Leaderboard

Popular Content

Showing content with the highest reputation on 09/15/18 in all areas

-

Pretty sure its a Pioneer-Waltham type 543 or 544. On the dial above 8 days there is writing but it looks like it has been deliberately hidden, maybe at some point in the past some 'liberated' it and then scrubbed off the serial number not to be caught. The line above 8 days had the serial on it and above that the type number, try and hold it in some light and see if you can read it. The clock was made by Waltham for Pioneer Instrument as an aircraft clock, the movement will be 37 size and either 7 or 15 jewels. Elgin also made a similar clock for Pioneer which I'm currently restoring, mine has worn the 4th wheel pivot hole oval and worn the pivot, so requires a jewel to be fitted to fix it. As a side note although these were originally made for aircraft they were also used in automobiles and desk clocks. The link above to the other clock with the winder facing down is a Waltham XA or XX aircraft clock of similar vintage to the one above. For those that like buying books this information came from 'Military Timepieces' by Marvin Whitney which is basically the 'bible' for military timepieces made in the USA, or used by the USA military.3 points

-

My first post so please forgive any faux pas. I bought this wonderfully old rugged looking clock at a salvation army today. I have looked all afternoon trying to find out what exactly I bought and sadly I haven't found much info. There seems to be the possibility that it was in some kind of military vehicle, everything I've found says that a watch maker/repair expert and not a clock maker is who would know about the inner workings, and I came across a picture linked to this forum that had a similar looking clock. So here I am hoping that I stumbled upon the minds who will tell me all the things! Waltham Watch Co. 8 day clock. found the serial #, chart says made in 1929. I wound it and it's keeping time.2 points

-

Having said that, having just additional cap jewels on the escape wheel is not unreasonable in my opinion. Just not all the way through the train!2 points

-

Those superfluous cap jewels were often added when there was competition between manufacturers to see who could have the largest jewel count. Felsa even started decorating wheels with jewels just to get the numbers up. As John says, you can oil these like any other cap jewel. I sometimes add a minuscule amount of oil to the end of the jewel hole to help the capillary action.2 points

-

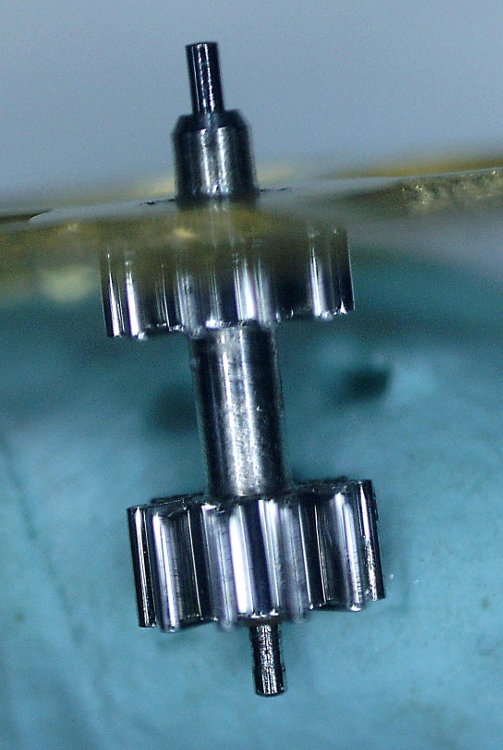

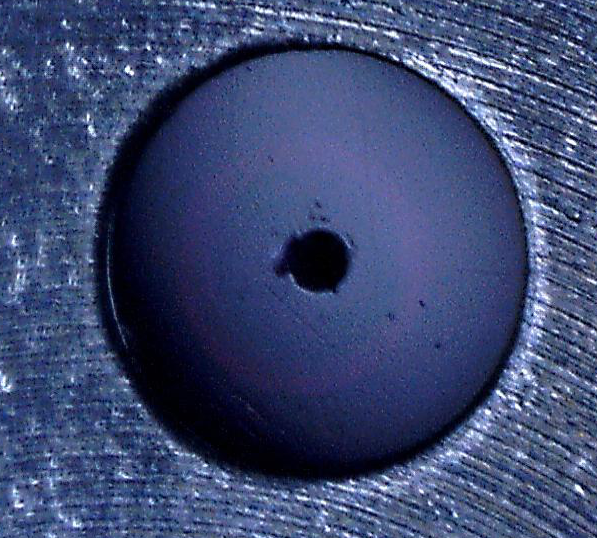

I've got a Unitas 235N pocket watch that I'm planning on attempting to make a balance staff for, but I'm first sorting out the rest of the movement. The pinion on the minute wheel had lost a couple of teeth, but I have a replacement one on the way, it had the wrong size spring in the barrel so I also have a replacement spring on the way. I had just finished taking my measurements for the new balance staff and decided to give all the wheels a once more over again. This time I noticed something I had missed, the top pivot of the third wheel was showing wear. Its the bottom pivot in this photo. So of course I went and had another look at the jewel. I could see a tiny spot on the edge of the pivot hole, but couldn't make out if it was just old oil that hadn't cleaned off or a crack, but under my USB microscope its clear its a chip off the edge of the jewel, atleast I know what was causing the wear now. I will attempt to polish the pivot, but that jewel is going to need to be replaced. The crack is the shadow on the left side of the hole, I could see it clearly as I wiggled the bridge under the microscope so the light caught the chip at different angles. I would of kicked myself if I fixed up everything else and the watch stopped again in a few weeks time due to the pivot being ruined.1 point

