Leaderboard

Popular Content

Showing content with the highest reputation on 02/09/17 in all areas

-

If it is the end shake regulators that is stopping the instulation of the balance then you might have to move them to their lowest setting so you can install the balance & then adjust them back gradually checking the end shake as you go. If no oscillation is happening after installation then something else is amiss.2 points

-

Like yourself , I bought a staking tool but don't have formal training to know how to use most of the stakes and stumps . I bought the book , "The Watchmakers Staking Tool " by George G . Lucchina and Archie B. Perkins from amazon . So far it has definitely been worth the price of the book and am glad I started out with this book . This quote is from a member of The National association of watch and clock collectors and mentions a couple of other books . " The most valuable info I've found on how to use the staking tool is contained in "The Watch Repairer's Manual", and "Bench Practices for Watch Repairers", both by Henry Fried. One book has a chapter on the various types of stakes and the other has a chapter on the various types of stumps. I think "Bench Practices for Watch Repairers" is not as commonly found as "The Watch Repairer's Manual", but it's every bit as informative. "2 points

-

I love the idea of "You have it in case you need it" but realistically I prefer to start with the minimum and cheapest tools needed to get the job done, and then gradually upgrade/expand once I know what's worth investing in2 points

-

1 point

-

I didn't intend it that way, I misspoke. I literally do that though, I will go all out on a project spending a fortune and then realize I could have saved a lot of money by making it myself or improvising. And I definitely agree, you want the right tool for the job but I think a beginner can get by OK without high end tools to start with. I have like a $20 "watch repair kit" from amazon thats got a lot of useful things in it. That being said I have already went through and upgraded most of those tools so...lol1 point

-

Caution: If you rotate the roller and hold the balance wheel, you may rotate the rivetted staff instead! Frank1 point

-

1 point

-

The Question is what idiot replaces a split stem with a full one on a front loader. I would take it back to the original repairer it his/her mistake after all.1 point

-

I suppose a clarification is needed what sort a roller tables are we discussing here? I spent a lot of time working on American pocket watches so I'm going to answer from that point of view versus a modern Swiss roller table as it's a little bit different and it probably can be safely rotated but there's a minor technical issue. American pocket watch roller tables are normally made out of steel occasionally brass or something similar to that. they friction on very tight. If they have a safety roller it's usually a separate roller. So both of them would have to be rotated to be in alignment. There's a danger of rotating these they might actually pop off depending upon how far you rotated or how many times to get things where it's supposed to be. So the technical problem is you will screw up the poise of the balance wheel. The balance wheel is always poised with the roller in place rotating it changes the poise of the balance wheel. Although it probably depends upon how obsessed you are with positional errors the size of the roller table etc. then this tool mentioned above Bergeon 3007 Swiss Tool for Collet Closing, is for tightening loose hairspring collets. for variety of known and unknown reasons hairspring collets can be loose with time. You go to rotate them and they just aren't tight enough to stay in place. So with this tool it's relatively safe to tighten the collet without bad things happening to the hairspring. At least most of the time sometimes you can still catch the hairspring where it shouldn't be and then you'll have to put it in the flat. usually the worst thing that happens to hairspring collet's is in restaffing is the size of the staff is somehow different than the original. Sometimes people try to force it on the collet can actually crack. then a course with all their watches they been re-staffed several times and things just happen. then at least at one time they made tools for rotating hairspring collet's. Somewhere around here I have photographs conveniently I'm not finding them if I find them I will attached later. The difference between them in a screwdriver is the taper is much longer. Whatever you put into the crack of a collet isn't supposed to open the collet when you rotate. Just the twisting action alone will open the collet a very tiny bit you shouldn't have to wage something in do it. There's a danger with screwdrivers because of the taper of opening the collet up too much and ending up with a loose collet.1 point

