Leaderboard

Popular Content

Showing content with the highest reputation on 10/15/16 in all areas

-

Finally got around to doing the battery change. No reason that i should not attempt it, Especially when one hangs out on a learned forum such as this. Just that this is a little more involved than popping in a battery in the wife's cheap disposables. First thing to do was to get out the Jaxa wrench and loosen the case back and use a toothbrush to remove any debris that may be caught between the cover and the case. And loosened all the way Sure takes a lot of patience to set up the wrench. One must be very careful not to scratch the watch, especially since this is Titanium and is so easy to scratch. I would not want to take a a chance on a precious metal case. Especially if it was someone else's watch. Inside was the Ronda 715.5 Gold plated five jewel movement. Nice to see a bit of an upgrade from the standard movement. The 371 battery was easy to remove, being careful to not slip and damage the coil while prying back the battery retainer. It was decided to remove the movement from the case so a proper cleaning could be done. Out came the stem and the movement followed. The case, band, and back were treated to a good scrub in dish soap and hot water with a soft toothbrush. I hope the wife doesn't mind that I used her toothbrush... The gasket for the back looked in really great shape and as advised, I re greased it and the threads of the back with silicone grease. Also lubed the O ring in the stem tube and the gasket inside the crown. I took the measurements of the gaskets at the same time so I can order them when i service the watch movement at the next battery change. I do not have the proper oil yet. The hardest part was cleaning the inside of the watch crystal to perfection as well as removing all specks of dust from the dial face. Any issues here and I would be looking at them for the next couple of years. All assembled and ready for the band. The specks you see are on the outside. And of course the obligatory wrist shot. Love the look feel and warmth of the Titanium, but hate that it scratches so easy. Bit of a mess after an evenings work... Thanks to all for the help and advice for such a simple job...2 points

