Leaderboard

Popular Content

Showing content with the highest reputation on 09/12/18 in all areas

-

One of the ways to look at learning watch repair is like learning to become a doctor. Go to school read books and then practice lots of practicing. This also means that each one of our watches is like a doctor's patient is unique. Symptoms can be the same may be the cause is the same but each watch is unique its background history timing machine results how and why it got to whatever condition it's in is unique which is why it should be a unique discussion.2 points

-

I'm attaching a PDF that you find interesting it's a couple of pages out of a eta documentation. ETA is interesting they have their service manuals but they also have their manufacturing information guide which I always find really fascinating. Because this is where you get all the nice little technical specs like these. so what you see is therefore different crates but in real life there's only two grades. There's a difference in the material in the balance wheel hairspring in the higher end so they are going to be better temperature compensation. In each grade is regulated higher and higher regulation which is why there's four of them. Which means you can take the lowest one and if you understood precision timekeeping regulated into the next category and conceivably into the chronometer category except the temperature problems which probably aren't going to really be that much of a problem. ETA-2824-2-Manufacturing-Info-Fr-Gr-En page 6 and 7.pdf1 point

-

1 point

-

1 point

-

Wishing you the best of luck! Do you have a generator - and a reserve supply of treats for the cat?1 point

-

Hello rogart63. Thanks for searching your drawers for a possibly matching handset. I have checked cousinsuk website with no succes, then email them and they say "sorry" so no chance this way. About Ofrei ... they didn't even bothered to answer my information request about the length of their handset (I asked if they are measured from the center of the hole or if they are overall lenghts). The only way I can imagine to get that handset at a "normal" price would be if a US member, already ordering some parts from Ofrei, would add it to his order then send it to me in an enveloppe at the cheapest shipping fee, risk on me of course. I would be glad to pay in advance for that if someone would agree to do that. This WE I will try to rework the cheap handset I have to lengthen the lume openings. I will probably ruin them but we never knows ... if I'm handy enough1 point

-

Dear all, this thread helped me a lot. Plenty of people shared their experiences. Let me say: "Thank you all, folks!" So is time to slightly return what I got and share my fresh experiences. I am newbie in watch repair but not in electronics. I can read plenty of stories here about sensors and amplifiers. I can read "simple" or "easy" or "cheap" or "work for me" solutions. No one worked for me as I expected . 1. sensor - piezo . All piezos have very low sensitivity. Does not matter of the size - (resonant frequency depends on size). Most of available circuits are based on a "knock" detector. For watch sensing have very low sensitivity. Also sensor frame construction takes account a lot - because of energy absorption. Holding piezo in fingers and trying to detect a sound - no way. So finally I decided to use a microphone. 2. sensor - electret microphone (common type). Described problem with a sensor frame construction is much lower and sensitivity is much higher. What is bad the mic can hear any other noise not just watches. So pay attention to any fans, wind, building works or a colleague typing very hard next you. 3. amplifiers - the sensor supports some signal. Input value extremely depends on where sensor touch your watches. Still is important signal-noise ratio (high sensor signal in very noisy background can be unusable!) not just absolute value of the signal. Just FYI the ratio between mic sensor attached to closed watches and opened (touched to a watch frame) should be 100times!!! Signal coming out from the sensor is very low and must pre-amplified about 90dB+ (partially in you external pre-amplifier and partially in you PC or phone). What is bad and not very suitable for the electronic enthusiasts - high gain amplifier can get easy oscillation. Oscillating amplifier is definitely not the amplifier. Without deep experiences what going on with your amplifier and an oscilloscope tool your are not able solve that problem. Another problem is any bread board solution hardly can be copied with success (still we are talking about high gain amplifier). Uffff, too many bad information. Yes I know, sorry. Just sharing mine. Is there any repeatable solution today? Yes, exists. I know it from today because finally this solution works for me and is usable without any special tools. You need: 1. microphone pre-amplifier from ebay based on max9814. https://www.ebay.com/itm/MAX9814-Electret-Microphone-Amplifier-Board-Module-AGC-Auto-Gain-ASS/263928751428?hash=item3d73612544:g:~BoAAOSwD5ZZxMVm 2. quitar sensor https://www.ebay.com/itm/Guitar-Acoustic-Clip-line-Pick-up-Pickup-Built-in-Vibration-Sensor-With-1m-Cable/282574713836?hash=item41cac3f3ec:g:EKIAAOSwf~ZZbI6k 3. some shielded cable, 3.5mm connector to your PC or mobile (I used PC because my Xiaomi phone heavy loaded pre-amplifier output. Actually don't know why), 5V power supply - prefer linear and external not USB or 4.5V battery, hot glue, solder station and basic electronic experiences or ask friend. Job description 1. carefully desolder the microphone from pre-amplifier 2. open sensor clip and remove piezo. Drill 9.6mm hole inside (hole depends on removed microphone). 3. cut off the connector from piezo sensor cable and solder on microphone (keep an eye of shielding) and other side connect to pins on pre-amplifier board 4. put microphone into the hole and fix position and cable with hot glue 5. solder on cable connector for your PC or mobile (mobile has 4pin and different connecting than PC - use google. 6. Connect 5V power supply and try out to setup your PC mic input as was previously described in this thread. How to test entire solution: Clip on microphone sensor to your opened watches (getting the strongest signal available). Eanable "listening" option in microphone tab. From your speakers you have to hear sound of your watch beating. Preset gains to level below you hear oscillating. If everything works fine just turn on a timing SW. Good luck and apologize my bad English PS: I was trying out to check accuracy colleague of mine OMEGA. Sure unopened. And I was not able to find proper gain level before oscillating. FYI. PS: Why my phone heavy load pre-amplifier output ... maybe next time. PS: You can see resistor 392 (3K9) in place of original (2K2). I lost 2k2 during testing.1 point

