Leaderboard

Popular Content

Showing content with the highest reputation on 01/16/17 in all areas

-

@chadders1966 whilst searching for a replacement, just for fun why not try and make one. You need some decent springy high carbon steel of about the right thickness, slightly thicker is good, something like an old (but decent quality) hacksaw blade for instance or a piece of old clock main spring. Heat it to a bright cherry red and then let it cool slowly to anneal it so that it can be worked. Next get it to the right thickness by working it on 400 grit wet/dry paper on a sheet of glass using an old champagne cork to hold it flat and keep your fingers out of the way. Work both sides and check the thickness often. Then drill the holes, one for the screw and two for locating dowels. Now superglue the broken pieces to the stock so that the locating dowels are in the holes and the screw hole lines up. Using this template you can cut and file to shape. Once you're happy, remove the template and carefully tidy up the finish, apply any chamfering or counter sinking. It might also be wise to test fit at this stage too although you don't have any locating dowels. Now bind the whole thing in soft iron wire in preparation for hardening. This helps to keep the heating even and reduces the risk of warping. Heat to a bright cherry red again but this time cool it quickly by quenching it in vegetable oil (some people also use brine). Unwrap it and check that it hasn't distorted. Also test it for hardness using a file, it should be glass hard at this stage. If all is well then clean at least one side to a bright finish so that you can see the tempering colours. Now temper it by placing it on a piece of brass sheet (the thicker it is the more evenly it will heat) over a spirit lamp and watch closely for the tempering colours to appear. The colours start with a very pale straw colour which gradually darkens and then goes to a light blue which then darkens. You want to make sure that the process happens evenly over the whole surface and you are aiming for a mid to dark blue. Once you have got that, quench the part in water. You can now polish the part back to bright, or even leave it blue depending on the aesthetic effect you want. For the locating dowels find yourself a sewing needle of the right diameter. Anneal it as above, and cut two pieces, slightly longer than you need. Install in the dowel holes in the spring and rivet in place. Now carefully grind to the correct length. Install the spring in the movement, sit back, and admire your handiwork over a glass of something suitable. Just a thought...2 points

-

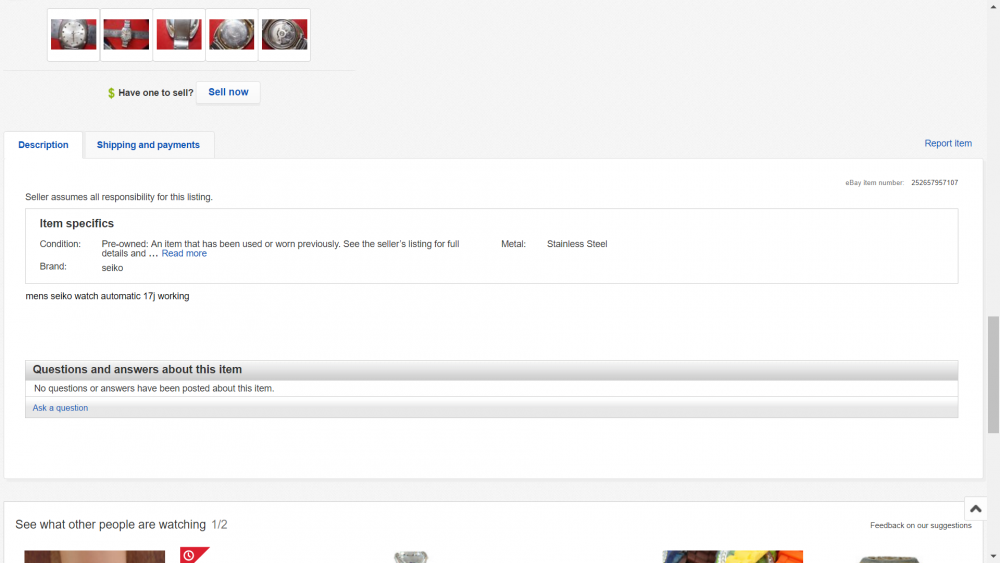

Got this very old Elgin Pocket Watch working again by giving it a good cleaning. After assembling it I noticed that the balance was not true to the round so I adjusted it with the truing caliper wrench, without taking the balance off the balance cock. A lot of luck I think. Enjoy. Sent from my iPhone using Tapatalk1 point

-

1 point

-

Well...still with shacking hands but following step by step while watching your videos ...thanks ! Sent from my iPad using Tapatalk Pro1 point

-

Yes it is running and in need of some care ..I love to hear the clicking..yep 90 degrees Sent from my iPad using Tapatalk Pro1 point

-

1 point

-

1 point

-

1 point

-

That looks much better than anything else suggested (by me included). Nice job. Vic1 point