-

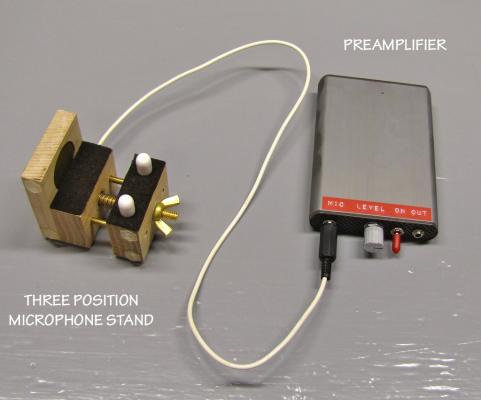

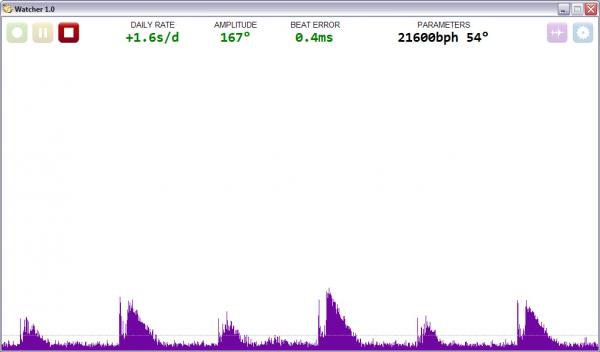

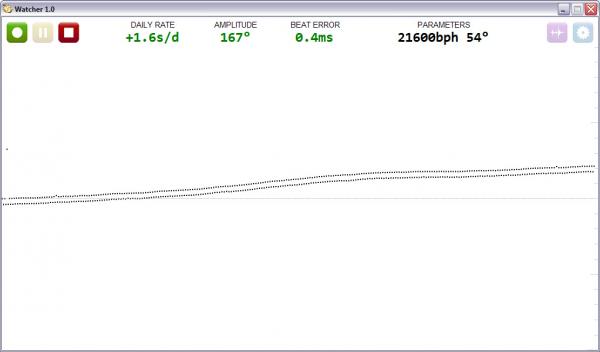

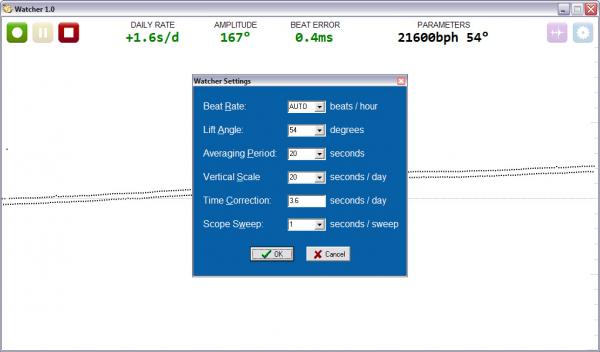

I'm a watch DIYer, having serviced two watches myself, partially using tools of my own making. One thing I've been working on over the last few months is my own PC based timing machine. I've finally got something working reliably, and thought I'd preview it here. My plan is to eventually write up a detailed article on my web site describing how to build the hardware, and providing a download for the software. I may also produce a "pro" version of the software with more features, to be sold for a reasonable fee. Here's the hardware, all home made of course: The next picture shows the timing trace from my "Black Lagoon", a modified Invicta 8926OB with a Seiko NH35A movement (yes, the amplitude is quite low and tends to fluctuate, topping out around 220 degrees - apparently this is par for the course for Seiko movements): In this picture, the software is in scope mode, showing directly the ticks and tocks. Notice how with this movement, they alternate in loudness. Since the scope mode was run after the timing mode, the scope also shows the threshold that was used by the timing mode to detect the start of each tick. And this is the settings window: Here's a brief list of features so far (I have to resist creeping featuritis): Numerical display of daily rate error, balance amplitude, and beat error. Horizontal "paper tape" mode with sub-pixel vertical resolution that can show fluctuations that are too small to see on a typical stand-alone timing machine. User selectable averaging period. Rate determination using linear least squares, which gives a more meaningful reading than just naively averaging the rate. Automatic signal and noise level determination. There's nothing to adjust. Aggressive noise filtering in the software to keep the hardware simple. Automatic rate detection for common rates. Simple, uncluttered, fixed-size display (1024x600). Scope mode to aid in diagnosis of various watch faults.1 point

-

1 point

-

Hi everyone, I've been interested in Horology for a long time, I'm guessing a big push in that direction was when I was 13 I was given my great grandfathers BTM watchmakers lathe. My grandfather and great grandfather were both watchmakers, so I guess it was only a matter of time until I caught the bug. Where I live they stopped running formal training on watch and clock repair over 10 years ago until the Master Clock and Watch Makers of Western Australia started running night classes staffed by volunteers 3 years ago which I've been attending since January this year. I've still got a while to go before I reach the point of being able to service and repair other peoples watches and clocks, but at least I've got a path to my end goal now. I have all the tools now to carry out basic servicing and repairs on clocks and almost everything I need for basic servicing of watches which was helped along the way by an out of the blue call by my step uncle offering me my grandfathers watch repair toolkit which was even more amazing because at the time he did not know I was studying watch and clock repair. I also have a workshop set up for model engineering complete with a Chinese lathe, Mill, drill press, cold cut saw etc which will prove it use especially with clock repair. I still haven't set up a dedicated service area as I've yet to convince the wife I need a space in the house as my workshop is not suitable as its full of a dismantled vintage BSA motorcycle, but I'm sure I will get over that hurdle within the next 6 months. I stumbled across this forum a few months back and figure now is about the right time to join as I'm hoping over time besides asking for help I may be able to provide some too. Attached below are a couple of photos of my BTM lathe, for those that dont know it was made in England during WWII for the military as obviously the German lathes were not exactly available. Tony1 point

-

I like it! It's in great condition. I notice it is showing 5 minutes after "hometime". We would have been playing football by then. :-)1 point

-

1 point

-

Way to go JD! BTW, can I send you my GPS refrigerator? The 20 stackable micro battery cells is not charging either and it misplaces my beer! Soldering those may be a little tricky but since you can do it... Cheers, Bob1 point

-

I'll take watches over chores, unfortunately, sometimes they are equally challenging, you have the patience of a saint....1 point

-

1 point

-

Really nice job. I buy my crystals from Dave"s he is great. http://www.watchpartsandtools.com/index.html you can even send him the bezel and he will fit it. I like to do my own but it's an option1 point

-

HI, I've got bigger cast iron too, for the bigger stuff as I built myself a workshop around 10 years ago for model engineering. I've got a larger lathe and a milling machine, photos below showing the milling machine set up with its dividing head for drilling the holes to make a lantern pinion. These photos were taken a awhile ago and my workshop isn't so tidy now. I'm very lucky that the night classes I go to are only about 20 minutes drive away. Thanks everyone.1 point

-

Still mucking about with this movement. It fascinated me with one train bridge on top of the other . The whole watch , movement, case and strap cost £10 brand new. The time keeping was awful, with a complete scattered pattern on the timegrapher. I stripped it down, oiled it and reassembled it. Just regulated it even with an unacceptable low amplitude. Better now but not perfect. See pics below. I think originally the hairspring was hitting the seconds wheel. Anyway was either doing this or jobs around the house this afternoon. No contest really. Sent from my SM-G920F using Tapatalk1 point

-

Just a small point on this....Don't forget to check bid history and be suspicious of intermediate bidders who are pushing the price up and have a large amount of retracted bids... CDT1 point

-

1 point

-

Accutrons are not for the faint of heart. My father gave me his Bulova which he received as a wedding gift from his parents and it also wasn't working. I popped in a new battery and it came to life except that the hour and minute hands don't move. From what I understand, rusty cannon pinions are common which result in a watch that appears to run, the hour and minute hands just won't move. I've looked under the microscope and there are two jeweled pawls that contact a wheel with the tiniest teeth you will ever see (it really is the most amazing mechanical watch), well long story short, I've had it in my desk now for about six months and still don't have the courage to attempt a service. I do have a PDF of the 218 service manual if you need it though. It's readily available on the internet although I cannot recall the site I located it from. Also have about fifty Accutron crystals too. Let me know if you need one and I'll drop one in the post for you.1 point

-

It's definitely your low battery power indicator with the four second jumps, I would change the battery myself, check the condition of the case back gasket, renew if the profile isn't round anymore, re grease the gasket and fit back making sure all contact surfaces are clean, I'd also remove the stem and crown, clean the case tube and relube it before returning the crown and stem to watch. Obviously you can't be 100% sure your watch is water resistant without a pressure test, but if you do this you'll give it a real fighting chance. Brian1 point

.jpg.6225a64433578a11e0218b27c20b13f5.thumb.jpg.d82b0cd1e370f3a3a59a06afa957d184.jpg)