Leaderboard

Popular Content

Showing content with the highest reputation on 04/04/19 in all areas

-

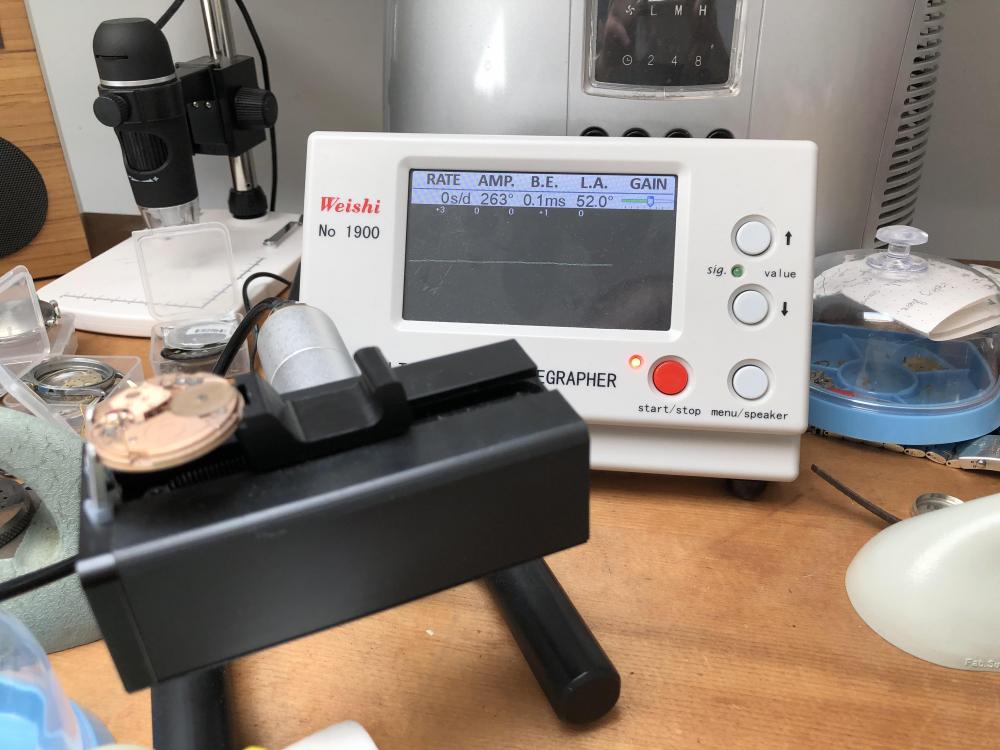

I was really pleased with this service and it's the first time I've worked on an Omega. It was a 1030 movement from the 70s with a broken mainspring. It looked like it hadn't been serviced in decades. Terrible reading as you can see. It was really nice to work with compared to the scrap I'm usually trying to rescue! I cleaned it, oiled it, replaced the mainspring and regulated it and just look at the difference! And it's within 10 seconds in all positions. Just made me happy so thought I'd share :)5 points

-

I'm really into machining and making my own tools (generally I spend more time doing that then the actual hobby itself...), so I thought I'd start a topic about DIY tools for watch repair. My first success has been making a watch winder on the 3D printer. Winders are one of the more expensive and difficult to find tools for me, so it really made sense to start here. Here's the watch winder, it consists of three parts (from left to right): the pluger, spring barrel, and winding arbor. The only non-printed part is to drill a small hole in the arbor and put a piece of steel through it to catch the mainspring. It's certainly more fiddly than I imagine a proper tool would be and will not last as long. But it gets the job done and you can make it any size you want! You can find the CAD files on thingiverse:https://www.thingiverse.com/thing:35406603 points

