Leaderboard

Popular Content

Showing content with the highest reputation on 08/08/18 in all areas

-

2 points

-

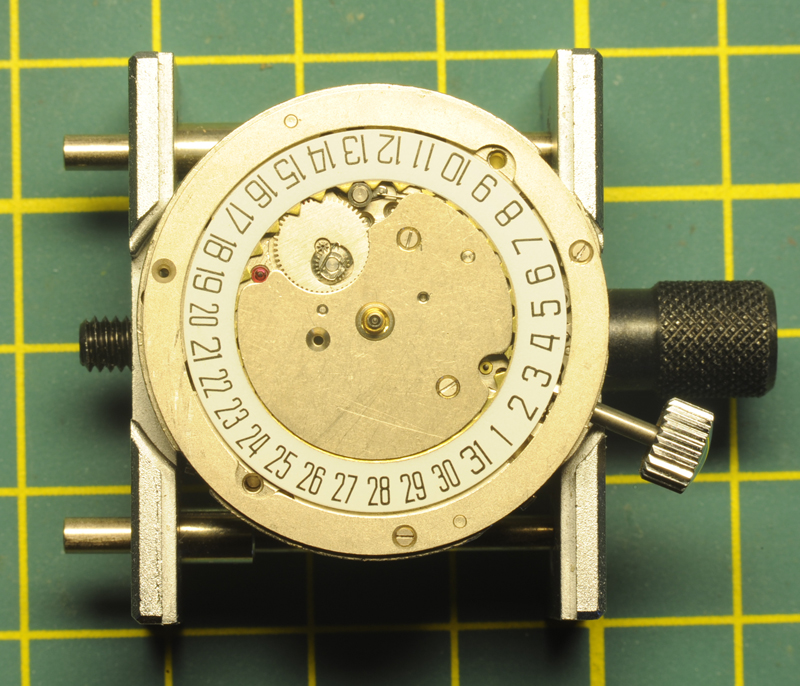

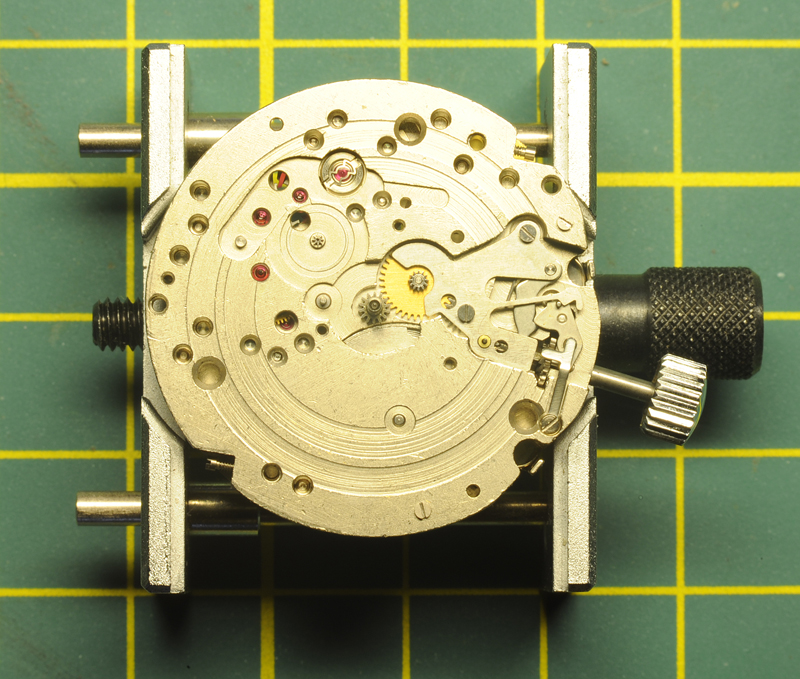

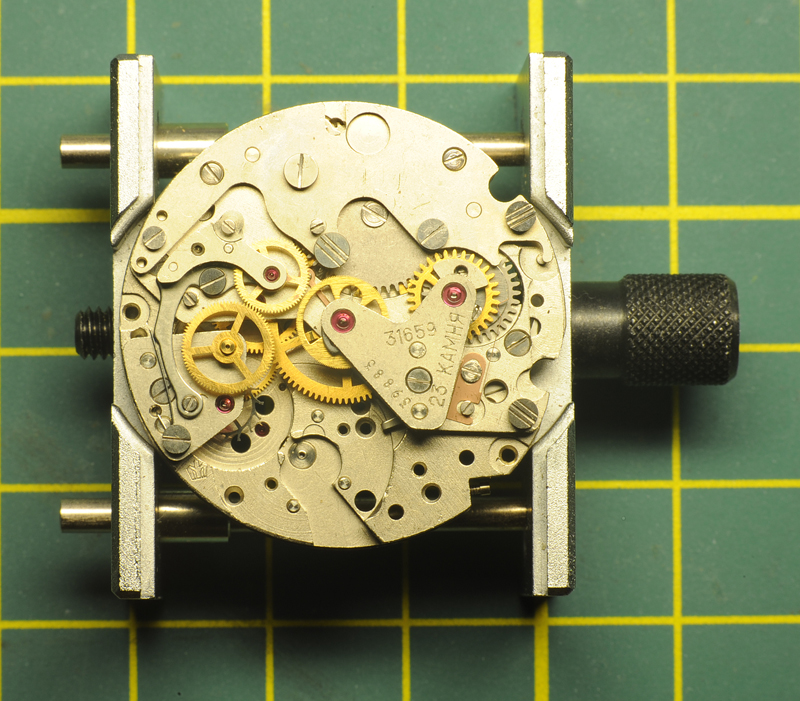

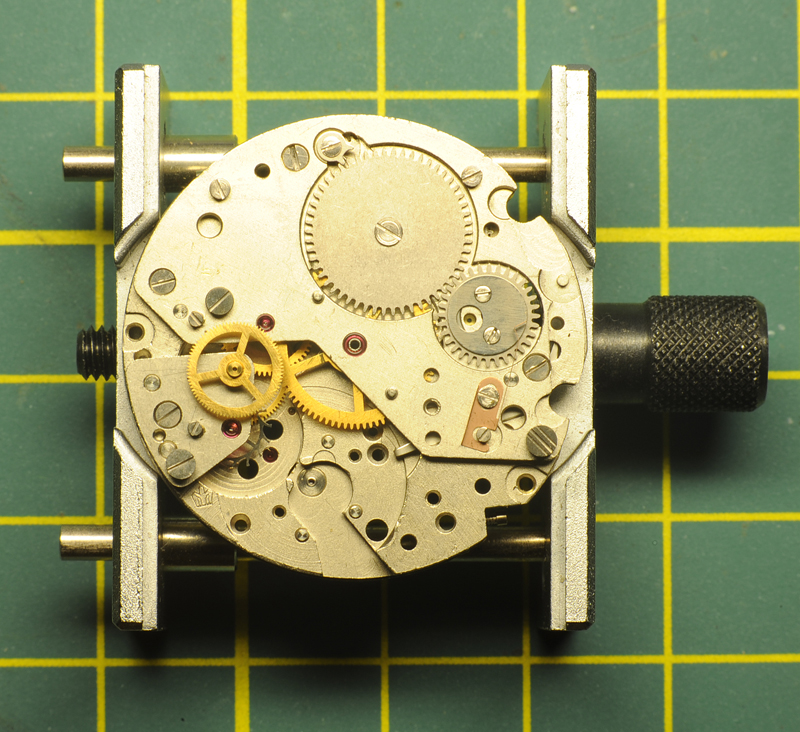

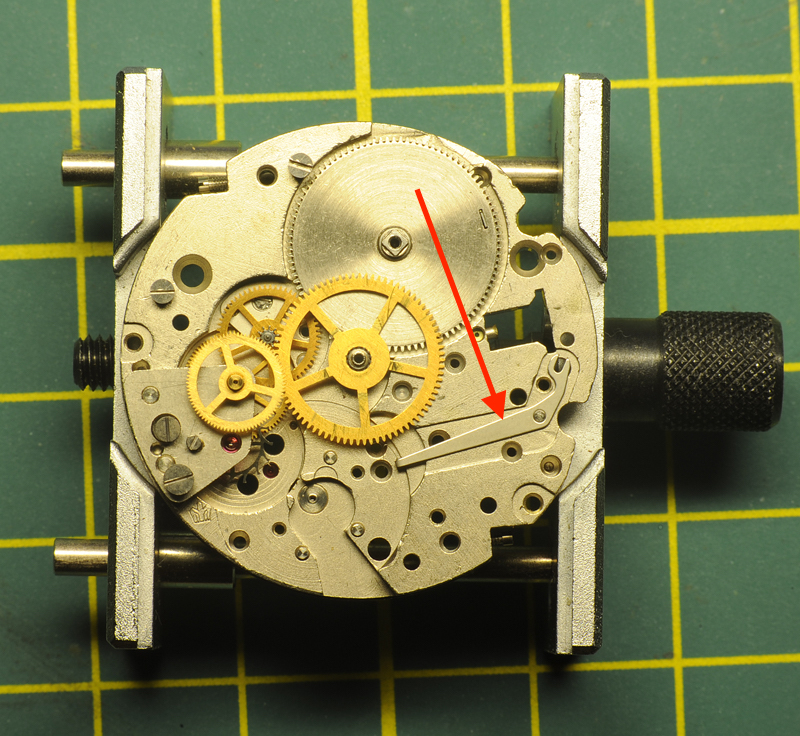

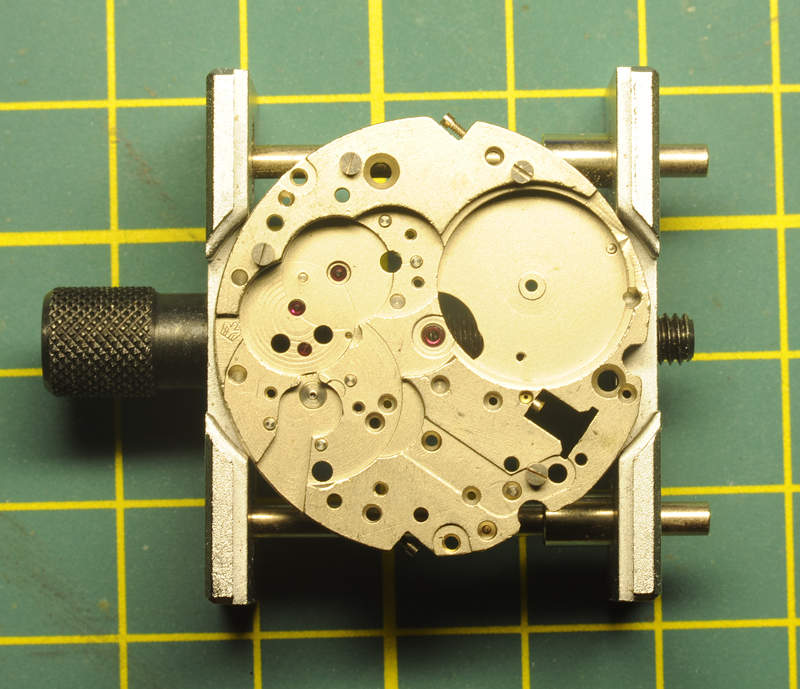

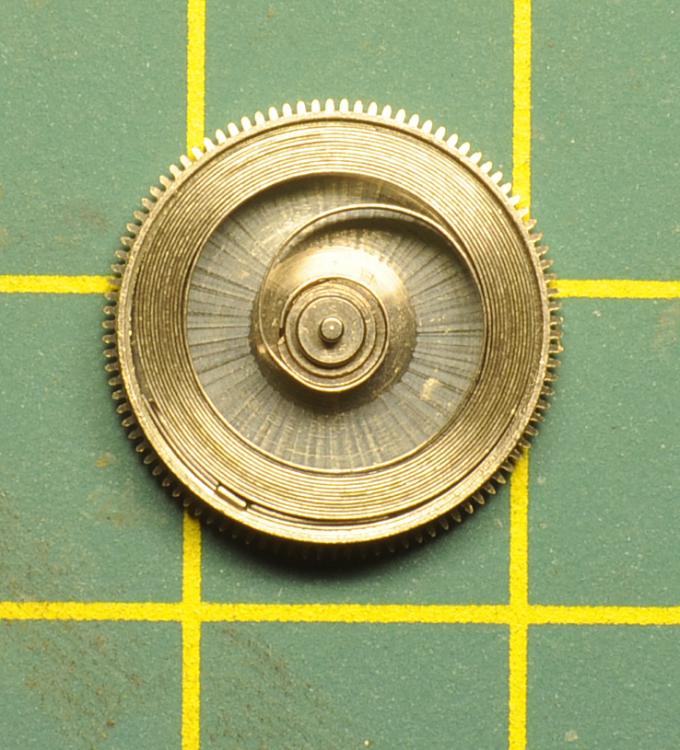

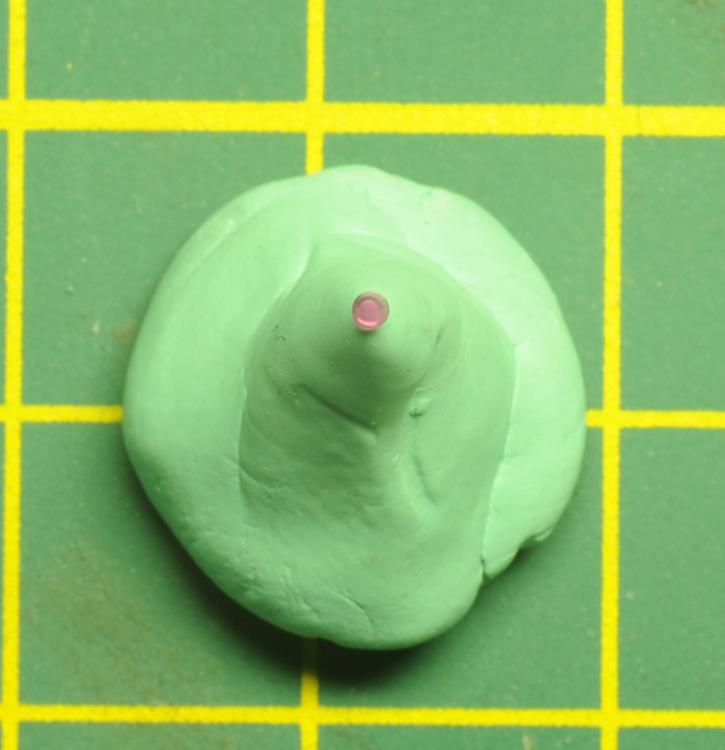

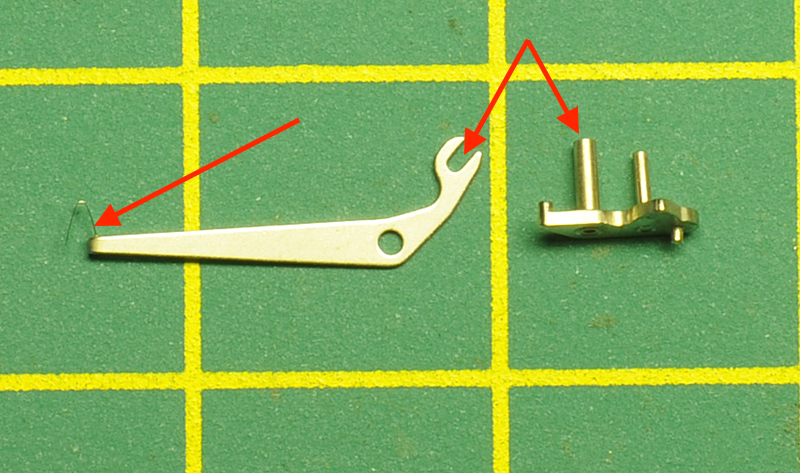

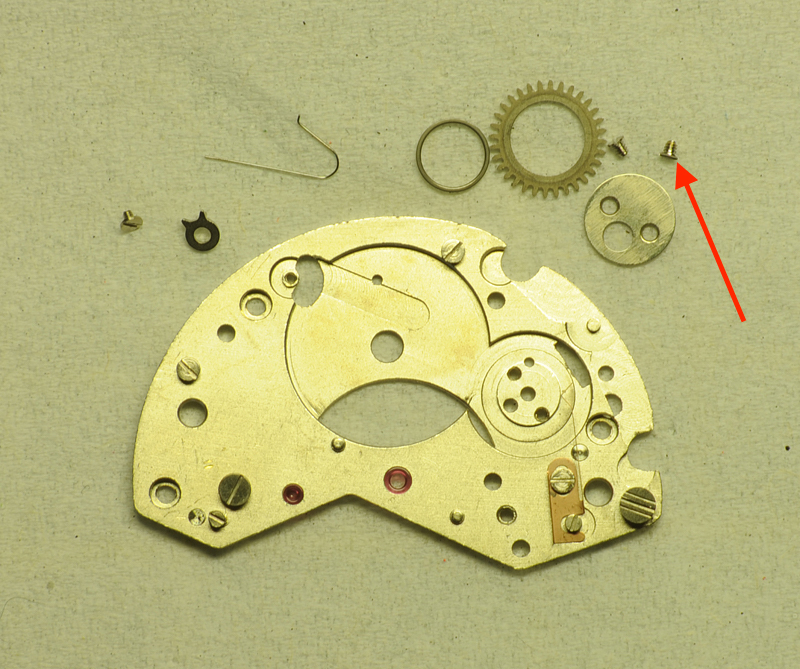

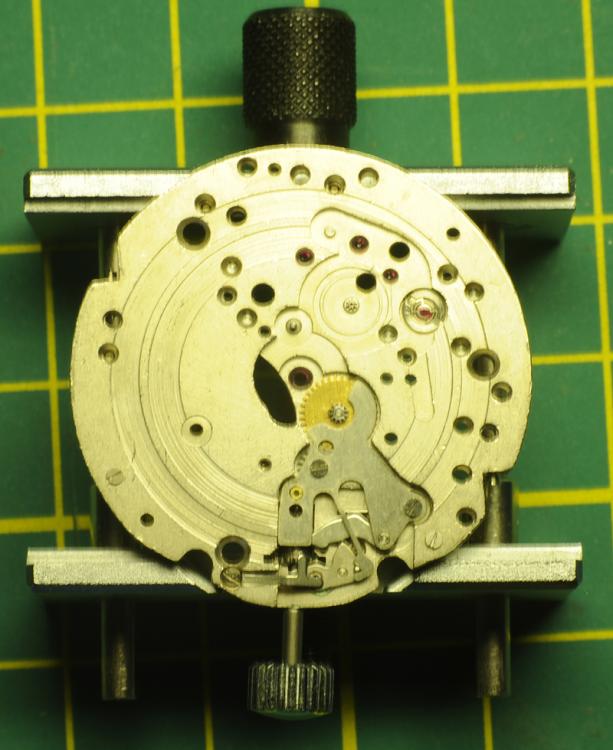

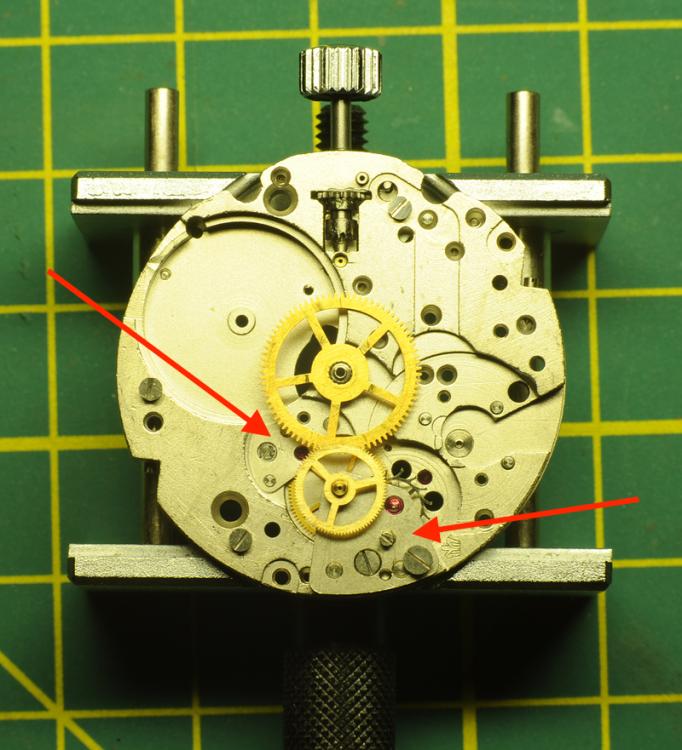

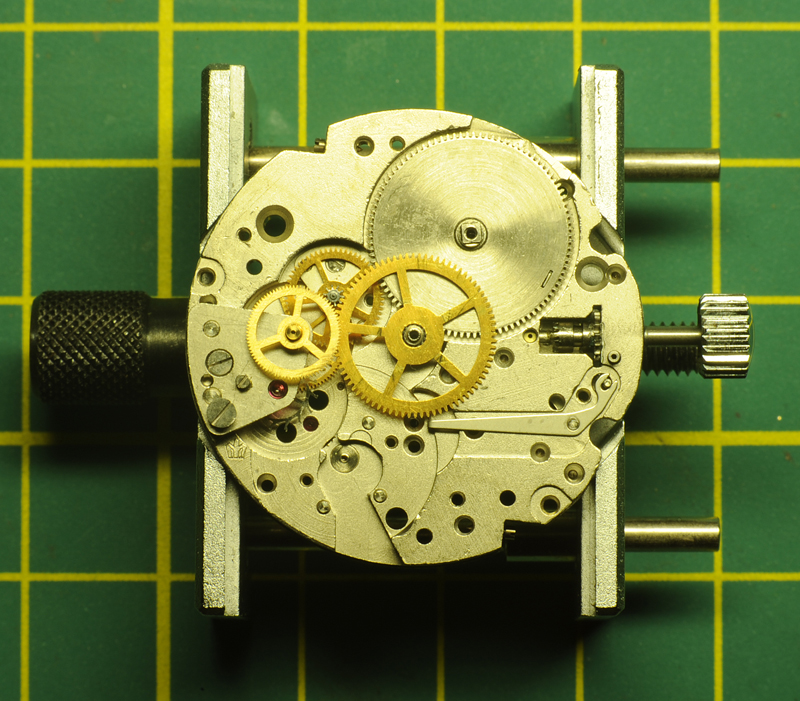

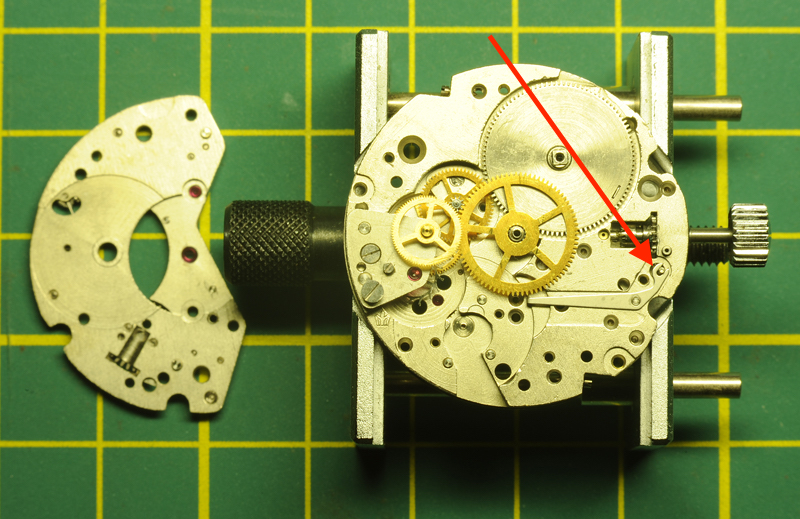

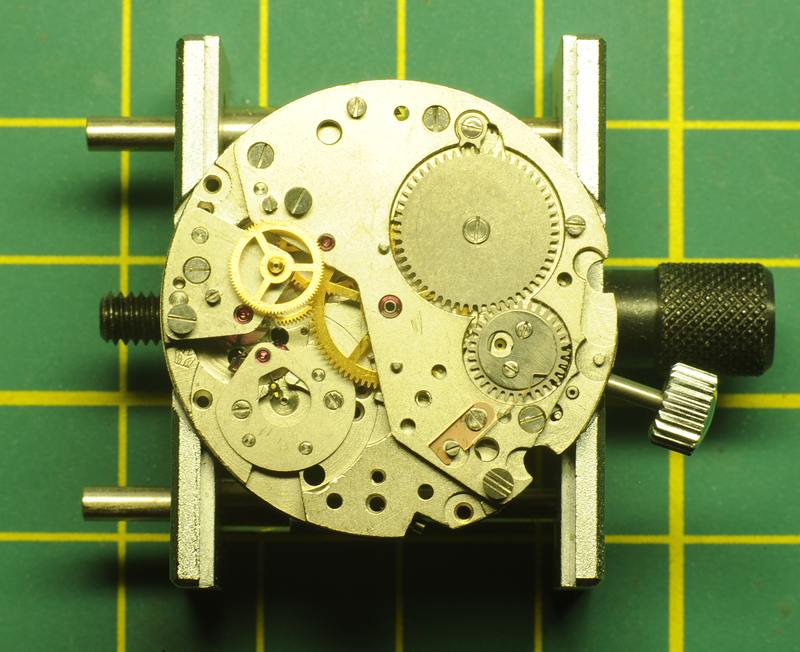

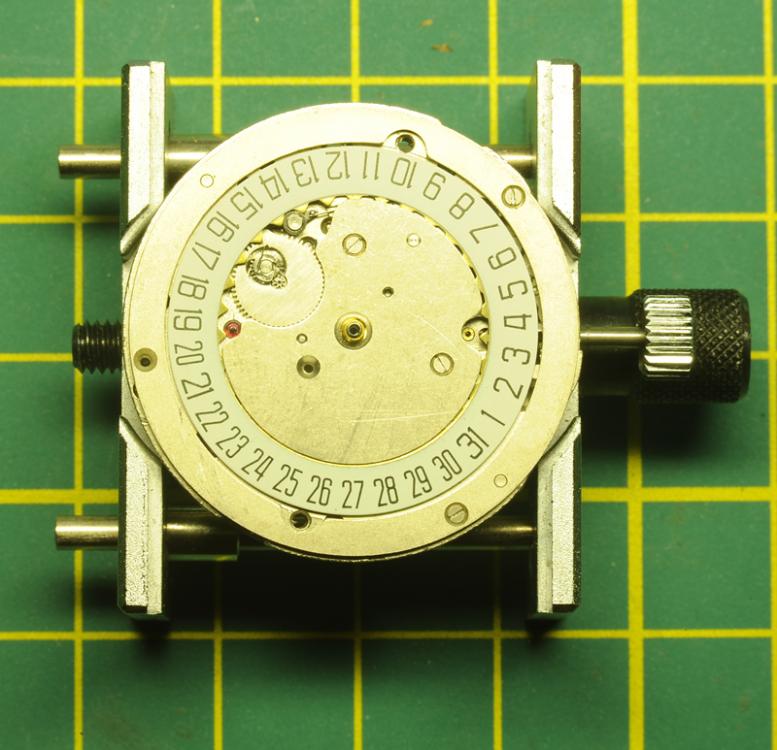

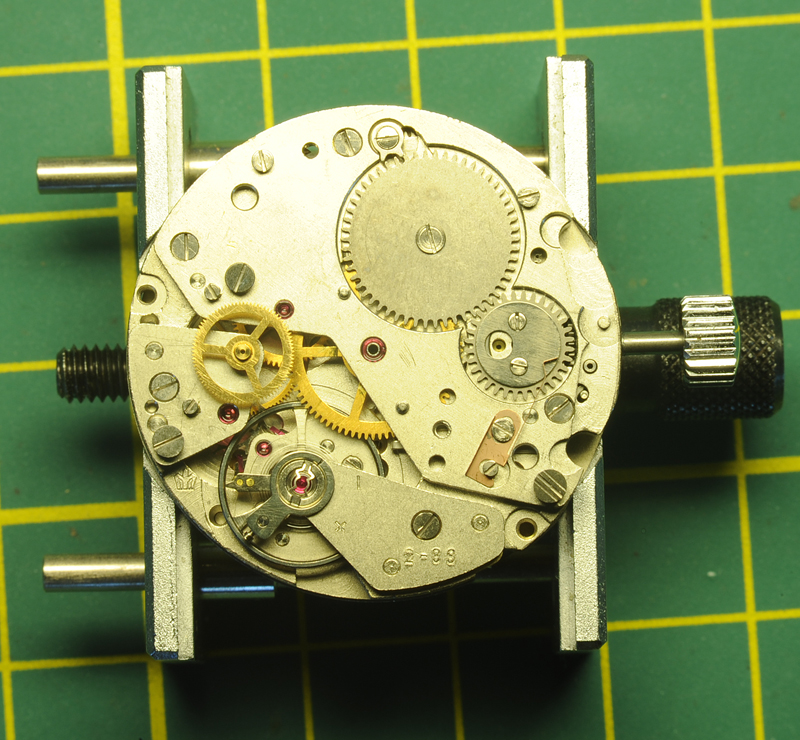

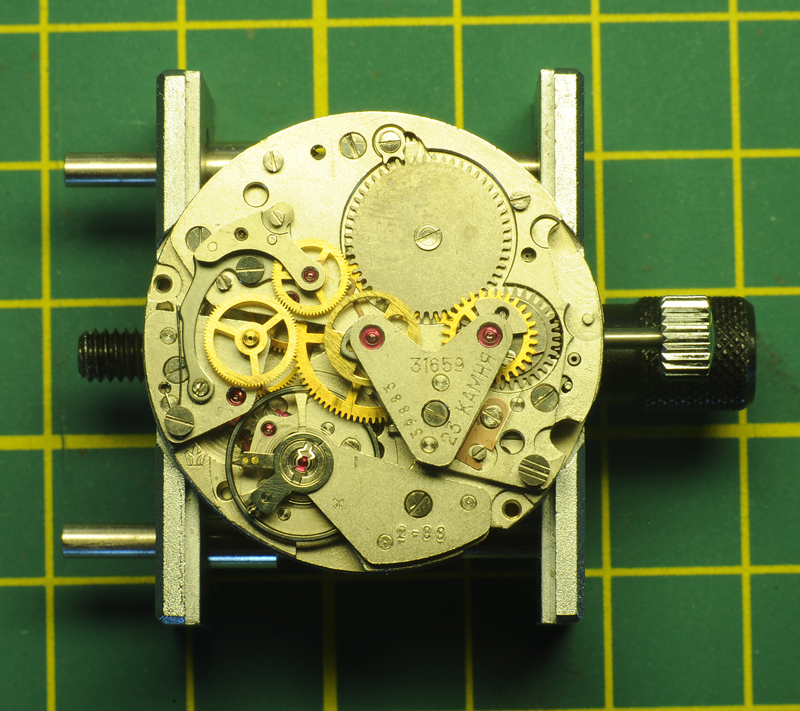

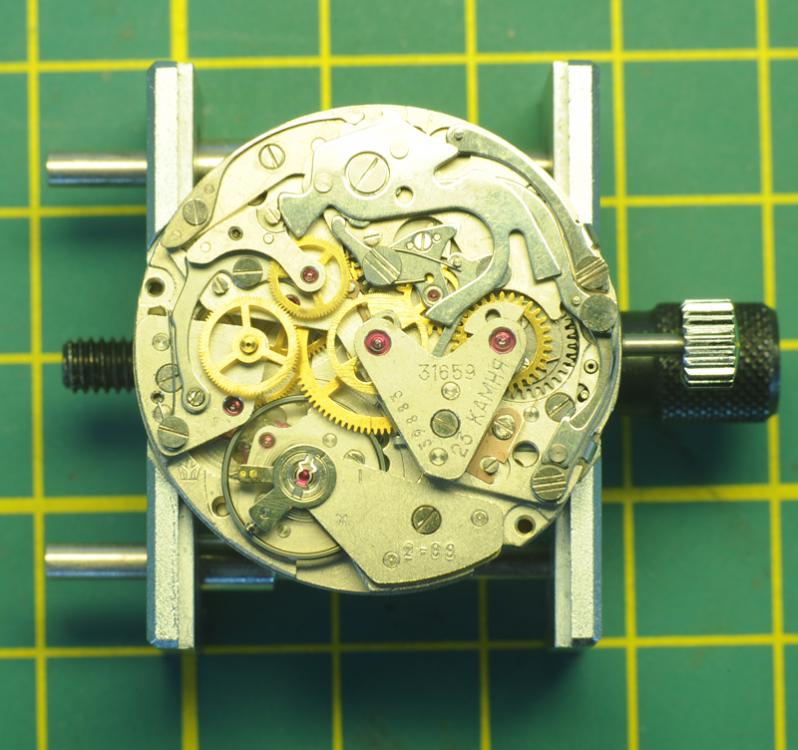

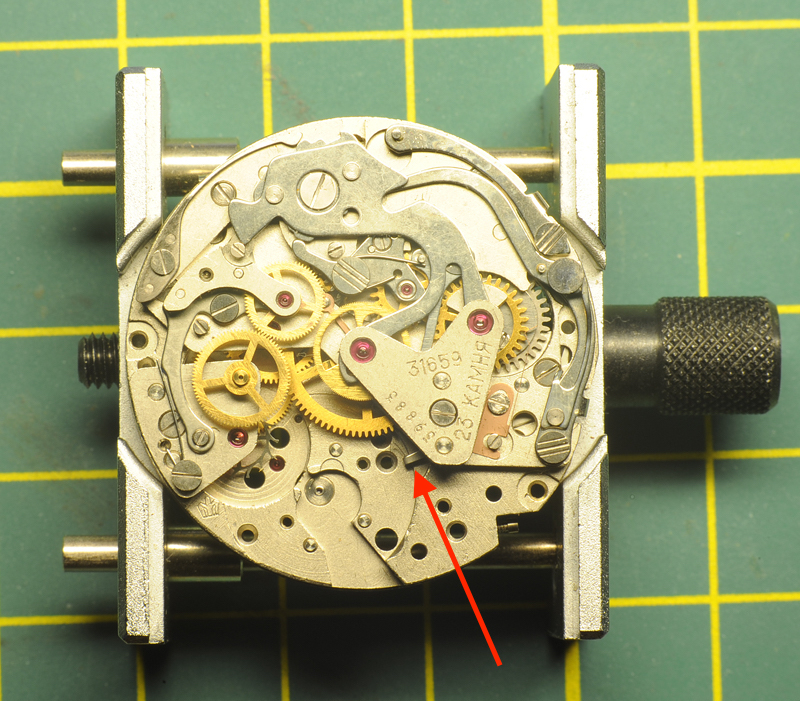

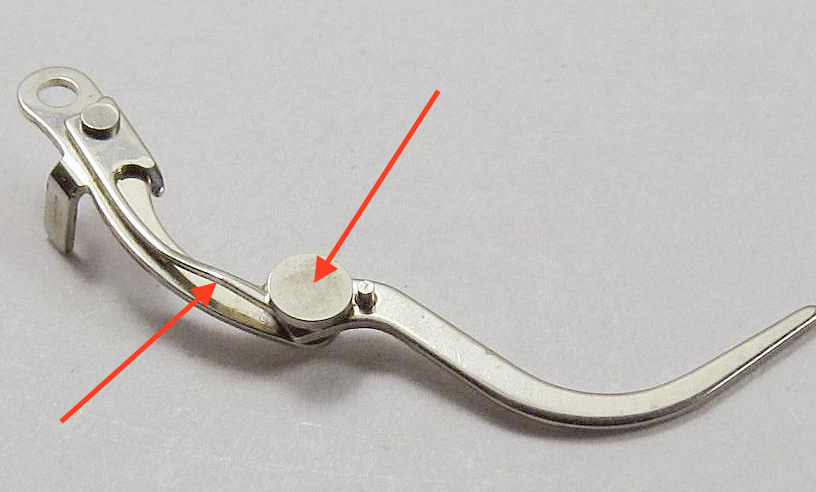

I bought from an ex. Poljot salesman, this undisturbed Shturmanskie "classic" with a Poljot 31659 movement. The Poljot 31659 movement is almost identical to the Poljot 3133 movement, but it has an additional balance-hack. The watch has never been used, never been worn, just sitting in a drawer waiting to see, after all those years, daylight again. Before it gets wrist-time, a service was overdue. The "pop-off" the back-lid was anything but "pop-off". The provided slot was of not much use and I ended up driving carefully a scalpel-knife in between the lid and the housing