Leaderboard

Popular Content

Showing content with the highest reputation on 08/19/17 in all areas

-

I identify movements all day long. It's a Miyota 1L12, Date at 3.2 points

-

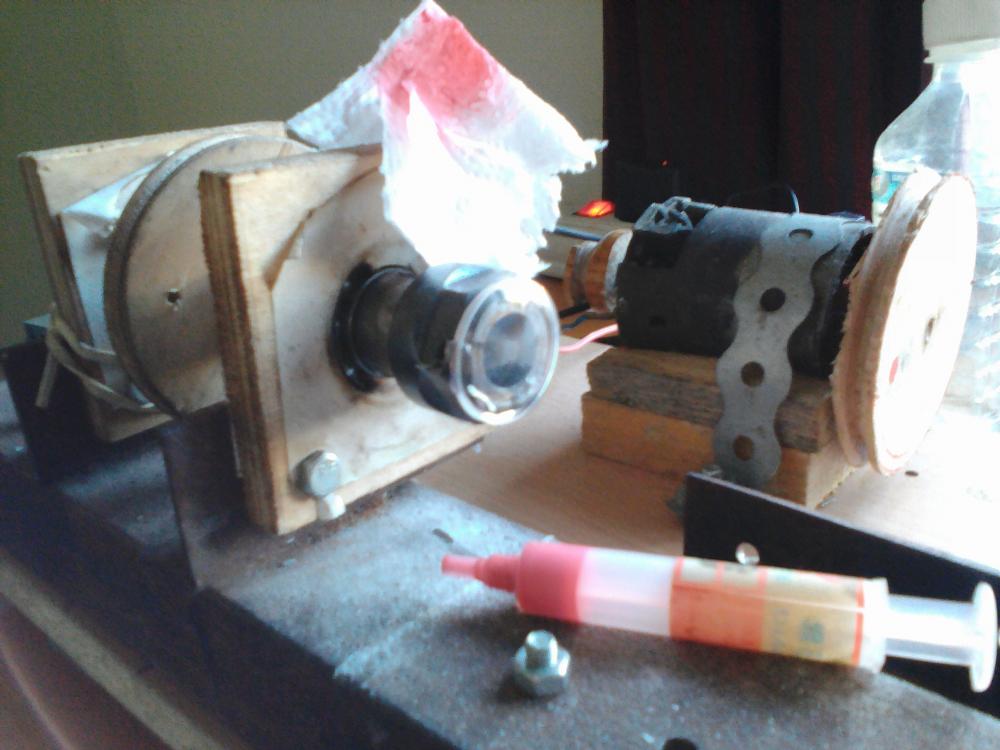

I was not hoping that it will turn out good but it did so no video of this only some bad pictures. Komandirskie crystal was mounted on the spindle chuck nut with hot glue. Sandpapers and diamond paste up to 10000 grit were used to polish the crystal. It was full of scratches, deep dents and there is also a crack. The latter is of course still there but this was my experimenting pice. The whole project took only 15 minutes !1 point

-

I was talking about other possible cases and watches, not this one. Just generally saying...1 point

-

Yes but you're paying for the style and the brand not so much the watch engineering. The construction of a YSL is pretty conventional as shown in this example. I have a problem with the common type of case knife because they can be a real liability with tight backs. I prefer my grandad's pocket knife. It is strong and reasonably sharp and eases into gaps that purpose made knives can't touch. Cheers Neil Sent from my iPhone using Tapatalk1 point

-

For clarification, it's a simple pressed in case back, cheap way of doing things perhaps but a YSL is not a cheap watch, that's worth keeping in mind. (just at the risk of getting confused on that) There are many watches like this out there that really have no lip or entry point and are for all intents and purposes, impossible to open with the conventional case back tools. You could try getting one of these, they may or may not work well. https://www.cousinsuk.com/product/bench-top-case-openers Failing that there is the 'tap method' which can either be done so wrong or so right, id hate to give remote instruction on it.1 point

