Leaderboard

Popular Content

Showing content with the highest reputation on 04/30/18 in all areas

-

I used the Bergeon 5430 leaver for Hairsprings to remove hands and the Horotec 05.009 for removing subdial hands. I find the Horotec ones are also useful in removing the pesky C clip used on Seikos to hold the day wheel in place too You could probably get away as rogart63 says buying the cheaper ones and tweaking them as long as they are made of good steel they will be fine, though looking at Cousins they are out of stock of the generic ones until June. You will find in some cases you do need to buy the expensive tools as the cheaper ones just won't cut it, but as long as you are willing to do a bit of polishing and adjusting the cheaper hand removing leavers will do.2 points

-

That holder would work fine.. From 19,5 mm to 42 mm . Have two and they have served me well for years.1 point

-

1 point

-

1 point

-

I use a pencil roll like this for many of my tools. Easy to roll up and put away when done. During use it lays out at the top of my worktable, makes grabbing a screwdriver, hand levers, pin vise etc. very easy. Best of all, not expensive. This one is Derwent.1 point

-

1 point

-

OK, so I ordered an automatic mainspring from Cousins. The spring ended up being of a different size than the ones you (rogart63) used in your Tissot. The spring was also broken into a few pieces. I guess that's why it looked so strange to me.1 point