-

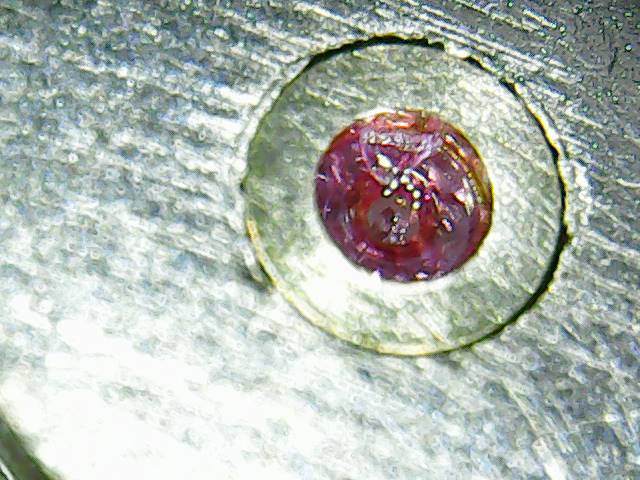

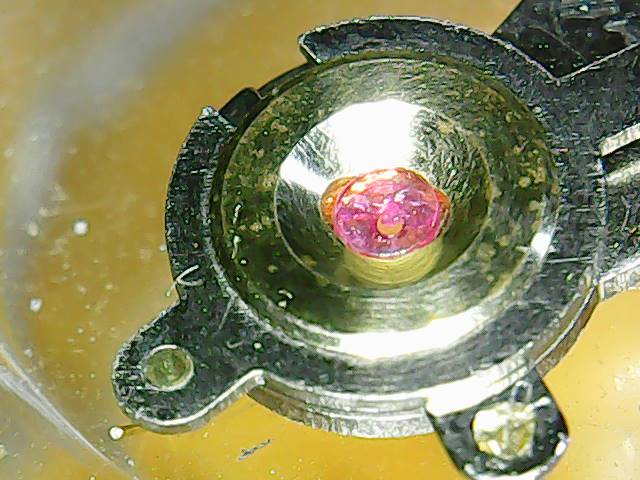

Received a similar to Ruhla wrist watch for repair. The owner gave me ~thousand balance staffs and a box full of parts of different manufacturers. Inc. some Ronda quartz movements. The watch has two issues. Both balance staffs broken and the jewels in the balance bridge are cracked shards. This is a low end watch with 4 jewels. I dont know how to disassemble this balance jewel setting. But i have noticed two notches on the top of the setting next to the cap jewel. Is this setting maybe a screw-out setting? Top view Bottom view1 point

-

One thing you might try is to make a drill guide that can fit into the stem tube and center the stem. You can then run a drill through the hole in the guide. and drill into the center of the broken stem. Once a center is established in the stem you can remove the drill guide and follow up with a larger diameter drill bit. Hopefully this will remove the top section of the stem or at least weaken it to a point where it will bend as you remove the movement from the case. david1 point

-

I snowed in on Quartz movement and thought it was a electronic movement? But that is was not That is a Ruhla UMF 24 pin lever movement.1 point

-

Because I care about horology and his disgusting practices, people like him gives the wrong impression to those who make an honest living and to those who enjoy clock repairing as a hobby.1 point

-

1 point

-

Why not just make them custom to the movement your working on at the time1 point

-

Very nice I like..Making tools like this is where you can save money to buy better precision tools also a lot of pride in knowing you made it yourself. I need to make myself a screw driver holder and an oil station also. I did purchase plastic oil holders I can fit into a base similar to the one you made.1 point

-

So far i have made a balance holder, working on an oiler station now..going to make brass hand removal tool (x2) , watch cushion, and possibly several movement holders....here are some pics that might help you out. The oilers were made from various needle sizes...heated them up and used a ball peen hammer to make the cup ends....the balance tool was made from a 3/16" brass rod with a file on my lathe or you could use a drill. Still gotta seal the oil station holes and make caps for them. Then i gotta glue it all up.1 point

-

Yikes. $45 on amazon for "the watchmakers staking tool". Yeah, I realized quick the tweezers were indispensable. I have a pair of Dumont 3c I like pretty well1 point