-

1 point

-

Is there much paranormal activity in your house, I have noticed that my screwdrivers and tweezers keep moving from where I left them when I am tinkering with my watches, sometimes they dissappear totally and re-appear underneath something else. When I complain my wife just looks at me and shakes her head and mutters something about "getting worse". Cheers, Vic1 point

-

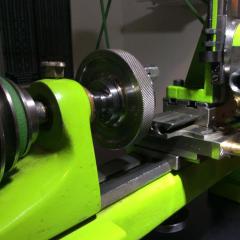

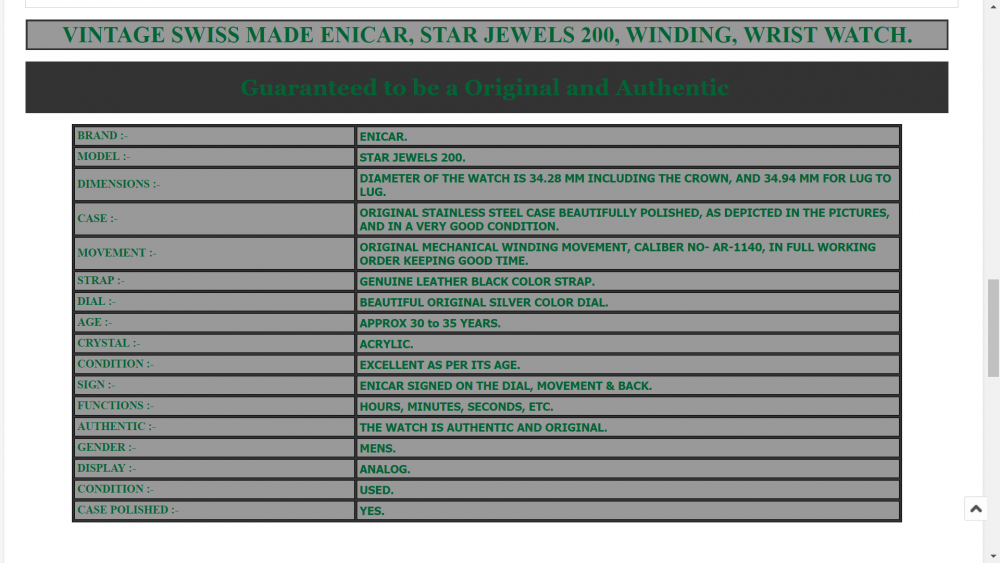

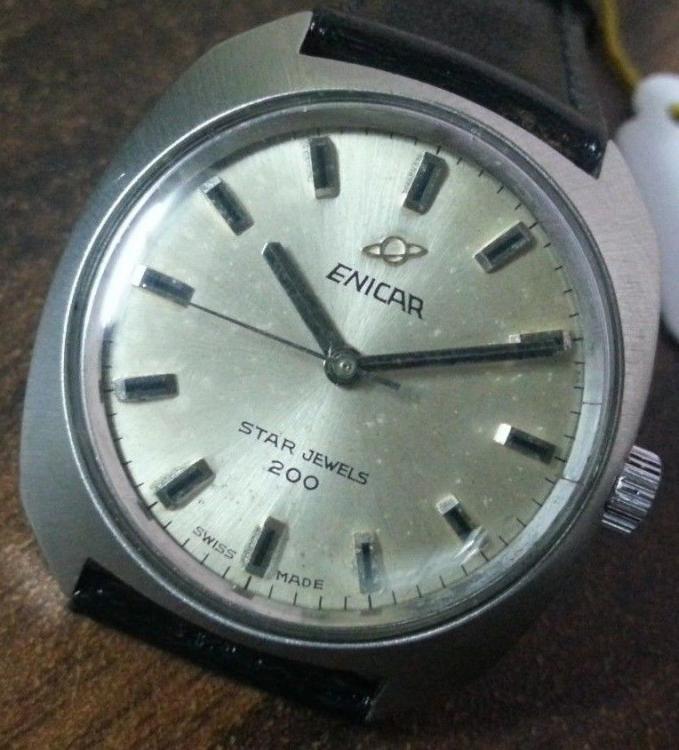

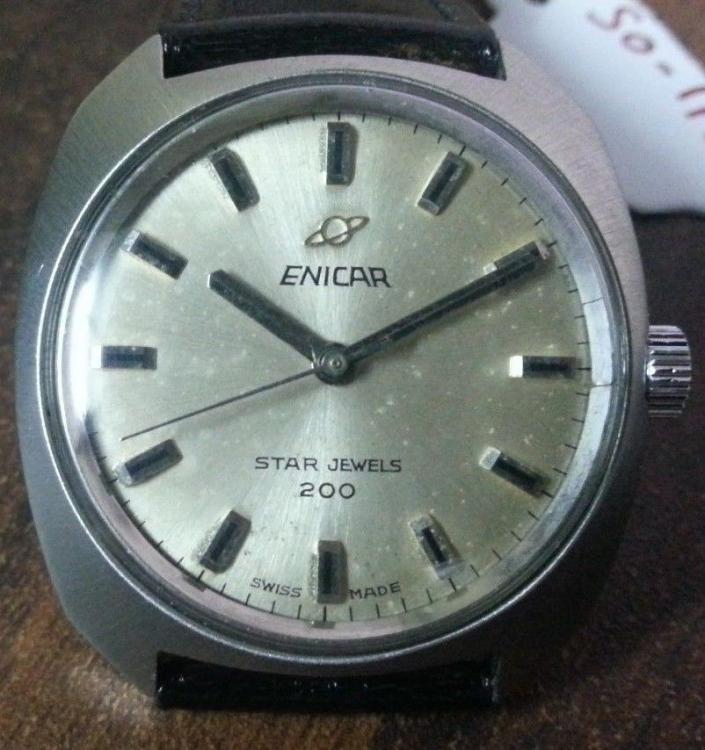

The second watch is from India. Buying watches from Indian sellers is a gamble as there are some real horrors out there. You need to be a bit alert and watch out for frankenwatches made out of bits of other watches. First up.. the ebay ad. Typical of Indian sellers, a lot of information is posted..they are usually truthful and if the dial is refinished they will say so. I was attracted to this watch because of it unusual shape, most from this period are round.. this is a bit tonneau shaped. The dial is also original with mile and even patina. Indian sellers often sell watches with refinished dials. Look out for painted dial in garish colours, generic markings (waterproof, automatic). Large 'Swiss made' at the bottom of the dial. Also if the dial has a raised logo (like the 'Saturn' in this watch) you may find the dial has been painted and the logo polished to bring it up.. the paint will be thick around the logo. Also Indian dial refinishers do not do the minute indices on the dial well, sometimes they leave this out altogether. Pay attention to the hands as well, they sometimes replace them with locally produced items which are basically stamped pieces of metal, the lengths of the hands also