-

My family has a long history in the watch and clock industry. My grandfather was a watchmaker, as was his brother. My great grandfather was a watchmaker and back in 1986 when he passed away at the age of 13 I was given his watchmaker lathe. My great great grandfather used to own a run a watch and jewellery shop on Oxford St in Sydney in the 1920s and although I have not found any positive evidence he was a watchmaker I would say it was highly likely he was. Three years ago I was given my grandfathers watchmakers toolbox which my steo uncle had stored in his shed for 15 years after my grandfather passed away, as a consiquence I have a number of old tools, some that I know where my great grandfathers, some my grandfathers and some that are old enough to of been old even if they had belonged to my great great grandfather. A couple of weeks ago I wanted to make a special graver for my watchmakers lathe and I was pretty sure I still had some old gravers in my grandfathers toolbox I hadn't yet refurbished so I went for a dig. I found one that had clearly started it's life as a needle file and as some point in the past the file had snapped off the square handle and this had then been made into a graver. I decided to clean this up and resharpen it as the graver I was making would only ever see little use as it was for creating chamfers on balance staffs. After sharpening it I noticed it had a brand name on it. 'Antonine Glardon A Vallorbes' I knew the brand Valorbe, but not Antonine Glardon, a bit of a Google search turned up the Valorbe company history page http://www.vallorbe.com/en-ch/company/history and it states ' in 1899, Vallorbe's three largest factories, Borloz & Noguet-Borloz, Antoine Glardon & Cie and Grobet SA merged to create Usines Métallurgiques de Vallorbe. ' So if I am reading this correctly this file must of been made before 1899. I also have a pivot burnisher labelled 'David Borloz Valorbe' so it would also date no later than 1899. A quick dig through my pivot files I use and other in my grandfather's toolbox turned up 8 or 9 files labelled 'Antonine Glardon A Vallorbes'. I am using the graver made from the handle of a file and the pivot file on the left in this photo below as it is finer and better than my new one I bought from Cousins, the otehr are just in the photo so you can see some other of these files. This would mean the oldest tools I am still using are atleast 120 years old. What's the oldest tool you still use?2 points

-

2 points

-

Check the stator, if it has been slightly deformed it can make the watch run backwards. A heavy bang or drop can be enough to bend it and cause it to run backwards2 points

-

My idea of a Franken is something which is put together to deceive. If the alterations are disclosed I don't see a problem. It's then up to a potential buyer to decide if he wants it or not.2 points

-

2 points

-

2 points

-

I got the watch in this picture in a buyout in which I got dozens of watches. I decided to take a look at it because of it's unusual name, "Robot". I am not familiar with this make but it has an A. Schild 1382 N movement. Now this movement is very interesting and because of it, its surprising to find it in this watch. It has a power reserve indicating device which is not used in this watch. It is possible it is not the original movement, though. But I think it was. Would welcome any information. The automatic works were shot so I went out on Ebay and for a few bucks found an A. Schild movement with the same automatic works and replaced the parts in my watch. I was a little more tricky than that because I had to re-staff a wheel and replace a brass bushing with a jewel (the parts movement was 21j). Also had to repair the set works which were corroded in the Robot watch. Watch works now and keeps good time so I'm happy. It's now an 18j watch whereas before it was 17j. So, an incidental question I have is whether this is now a "frankenwatch"? I wouldn't sell it because it's not worth selling as I could never get back the labor I put into it. But for future reference, do modifications like replacing brass or plate bushings with jewels make a watch so different from the original as to classify it as a frankenwatch?1 point

-

1 point

-

Regardless, something has to be done about that bushing. You aren't doing that movement any favors in running it that way. Egg shaped holes mean misaligned shafts, misaligned shafts mean misaligned gears, and a cascade of new problems.1 point

-

there are many used mvts. out there. elgin had a 21 jewel one in their "rail road watch" would fit in your warch. vin1 point

-

Yes, you should fix it! Have you tried polishing the pivots? A bit of jeweller's rouge and clock oil on some peg wood works wonders for me!1 point

-

Nope, it certainly isn't franken, in my opinion, it is a watch that has been skillfully repaired. Re-bushing or adding a jewel to a watch or clock doesn't "en-franken" it. To be a true frankenized piece, in my opinion, there must have been some modification that is either intended to deceive, or has been done in a misguided attempt to "enhance" the watch, but has instead lowered its value. So building a watch from a bunch of scrap parts, and slapping a garish "Fortis" fake dial and some over-lumed modern hands on it... then claiming it is a rare 1960s model, that has all the hallmarks of en-frankenism. Replacing the balance or the mainspring in an EB 8800 pin lever with a better one from its scrapped, jeweled cousin, that is a repair. If I then slap that EB8800 in to a dead genuine Fortis and claim it is all original... Franken.1 point