-

In mass produced Japanese watches, mov.t ALWAYS comes out from the back. No need to overthink when things are immediately evident like in this case.1 point

-

Also, please be aware that in some cases the movement+dial is removed from the front. Sometimes you have to remove the crown first through a certain technique and then the dial and movement comes out, after the crystal has been lifted, of course. Sometimes there's some sort of a chassis that is attached to the movement, dial, crystal and case back and it comes out of the case. Roamer had this system.1 point

-

No tricks here. Just be aware that if the back is real tight, you'll need a press to close it.1 point

-

1 point

-

No need for expensive tools. Work around it with an x-act type knife first. Watch your hands, wear gloves, etc. Then when you have got a leverage, use the other tools.1 point

-

I’m not saying this is right. You could try removing the bracelet by taking out the lugs and see if there is something to press in then push the movement out of the case. I have come across this method in some old mechanical watch movements.1 point

-

Aaahhh... E.T. Is short for ebauches tavannes..? And thanks for the hint regarding the the dial side characteristics being the identifying point. It's easy to get blinded by the cosmetics on the train side when (as you point out) it's the underlying geometry that counts. Btw, the movement is now up and running nicely. Definitely worth a new setting lever spring! And I attached a photo of the dial that many may find deteriorated but I see a "pointilistic charm" Sent from my iPad using Tapatalk1 point

-

You need to check the ad yourself but yes it includes line release. Cheers Neil Sent from my iPhone using Tapatalk1 point

-

That's great - Thankyou for your help! Turns out there were two versions of the J59 movement depending whether it had a sub dial for the seconds, so that's the front runner at the moment! I've sourced a balance staff, so it will soon be time to dust off the roller removal and the staff removal tool.....! Cheers! Andy1 point

-

The eight pointed star is associated with the Junghans brand. Do a web search for something like 'j59 movement' and you should be able to find some info.1 point

