Leaderboard

Popular Content

Showing content with the highest reputation on 04/12/18 in all areas

-

A safer route would be a small pin vice, less chance of damaging the screw...4 points

-

OK. This is the sort of thing that I might get into. I'm happy to help if I can when you get stuck. With regards to the movement, here's the easy answer: Log in and join RolexForums.com and check the for sale section. Recently a member there had (several) NOS 3135 movements for (if memory serves) $2000.00 each. That's a good price and it will have that off your plate. Yes, it's two grand, but you can easily amass that in replacement parts, assuming you don't cause collateral damage during tear-down or re-assembly... And, the upside is that the swamped movement can be retained for you to learn and work on at your leisure. I noticed a question regarding refinishing the dial. I would avoid this. These Yacht-Masters have a platinum plated textured dial. I encourage you to make friends with your local dealer's watchmaker (if they even have one on staff) and arrange a service dial from Rolex. This is ONLY done on an exchange basis, and must go through an authorized retailer. You may be able to get one through the selling members on RolexForums too- I do see loose dials there often so it is possible. I don't know if the exchange will be less than a purchase through the forum, but you should avoid refinishing because it's not a simple job (and therefore will be expensive). DO NOT buy this dial on eBay unless it is sealed in a Rolex blister pack. Fakes abound... You will need a new set of hands too. And the bezel assembly (I think the insert is Platinum as well so sit down before requesting the quote) Case restoration- you need gaskets at the very least, crystal obviously (these are easy to get) and a crown tube tool. CasKer has the tools (decent quality) for not a ton of money. The tube needs to come out, have all threads inspected/cleaned, new O-rings installed and the tube re-installed with low strength locktite (purple). Maybe you should consider new tube and crown (I would). That's a 703 crown and tube. Those can be found on eBay for a few hundred bucks pretty easily. Again, make sure they are sealed in their blister unless you are VERY sure of the seller and the part you are buying. Maybe the case needs a buff. There is no easier way to destroy a Rolex case than to take it to the buffing wheel. THIS is an absolute art, and should be left alone. Get a Sunshine cloth for the polished sides and be happy with that. Seriously. If it's really ugly, send it to a pro. Maybe ABC watchworks out west- someone who specializes in vintage stuff. They will preserve the case shape where even the local Rolex repair center may not. I do my own, but I know my limitations and those were learned the hard way... But the case needs to be absolutely clean. Tear it completely down (you will probably need the bezel removal tool in addition to the case back tool shown above) and reduce it to all it's parts. Remove all traces of old o-ring that may be present. I like Acetone for this- it may need to soak a while. All oil, dirt, old o-ring etc. must be gone. Then, assuming it is polished to your satisfaction, the reassembly process can begin. Also mentioned above (I do this exact same thing) take a picture of EVERY disassembly step as you go. That goes for the case as well as the movement. Something you were not focused on during disassembly may become critical for reassembly. This is really easy now with phones.2 points