-

A good looking "designer" watch. With no further info to go on but the styling I would suggest late 1970s, but I'm probably wrong.1 point

-

Your run of the mill solar cell has a a threshold wavelength (energy per photon), A photon above that wavelength will release an electron and a photon below that won't. If you shine shorter wavelength on the cell you get no extra electric power, that extra energy dissipates as heat. You might be able to make multiple layer (and multiple threshold) cells, but that would cost and you would be dealing with multiple voltages. I don't see that happening in a watch,1 point

-

Your clock appears to be a desk clock of the strut variety, it should have a fold out strut at the back for standing the clock up on a desk, A.lecoultre merged with Edmond Jaeger in 1937 becoming Jaeger lecoultre there after, although in some markets they still marketed clocks and watches under the Lecoultre name alone mostly in American markets. Sandoz used various other names for watch production Tavannes, Cyma, being the best known, the link with lecoultre is that Sandoz supplied Calibres to other companys including Lecoultre, the first two years of production of Lecoultres most famous watch the Reverso used a Tavannes movement. I would say that your clock would be from around the 1920's.1 point

-

Bought it used, have had if for nearly twnety five years, says Louis Russel on the dial, houses a good grade genuine swiss eta2836 variant, the case is satin finished, water has never got inside. Keeps 34 hr power reserve, all original parts. Probably retailed for less than a Rado or Fortis of the same grade.1 point

-

I made this pivot polisher lathe using a Levin pivot polisher, old cigar box , 12V 500rpm DC motor, 1.5-12V speed controller, 9V battery, 6mm pulley, and 4" rubber oil filter gasket. I added the speed controller for better results. Let me know what you guys think1 point

-

1 point

-

A bushing will be fine. What will be tricky is getting the hole open large enough for one without drifting its position. The best way to do it would be in a faceplate using a cross slide to bore the hole. Lacking that, you can drill it, smaller than desired, and correct any error in concentricity with a round file comparing with the original oil sink. You'd want to be close to the edge of the oil sink by now, and can now ream it out with a jeweling tool and turn up your bushing to fit. As it's the upper hole, it's quite a ways away from the wheel itself so a small error in placement won't have much effect if any. It's way more critical on the lower one which is right next to the wheel.1 point

-

1 point

-

Life expectancy of solar cells, declaired by swiss as fifteen years and twenty by Japs. I figured solar cell powered watch faced down such that light wont get to the cell, would spread out the useful life longer, soon this " Home grown know-how" developed to, motor off with the watch face down, for couple months of storage, so longer life can be expected of the watch. Sounded good, but I wondered if the rechargable battery/ capacitor would get damaged by irregulare chargeing. It is incombant upon the members of this, not just friendly but top notch technical forum to come up with a valid recommendation for all. Here is a picture of and old echo-drive, having retained near 100% photonic energy reception efficiency. Regards1 point

