Leaderboard

Popular Content

Showing content with the highest reputation on 08/09/18 in all areas

-

Just my 5 cents as a good oil to stop rust. Many years ago I bought a bottle of Camellia Oil to stop my Japanese woodworking saws from rusting. It is a very light oil that doesn't leave the item sticky. The japanese used to use it for protecting their swords first and then when the swordsmiths turned to making woodworking tools it was used on these high quality tools. I now use this oil on anything precision that I want to protect from rust. This is the stuff https://www.kriscutlery.com/other-weapons/camellia-oil-for-knves-swords-and-tools Of course this only helps you after you have cleaned the items.2 points

-

Oldhippy may be a Moderator but he knows more about timepieces than most of us put together! I wish I had as much technical help to offer the good people on this site as he does! Even 1/10th of his horology wisdom. Instead I stumble around giving my thoughts on what sharpening stone is the best, and mundane information like that. Or deciding weather this word or that word is politically correct? We have to be more civil in this world of barbarians world we live in today.2 points

-

Why is that useless. It's a regular statement which conveys something is very common. Sent from my SM-G950F using Tapatalk2 points

-

Hello, I recently bought one old sewing box with an idea to make alternative watchmaker's bench which would not take up too much space and which could be mounted on standard desk, so it can be put away when needed. It can be opened from above only, which is a disadvantage, but I always keep all my repair tools in one bigger blue box and take it out during the work anyway (right lower corner), so no need to open and close the box very often. The height of the box is around 5,9 inches (15 cm). My desk has height of around 30,3 inches (77 cm). The height for the work is then around 36 inches (92 cm). According to the commercial products like this here http://www.ofrei.com/page241.html the height of this mini-bench should be around 10 inches (25 cm). Not sure how to raise the bench properly (putting books under it?) and I do not know on which height I should properly work? Another thing is some kind of rail around the box, which could prevent parts from falling down and around the box. Any idea how to make such a thing?1 point

-

thanks all will try to build up a collection and also buy a hand guide so i dont have to fiddle around for hours sorting them out!1 point

-

1 point

-

Think you should look for 2,00x 1,40 hands and 1,90x 1,10 . Or 200x140 and 190x110. Not sure what you are looking for. cousisnuk have this. https://www.cousinsuk.com/product/luminous-horotec-swiss-singles11 point

-

If you get the chance, grab as many watch hands as you can. You never know when you are going to need them As Landman says go on ebay and pick up what you can.1 point

-

I used a soft solder that when cool looked like silver solder and bog standard tin of flux1 point

-

As already mentioned garnet was popular at one time. Then if you look really carefully at your jewels notice the Sapphire in pocket watches looks different than the modern wristwatch? Pocket watches typically have pale jewels sometimes a little mixed in color they almost always have flaws because their natural Sapphire. If Wikipedia's correct synthetic sapphires don't come into existence until 1902 with a much better process in 1916 which would mean full scale production for watches probably wouldn't occur to at least the 1920s possibly even later. Then the source of the sapphires used in American pocket watches is typically from the state of Montana which is really big in natural Sapphire production. Then also mentions pocket watches are big and heavy and they don't like to be dropped on the floor or drops just about anywhere. Worst case hard impact of the balance assembly you lose both pivots and cracking or destroying the hole jewels and worse case I've seen cracked cap jewels. Because natural stones tend to be naturally flawed you're going to see cracks in the stones. So what you have to do is figure out whether that natural flaw or crack is an issue? You need to look very carefully at each jewel look at the hole is it smooth even with a crack? Look at the pivots are they smooth if everything looks smooth and you don't see a problem just leave it alone. sometimes even with a visible crack the pivots are fine it depends upon the angle of crack. balance jewels you're not going to be that lucky usually if there's a crack it's going to be a bad crack other times the hole is going to be anything but round and is usually going to have sharp edges. Then why am I advising you to keep flawed place? on modern wristwatches typically you see a problem you just replace the part on 100-year-old pocket watch even American pocket watch that the parts were available jewels probably aren't available anymore. out of curiosity I'm looking at the 1915 Elgin parts catalog? Looks like way more of the jewels were available then I thought plus they come in all sorts of colors. The various shades of red from pale to rosy are described as Ruby, Sapphire I assume is blue then of course garnet is mentioned and for some cap stones diamond. so if this was 1915 no problem but today replacing all the jewels that's going to be an interesting challenge.1 point

