Leaderboard

Popular Content

Showing content with the highest reputation on 08/30/17 in all areas

-

Hi all, Since I haven't found an Accutron yet, I jumped on this vintage Timex Electric. It's far from a tuning fork movement but it's satisfying me for the interim. It had a neat calendar band with 7 changeable cards for the appropriate month. Runs great and looks sharp. I thought it was kind of unique; can't make out the serial number but I think is a '67 model/style 84. Not too familiar with thier Taxonomy. Sent from my SM-G920V using Tapatalk2 points

-

2 points

-

2 points

-

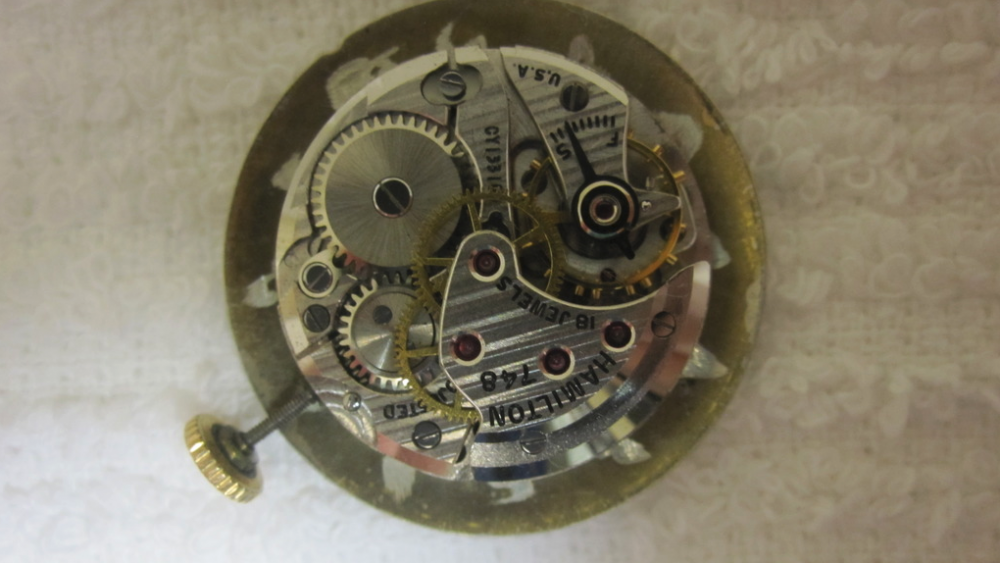

A few weeks ago I was following the auction on a very Minty Hamilton "Rodney" watch . This watch has what is called a Quadrant colored dial which I am partial to . I shared this Bulova Royal Clipper on this post a while back that also had a quadrant dial.... The Hamilton Rodney finally sold to some lucky bidder for $300 . A few days later another Rodney came up for auction but the dial looked dark and the quadrant didn't show up very well in the pics . I figured that there was a gem hiding in the darkness so I got the watch for $74 . After I got the watch I took the movement out and cleaned the case and crystal in my ultra-sonic and indeed , the dial had a smokey dark look to it . I took a BIG chance and decided to try and clean up the dial knowing full well that I may do irreversible damage to it . I am talking from more then 1 experience here ....... First I said a little prayer ,..."Oh Please Watch God , don't let me mess this dial up....Pleeze "...then I proceeded . Well somebody up there must like me cuz it came through the operation OK....Whew !! Feeling ahead of the game now , I ordered a nice retro looking Hirsch watch band to compliment Rodney ... Looking pretty Spiffy if I do say so myself .2 points

-

1 point

-

Well, is more of a post, it have no thread, will go straight down, is also the pivot for the setting lever on the dial side. Be careful don't apply too much pressure just enough to make it free the stem.Best regards. Enviado desde mi SM-N910C mediante Tapatalk1 point

-

Try pushing the button remarked while you pull the stem from the crown outwards. Enviado desde mi SM-N910C mediante Tapatalk1 point

-

1 point

-

The one shown would be very simple to make, but as you point out its missing a great deal of the Feintaster's functionality. As well as the table, "claw" and complexly shaped contact points, there is also the lever controlling the plunger - a very important bit of kit on a comparator. I agree with you those extras are quite tricky. The parts should be hardened and achieving perfect alignment so all surfaces are the same distance apart is far from trivial. In making a gauge you need accuracy and precision, and you must work to a higher standard than .01mm if its expected to be reliable to .01mm As for what indicator, I'd thought a mitutoyo digital reading to .001mm would be good (and I have an extra lol). There is a convenient hole to use with a lever to actuate the plunger (as these indicators often are used on comparators) and with the press of a button you move from metric to imperial (while watchmaking might be all metric, most of other things in North America are still imperial, so for me there's an advantage in both) You also have instant zeroing which is convenient. I'm 60% through drawing a Feintaster with the view of making one, but secretly hope I stumble over one as there are some challenging bits and pieces. For anyone interested in having a go at it, here's a close up of the contact points - a unique design so you can get part of say a balance staff i the V and measure the rest of it1 point