seam; slowly creating a gap big enough to insert a blunt knife. Even then, it took a huge force to get the lid to "pop-off". Needless to say, the nice, nearly virgin lid has now its first unavoidable marks. The light surface scratches on the lid are very minor, but appear more severe on the picture due to the light reflection. The Plexiglass crystal is scratch free, but has some minor aging-cracks. The inside reveals an undisturbed 31659 movement, with 2-88 stamped in the chronograph bridge. February 1988, that's to date exactly 29 years. I took the movement out, removed the hands and dial. This time the small seconds- and minute recording-hands came off unharmed. However I wasn't that lucky with the big chronograph seconds recording hand. It was so tight, that even with great care, in the end the hand stripped off its pipe-bushing With the hands and dial out of the way, I managed to get the pipe bushing of the pinion without any further damage. As you can see on the picture, The outer ring has one screw missing, so has the calendar center plate ....... I guess the factory worker in 1988 didn't feel like it that day!? Can we still find out ? Stripped the calendar works; Stripped the keyless works, flipped movement over and removed balance assembly and pallet fork. One can just see the hack appearing from underneath the barrel bridge; see arrow; Time to disassemble the chronograph components. Even though for a 31659 one has to deviate from the guide slightly during assembly, I can highly recommend this service guide made by WUS member SLLS on June 2015. Click