-

Thank you all for the warm welcome! I have successfully completed two restorations so far, and a few others in the works. 1) Rolex 1680. I got this from an online retailer at a reasonable price based on condition and the serial number- it MIGHT have been a "red" sub when sold new. It had a nice service dial, updated crown, wrong crystal etc. I changed the crystal first, since that's the iconic look of the 1680 "top hat" crystal. Then I had the case restored by Michael Young. Then a new bezel ring was added, with a period correct insert. The insert was missing the "pearl" so I installed an NOS Tritium pearl. An NOS 702 crown and tube complete the mechanicals. A correct for the serial range "Mark I" white dial was sourced and installed. (Mark VI red dials are very rare and cost more than I have into this entire project, but the print and color are very crisp and vibrant) I also changed the service (white) date wheel to a correct silver one. The bracelet is also a bit of a "unicorn". Rolex guys know the bracelets all have date codes, and you want your clasp code to reflect the date of the watch head. Except, there was one bracelet without a date code... The very first use of the 93150 bracelet did not have a date code on it. Michael Young also resurrected my bracelet parts collected over several years to put the early 93150 links with the no-date early 93150 clasp I had. Now it represents all period correct. I'm quite proud of the effort and research to make this watch "right" again. 2) Tudor 9411/0 black (my avatar photo). This was an eBay "score". I took a big risk on it due to poor photos, and it paid off in spades (I bought it well under the market price at the time). This watch appears to have been serviced one time since 1978, if that. It still had the original crystal and original crown installed. (I saved those for posterity) I installed an NOS crystal and crown, leaving the original tube. Cleaned the case (which was NASTY- bezel did not rotate at all!) and replaced the gaskets. Installed a much newer 93150 that was a take-off (not a service bracelet) that was/is really mint. One of my favorite watches for sure. My current projects include another 9411/0, but with a coveted blue dial. It's currently assembled with an aftermarket case I shaped a bit better than as it was received. The bezel insert is also aftermarket, but I did an overlay comparison with the genuine one I have, and it is so close (color, font everything!) I never bothered to switch them. Movement is a Tudor movement (not just a regular Eta 2784) and the dial is an original, first issue blue dial. These blue dials all suffered from "dial rot" and 99% of them got replaced either as a warranty claim, or at the first service of the watch. So, they are VERY hard to find in good condition- large chunks of the blue paint will fall off them. I found one in Italy as I recall, and it is rotted, but fully intact. Hour hand is genuine and I have a genuine seconds had as well for it. But, the seconds hand did not fit the pinion- it needs to be broached. I don't understand this but that's why I currently have an aftermarket seconds hand. Normally not a big deal but due to the extreme fragility of these dials, it is major anxiety for me whenever I need to pry hands off. A hand holder and broach set is on my shopping list... The real excitement is that I just received an original case for this watch. A 1976 9411/0 case in VERY good condition. Some crevice corrosion on the back and top (which helps confirm it's genuine in the Rolex case minefield). I will install an NOS crystal 702 crown and tube and then continue my hunt for a genuine bezel assembly. I have another NOS pearl to add to the original insert, so that's covered. It currently wears a Navy blue Isofrane strap, which is quite nice, but I'd like to find 9315 folded link bracelets for this, and the black, Snowflakes (with those correct date codes!) to really call them "done". The last project that has taken me literally years to collect parts for should have been the easiest. An Omega Seamaster 300 (166.024). When I started it, Ofrei had all the parts, including complete cases. Then the case price rose sharply, and finally, no more stock. I procrastinated too long, focusing on my Rolex projects. But I have everything but a case tube in stock now. The mid-case is aftermarket, but everything else (down to the movement clamps!) are Genuine Omega parts. The old 565 movement runs strong and it's fun to have a movement that is not just like every other movement- the quick-set date operates by pulling the crown in and out). This has a new production dial, hands and bezel, so it has very bright Superluminova. You really get the experience of how bright these things were when new back in the late 60's. Some may argue it's faster and easier to save some money up and then hunt down the best example of the watch you want. But you know what? I enjoy the process of hunting down the right parts, at fair prices, and putting things "right" on otherwise neglected watches. I hope to expand into other Rolex and Omega watches, to then offer them for sale. I prefer that path to repairing or restoring customer's watches as I can do my job in my time; and only when I'm ready to, will it be offered for sale. Thanks for reading my life story!2 points

-

Ok. This has gone far enough. We are all here to help each other. I fear this thread is not going in the direction the OP intended and as the issue is pretty much resolved I will close the thread. To the OP: if the issue is not resolved and you wish me to reopen the thread then Please PM me and I will do so. Anybody who does not wish to be involved in any threads can easily unsubscribe from notifications at the top of the page. I think we all need a beer and chill Sent from my SM-G950F using Tapatalk2 points