-

Make sure you get good tweezers . I bought 2 brass tweezers for an ebay seller that has some from Italy for $10 - $11 and I love them . I finally got a used pair of Dumont SS tweezers for $40 and the difference from the much less expensive ones I started out with is like night and day .1 point

-

1 point

-

Hi there, I've just signed up. My name is Lee. I am a computer technician by trade, but for several years now I've wanted to try horology as a hobby. Lately I've decided the time is right to make a start, I'm currently looking into tools, oils etc. Thank you mark - Your videos have been a valuable source for me, and have helped push me over the edge! Kind regards, Lee1 point

-

1 point

-

To be clear - the pusher is used on the brass fitting - not the jewel. The jewel and chaton come out together. Replacing the jewel in the chaton itself is another matter. It may be rubbed in (that may be what those notches are from) - hard to see for certain.1 point

-

Looks like a press-fit setting. You would need to use a jewel pusher from the underside (same side the balance is on).1 point

-

Welcome to one of the friendliest and most helpful forums on the web. You're embarking on a hobby that puts your entire existence into one square inch for entire moments, interrupted only by hours on your hands and knees looking for pinged springs which are looking down at you and laughing an evil laugh from somewhere in the upper atmosphere. (Of course there is that rare aha! moment when you find the dastardly creature hiding in the crevice of your shoe.) Those are the moments you live for. Well, those and the even rarer moments when you see straight lines merging on the timing machine... but those moments come many, many springs later.1 point

-

1 point

-

Adiorio, It isn't so much that the Sherline can't do it, the problem is that the machine was designed and built for a market with applications that have nothing to do with micro machining extremely tiny high precision watch parts. The Sherline lathe was initially designed to provide an improved alternative the the Unimat 200 which was a desk top hobby lathe. It succeeded in that goal and after a short period of time Emco stopped producing the Unimat 200. This is not necessarily a reflection on the quality of the machine but has more to do with the operator being able to get physically closer to the part that is being machined. The traditional way to operate an instrument lathe or engine lathe is for the operator to position themselves away from the cutter and part. The machining process is executed by turning hand wheels that move and position the cutter. The traditional way to operate a watchmaker lathe is to have the watchmaker's face inches away from the part removing metal with a handheld graver and watching the operation through an eye loupe. A certain part of the process has to do with feel. Since the cutter is held in the operators hand and not in a mechanical fixture, vibrations and pressure from the cutter can be felt. The watchmaker lathe lends itself to this technique by design. Trying to work around the larger lathe bed and cross slide mechanisms can become extra burdens if trying to use a T-rest and graver. This video should give you an idea of the process: https://www.youtube.com/watch?v=M6svZzTBIeM&t=5s david1 point

-

Hi for all. I read almost of the posts and I only can congratulate for a nice job in the restoration of these machines. Just a comment, may be to help understanding the work of the motor. This kind of motor is called induction motor or inductive motor. The speed is a directly proportion to the frequency of the source that supply it. In this case, 50 Hz. The tension applied to it's terminals only give the power to turn. The number of the coils of the motor fix the speed and less coils more speed. Normally in this application the motor have two or four coils (two will turn faster than four). This kind of motor was used in vinil record players because as the source frequency is very stable, the speed of the turntable will be too. With a reostat in series with the motor supply you only change the power making the motor strong or weak. O course if you have some obstacles to fight like the fluid resistence of the cleanning liquid, reducing the power, indirectly you will reduce the speed. That's why when you turn it on outside the liquid the speed raise to the top limit. You can lower the speed outside the liquid using a reostat with high resistece value, and the motor will lower the speer against the atrit between the axis and the supports, that it is not perfect. However, if you do this, when the basket is inside the liquid, the reostat will only increase the speed at the end of his cursor, and the speed will have a fast icrease with a small turn of the reostat. One more tip. The energy that is not used by the motor (in the lower speed) will be burned by the reostat. So, when you adjust for lower speeds, it is normal to the reostat to heat. I hope this can be helpfull in future jobs.1 point