on the link below to download. Thank you very much SLLS for you excellent and clear servicing guide Service Guide Poljot movement 3133.pdf Remember to re-insert all the screws in their respective holes after removing the component. A bit more work, but it makes life during re-assembling so much easier !! See service guide for part-numbers, additional pictures and guidance. First the Hammer (8220) followed by the hammer-cam-jumper (8356). Before removing the operating lever (8140), I lifted the spring on top of the rivet. This prevents the lever from popping out after the LH-screw is undone, but also makes the installment much easier. Obviously, the spring has to be put back after re-installation. Removal of the operating and fly-back lever-spring (8335), fly-back lever (8180), blocking lever (8200), Blocking lever spring (8335) and sliding gear (8100). Left is the chronograph plate (8281) with all screws inserted in their respective holes. Next the chronograph plate (8281), the Chronograph bridge (8500), the seconds recording wheel (8000), the friction-spring (8290) and the minute recording wheel (8020). According to the guide, the very delicate minute recording jumper (8270) is removed, but I left it in place. If you also leave it, be very aware during subsequent handling of the barrel-bridge !! Next is the coupling clutch spring (8320) and the coupling clutch (8080). This has stripped most of the chronograph components, apart from the chronograph drive wheel (or wheel over 4th wheel if you like); Next is the ratchet wheel (415) and the barrel-bridge (105). Now the hack-lever can be seen. The little spring at the end is very delicate ..... Next is the 3th wheel (210) which has to be carefully manipulated from underneath the center-wheel. This reveals a plate (no number) for the 3th wheel which has to be removed. Instead of pulling the chronograph drive wheel (wheel over 4th wheel), to reduce risk I removed the whole assembly; the train wheel bridge (110), 4th wheel (225) and driving wheel (8060). Be aware of the long pivot on the 4th wheel ! As soon as the train wheel bridge is undone, the escape wheel (705) comes free. Spring barrel, cannon-pinion and center wheel as last. Left is the bare main-plate. The main-spring seemed in a good shape; Time to clean all the parts and lubricate the balance cap-stone in the main-plate. I use Rodeco as a support. Once to small droplet of oil is on the cap-stone, I turn the Rodeco top-down and insert the cap-stone in the chaton. Works very well for me As far as I can see, next to an additional recess in the main-plate, the only difference between the 31659 and the 3133 are these two components. The setting lever has an additional post and the additional hacking-lever. To the left of the hacking-lever the tiny spring which pushes against the balance wheel when engaged. Next up the servicing of the barrel-bridge with click (425) & click-spring (430) and crown-wheel (420). The little screws holding the crown wheel core (423) are known for shearing off, so be careful if you decide to proceed with this step ... Now I had to deviate from the guide. Due to the fact