Leaderboard

Popular Content

Showing content with the highest reputation on 09/16/18 in all areas

-

A few months ago I spotted what I considered to be, a rather nice looking chronograph watch for sale. On the dial, the name was, Ravisa. Inside, the movement was a Harley Ronda 726. I bought it as non working and soon got busy, stripping it down. There was no strap fitted, but that didn't matter for now............one thing at a time. This watch incorporates two coils and, when checked, one of them proved to be open circuit. With the use of a stereo microscope, I was able to see the breaks. Yes, breaks.............both of them! Somehow, both ends had both become disconnected. Using my soldering iron, I was able to pick up the ends and successfully reconnect them........which my ohm-meter confirmed. After that, it was cleaned and reassemble/oiled. Once done, the battery was fitted and let's see what we have. Unfortunately, the chronograph section didn't work, but the watch did. At first, this wasn't apparent because the coil pulses for the watch section are spaced about ten seconds apart. After thinking carefully, I could only think of one thing being responsible for the chronograph section not working...............the circuit. Now, for some curious reason, I never checked the circuit when the watch was stripped and I had the chance to. Whenever I strip a quartz watch down, I always check the circuit to make sure that it is working. Why, then, didn't I do so with this one? (Murphy's law!) Well, it's my own fault and now I had to strip it down again to get at the circuit which, in this watch, is buried a few layers down and takes quite a bit of getting at. I got the circuit out and checked it for pulses. Yes, one section was 'pulsing' (The watch section) but the chronograph section was emitting nothing, apart from a high pitched whine. Damn! After a long search, I found a firm in San Francisco ( S.T. Supply) that had the the circuit and got busy ordering it. It took about three weeks to arrive and, once it did, I eagerly fitted it to the watch. It's a tricky business assembling this watch, but it got done. Right, I fitted the battery again and this time the chronograph section sprang to life................success! Everything was working, so I left it to 'soak test' for a while. A couple of days passed by and the watch was working fine. I saw a really nice, shiny S/S bracelet with black ceramic sections and immediately thought how nice that would compliment the black bezel on the watch. The only problem was that the watch measured 19mm across the lugs and the strap was 20mm across. I couldn't find the same bracelet with 19mm and I just had to have that bracelet. A long story cut short, I very carefully altered the watch case and the bracelet and, voila, job done. With its new glass and shiny bracelet, the watch looks absolutely smashing. I just love this watch and I intend to keep it. I wear it daily now, while giving my mid 1960's Valjoux 72 a well earned rest.1 point

-

Also lined up the impulse jewel to the center of two arms and then drew the line straight from the jewel to the pallet fork pivot then placed the hairspring on the balance loosely to align with stud; while the impulse was perfectly centred with between the banking pins. Sent from my iPhone using Tapatalk Pro1 point

-

Done and dusted. I shimmed the balance cock because I did not want to shorten the pivots and more and the pocket watch was running with good amplitude. Sent from my iPhone using Tapatalk Pro1 point

-

1 point

-

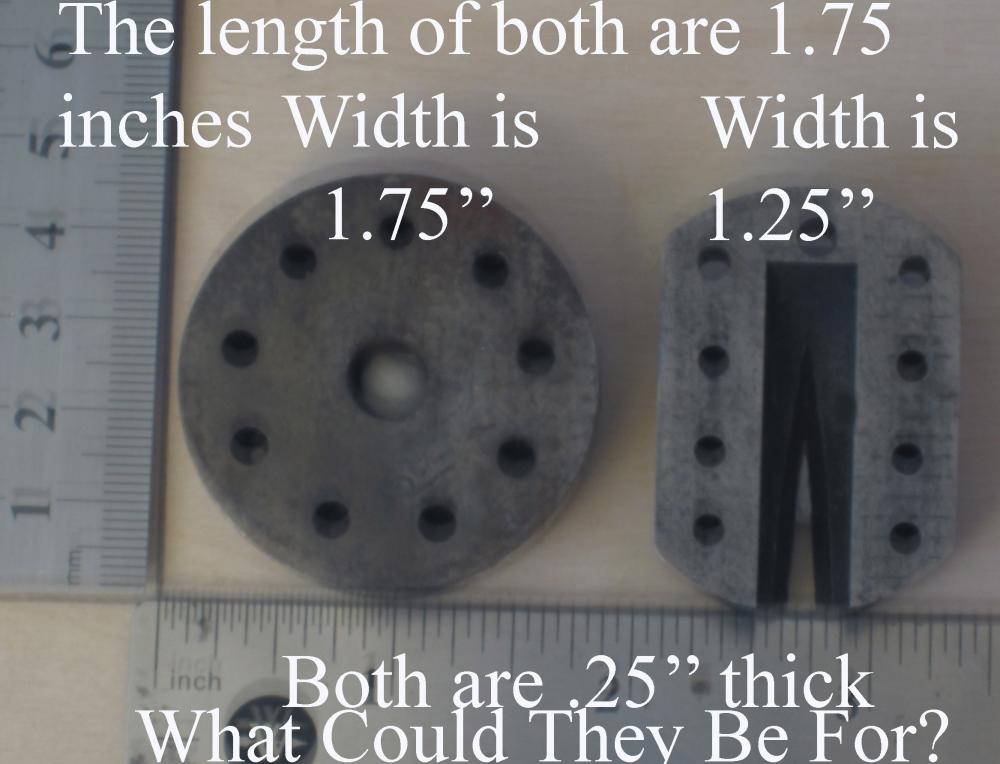

Hello and greetings to all!, I have 2 "tools" perhaps. I don't see a spot for it on my staking tool. Let me back up as well. I have introduced myself on Watch Repair Talk. I said I am a fledgling watch repairer.However, I am more like still in the egg. I have fixed quite a few watches and destroyed even more. Its ok though, I get a box of watches and practice. One time I even got a great deal on a box of watches price wise and it contained 2 working Suunto watches and even a couple of watches that were solid gold. You have to admire and love young adults that sell granddads watches on eBay for pocket money without a clue what they are selling. If people spend a few bucks to have it appraised it would knock their socks off at what the watch is really worth. Sorry I am babbling . If anyone kind enough that knows what these "Tools?" are I would be grateful and possible name my next child after you. The one thing you can not see from the picture is some or most of the hole are tapered. Thank-You Matt H. Clearwater, Florida1 point

