comes to returns, and if you wish to shop from them you must approve of these terms. However, don’t automatically assume it’s no use to get in touch with them if you feel that something has gone wrong. In my experience Cousins are always willing to listen to your arguments with an objective and humble attitude. My experience with Cousins’ service, prices, and treatment are really the best!1 point

-

Hi As jdm says not easy, probably easier sourcing another bracelet that being the most cost effective,1 point

-

I'd suggest, knowing how hand setting works, friction slippage of the cannon pinion via the keyless works it would be logical to say it's a risk unless you have an urgent need to turn the hands in reverse then don't, I tell people it's bad practise and I do know people who've damaged watches by doing so harshly. Even referencing this. Specifically the 'secondly' part, if you can stop and make a movement run backwards you know that can't be good, it's simply not designed to do that. The 'first' point however is valid when done carefully and something I use with non hacking movements as I'm pernickety with time setting. Vostok are a bugbear because their instruction manuals tell you to use the back and forth 'quick date setting' shortcut but, yet again. I've known people with Vostok watches damage them by doing this. (Typically it's when done roughly or snapping from forward to back) but better not to do it I think.1 point

-

1 point

-

I would think a genuine replacement band would be a little harder to find. if you were looking to replace with a different blue rubber/silicone band I would start at: https://www.esslinger.com/blue-color-silicone-rubber-watch-bands-1/ Good luck in the search!1 point

-

1 point

-

So ... I'll shoot some pics as I'll relume a gilt dial in August. What I do with such a dial is to first "draw" the oulines with a really "liquid" lume, using the thinest oiler I can get, and let dry. Then I use the "lume drawings" as surrounds to help while luming ... it works pretty well1 point

-

I'm anti Brexit but must say there will be no consequences for EU customers buying from the UK. Even if there will be no customs union, UK sellers will stop charging 20% VAT on EU orders, and one may (or may not, depending on invoice value) have to pay it at a slightly different rate, plus service fees, when it arrives in EU destination country.1 point

-

Great! Stamping set is yours! Send me your mailing address via PM I'll send it out over the next few days. Cheers...1 point

-

1 point

-

No need to let the mainspring down before removing the stem or replacing the movement in its case. No need to let it run overnight to determine if the hands rub on each other. Just pull the crown all the way out and gently spin the hands for 12 hours. Let the seconds hand tick on for a minute on its own to make sure it doesn’t bump into the minute hand. Once I’ve attached the hands to the dial, I flip the movement on the movement holder (Bergeon 4040) and remove the stem. That is, I let the movement holder hold on to the dial. I sometimes place a bit of plastic film (the kind you use to protect food) between the movement holder and the dial. Never had any problems with scratching the dial or scraping off lume. Finally, I place the movement on a watch case cushion dial-up, place the case over the movement, hold on to the cushion and the case and flip them over, replace the stem and the case back lid. You can see it here. Yes, good thing there are cheap Chinese clones, but if you truly want to save money, I recommend practising with the Vostok 24XX movements. Just incredible value for money!1 point

-

So everyone knows that's interested, all these tools where owned and used by the same watch/clock repair, jeweler that owned the Boley C60 I refurbished and posted about here in the forum. Best I can tell he was still in business back in 1979 locally. Of course since, retired, and passed away. As stated, I'm just trying to pass on some little things I managed to aquire that were his tools of the trade. Not the Boley C60 though.. that one I'm keeping for a bit. :-) It's a real nice vise. Cheers...1 point

-

.. or maybe you are meant to print your own instructions and place them inside, using the current contents ground down to make ink, and stamped on the paper of your choosing with the Dura Type letters.1 point