that the hacking lever engages onto the additional setting lever post, I installed the keyless works first; Flipped the main-plate over and installed the center wheel, the complete 4th wheel assembly with escape wheel and 3rd wheel plate (left arrow). Before installing the 3rd wheel, it is now to lubricate the jewel of the 3rd wheel; Install 3rd wheel, barrel and hacking-lever; Make sure the hacking lever is engaged onto the additional setting lever post; Install barrel bridge, make sure 3rd wheel finds its jewel and ensure all the gears are running smoothly before tightening the screws. Lubricated pivot jewels and pallet stones. Install pallet fork & bridge, check correct working and install ratchet wheel. Thereafter I did the calendar works and check functionality. Now a little lesson I've learned: I left the keyless works in the time-setting mode. Later I couldn't get the balance wheel to seat properly ?? So, if you later, during assembling of the balance assembly, wonder why you can't get the balance wheel to seat, better is the retract the hacking lever by setting the keyless works in the winding position. That does help ! After some scratching my head (see above), the balance wheel was back in and the movement came alive Lubricated the balance-bridge cap-stone. No parts reference number mentioned for re-assembling; Replaced the coupling clutch, the coupling clutch spring, minute recording wheel, friction spring, seconds recording wheel and chronograph bridge; Re-installed the chronograph plate, sliding gear, blocking lever spring, blocking lever, fly-back