-

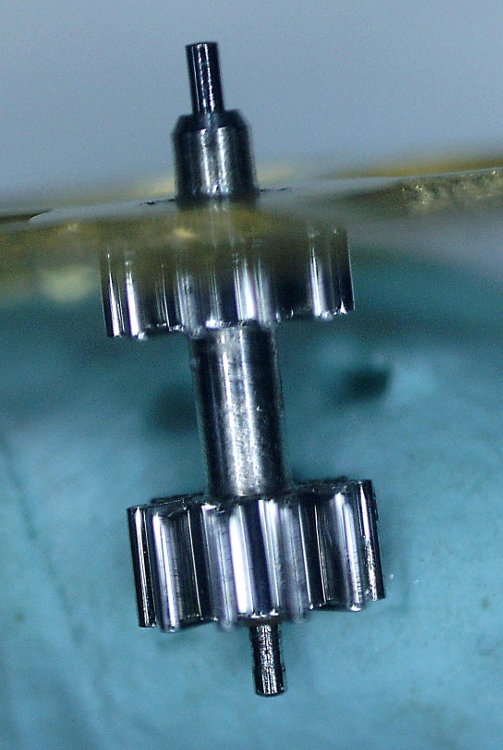

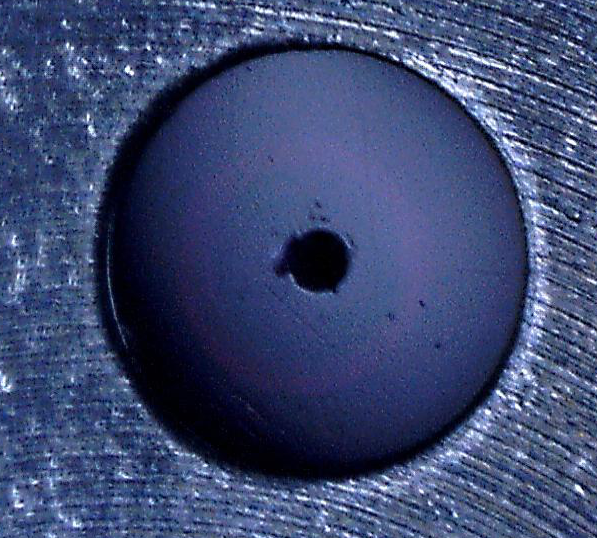

I've got a Unitas 235N pocket watch that I'm planning on attempting to make a balance staff for, but I'm first sorting out the rest of the movement. The pinion on the minute wheel had lost a couple of teeth, but I have a replacement one on the way, it had the wrong size spring in the barrel so I also have a replacement spring on the way. I had just finished taking my measurements for the new balance staff and decided to give all the wheels a once more over again. This time I noticed something I had missed, the top pivot of the third wheel was showing wear. Its the bottom pivot in this photo. So of course I went and had another look at the jewel. I could see a tiny spot on the edge of the pivot hole, but couldn't make out if it was just old oil that hadn't cleaned off or a crack, but under my USB microscope its clear its a chip off the edge of the jewel, atleast I know what was causing the wear now. I will attempt to polish the pivot, but that jewel is going to need to be replaced. The crack is the shadow on the left side of the hole, I could see it clearly as I wiggled the bridge under the microscope so the light caught the chip at different angles. I would of kicked myself if I fixed up everything else and the watch stopped again in a few weeks time due to the pivot being ruined.1 point

-

More progress. As well, made a video on how to use Jewel Hole Gauges. So I staked the balance wheel onto the newly made balance staff, friction fit, and it fit really well. Very pleased . I then used the jewel hole gauges to determine the hole size and this the pivot size. Turned out to be 0.10. Now I need to burnish the pivots to that size, fit the part in the movement and once fit perfectly, I will add the rolled table and the hairspring. Sent from my iPhone using Tapatalk Pro1 point

-

if the pivot look fine what about the balance jewel assembly? I looked at the tech sheet both the lower and upper are identical so you don't have to worry about swapping those around. then image from the tech sheet to show you that the cap jewel assembly does have to go in a specific direction.. The flat side goes in the curved goes out. then when the watch is dial up visually what does the balance wheel look like it's doing and listen what does it sound like? t is one of the minor faults the Chinese machines it would be nice to have the actual audio sound versus the beeping.1 point

-

The roller can be moved to make slight adjustments to the beat. There were fairly elaborate tools made for this (will post a pic when I'm back in the shop). If the staff moves in the balance when moving the roller then the staff was not rivetted properly. Large adjustments must be made at the hs collet to keep the poise and balance position correct. Fine adjustment at the collet is usually easier as well unless the above special tool is on hand. The tweezers are just too awkward. A microscope helps, the angular movement can be really tiny. The tweezers from the OP are handy for adjusting a roller position after a restaffing or for getting a roller off when other methods don't work. The tool for turning the collet is good and works well and safely as long as the cock can be manipulated far enough out of the way, not always the case.1 point

-

I've got some watches who aren't ticking ....... I will try the "googling" part Great find, congrats !!1 point

-

1 point