-

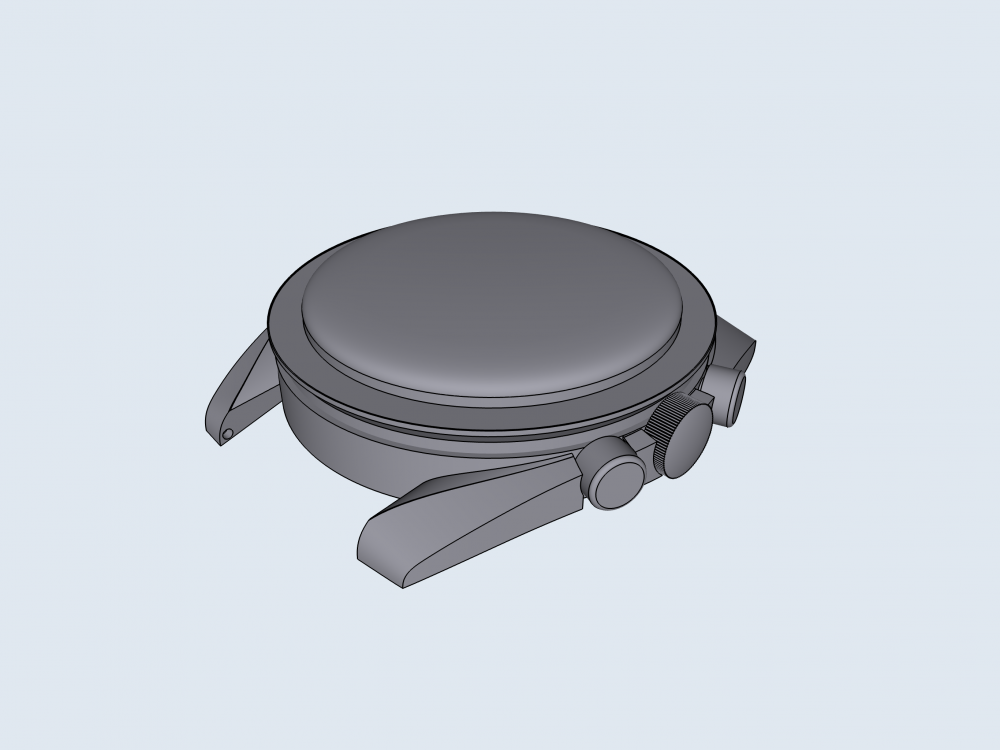

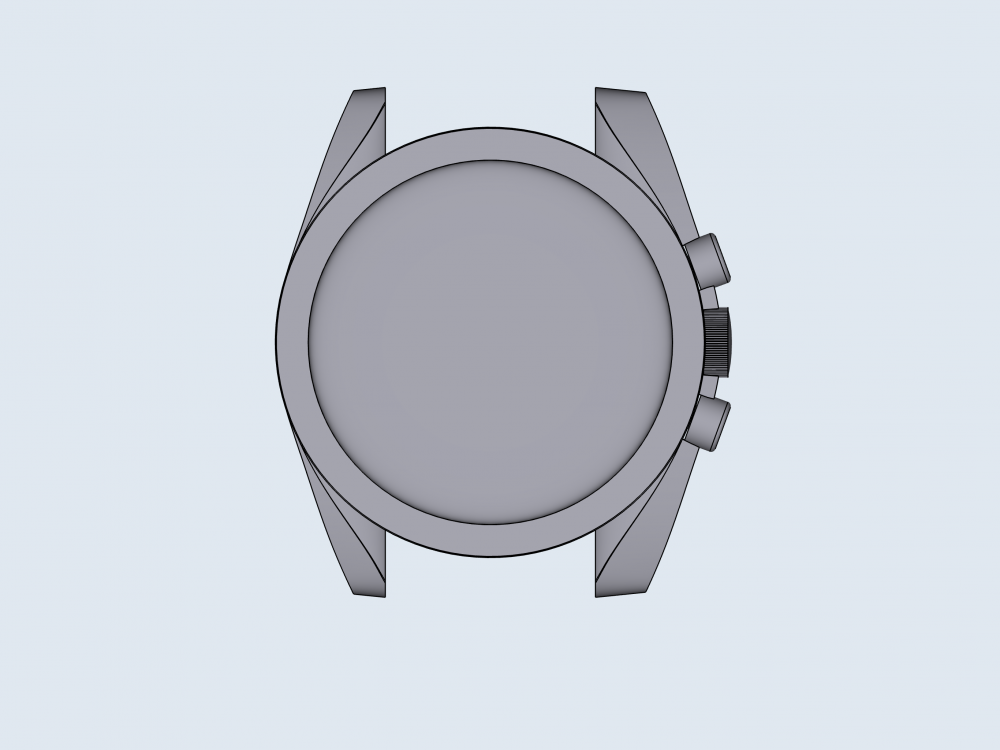

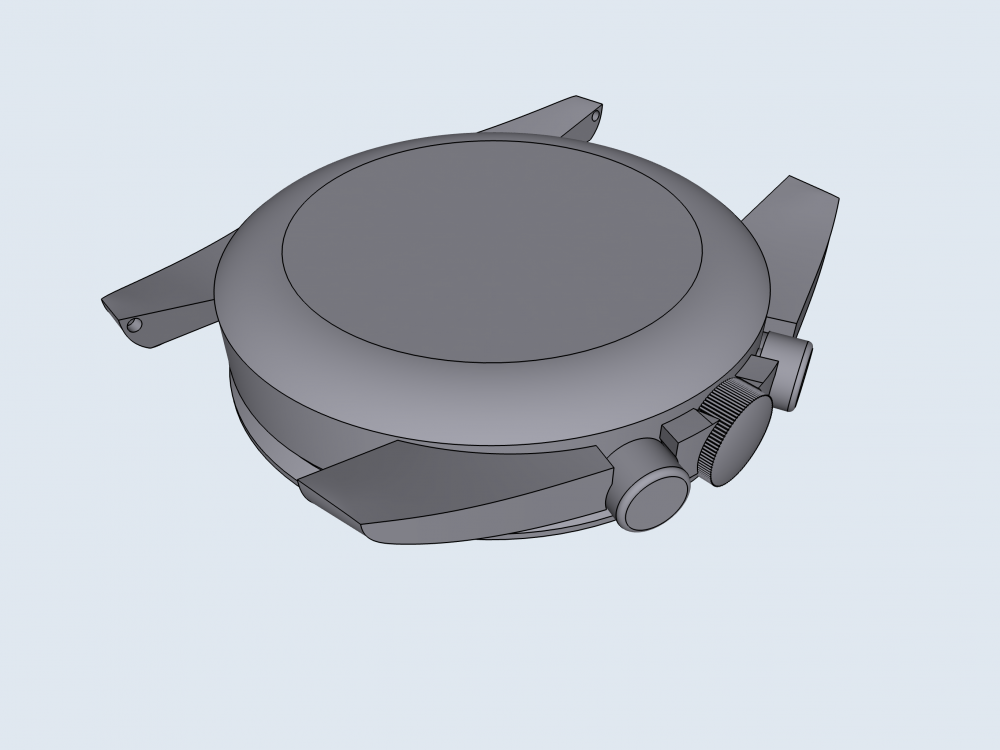

This would be an incredibly easy 3D print. It would need to be measured movement specific and you'd have to melt in a pin or similar for the setting lever release but very much like the 3D printed movement holders I design for myself.1 point

-

You really cannot skimp on a watch fitting glass tool. You need to have one that you can trust and get the repair done without worrying about is it going to work. The cheap tools will not do a good job, they do not fit properly, and they break, not lined up and will not last long. Buy the best and it will last a lifetime. I had many including the Robur. It is necessary have tool.1 point

-

As a reminder you need to pay attention to the data sheet when measuring electrical parameters of watches. For instance to measure coil resistance with the coil attached the meter cannot supply over 0.2 V otherwise the circuit may turn on and give a false reading. The data sheet says anything over 0.4 is unsuitable for measuring coil resistance. Normally when you're buying a meter you not paying attention to this. Occasionally some meters will have a diode symbol indicate though supply enough voltage to turn on a semi conductor device you can test. Then I'm attaching a PDF that explains about measuring current consumption. Whether it's an analog or digital meter you need either a capacitor or capacitor and a resistor to basically average the current consumption. When the watch is not driving the stepping motor it's drawing of a very tiny current. When it's driving the coil it's a very short high current pulse and the tech sheets have the average. microamp.pdf1 point

-

I'm trying to concentrate on tools that I need to use to disassemble and assemble a watch movement for now. I know calipers are not expensive but it’s not needed it for it. I’m trying to work out whether the set of mainspring winders is what it should be or whether there is a problem.0 points