-

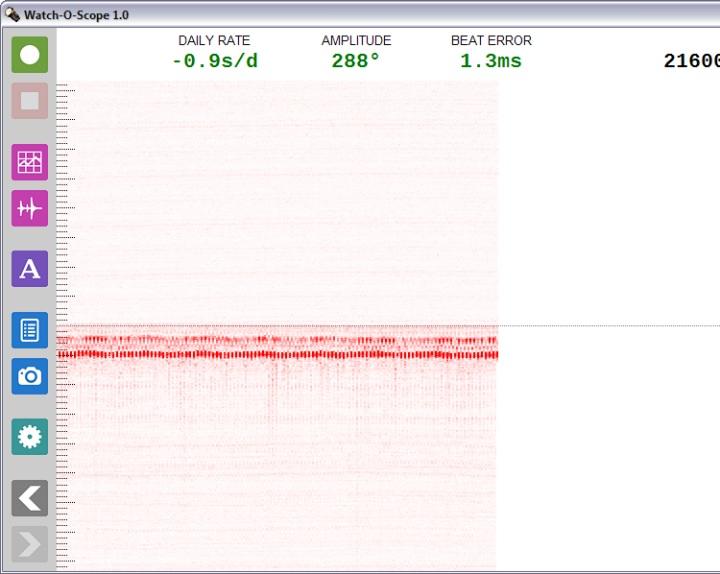

to understand what I'm looking for at least as far as the raw waveform goes I swiped an image off of his website. so I'm way way past my bedtime and the ability to produce legible responses rapidly declining soil see what I can do hopefully it will be legible? So let's look at the basics first in order for us to help proper diagnosis we have to have proper results from the timing machine or the timing software or the timing whatever. So the oscilloscope wasn't exactly what I asked for but is actually extremely helpful. So I swiped two of your images combined together in one attached below. I circled where there may be problems and I drew straight lines where it may be okay I'm not sure and I'm guessing because this is a really quiet watch that the software is just struggling entire pickup everything is just having problems. But if it looks like you're triggering off more or less where you're supposed to be notice your graphical display looks decent. If you start triggering off the wrong part of the waveform graphical display looks like crap the diagnostics they go for why do I have a craft be graphical display isn't necessarily going to be helpful because we may be diagnosing off faulty information. Then I'm not entirely sure that the amplitude is correct even if it's getting a reasonably decent graphical display because it's hard to tell if there's enough of a proper pickup for the machine to get what it needs off the waveform? So where it looks really nice graphically the rate in the beat are probably correct everything else is probably not. So positional timing is an issue because were not getting a good pickup we won't get a good diagnostic without a good pickup which we already grasp. so here's a test for you if the amplitude is really this bad and I assume the watches fully wound up? With a note here when timing a fully wound watch you'd let it run 15 to 30 minutes roughly in other words you normally don't time a watch wound up tight. Who needs a little bit a sampling time. So if this is a fully wound up watch an amplitude looks as bad as it does is this watch still running at the end of 24 hour's? Because I'm not sure your amplitude is right based on the timing machine software and if it still running it 24 hours it indicates it's probably not right.1 point

-

Mike, make sure the jewels and pivots (aspecially at the fast end of the train) are extremely clean as these later Omegas have very fine pivots with less torque to drive them than older movements. And as the others suggest, maybe start another thread.1 point

-

One thing you maybe didn't mention, @Endeavor is if the motion works are installed? I think at this stage it would be a good idea to take them out of the equation.1 point

-

@Nucejoe: With all respect for your willingness to help @mikepilk, but as JohnR725 already said, best is to open a new thread. As you said yourself, this thread, with only one movement under discussion, has already become very lengthy. @JohnR725, thanks again for taking the time to list your random thoughts. I'll try to tackle them one-by-one and report back1 point