-

Yes I suspect you are right that is probably what originally came on the watch. I was originally looking for a stainless but I would like to put the watch back to what to the way it came from the factory. I have noticed a couple more watches on ebay that are missing bezels, looks to be a common problem.1 point

-

Aloha I have a similar case back opener. My issue was with the amount of force required to open some backs that came into my possession and why were they tightened to such a degree ? I did some tests with a ball, which initially seemed favourable but had no means to check the watches under "Stress". I acquired a water pressure tester and as already stated had a 75% failure rate using a ball as a means of securing a water resistant seal. Therefore I withdraw my original comments on the efficiency of using a ball as a means of attaining a water resistant seal. Also I find your type of case back opener to be "Best" and certainly more efficient than a jaxa. Though this could be down to faulty manipulation [emoji4] Sent from my SM-G920F using Tapatalk1 point

-

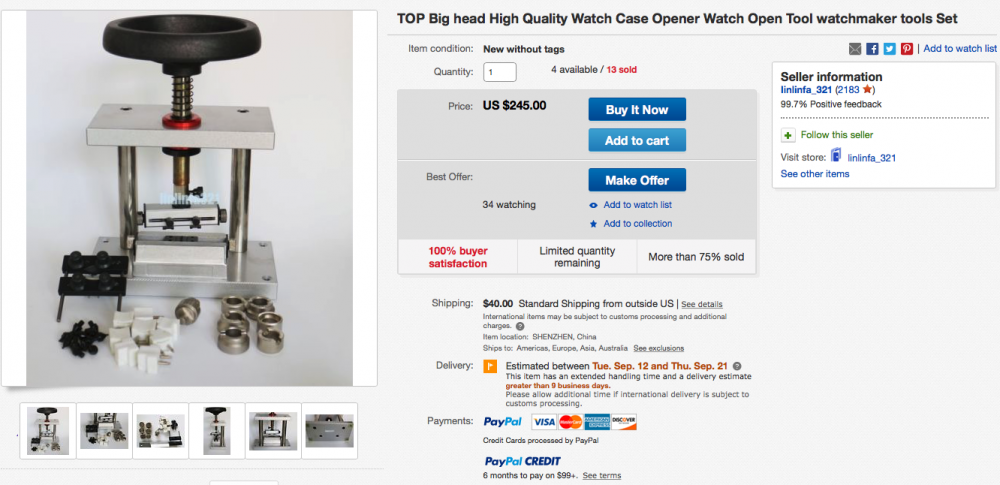

Aloha digginstony , I splurged earlier this year and got this puppy . I believe I got it at the make offer price of $224 .00 and free shipping . Man , I love it . From China , Yes ,...but very well made ....all machined and fitted parts . http://www.ebay.com/itm/TOP-Big-head-High-Quality-Watch-Case-Opener-Watch-Open-Tool-watchmaker-tools-Set-/221278174618?hash=item338534fd9a:g:9kcAAOSw~FNUacGd The first watch I opened was a vintage Seiko that must have been cross-threaded and stuck with super glue guck . I had been trying to open it for a couple of weeks using my jaxa tool , penetrating fluid , coaxing it by putting it in one of my case holders that can clamp down to my desk so it won't move and tapping the jaxa notches trying to unscrew it ,...all to no avail . After letting the penetrating fluid sit overnight on a few occasions and then tapping all around the case back with a small rubber and neoprene headed hammer , once again , No Dice . So I went ahead and got this super nifty case back opener, set the watch in the nylon holders that fit , adjust , and hold the watch between the lugs . turned down , fine adjusted , and locked in the jaxa type fittings in this case to the notches ,and Voila ,...I turned the large top wheel and had no problem opening the case back . No slipping , no scratches or gouges . Just smooth as butter . I have since opened a variety of case backs including Rolex as this tool comes with the openers that fit the tool . More pricey then a Jaxa tool , but I can easily recommended it .1 point