-

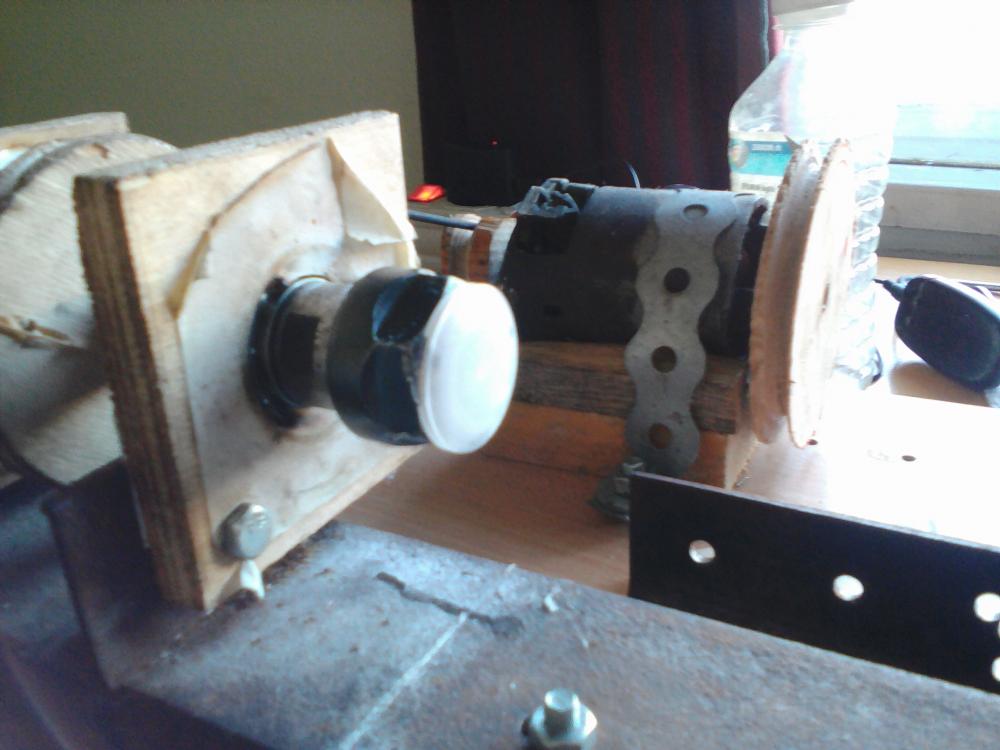

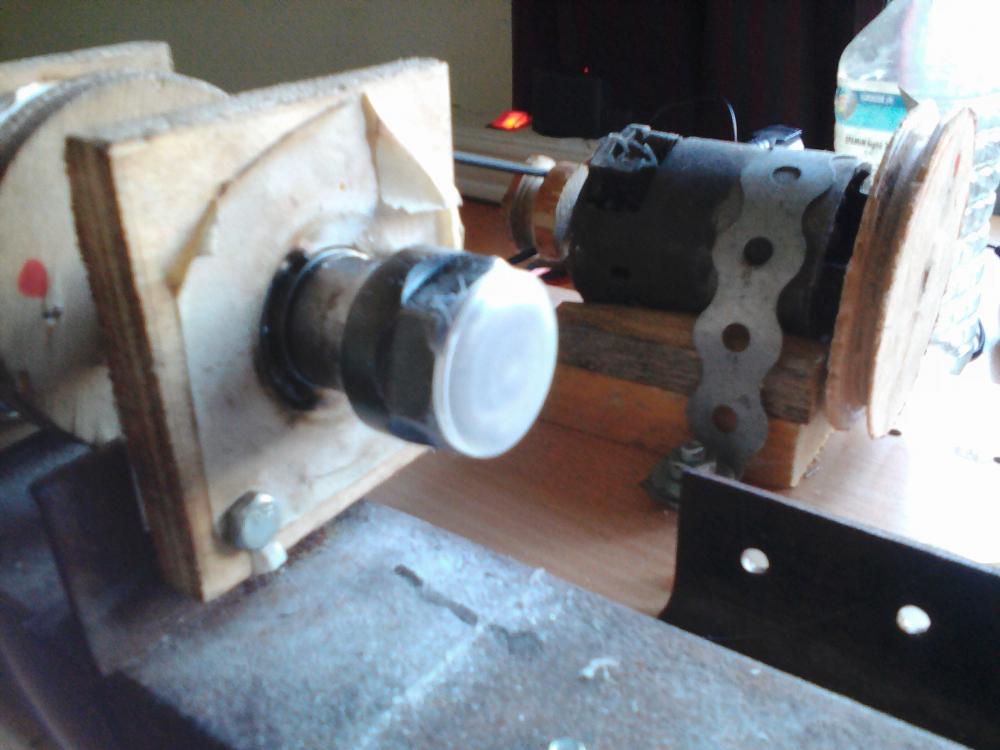

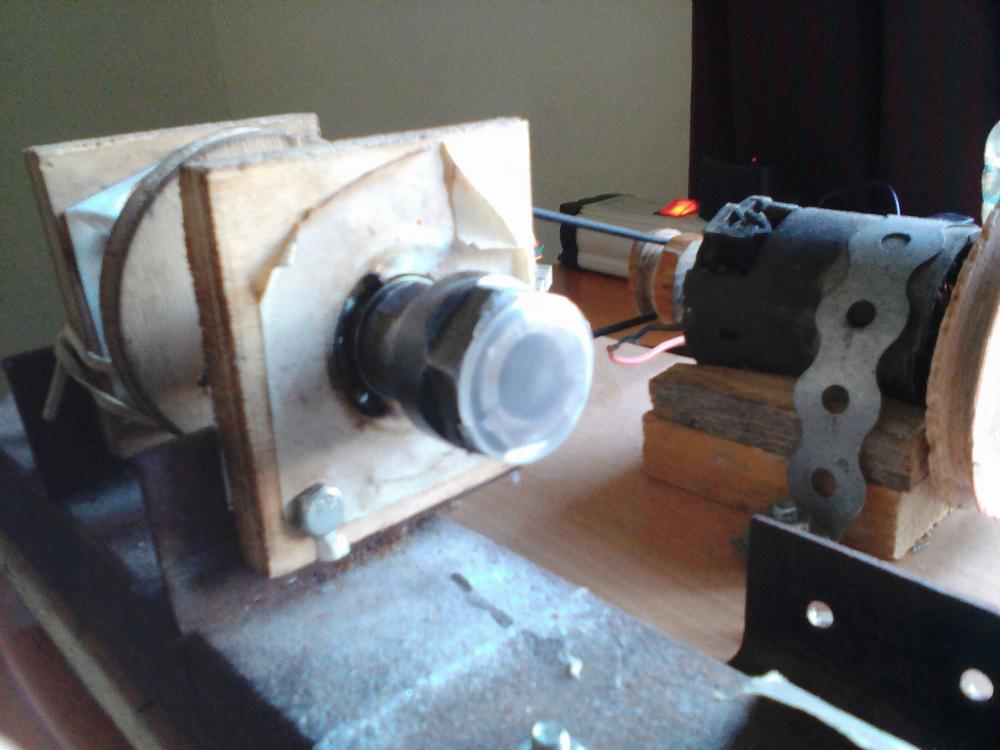

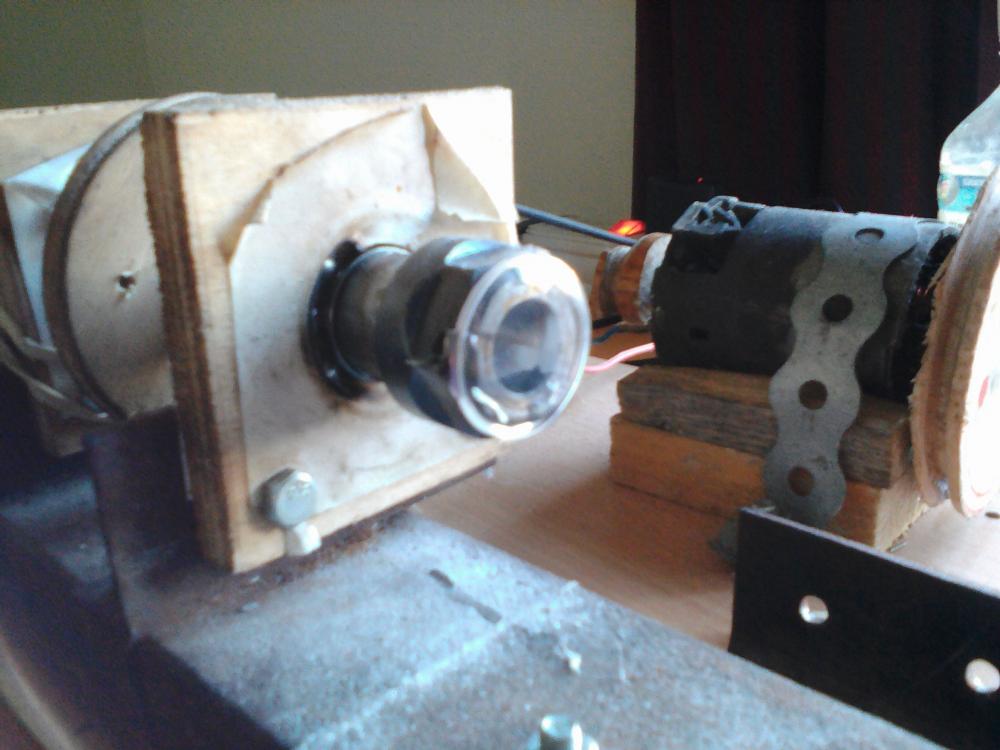

So it looks like I was I a bit dense on this whole affair, what I had tried to use could not have been shellac....although it look like it. Comparing them side by side, the real stuff was a bit more translucent. Anyway, with proper shellac fixing to a chuck was quite easy. Its a screw with a shoulder on which a wheel turns, out of an alarm mechanism in a pocket watch. It had a bit of rust and needed a clean up (watch is of low quality, the whole exercise is for learning). I first cleaned up the top of the screw (it had some damage and rust) so it would sit true on the face of the chuck. Centreing is a neat process that took a couple of tries to get onto - after cementing I held an alcohol lamp under things and with a small piece of brass wire nudge it concentric - with just enough heat to make the shellac flow, but not so much that the piece falls off. Two false starts, fortunately I found