-

Hi, are you sure of pivots, not bent, no flattened or chipped off pivot tip. How do you check for those? I normally keep several movements as parts for calibers in my collection and try another balance or other parts I suspect. A balance may seem to turn freely when repairman provides energy, but not with the enrgy supplied by the fork. A bridge may get warpped, residual pretension, damaged pinion, in my book every part and step of reassembly requires testing. Regards1 point

-

It's probably possible to get movements in that class to be more accurate. I have a Hamilton that consistently hits COSC specs. I've heard of someone (maybe here?) getting a Seiko 5 to run around +2. But, numbers like that aren't normal. The accuracy of a particular movement is largely a function of the accumulation of tiny flaws in manufacturing of all the parts. Lower end movements that haven't been painstakingly gone over will have more tiny flaws and will be less accurate. As long as my variance is within spec for the movement, or if you can't find that, within +- 20 with good amplitude, I wouldn't worry about it much. Also, how are you measuring? If you're not using a timegrapher, the results are going to be suspect. I was using an app (toolwatch) to track the accuracy of my watches, and it was all over the map. Turns out, that was mostly due to user error. I borrowed a friend's timegrapher to get a real look at how they were doing, and they were all fine. I'm probably going to get one for myself soon here, they've gotten to be fairly cheap. More info: http://www.wristtimes.com/blog-1/2014/6/24/how-to-use-a-timegrapher Sent from my ONEPLUS A5000 using Tapatalk1 point

-

Think it could be as Melt say. It's probably the chronograph wheel. It's nothing you can do except to replace or live with it. Either run the chronograph all the time and adjust the watch so it runs good. That is the best for the wheel as it doesn't slip in the clutch. Or let it be as is and when i break find a new wheel. They are superhard to find .1 point

-

From TheWatchbloke web site........A big potential problem with the 6139 (and 6138) is if the centre wheel vertical clutch is worn. This is the component that engages and disengages the power from the drive train to the chronograph hands and can be seen in the centre of the movement. Once these are worn there’s very little that can be done in the way of a permanent fix to bring them back to life. It means the hand slips when the chrono is running and it also will start resetting to random positions. The proper fix is to fit a replacement, if you can source one!1 point

-

was chronograph running fine before serviced? Then if you run the chronograph over several minutes does the error accumulate? In other words in one minute it's 2 to 3 seconds fast 10 minutes it's running 20 to 30 seconds fast?1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)