-

Have you looked on Ebay you can find various watch hands. I'm not sure if they will have what you need but worth a look.1 point

-

Some earlier watches used garnet jewels which are very easily cracked too.1 point

-

The reason your circuit does not work with the guitar mic pic up Is it's been designed for a capacitive microphone which has a built in amplifier. I have a image below of what capacitive microphone circuit looks like internally. Then the reality is you don't need the circuit because computers have that built as it was designed for capacitive microphone. Guitar pickups are typically piezo it require a different type of preamplifier to work with the computer. Then regarding the computer they're all different. The last link I have below is a US patents for a different kind a microphone not relevant for this discussion. The relevant part of the patent for this discussion is different input circuitry or specifically the bias voltages. This becomes relevant if you're trying to power your microphone off the biased voltage of the computer. The voltages are all conceivably different. If you start looking at the integrated circuits found in computers circuitry microphones a lot of them will supply different voltages. Then regarding the computers audio processing some computers it's almost an afterthought they weren't designed for audio high fidelity others are better. So if you have everything else works right you may have a crappy computer input. One of the ways around that is to get a USB sound device. Another advantage of USB devices is you can steal 5 V off the power four your circuitry. then below I've listed out some of the software-based timing machines there are or were others. Because were discussing microphones and some of these sell the microphones separate or they will convert microphones for their software. In other words there relevant for this discussion. So software ranges from free to costing some money the pickup is what were concerned about. Watch Escapement Analyser - eTimer if you look at the eBay link you can see the microphone a clip on microphone is really nice unfortunately it's not sold separately. Also notice they're using a USB device. But if you go to the UK source he will convert older watch timing machines by adding in new circuitry. So that's an option you get a microphone that rotates it just not cheap. PCTM s interesting if you look at the discussion the circuitry for the microphone is given. Plus the person who wrote the software is in this discussion I was hoping he could try an experiment for us? if you look at the price list a variety of microphones are available separately I'm curious as to whether the microphone works with the other free software out there? Another option for a DIY microphone is to start with something that we know that works? the Chinese on eBay sell their microphone separate from the timing machines it runs around $80. It looks like they've loosely copied witschi there is a Bimorph sensor with a dual op amp which should supply enough signal to the computer. this is on my list of projects to do which is one of the reasons I bought a cheap slightly used 1000 machine off of eBay was to hack the microphone. Unfortunately my list of things to do is rather long and it's not at the top of the list. Windows Software Timing Machine PCTM https://www.watchrepairtalk.com/topic/6333-windows-software-timing-machine-pctm/?tab=comments#comment-63918 https://c.web.de/@337134913998293880/YuEh_TobSjaCfyBDix_1gg Open source timing software https://forums.watchuseek.com/f6/open-source-timing-software-2542874.html https://github.com/vacaboja/tg Watch Escapement Analyser - eTimer https://www.ebay.com/itm/112473962615?ul_noapp=true http://www.delphelectronics.co.uk/products.html Watch-O-Scope - D. I. Y. Watch Timing Machine http://www.watchoscope.com/ https://www.watchrepairtalk.com/topic/3002-d-i-y-watch-timing-machine/ Amplifier circuit for electret microphone with enhanced performance https://patents.google.com/patent/US6580797B1/en?oq=65807971 point

-

1 point

-

Its a early Landeron Hann I think possibly a calibre 2 but the usual applies photos of the dial side please for positive identification Is it a 30 minute register or 45 min on the chronograph ?1 point

-

On the topic of treatment, another idea is mass. Pocket watch gears are much bigger and heavier than wrist watch gears. If you drop a pocket watch, the forces on the jewels from the pinons is going to be much larger than a wrist watch.1 point

-

Could be P/W's tend to be just in the pocket and get dropped. Used at work, get rough treatment. I know many are on albert chains and alike. Also years ago money played a big factor, you had lots or nothing. Wrist watches tend to be on straps or bracelets. They wear and break but do not get so mistreated. I don't know if I'm right or wrong.1 point