lever, fly-back lever spring, operating lever (remember to put the spring on top of the lever back under the rivet after replacement !), hammer and hammer cam jumper ....... Tested and all chronograph functions are working fine. The initial amplitude is a bit low, around 270 degrees dial down (?), but I'll let it run for a while to see if that improves ..... I managed to get the chronograph seconds-recording-hand back on its pipe-bushing, but time will tell if that holds. Also closing the watch case will require a hand-press ...... not a simple "pop-on" ........ this phenomena has been reported by more people .... Hope that this Poljot 31659 movement walk-through is of any use? ....... else it will be a nice reference for myself That was enough adrenaline again Regards: Roland.1 point

-

it's great when you have the tools and knowledge to make your own tools. I struguled to make 3 simple discs...1 point

-

Great information and thanks for posting. I could not find those arbor diameter sizes anywhere so that is really useful. I had the same problem with no winder for Landeron 48 etc so just started to make one. Waiting for a 1mm carbide end mill to arrive from China to add the hook piece, and a M3 die to finish winding handle. The winder bit is going to be Nivarox style as this is what I saw to copy, but if that does not work the spoke type looks probably easier to make. Not sure if it is going to work, but cannot really see why it should not1 point

-

How about taking it to a qualified electrician and get him or her to check it over.1 point