-

I don't think there can be too much debate as to whether aesthetics is as vital as functionality in watch repair, but when carrying out a service for someone else, obviously it would seem advisable that both constraints are met. I have a small, 7-jewel Swiss-lever pocket watch (around 1880) that I'm servicing for a friend, which presents no problems at all; however, I find that my cleaning machine (I am an amateur, having gained the majority of my experience from books and forums such as this one, though I have indulged in more professional equipment at times) and associated fluids and rinses don't remove oxidation on brass components - in this case, the wheel train, barrel, balance etc. - but rather just removes residual grease, oil and dirt. Assuming that there isn't an issue with the fluids I'm using, or my machine (all of which are L&R), does this mean I need to clean the train wheels with a brass cleaner/some other polishing compound or product to restore their lustre? I tried something with a scrap movement (similar age to above) which I imagine is likely to be met with some gasps of horror, but I'll talk through it regardless... Having dismantled the movement, and just prior to cleaning, I took a benzine jar full of benzine (left over from the days before I bought my cleaning machine) and dropped a brass train wheel into it. Once it had shed most of the visible oil and dirt, I used a dust blower to dry it, and placed the wheel on a block of clean, scrap hardwood with a small hole drilled into it (one pivot being placed into the hole so that the wheel was lying flat). From here, I applied a small amount of Brasso to the wheel, holding it still with pegwood, and used a leather buff stick to polish it to a high shine, before repeating on the other side. Brasso is abrasive and produces a black residue when used (any that isn't washed off will also turn white and dry hard), so to remove this I dropped it again into a jar of benzine, and used sharpened pegwood to clean the teeth and leaves. At this point, the wheel is gleaming and I'm fairly happy with the results. I burnish the pivots using a jacot tool, run all components though my cleaning machine, and finally oil and reassemble the movement. All seems to be good with the polished wheel as far as I can tell, but I wanted to ask whether there is any better method, or whether the method I employed could yield adverse results when I do the same with the pocket watch mentioned above?1 point

-

I've never seen one, but standard O-rings are identified by inner diameter and cross section. There are certain parameters for O-rings as well. I have an old print copy, but I think it's online too: Parker O-ring handbook. Just finding one that "fits" is only part of the issue. The other it that it actually seals for you. Check out that book and learn more than you ever wanted to know about O-rings... (you can probably identify the one you need from that book as well)1 point