-

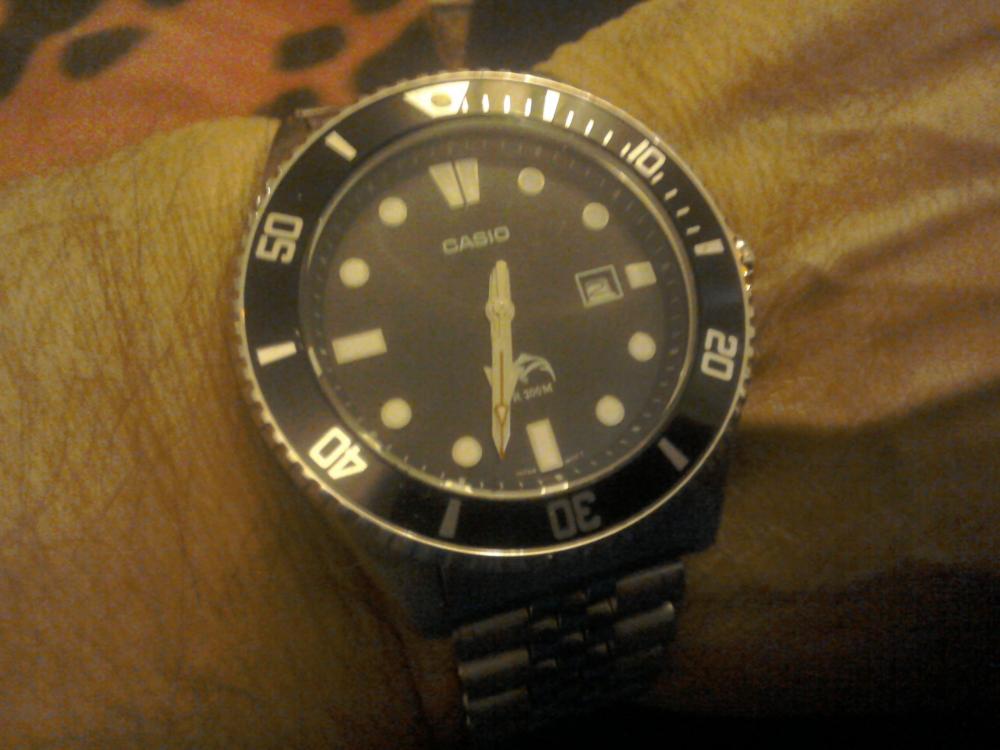

Hi fellow watch fans, I am not normally into quartz watches, but this Casio has impressed me enough to admit I am smitten with it. Accurate, waterproof, (I have well tested it) nice looking, wears well on the wrist and cheap as chips ! £73.00 including jubelee bracelet, £53.00 on black rubber strap.1 point

-

1 point

-

1 point

-

1- Dispower the barrel at the click. 2- move adjust arm through the entire end length of the HS, ( from max retard, to max advance) if that causes the BW move at all, the end length is wrongly shaped, In which case you are varying the impulse jewel beat as you move the adjust arm. The impulse jewel should stay in beat as you move adjust arm.1 point

-

From the video you can see the yoke isn't moving at all, this indicates it might have jumped out from the groove in the sliding pinion and that is why there is no spring action when you put it in the Winding position.1 point

-

I stick pivots into pegwood or cut the tip of a tooth pick with nail clipper to stick the pivot into, rotate the tooth pick " not the pivot" repeat , best to soak the part in your cleaning solution. If the shock system lets, remove the jewel ,enter the tooth pick inot the housing, in which case I rotate the wheel. Soak and rinse again.1 point

-

Clean hair spring before you do anything..dirt and oils on it are easily eliminated.1 point

-

1 point

-

1 point

-

Hello after a long time. To help in purchasing one, I have published a price list of the lathe and accessories sold on Ebay by sincereclocks. https://docs.google.com/spreadsheets/d/e/2PACX-1vSWfhOjlAfpI_c1EWF8MPSKnbIVIPoIH6mxCC1nVYQPQ8cJbiwBhLc1v597F9Z_AZteVKsfJ1lZDOOe/pubhtml That is the same classic "Geneva Pattern" C0608 lathe as described on the specialized website: http://www.lathes.co.uk/chinese-watch-lathe/ Its qualities have been already been discussed here and on many other places, so all I wanted to do is to summarize the options available, using a more conventional part naming.My opinion is that the product is still overpriced in relation to its industrial cost by a good 100%, especially for some parts. For example, the 3 jaws chuck sold for $155 is a common Furda K01-50 plus adapting arbor, available elsewhere for $60. And the seller make no discount on the lathe purchase with an accessory set, howeve a 5% discount is offered if the transaction is made directly. Since the same product is also sold under the bran Vector by Boley.de, and described as "inexpensive". I've included a summary of that option. I'll make no comment on its price, but at least the wooden box looks great. In another post I'll summarize the ready choices available for getting a new micro or mini lathe.1 point

-

I have been notified that the links to the PDF's of the 7750 walkthrough have been damaged. I have re-uploaded them to help all those wanting a copy ETA_7750_Service_Walkthrough_-_Assembly.pdf ETA_7750_Service_Walkthrough_-_Disassembly.pdf1 point