-

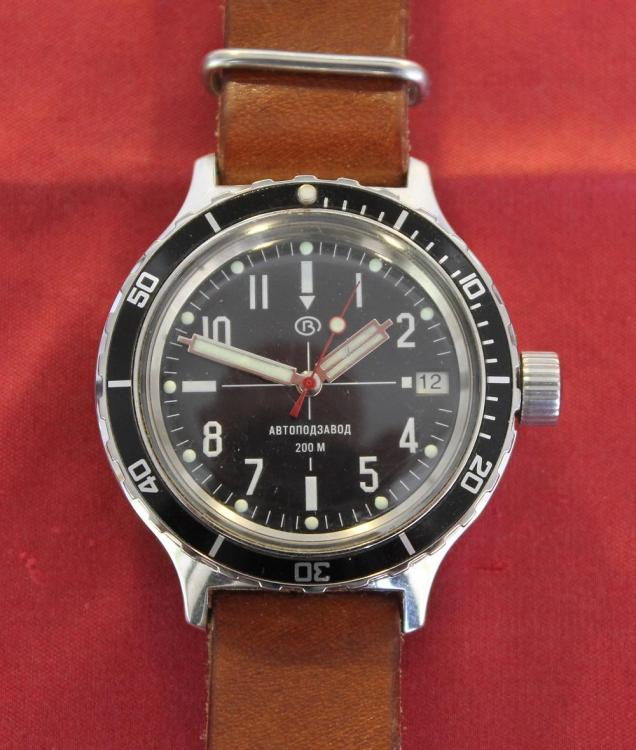

@VWatchie: it's to hope that more people on this forum will get bitten by the Russian watch "bug" ! For people who are interested in servicing the Poljot 3133 (31659) (the old Swiss Valjoux 7734); I did a walk-through a bit more then a year ago; https://www.watchrepairtalk.com/topic/6189-poljot-31659-chronograph-service/?tab=comments#comment-62446 So far, I also don't have much experience with other Russian watch-brands either. There are probably valid reasons why Poljot , Molnija and Vostok are well known brands. In the end of the day, Poljot & Molnija are ex-Swiss ...... Looking very much forward in seeing more (people with) Russian watches, talk about them, exchange (modification) ideas or chase the more rare examples...... even though I have "a few", I just can't get enough ...... I enjoy very much that you are one of Russian watch fans !1 point

-

Thanks for sharing your collection of Russian watches! I always get warm at heart seeing these watches! Yes, definitely the downside of these watches is that you get so many of them (as they are so affordable) that it's hard to choose which one to wear. I have very little experience with other watch brands, but I suspect that positional deviations are somewhat larger than on the finer Swiss and Japanese brands. However, in my experience, they are consistent and can, as you say, be regulated to within +/- a few seconds. Well, that link you shared about the Poljot cal. 3133 Chronograph was certainly very serious and very useful for anyone into these movements. I'm sure it will come very handy one day. Thanks!1 point

-

Read this from Mark. It will help you. https://www.watchrepairlessons.com/2011/06/28/poising-a-balance-and-positional-error/1 point

-

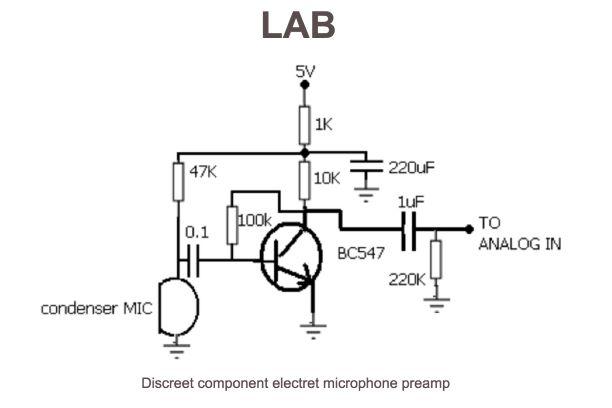

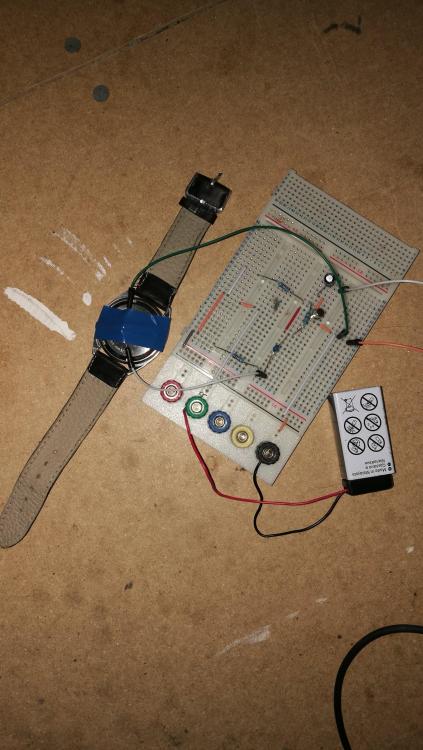

I decided to have a go at using a pre amp with the web cam mic because i'm really interested in getting this working. I used a basic circuit from google search and bread boarded it. output is from a seiko 5. Works but obviously it would be impossible to work on the watch. This setup does not work with the guitar mic pic up i bought so i'm going to try and build the watch o scope amp next and make a clamp. Thanks for all the input so far.1 point

-

Found some more in the drawer ..... and "finally"(?) an immaculate N.O.S. Molnija 3602 Serkisof "Rail road" pocket watch; The Molnija's do have an interesting background and the 3602 movement was used, among others, by Rolex. I sold off a more rare N.O.S. Molnija "Rail road watch" with a "shock-proof" 3603 movement; Here is some more information about Molnija: http://linuxfocus.org/~guido/molnija-pocket-watch/1 point