-

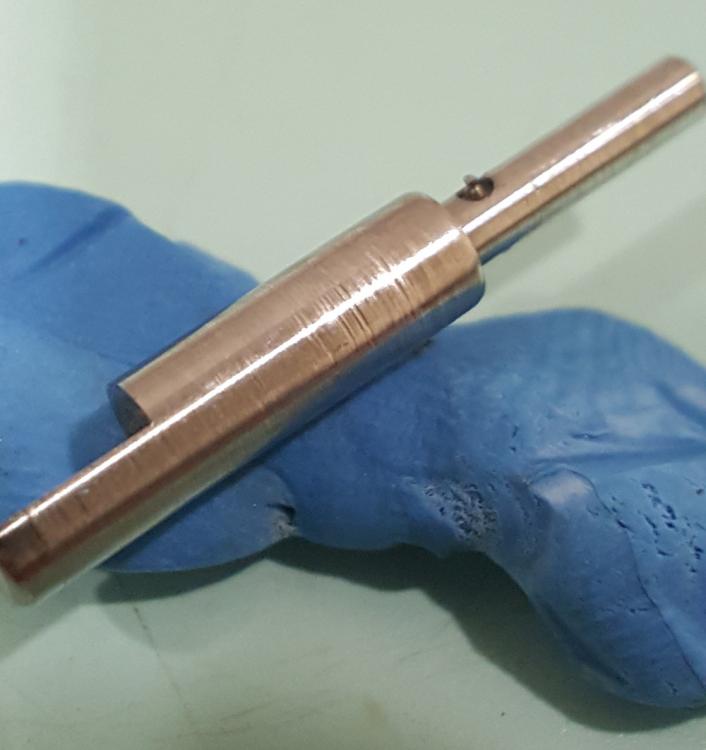

One of the problems with the timing machine software discussion is how many pages have accumulated. So interesting ideas or pictures have been shown such as the two pages below. So I'm extracting out some of the keys stuff. So the clip on microphone is relatively simple to make As you can see from the images below. There's more to it than just a disk attached to the alligator clip. Also attached images of their watch pickup. On one of the pages below there is also the Microset version of the watch pickup. Basically the same concept protruding pin to transmit the vibrations the disc. So the disc itself is protected by being a box and isolated from audio sounds. It's why I think of the TimeTrax version they put the hot glue across the desk to minimize sound pickup as a guess. Strangely enough the Microset version just has a disk. So better than the disc would be the Piezo Bi-Morph Vibration Element Found at the link below. Then if we can figure out a design 3-D printers would allow complex designs to be made cheaply. His 3-D printers are more common on people's kitchen tables now or their companies out there now make stuff for you that opens up a nice possibility. https://www.watchrepairtalk.com/topic/3002-d-i-y-watch-timing-machine/?page=6 https://www.watchrepairtalk.com/topic/3002-d-i-y-watch-timing-machine/?page=21 https://uk.rs-online.com/web/p/vibration-sensors/0285784/1 point

-

I gave up on these generic no size selections some time ago as you need to measure each jewel accurately to be of any use. Not many of them seem to end up the type you need either. I buy up, as cheaply as I can, small second hand jewel lots where they are already graded by size and type. I have managed to build a good mixed selection that way. Stephen1 point

-

Hello, GACHO ,from texas. My experience with watches is like a hobby. I have put together a nice watch with a ETA 2824 movement and keeps crazy time! 1 sec. every three days. I have finally disassembled and assembled another ETA 2824 for practice and got it right. i'm going to get a time graph machine and learn to regulate/adjust watches. cool science this horology1 point

-

I am a graduate of the School of hard knocks. I am by no means an expert, but I have immersed myself in the minutiae of the vintage (read: plastic crystal) Rolex and Tudor offerings. I may get a 16610 in the future, but not sure. I started out about ten or 12 years ago with a case back opener, hand levers and a set of screwdrivers. (still have the hand levers!) I buy new/better tools as the need arises. My latest purchase was a crystal lift- I need that to compress the Omega crystal for my Seamaster 300. Unlike Rolex, where the crystal sits on the outside of the rehaut, the Omega sits on the inside. So, it needs to be compressed (SLIGHTLY) to drop in place. It also has the Omega symbol in the center and I would like to keep that oriented correctly. Maybe it could be pressed in, but as you press a crystal, it expands, so that's great for Rolex; bad for Omega. My Grandfather was an inventor (which I never knew until I saw patent documents in his name while clearing his house after his death); Dad was an auto mechanic with his own "Foreign Auto" repair shop. I was rebuilding engines before I could drive, and one of his employees was doing two VW boxer engines a day- tear down and rebuild. I learned a lot from him... I was an inventor of sorts for a while in a previous job. I really enjoyed that actually. I just figure stuff out. Yeah, I break stuff and loose it under the bench, across the room or in my shirt, but that's how you learn. You can watch youtoob videos until your eyes bleed, but until you "get your hands dirty" it's frankly worthless. to get the most from a video like that, you need to have a first-hand knowledge of what you are looking at. So, start with plentiful cheap movements (eta's are quite cheap, especially when not "working"); get two or three of the same reference number and make (at least) one good one out of them. 2824's are plentiful but expensive as they are desired by the replica guys. Go for older references, which can even be found NOS for less (I see 2784's quite a bit and have parts for such as well)... I'm a 2892 fan, as it's the refinement of the 2824; however, since it's thinner overall, the parts are too. You need to have experience with the more robust 2824 and earlier variants first in my opinion. Better still, pocket watch movements but parts can sometimes be a challenge, although on average, they are quite a bit less than wristwatch movements. One of my projects in this vein was a swamped Omega 2500 (gen 1 Co-Axial 2892-A2 variant). It was a cheap eBay find. I tore it down and rebuilt it without doing further harm. Maybe I could have restored it (I did not clean or lubricate it) but I had no need for it at that time and sold it on for what I paid for it. Free lesson for me! But, I did that after working with several Eta movements prior, so I had a good idea what I was in for.1 point

-

1 point

-

Not true! Someday soon I'll have to put together a walk through to demonstrate how this is done, both the factory recommended way, and taking a movement to pieces. It is not easy, as they are full plate movements, but so are a lot of other watches of historical interest. Cheers!1 point