-

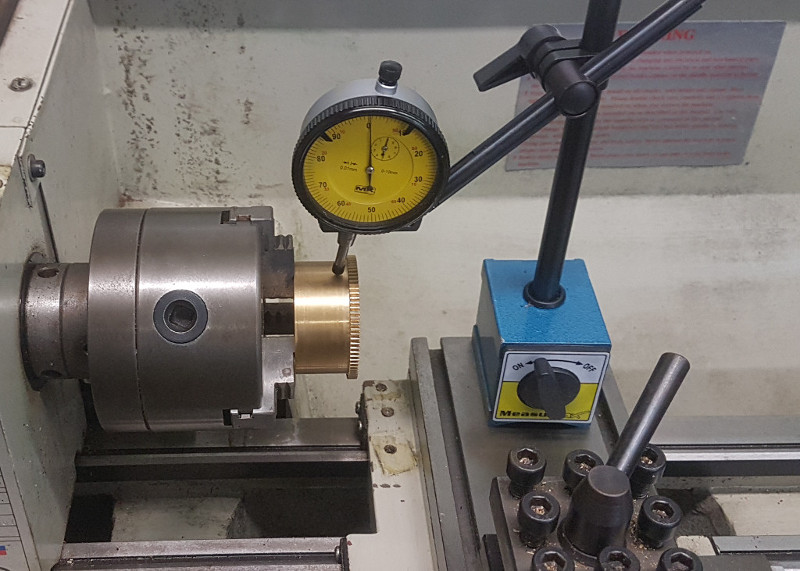

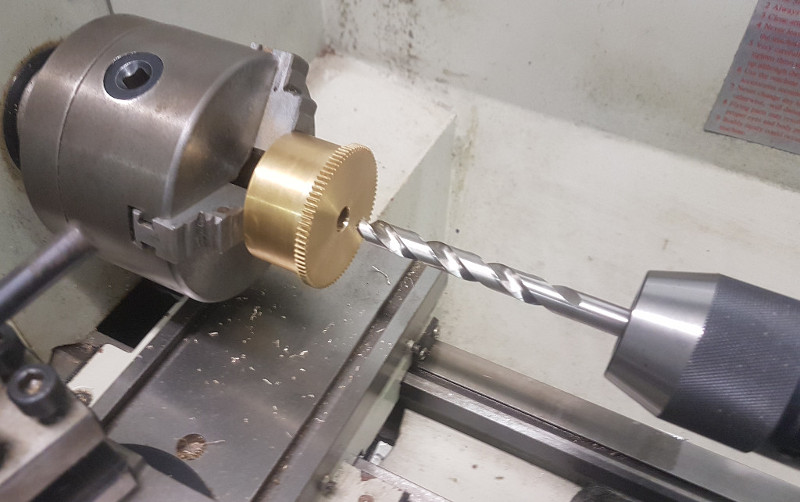

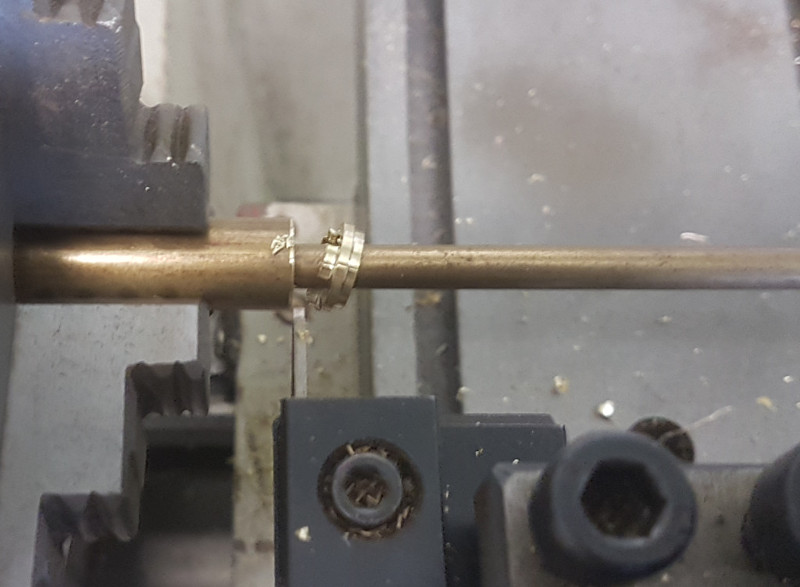

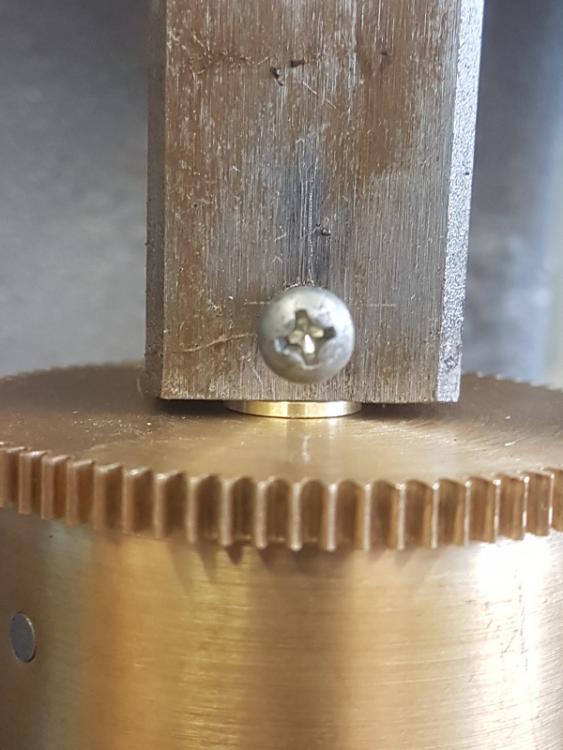

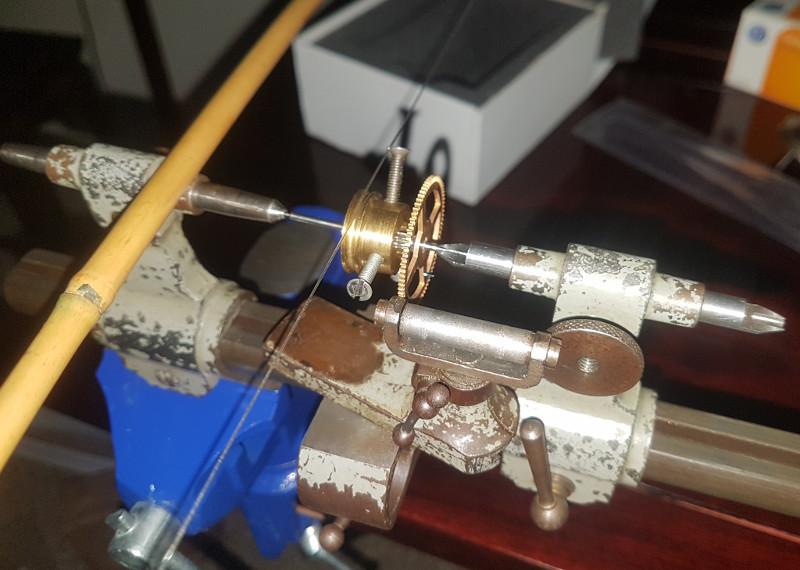

The clock is now ticking and chiming, just need to finish regulating it. I won't go through everything I did, but just show what I think are the more interesting things. Firstly the Chiming barrel arbor hole had worn oval and need bushing. First the barrel was set up on my large lathe and centered using a dial test indicator It was then drilled out to 10mm and the hole was measured to ensure it was exact A brass clock bush tube was selected that was 11.4mm outside diameter and 8mm inside diameter. The thickness of the base of the barrel was measured and the height of the lip of the bush was machined 0.2mm taller than the thickness of the base of the barrel and the diameter was machined down to 10.05 to be a friction fit inside the barrel. A 1mm lip was left to sit on the outside of the barrel as this would not impact end shake and gave added strength. The bush was then transferred to the watchmakers lathe to clean up and add a leading edge chamfer to make it easier to fit. Finally it was pressed into the barrel using an arbour press. Once the mainspring arbor had been polished the bush was then broached to size using clockmakers broaches. I needed to polish a number of pivots that were all 0.8mm in diameter. I know some people can just hold the wheel in a pin vice and using a pivot file and a block of wood polish the pivot, but I'm not that good. I got some bar stock that fitted the tailstock on my watchmakers lathe and drilled it 0.8mm. I then turned a taper to the end and transferred it to my mill and milled just over half way through the bar so just slightly less than half of the 0.8mm hole was left. I then set up my watchmakers lathe as a turns and using a pulley that I had made previously which has 3 screws 120 degrees apart screwed it onto the arbor and using a bamboo rod and finishing line made my bow so I could use my lathe as an oversized jacot tool. The pivot was filed with a pivot file, finished with a triangle Arkansas stone and burnished with a pivot bunisher. Hope this is of interest to some people.1 point

-