give a clue to their originality. Below 'seem' ok but who knows? Something which was only apparent when the watch was in my hand was that someone had done a good job polishing the case, with radial brushing done so fine it could pass for original. If I were to find a fault, I would say the transition from brushed top to polished sides was not as sharp as it would be from the factory. The polisher had popped the caseback on a lathe and left a rough grain, leaving the centre graphic polished. This was probably an attempt to disguise some caseback damage, these Enicars are difficult to open as they required a custom wrench. Personally I think its too rough and I may try try to polish it in order to tone it down a bit. A pic of the inside of the caseback. and the crown Finally, heres a picture of the movement. This is definitely an original Enicar, an AR1140 as the seller indicated. Quite a nice movement, there are some markings on the ratchet wheel where I imagine sandpaper has been used to get rid of some rust, also it seems that one of the bridge screws is not original (the lower one on the barrel bridge) otherwise all seems ok. One thing to stay away from are watches which have no markings on the movement except for 17 jewels etc. If there's no manufacturers markings then its a 'bitsa'. Running a bit slow so it'll get a service soon. There is some corrosion around the trough where the o-ring would go, this shows that the watch is really old and has seen some abuse in the past but the case polisher has done a decent job to get it back in good condition. Apart from a service, I may try to source an Enicar crown as the one currently fitted is an unsigned generic one. All in all a good buy for less tha USD40 all told. cheers Anilv1 point