the right balance before losing the part. A bit of heat detaches the screw from the chuck and the remaining wax was removed by boiling the screw in alcohol - done in a small test tube over an alcohol flame. Overall (once I used shellac) it was a fairly easy process and a convenient way to chuck small items. I've been polishing and cleaning parts on the watch with the hope of getting it running. The main thing needing repair is that the barrel arbor is broken - that's next! Screw original condition after nudging into place, things are running true After a bit of burnishing then polishing1 point

-

yes, "clean by hand" (see le clairs book). it was the original way to clean (total take down). AND, a valuable learning lesson. vin1 point

-

I have used naptha and isopropanol for years. With good result. Bought some Elma 1:9 fluid recently just to test if it would be cleaner? Not so impressed that i would go over to it. The parts gets a little shinier but thats it. And it destroys my fingers and skin as it contains Ammoniac. However it's very economical as a bottle of fluid cost £25- £30 and then diluted 1:9 . Where protection or rinse in water afterwards.1 point

-

I suggest you clean by hand to start with & if still enjoying watch repair then move on to a ultrasonic cleaning machine. There is lots here on the forum re-cleaning.1 point

-

Easiest and cheapest way to start is probably to use naphtha which you can buy anywhere as cigarette lighter fluid (Zippo type not gas). Peg out the pivots with Peg wood, then clean in the u/s bath in small jars of naphtha in a water bath. Particularly dirty movement plates may benefit from brushing using a soft toothbrush, wear nitrile gloves if your skin is sensitive to naphtha. Those little interdental brushes (like miniature bottle brushes ) can also be useful here. Rinse in a second bath of clean naphtha and then a final quick rinse in isopropyl alcohol. Impulse jewels and pallet stones are typically secured using shellac which is soluble in alcohol so the balance wheel and pallet fork should only get the briefest of rinses. Then lay out on absorbant tissue to dry.1 point