-

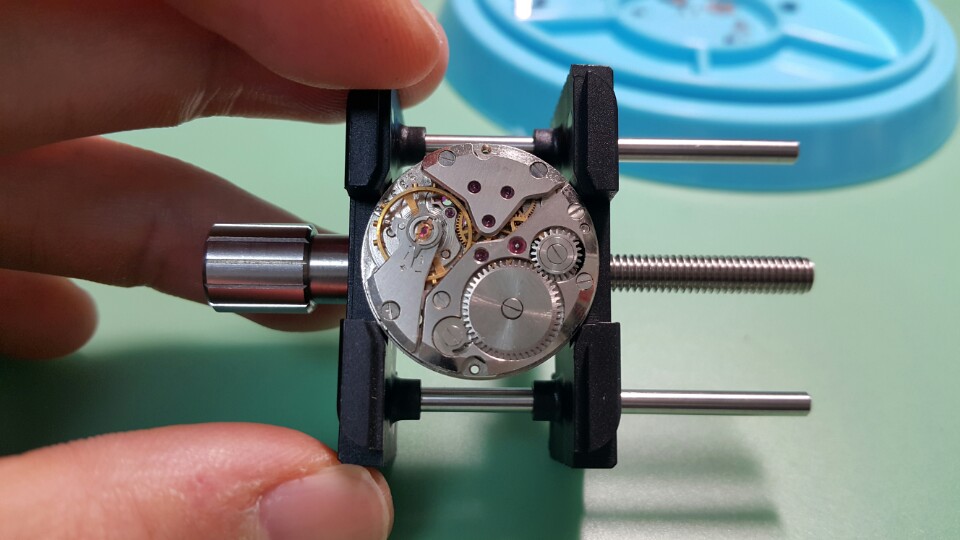

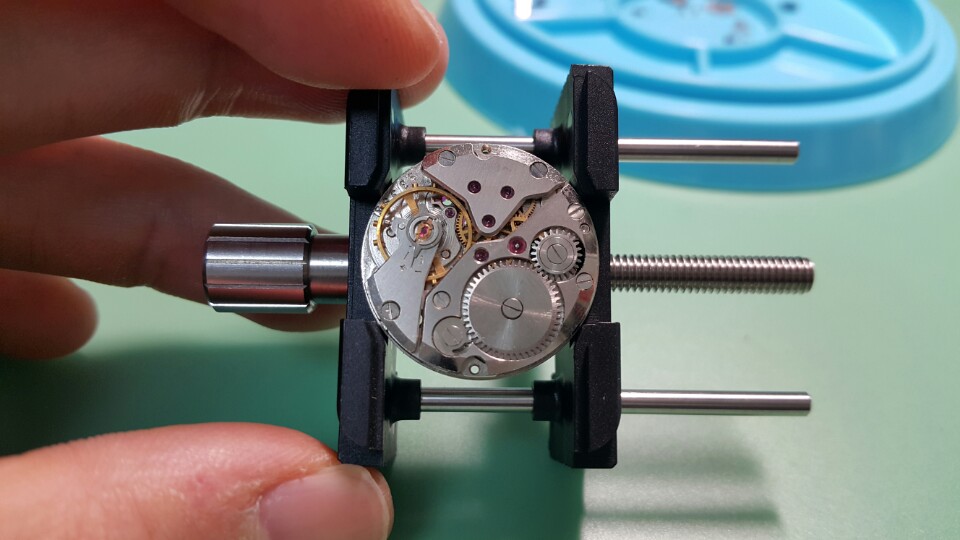

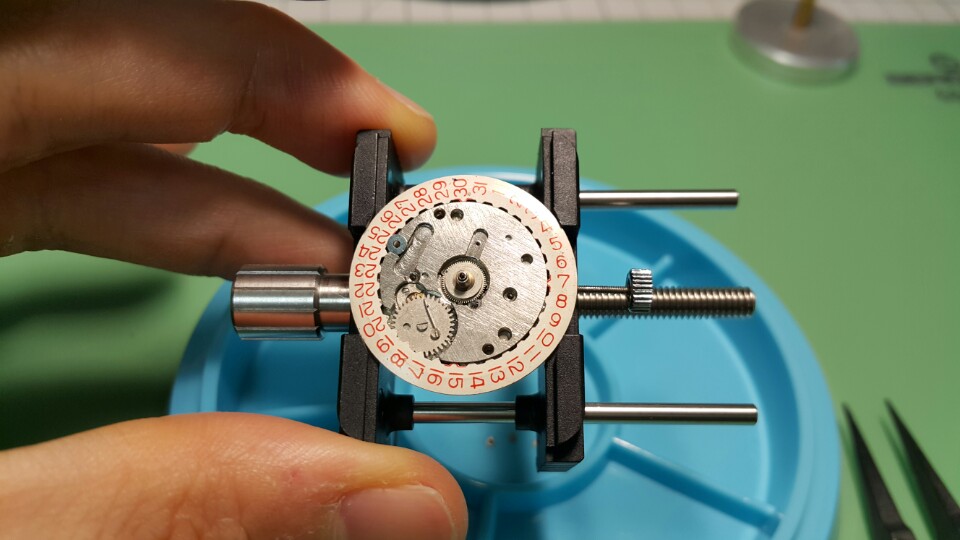

Hello, thanks to all of you who helped me out on my last question about Molnija pocket watch. Yesterday, I opened up my new vintage watch, Justex 21 jewels full anker hand wound watch. I took the movement apart and serviced it but I could not figure out what kind of movement it is. All I know is that it has 21 jewels with frequency of 18000A/h .Any ideas would help.1 point

-

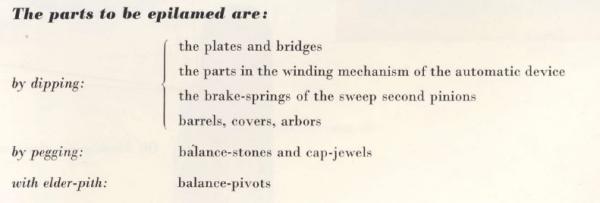

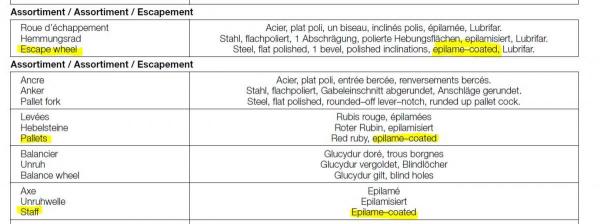

Somewhat hijacking your question I find this an interesting subject in that it's not always that visible on the normal service tech sheets. The reason I'm pointing this out is we usually try to follow whatever the manufacturer recommends but if we are unaware that the parts have been surface treated to prevent the spread of oil and we use the oil they recommend without the surface treating the oil is much more likely to spread. So I'm attaching some images two of them are from an Omega 1957 guide on lubricating their watches. Even though it's a lubrication guide is spends quite a few pages on cleaning the watch because that is a requirement before lubricating. So in the fifth jar of their cleaning machine they have the epilame. Then I've attached some images from that guide telling you what they would use it on and the write up. On the write up I've circled what they're not using it on. Then you'll notice there's a discrepancy between modern surface treating which is the surface treat the pallet stones and their recommendation to not. Then ETA used to publish manufacturing guides for their watches in addition to their tech sheets. Manufacturing guides are really interesting in that they tell all sorts of technical specifications. So I've attached the interesting part for us and highlighted where surface treating is being used. What I find interesting is the balance staff is treated. Then some links one explaining about the various substances. Another explaining of the cautions. The problem with the solvent is when it evaporates the parts get cold there is a possibility of condensation which conceivably could lead to rust. http://watchmakingblog.com/2011/07/29/one-hazard-of-epilame/ http://hiro.alliancehorlogere.com/en/Under_the_Loupe/Epilame Then on page 7 of this document the special bottle that you're supposed to have aMicrophone off microphone offnd how to use it. http://www.bhi.co.uk/Documents/certificate/Tech/PractLub.pdf Than as Eta surface treated the balance staff to prevent the spread of oil incabloc Uses it on their jewels and they talk about it at the link below. http://www.incabloc.ch/en/huilage.php1 point

-

0 points

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)