-

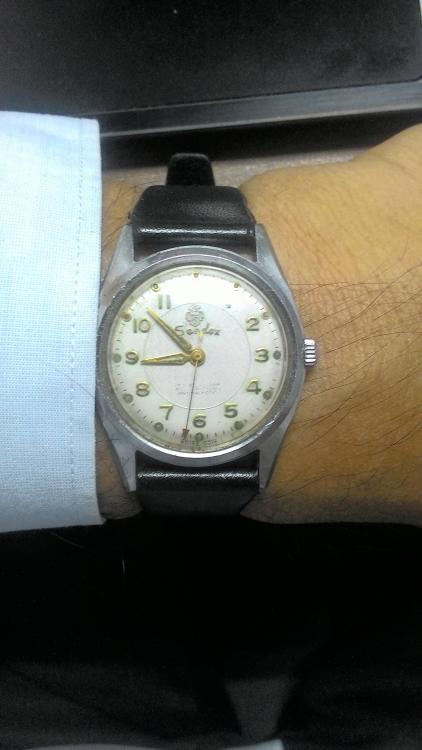

Hi guys.. its the middle of the week but here in Malaysia we're starting a 4 day weekend (independance day on the 31st Aug, Eid al-Adha on the 1st Sept)..yayy! There is also a strong possibility that next Monday may be declared a public holiday as well as we have exceeded our target for the Sea Games... If it happens it will be announced during the closing ceremonies this evening... heres hoping! Anyway, back to watches! Today I pulled out this neat Sandoz hand-wind. This is a stainless steel model and would have been one up the ladder compared to its lesser and more common base-metal cased brethren. The lume has aged and even fallen off the hands. There was some writing on the dial.. I believe 17 jewels, shock-proof and anti-magnetic but its pretty much gone. Luckily the hour markers and indices as well as the 'Sandoz' script and logo were stamped/cast (?) into the dial so they're all present. They have a goldish look and I believe they're plated but how they did this is a mystery. The minute markers are all present and the textured surface of the inner part is nice and its topped off by some nicely plated hands and a seconds hand with a pointed tip painted red. This shot shows the plated indices and hour markers.. The crown is an original Sandoz And the caseback is typical for a watch from the 50s. Inside we have a trusty ETA 1080 but looks like Sandoz made some effort to make it look a bit different by designing the bridges a bit different. The usual 1080 bridge has straight sides and this has more curves. Simple and reliable. Inside the caseback.. Wrist shot. It is a 'boy size' around 32mm without crown but its not really noticeable. Have a great day! .. or night/afternoon .. Anilv1 point

-

Seiko kinetics as noted above do not hand wind because it would greatly add to the mechanical complex of the watch. So as an alternative Seiko has the YT02A-A kinetic energy supplier charger. I've attached the PDF below. Seiko YT02A KC_2005(Eng).pdf1 point

-

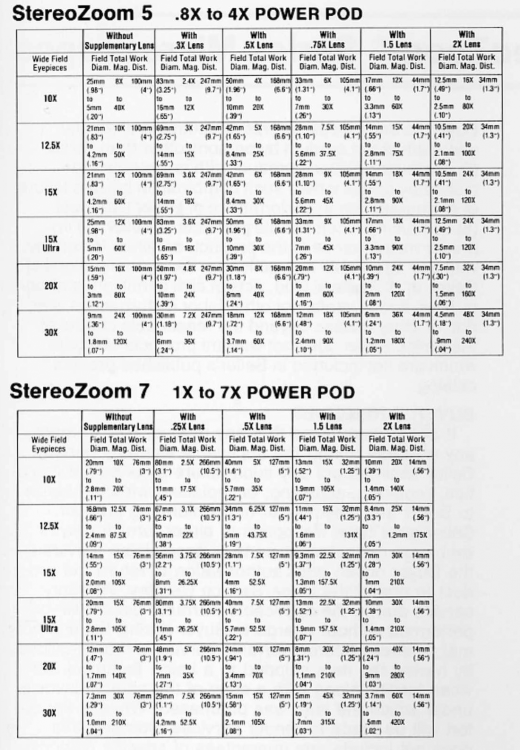

The lenses have a special construction with metal pins on the sides, so you need lenses specifically made for the StereoZoom 7. (The ones for the StereoZoom 5 are different for example.) The catalogue numbers for the lenses are: 31-27-08 = 0.25x 31-27-04 = 0.5x 31-27-05 = 1.5x 31-27-06 = 2x I have all except the 1.5x one, and I got them all from eBay. They usually show up there from time to time. Note that the 0.25x one has a working distance of 266mm which makes it unsuitable for horology work unless you have very long arms. Here are some images with dimensions:1 point

-

Hi Roland, co**BLEEP** would be 150, medium = 400, fine = 600 and extra fine = 1000. Sometime you want a mirror finish on the tips if you are handling very delicate stuff or want the tweezers to slide under something (I don't know it happens I guess, like picking up hands...but I avoid metal to handle those), otherwise medium grit will do. Of course, this is not written in stone. Maybe we can hear from some other members' experiences on the subject. Cheers, Bob PS. The editor doesn't recognize the "rough" equivalent of the grit, it thinks it is profanity! :D1 point

-

Here's the set of hones that I use on a regular basis, they are especially good for keeping a good edge on tungsten carbide and high speed steel lathe tools. Having the plastic handle built in allows you to use it like a file. The grades I use are medium, fine and super fine. PS. They are great for dressing the ends of stems to achieve the correct length after I have snipped off the major excess.1 point