-

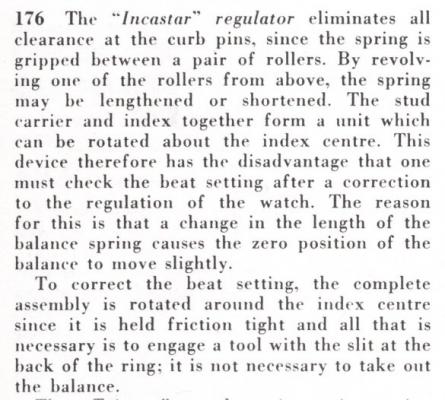

It's a pain in the ... to put back the hairspring on this incastar . Easier to remove . If you need to replace the balance.1 point

-

If I had found that in a charity shop I would of happily paid over $100 for it, and if it ticked then would pay $150 (USD), but then I'm in Australia and things like that are very hard to come across here.1 point

-

A5, ok not made for Pioneer, but same movement as the ones made for Pioneer, as Vinn3 says getting hard to find now and collectable. Only other thing I can add is the dial and hands will have radium paint on it, not really an issue unless you service it, but then only an issue if you are not careful about the dust from it and don't wash your hands afterwards.1 point

-

definatly aircraft, aluminum. very good quality, U S made. at the end of ww 11, panel clocks like yours were very common in hock shops and military salvage stores. quite rare now. AND IT RUNS, good show. vin1 point

-

I forgot to say, what a great find, wish I could find something like that in a charity shop. I've got a small collection of Military timepieces and would like to grow it.1 point

-

Could it be aviation related .......? If I search Waltham aviation clocks, similar looking clocks appear .... this one being a WW1 clock. https://historicaviationsupply.com/products/ww1-waltham-xa-army-air-section-military-aircraft-clock in case it is aviation (1929), you've a nice find .... of course it may just as well be from a vehicle ... worth to check it out a bit further ....! Nice clock and nice find BTW1 point

-

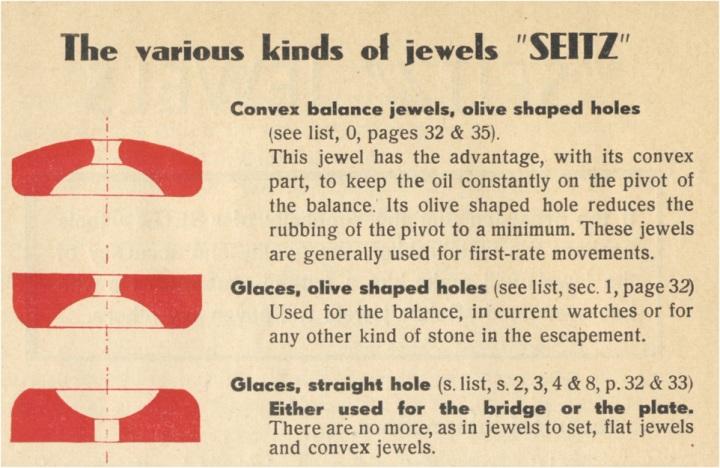

jewels like this are used to reduce friction. I have an image where you can see the side view Then for lubrication you can try to put a small drop on the cap and carefully put it back in place without moving it around but that usually isn't the best way.I also have an image showing how to do that. then at other option for lubrication is a automatic oiler. You can insert it through the whole from the backside the oil will flow out.1 point

-

When you remove the roller for what ever reason you want to try and position it back in the same place, that is assuming someone else hasn't already been at the watch and replaced it incorrectly previously. The reason being if you place it differently it could impact the poising of the balance staff. On a 2 arm balance staff the impulse jewel is generally positioned 90 degrees away from the balance arm. I would of thought you would use that tool if when placing the roller jewel on you needed to adjust it to get it back to the correct spot, not for getting the watch in beat as you should be able to do that with just adjusting the hairspring unless you placed the roller jewel back on in the wrong spot. If you look at balance from a vintage watch you can usually spot tiny marks on the balance rim that a watchmaker did in the past to show where the impulse pin should go and the hairspring stud to put the watch in beat (and hopefully keep it in poise).1 point

-

I've been scouring the internet for some mainspring winders that were in my price range and came across these little gems. Strangely enough, it was advertised in Polish and again in English which were both on eBay, but not listed as 'mainspring winders', they were listed as 'GB Federwinder' Maybe that's why they were still on sale. It appears too good to be true... Anyway, the English advert was £20 more than the Polish one, even the postage was more, needless to say, I bought the Polish version! for what I think is a draw dropping price of £125 inc P&P for 18 mainspring winders! Right place at the right time, I suppose... I actually managed to get a 9.5mm mainspring into an adjustable winder that technically only went up to 7 mm. Jeez... that was a struggle but it worked a treat. I'm getting a feeling that these winders are going to make my life a whole lot easier!1 point

-

1 point

-

That’s nice to know. You can never stop learning. The internet was not around when I was an apprentice. I learned from my master. It just goes to show I’m an old fart. I enjoy the forum so much in helping others with knowledge that I have gained over the years.1 point

-

One of the interesting aspects of watch repair is the discovering of variations. Not just case variations dial variations the hands but movement components. The watch companies seem to have an endless supply of ideas of how to do things giving us an incredible quantity of things to torture us with. Although I'm not sure they were actually specifically designed to torture the watchmaker they can end up doing that. So the links below have additional information lots of pictures lots of variations of using this regulation system. The third link if you scroll down far enough has a picture of the inside of the case back which has the setting instructions. http://forum.chronomania.net/mix_entry.php?id=120965#.Vh6V9viyJyx http://www.ceasornicar.ro/forum/viewtopic.php?f=13&t=6234 http://goldsmithwatchworks.com/MAY-2012/ERNEST-BOREL/1954-ERNEST-BOREL-14K-GOLD-CAPPED-STAINLESS-STEEL-CASED-LUXURY-WATCH.htm Then I've attached a image for an advertisement for another system called a triostat1 point

-

1 point