Also an auto mechanic... Once I tried to get my screwdrivers organized by handle color to tip: i.e. the Phillips tips were green and straight tips were red. That didn't last long, as some specialized tips were only available with certain handles (usually black) etc. Seemed like a good idea. Now I have every color in the catalogue mixed in the drawer... For wood working I organize my drill bits and router bits on wood blocks. No reason that wouldn't work with precision screwdrivers too...1 point

-

1 point

-

as an auto mechanic, with a degree of "color blindness", organizing tools is very important. those color coded screwdrivers stands are no good. I too would like to design ( or find) a good stand. make a " prototype out of card board" - build it out of wood. vin1 point

-

1 point

-

A collection is when you have some, but keep thinking about the next one you are going to get1 point

-

1 point

-

1 point

-

These m/springs are no to be replaced. You are supposed to replace it with a new unit. The trouble is these days many parts have become obsolete. So you need to open it. Turn it over and tap the arbor with a small mallet so it does not damage the arbor and see if the cap comes off.1 point

-

1 point

-

Very well done indeed Douglas, and thank you for a great description of your journey. I too am sixty six, but did not have the dedication to complete a full course on horology, may path was very much a self taught one with help from folk on this forum, and Mark Lovic in particular. I wish you all the very best for your future life in horology, and look forward to reading your posts in the future.1 point

-

Out for a test drive... Just finished putting this one together... The movement is a dual train design. Basically, it's two movements on one plate.. The left side train just runs the left balance wheel while the right side side balance and the motion work. If any one is curious, the extra function of the motion work does reduce power to the balance wheel. The left balance wheel has an amplitude of approximately 310 degrees while the right balance will has an amplitude of approximately 285 degrees. For some reason I was not equating this difference to the motion work and thought there was an additional problem. I spent a good amount of time looking for the cause and after switching all the components from left to right I got the same result, lower amplitude on the right side with the addition of powering the motion work as opposed to the left side that just had to transmit power to the balance wheel..1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)

.thumb.jpg.ec35868a5f7aba73ac3056123ab44a9a.jpg)

.thumb.jpg.6f3f182c797ed6c7cc62fd39cce8e528.jpg)