Leaderboard

Popular Content

Showing content with the highest reputation on 02/12/18 in all areas

-

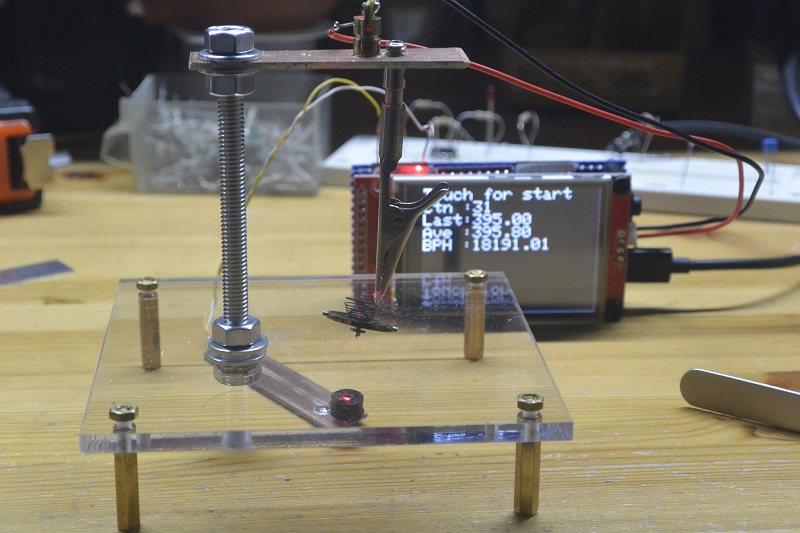

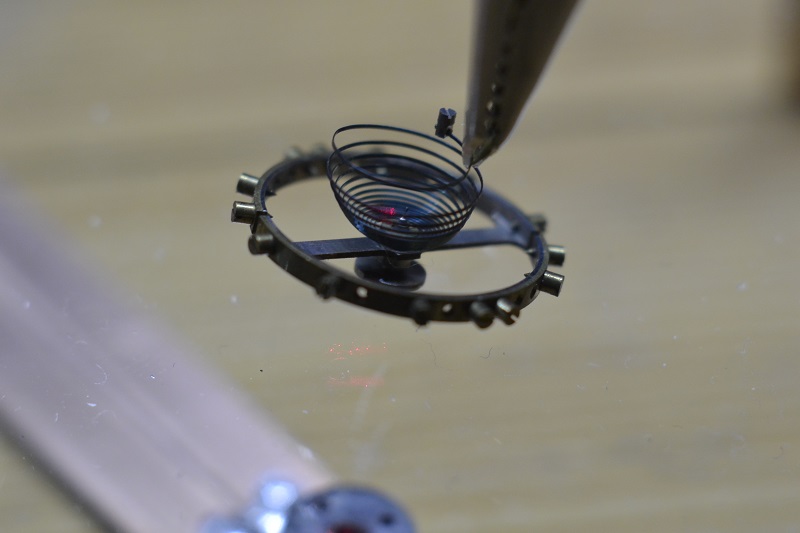

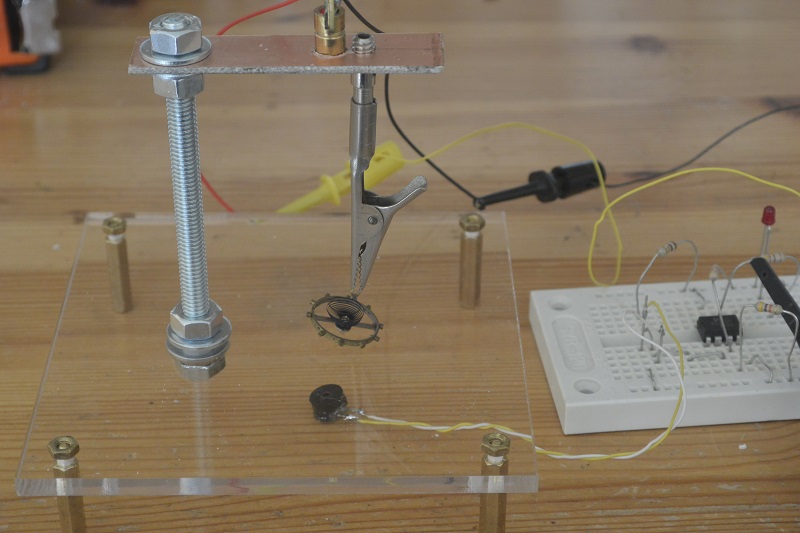

Hello guys, An attempt to make a low cost hairspring vibrating tool : Prove of concept : The hairspring (here it's a 18s balance) is clamp in a crocodile clip which has been grinded to be as fine as possible, a laser beam is set so that the beam is cut by the balance arm. The photo diode (from an old pc mouse ) is en-capsuled in a little housing to avoid parasite light (from what i thing to be an old TO3 transistor spacer found in my spare screws box). The IC is just a simple op amp acting as a comparator, the led on the output is used to visualize the that the laser beam is on the detector. First measure on scope : Doing some simple math show that an error of 0.1 ms on the measured value (which is 400 ms for 18000 bph) correspond to an error of 21.5 seconds / day. At that time base setting my scope has a resolution of 4 ms ! I switched to an Arduino based measuring system : I used an existing Arduino module based on a cheap stm32 and add a led (indispensable to adjust the beam) and the power output for the laser. The comparator is no more required as the stm32 has schmitt trigger inputs. The soft is triggered by the touch screen and accumulate a couple of measures in a circular buffer to compute an average value. This permits to eliminate aberrant measures that you can have when the balance starts to swing. Detail of the crocodile clip : In conclusion this is little tool (cost me only the plexyglass sheet, around $1.5) could be useful to match a new hairspring on an existing balance. The measures are relatively simple to do with a good consistency and surprisingly the croco clip do the job and you can get the balance swing for tens of second on the plexy. You need a resolution of 0.05 ms to be at 10 s/d and probably calibrate your measuring device. The main difficulty was to adjust the position of the laser beam. Hope this can give you some ideas. Regards3 points