-

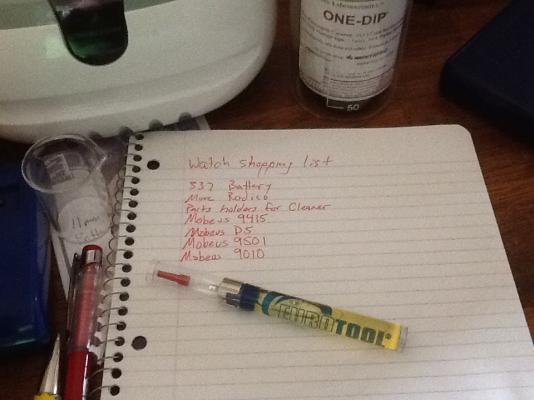

Hey everyone. So I am at a loss here, I have done tons and tons of reading and am still stumped on how I should go about cleaning watch parts. I have never serviced a watch and am completely new to this. I can't buy an expensive 3 jar machine or anything like that. I was looking at a Harbor Freight ultrasonic machine and maybe putting some glass jars in it. I would buy LR ultrasonic cleaner and rinse. I'd clean the parts for 6 minutes in the cleaner and then rinse for 3 minutes all in the ultrasonic. However, the solvents are very expensive at $50 each since you can only get gallons. Finally I know that ultrasonics are dangerous for the older plated movements of which I'd like to service as well. I would be open to hand cleaning movements as well but of course the watch cleaner is dangerous on the skin! Can anyone recommend some simple solutions for a beginner? I am just looking to do a basic cleaning and service for watches that run already. One of the easiest ideas I came up with was to peg the pivots and jewels, use rodico on the surfaces of each part, and then put the watch parts in water with this cleaner http://www.esslinger.com/gemoro-ultrasonic-jewelry-cleaner-solution-concentrate-quart/ . After I would take the parts out and gently scrub them with an brush then into a small cotainer with denatured alcohol as a rinse and then dry... How does this sound? Probably very insufficient I would imagine. How would I clean the balance and pallet fork in this manner? Would I have to buy a one dip solution?1 point

-

Well in this thread http://www.watchrepairtalk.com/topic/822-basic-oils-and-greases-again, I mentioned that I ordered small quantities of SIX lubricants for 100 EUR (120 EUR including postage). The vendor is http://www.kalyanediffusion89.com (although I used their ebay store, which seemed to have a different selection ?). They're in France.1 point

-

Good points, Bob. I did an awful lot of reading before buying my lubricants and cut corners where I thought I could. I bought Jisma 124 ($44.50) in place of 9501 ($72) for the canon pinion. And, with shelf life and other factors in mind, I bought HP1300 in place of D5. Less money for a much smaller quantity, but twice the shelf life. One of the books I've read, "Amateur Watchmaking" by Per Torphammar suggests the hobbyist only needs 9010, D5 and 8300. "...one "high-speed low-load oil" and one "low-speed high-load" oil, plus one grease for the barrel walls."1 point

-

Is this acceptable for Molycote Dx?? http://www.amazon.com/gp/product/B00CAD6AAE/ref=ox_sc_sfl_title_1?ie=UTF8&psc=1&smid=A8FEBY5XL3B8V Thanks, Alec1 point

-

Thought I would round this one off. I bought the watch for spares or repair as the minute hands "were not working". It transpired that they were actually working but to accomplish that task you had to press in the crown for 5 seconds then release and hold it in then off they whiz. It turned out to be a Tissot Seastar Quartz, Tissot Le Locle with Caliber 2031 movement badged as 22265 which makes it 1980. It also came with original tag and box. I cleaned it up and after taking it apart because I clumsily popped the stem retainer , it is working nicely. There is a bit of patina on the face but nothing really bad and having rubbed out the ding and scratches it is not too shabby so I might get a little return on it but mainly I learned a little along the way so it was fun. All the parts are still original as well.1 point

-

I would not trust it. The last thing you want is for oil to spread out of where it is intended to be. Its probably still good for some things though. I use cheap clock oil for lubricating my tools like my lathe, the threads on pin vices etc.1 point

-

About a year ago when I was just starting to get a bit serious about starting this hobby I bought one of those cheap watch repair kits. I have since replaced all the crap in there with quality versions of what they were supposed to be. My question relating to this topic is this little tube of oil in the kit. Is this just more junk from the kit or does it have any purpose or can it be used in place of any of Marks suggestions? Seems VERY light and my feeling is that the trash can is its new place.1 point

-

Well I would definitely start with Moebius 9010 (for train wheels and balance endstones) and 9020 (for train wheels) if you are working on Pocket Watches. Moebius 9415 is a must for Pallet/Escape wheel teeth. A quality silicon grease. Moebius D5 is essential (barrel arbor, motion work). Molycote DX or Moebius 9501 grease for keyless work. Moebius 9501 or 9504 for high friction (e.g. Cannon pinion, Setting lever spring and anything at high friction). Moebius 8200 grease for mainspring. Moebius 8217 for barrel wall (automatic watches) It's a lot but at a minimum get 9010, 9415, D5 and 8200 I hope this helps. Recommended Lubricants for Getting Started.pdf Moebius_Oil_Chart.pdf1 point