-

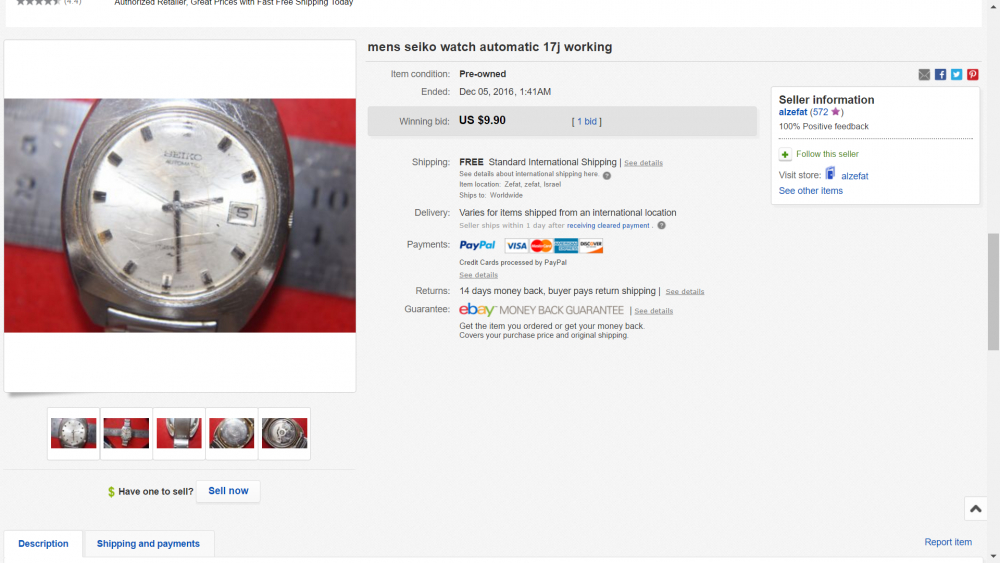

Just received 2 ebay purchases over the weekend and thought I'd share why I bought them . First up is a Seiko, Nothing fancy in the description, some basic pics... The pictures the seller posted showed that although the crystal was shot, the dial and hands were reasonably decent. It had an original bracelet and Seiko clasp, this is important for me, not only because it's getting rarer, but the fact the strap is still there probably meant the watch was not used that hard!. Caseback has survived without the usual mangling .. and it's a 'proof' watch. Post 1970 they went with 'resist'. Small point in its favour.! And the mechanism had no visible water damage. The crap around the caseback can also be a plus in that it shows the seller hasn't bothered to tidy it up and what you see is what you get! Well, when it arrived, I was happy to see that it was as advertised.. what I did not really like was the associated DNA from the previous owner.. if you have a weak stomach I suggest you stop reading here!! I believe this watch was unused for a long time as the crap had dried to a fine dust.. Needless to say this required drastic action. My favorite is boiling the thing in a saucepan for about 10 minutes. The boiling action is similar to an ultrasound. After boiling its into a jar with some washing up soap and then into the jewelry ultrasound. The water in the ultrasound was quite clear after the cycle so practically all the stuff was cleaned out during the boil-and soap sessions! The movement is sluggish and stops so it will need a service and the case will get a mild polish. The dial is almost perfect and I couldn't resist putting on a new crystal to see how it looks. All in all well worth the USD9.99. Part 2 to follow. Anilv1 point

-

Thanks Vic, I decided to go with a generic heating element, 110W. It takes a little while to heat up, but seems ok. I was worried of going higher in wattage, because nowhere does it say what the circuit can take, so decided to play safe. I also added a ceramic block for safety. Thanks again to all for their ideas. Loved Hamish's light bulb concept, but no one here in the UK I have asked has seen these bulbs. Machine is re wired and works great now.1 point

-

Hey @RyMoeller, thank you for the hands. The hands I got from you are perfect size, but just a little short. They will do for now. I am glad you received the remainder and the extras. I got those in a lot of stuff I bought and I don't think anything is wrong with them because they will tick if you wind the barrel. I will post an update when the GP watch is all together. JC1 point

-

Hi Stephen, glad you found My videos helpful in some way. Since you already sourced the jewel I'll jump to the next issue: the hammer jumper/spring. Honestly I've never seen a spring snap like that, and the only solution is replacement, unfortunately. On eBay you will find many that sell incomete movements for under 80€ so I would search for the occasion and grab it, you will have some spare parts aside just in case, which is always good. I bought some time ago a lot of 5 incomete movements, from which I then managed to fix 3 complete watches, spending 50€. Not bad... The PDF linked above with the compatibility chcart amongst model numbers will be really helpful. And should you still need them, I got the service manuals in PDF too for almost all models of Landeron movements.1 point

-

After cleaning the movement parts I checked the endshake of the balance wheel.the result is clearly visible in the small video I made: Comments?1 point

-

My name is Shirley. I have been fascinated by watch repair since the sixties. My father was a watch repairman for over fifty years in San Antonio, Texas, USA. He was a railroad watch inspector for Southern Pacific Railroad back when they used to have their watches inspected. That was before quartz watches. He worked on a lot of Hamilton, Illinois and Elgin pocket watches. When Bulova Accutrons came out, he worked on a ton of those. In fact, he wore a Railroad Accutron for many years. For a decade or so, he did watch repair by day (in my uncle's jewelry shop) and worked on the railroad at night. Eventually, he retired from the railroad and bought the jewelry store from my uncle and did watch repair full time. When he got older he developed Parkinson's and his hands became too shaky to repair watches. I bought his tools and thought I might try my hand at it, but it wasn't as easy as my father had made it look. I decided to take a watch repair course, but didn't get very far before my father became too ill and I had to quit and move back home to help take care of him. In the course, I had learned just enough to strip me of any false confidence I may have had. I can take a basic watch apart and put it back together... I don't promise I could repair it. But I'm dragging the tools and a few old watches out and trying my hand at it again. Mark's videos have given me back the confidence to try. I really look forward to interacting with any fellow watch repair friends here. I hope not only to learn a bit, but maybe share a bit of what I learn also. I will definitely take photos...1 point

.jpg.030324451a8b6256e95eb7625481e940.jpg)