-

1 point

-

1 point

-

So if I go back to look at everything the scope mode and the raw signal just looks not quite right. If you don't get a good clean signal you're not good get good results. I think about every timing machine I've ever seen except the apps for phones and tablets where they have no other microphone everything else is picking up the vibration. The idea of a cheap microphone is a great idea but it just isn't getting a nice clean signal. Then even the other software examples PC Timing Machine The graphical display looks rough. Which could be the way it's supposed to look or it could be an interpretation of the waveform is not correct. Then for Open source TG There seems to be zero graphical display? Audacity The signal looks soft which may not be a technical term I'm not seeing a clear signal. It's where we were testing something like this we need a standard watch that we know what it's doing or some other timing machine to compare results to. Otherwise when testing with a watch that may or may not have issues that could be entering into the picture So how should an oscilloscope look like? I'm attaching some diagrams this watch has seen better days. It's a small seven jewel Elgin that has issues. So we'll see from the oscilloscope nice clean signal. Then the graphical display yes it's all over the place it gets worse when it goes into a pendant position. What I find interesting with the oscilloscope mode is I've never seen it look like the graphical representation of what it's supposed to look like. Then I zoomed in the one section you'll notice a red dashed line the machine is telling us where it thinks locking is occurring. So on the top it's where it should be sort of notice how it's not parallel to the signal it's in the signal a little bit? Then the lower one notice it's not where it's supposed to be. Basically it has a window where it's looking for a lock to occur if it finds a signal it assumes it's the correct signal. It's not apparently looking for the loudest Signal. Then yes the lift angle for this particular watch is 62°.1 point

-

I think you may be right. They changed the pricing and told me it would take 6 months to a year. When I asked why the difference in pricing they simply said "Oh it'll be perfect when you get it back don't worry." I've got the case back opener on the way and I'll be posting pictures once it has arrived. Fingers crossed that it'll just need a good cleaning!1 point

-

Just to give you all an update on this repair. Firstly thank you to all who have offered positive and useful advice, especially OldHippie. Without the advice I have received on here I would not have started this project. I’m currently sourcing a replacement fusee chain from a gentleman on eBay who literally has too many lengths and sizes of chains to list then all, so I’m hopeful he can find one. I’ll keep you posted when I have a replacement fusee chain and have it installed back in the watch. Until then, onto my next movement Deggsie Sent from my iPhone using Tapatalk1 point

-

My thinking goes along these lines: The name - Ingersoll-Trenton. This must be after the purchase of Trenton by Ingersoll in 1908 The Serial number. I get a range from 1885 to 1908 The case - manufactured in 1908 So the purchase says it can't be before 1908 or it would not have the combined name. The Serial number says it can't be much after 1908 The case was made in 19081 point

-

https://members.awci.com/AWCIWEB/Core/Orders/category.aspx?catid=5 Here you go.....:)1 point

-

I bought the what looks to be the same "Bergeon" set from a watch fair in Holland. The seller had even put a nice yellow Bergeon label on the box. It was a good deal and it works great, but it isn't a proper Bergeon. I don't particularly care, but I was kinda miffed that I fell for the scam. As others said, this only winds in one direction. Another problem with it is that the arbor sizes are rather large. I was trying to wind in a 2824 mainspring yesterday, and the winder arbor size was twice the diameter of the barrel arbor (and would completely stretch it). I wonder if a proper Bergeon set uses much thinner arbors. Sometimes I fall back on my trusty old winder, which has the benefit that it's much easier to make new arbors for. The hook on my new arbors allows winding in both directions. I've also drilled out the hook in existing winder arbors in the same set in order to replace them with a bidirectional variant. One of the arbors I made before was perfect for winding the 2824 spring. I've added some pictures of the old set and new arbors below. Cheers! Rob1 point

-

I have one with two different eyepieces (pairs), a 10x and 15x, and the scope itself has 1x and 3x, giving a total of 4 magnifications, 10x, 15x, 30x, and 45x. I find 30x to be optimal for being able to see what I need and still have room under the main lens to work.1 point

-

Greetings and Salutations! Yes, be careful not to learn form the unskilled like me, who will spout off anyway The trick is learning to spot the difference!1 point