-

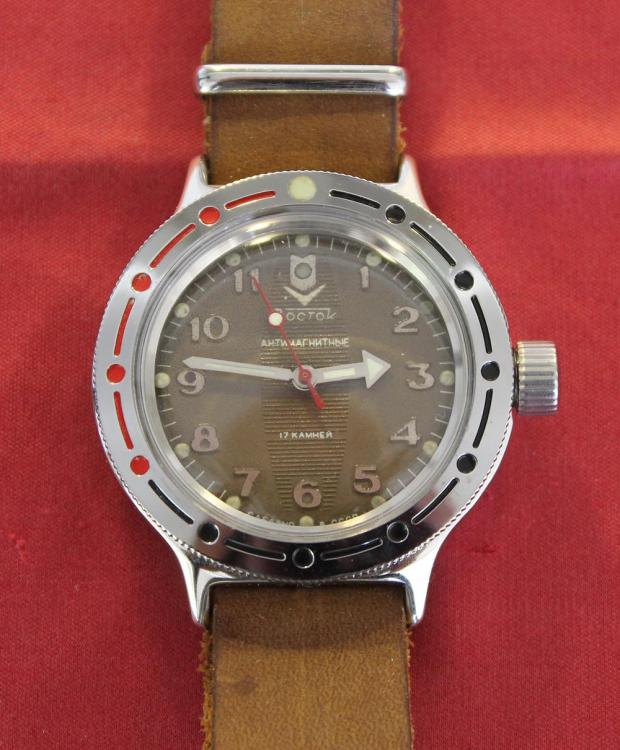

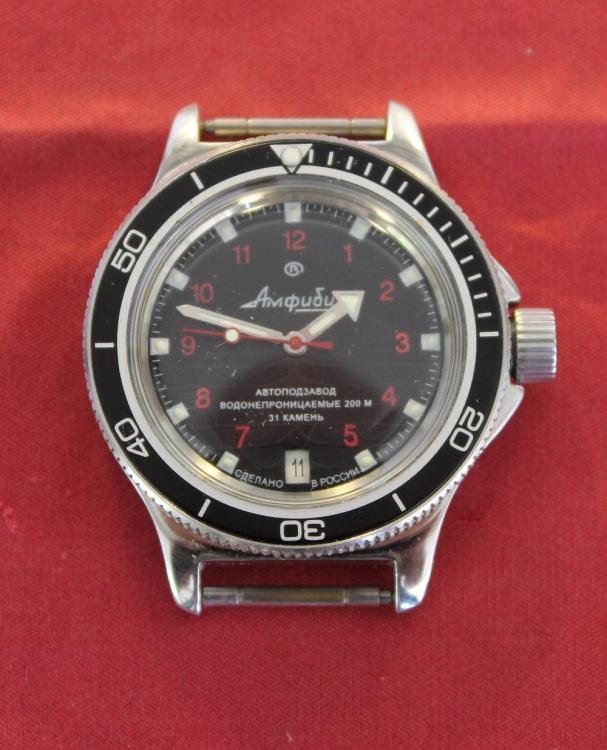

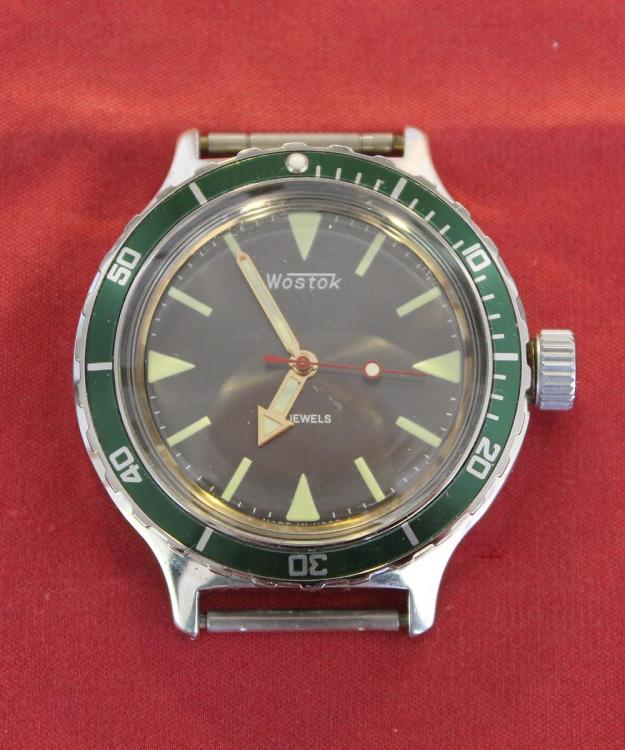

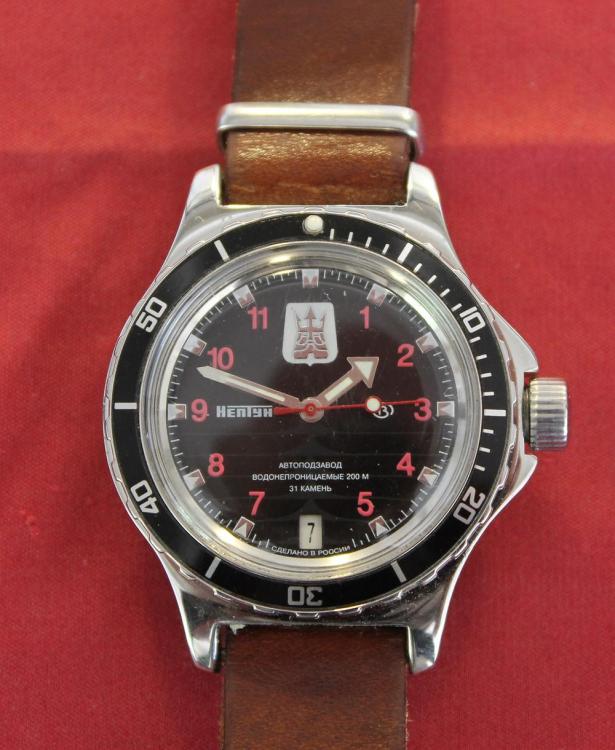

To add to the Russian watch fun, I opened the drawer (sorry not an Ikea ) and pulled my working Russian watches out. I do have more Russian "projects" (Vostok & Poljot) to assemble, but with already so many watches to choose from, these "projects" have to wait ...... Sorry for the poor picture quality, my Japanese camera did "funny" today ....... perhaps affected by the heat-wave? The Vostoks below do have various types of Vostok movements; 2209, 2409, 2415, 2416B The watch below has a well made, but fake dial ...... unfortunately even the Vostok (eBay) market gets flooded with fake dials, especially the "sought after" older (USSR-, CCCP & 3AKA3-dials. Vostok 2209 movement. Top twp dials are originals, bottom one is fake; Nearly original N.O.S. Poljot Sturmanskie 3133 (wrong chronograph seconds-hand, the original hand got damaged when I, after nearly 30 years, pulled it off for a watch service. I still have to find a way to repair the original hand pipe-bushing ) Original N.O.S.Poljot Sturmanskie 31659 but in a different new, original 1980's Poljot housing: As @VWatchie says, the Vostoks are AKA AK47 but can be a bit "off". However if you spend enough time in adjusting them (while wearing), they can run pretty accurate. Some of my watches run on the wrist within +2 sec / day........ better than my Rolex ! Be very aware of 3133 "Franken" Poljots !! There are many fake dials out there too ....... Here a link to educate yourself of what could be fake, but the list has grown a lot longer since ....... : http://www.polmax3133.com/guide.html Hope this forum will get some more Russian watch enthusiast ......... Hmmm ......... which one shall I wear today ??1 point

-

@oldhippy: I like your approach. We all, and all the new posters do their best. Of course, nobody is perfect and so now and then we need a gentle, moderate touch in the right direction. Still miss moderator Bobm12 (Bob) who, next to his know-how, brought also humor to the forum and made you feel "home". I've done a quite intensive search to find out what happened to him, but all trails (also on other forums he was a member of) go cold and (email) addresses are all suspended. Unless somebody knows better, it seems to me that he sadly is not among us anymore. He was/is of the same age as I'm, begin 60's. I wholeheartedly agree with @dadistic : "I think things will be just fine, and I certainly appreciate all the work that goes into maintaining this forum". @anilv: This forum needs people like you ....... lessons are now learned. Please reconsider ..... !!1 point

-

I’ll use lighter fluid, discard in a 1/2 cup of cat litter, then let it evaporate. My township tells me to add cat litter to discarded paint then set it out for pickup. Sent from my iPhone using Tapatalk1 point

-

I personally think it would be much better if there was more restraint shown about moving posts. Moving a newbies post is one thing, but for a long time user to have a post moved is annoying. Not even the courtesy of finding out the users intention, just wham. post moved. It's annoying, and I have enough trouble finding time to participate, and having to deal with these little irritations makes me less likely to make the effort. That's why I don't do posts that take a lot of effort, like walkthroughs, because I know they they won't stay unmolested, regardless of my intentions. This is a solvable problem. Either leave the posts alone, or provide a way that these posts can be built without having to do them in one swell foop. Using too narrow of a definition is not helpful, either. If you want a category of "make-overs" then please provide a place for them. Just be aware that if you go down that road, you will find that you have to move *every* post, and not just the obvious mistakes. People will inevitably gravitate toward the most general category, and pay less and less attention to the sub-forums. More work for the admins. Maybe that's OK, but notice that this forum software wasn't built to be operated that way, and some features will break. It happens now. David1 point

-

When you get to using it you have to make 110% sure you've cleaned the screw perfectly when going from one lap to the next. Otherwise you'll contaminate the lap and it will need to be resurfaced. Artist's gum eraser and old rodico do pretty well, finish with pithwood and a friendly solvent like isopropyl alcohol. It's tedious but less tedious than redoing the lap.1 point