-

Even a skilfully handle syringe will dispense more liquid that an oiler. I think I paid a pound for my cheap oiler and it works fine. Neil Sent from my iPhone using Tapatalk3 points

-

Hi syfre, I like your prototypes and your spirit of research. Who ever had to make a flat or a Breguet hairspring (happens now and then in my shop), knows why you need such a device. Years ago I made my own device as I did not like the traditional boxes that can test one beat rate only and are ridiculous expensive, very similar to your setup: Advantage: box has a built-in 3 V battery that lasts for years (or one month if running permanently). Frank2 points

-

Hello Thomas please pm me when you get the watch back and I will be happy to guide you through the procedure to replace the quartz movement and hands. With regard to removing the winding stem and afterwards the hands, I would suggest you procure the following which are readily available off eBay (just check origin and associated delivery date first or you may be in for a long wait): - Brass watch tweezers Watch movement cushion Hand removal levers (pair) Hand re-fitting tool Watch makers screwdriver set (budget / low cost unless you intent to make this a future hobby) Adjustable watch back removal tool Clean table, some time and a patient mood. Sadly, I cannot comment on authenticity of your watch - but would tend to think you would have been advised if the watch was not original? Regards Deggsy Sent from my iPhone using Tapatalk1 point

-

The clock certainly does require a suspension spring the one in your picture is clearly twisted and broken, you also need a pendulum of the correct length, french clock movements usually have a serial number and a number that indicates the correct pendulum length the number is in old french units called pouce and lignes these can be converted into millimeters to give you the length you need. If the price of £300.00 includes servicing the clock that to me would seem very reasonable, it is a time consuming and surprisingly messy job cleaning a clock.1 point

-

My 2 pence worth...... It could just be a faulty battery You ideally need a consumption test doing on the movement, every watchmaker that does quartz watches will have a way of testing the consumption, I would suggest you take it to someone local and get it tested if you can't test it yourself. As you already say these movements are very flimsy and the plate can easily be bent, normally either someone putting the wrong thickness battery in or putting too much force on it whilst fitting it. There is a very good chance someone in the past has done this. It may need a service, cleaned and a very fine oil like 9030 on the pivots, don't over oil it or the consumption will be high. If after servicing it the consumption is still high and you are sure everything has been checked, scored pivots, bent wheels, end shakes, etc, I would guess the plate or bridge is bent, this is very common with this movement and would suggest a movement exchange or send it to swatch and they will movement exchange it as part of a service. I wouldn't recommend buying a second hand movement off eBay as chances are you will have the same problem.1 point

-

Nice, I have thought about doing something similar as I have a couple of spare Raspberry Pis with displays and a couple of laser diodes lying around, but on the list of tools I still need to make a hairspring vibrator is pretty far down on the list. For pure tool porn you can't beat the look of the old fashioned hairspring vibrators though.1 point

-

The other things to consider are stem height and date window position. I think only the early 536 calibre was interchangeable with the 28** Series mechanicals, which was basically because the 536 was based around the same design as the mechanicals and they didn’t attempt to slim it down. If the case is the same design as the mechanical version then they may have used a movement ring to compensate, but that becomes more complicated when stem heights change due to the dial being shifted away from the front of the case if you try to compensate for lack of stem height. Looking at other full-size “Pre Bonds”, I think the date window may be in a different position (see attached photo).1 point

-

As far as posting pictures of replica watches are concerned, I have no problem with it BUT I am afraid we may be hitting a potential area where lawyers acting for the brand owners would take issue with their brand name being used in such a way on a public forum so I would prefer not to have potential problems and therefore would not really want pics of counterfeit watches being propagated via this forum. Discussing repairs to Chinese movements is not a problem though.1 point

-

I guess so but the question is WHY would one do it ? The traditional oilers are cheap. Not the bergeon I mean. Surely one could afford an entire set and they do the job just fine right ?1 point

-

1 point

-

Super nice collection and work behind! I have bought a few PW's myself in the lower price range and usually find them being cylinder movements with broken balance pivots, which kind of halts my further advance since I find very little options for replacement parts. I do have the staking set and have managed to swap out balance staff a few times on regular wrist watches, so if could just get the parts I would jump on it, even though I realize the cylinder movement has it's own issues to work around. Any hints or experiences in this direction would be appreciated. /Bsoderling1 point

-

For those who think this is a pipe dream have a read. http://wornandwound.com/the-240-year-old-pendulum-clock-thats-more-accurate-than-your-watch/ @watson1 I admire you ambitions and wish you the very best of luck. I hope that you might document your progress here.1 point

-

All I mean is to make sure the tip is perfectly flat. You don't want to sharpen the angles of the blade like a knife blade, to an edge. When you break a tip, you are getting into thicker metal the further up the blade you go. When you sharpen them, you need to do both sides of the blade at the angle which will thin it back out and then sharpen the very tip at a 90 degree angle, as flat as possible with a very fine stone, to get the width you need to match the screw head openings. That's all I mean when I use the term "blunt".1 point

-

0 points