Leaderboard

Popular Content

Showing content with the highest reputation on 04/25/16 in all areas

-

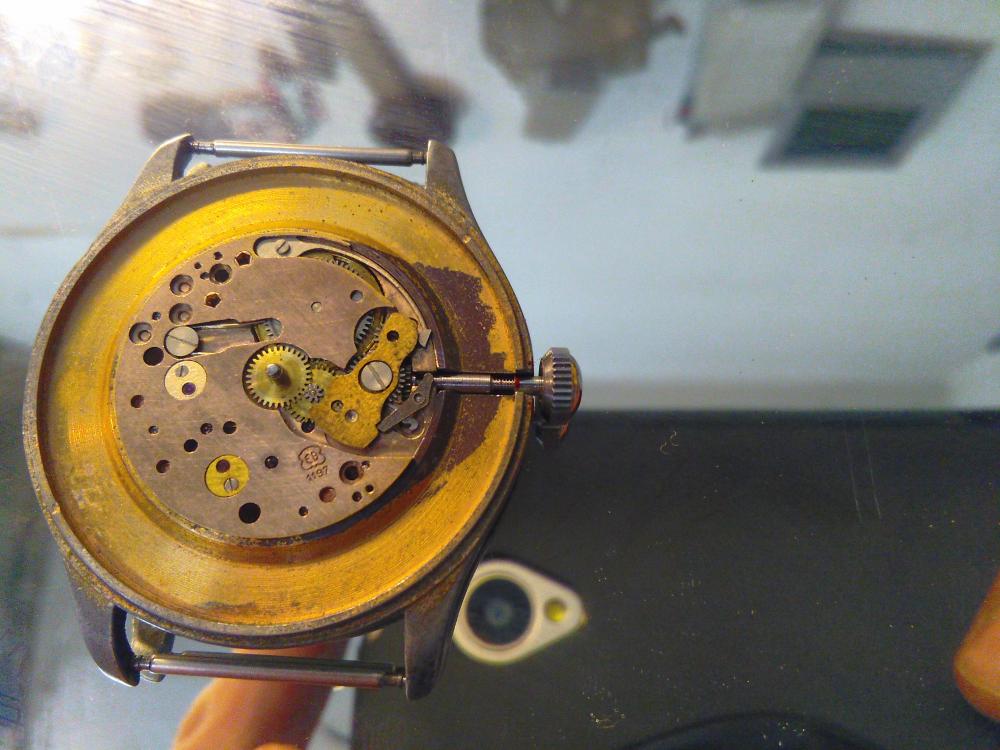

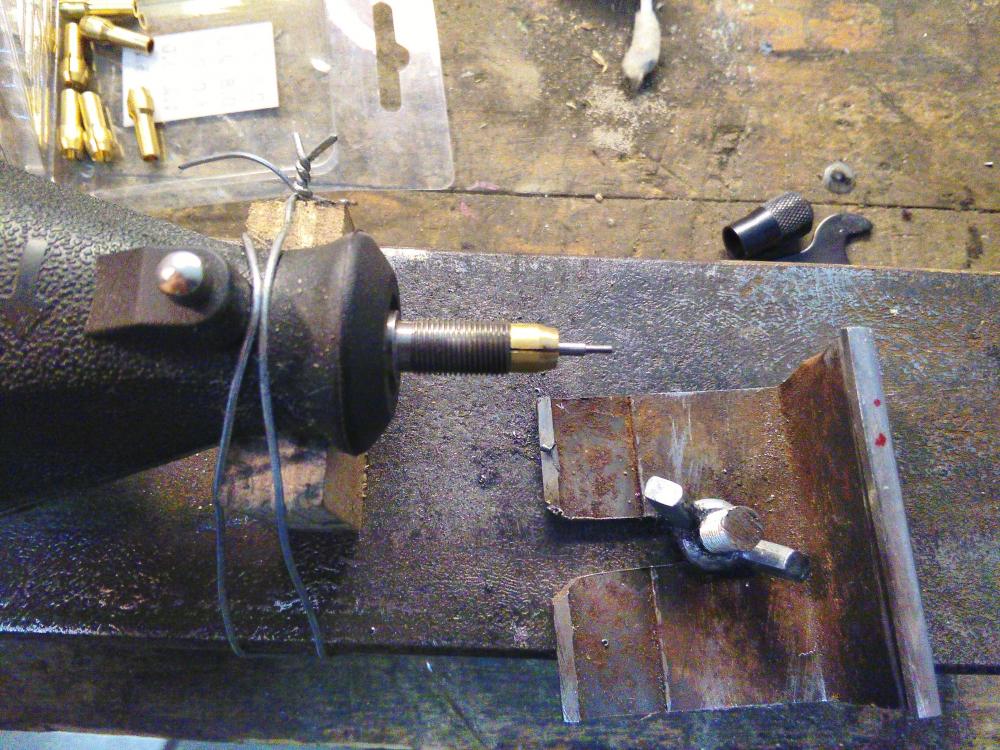

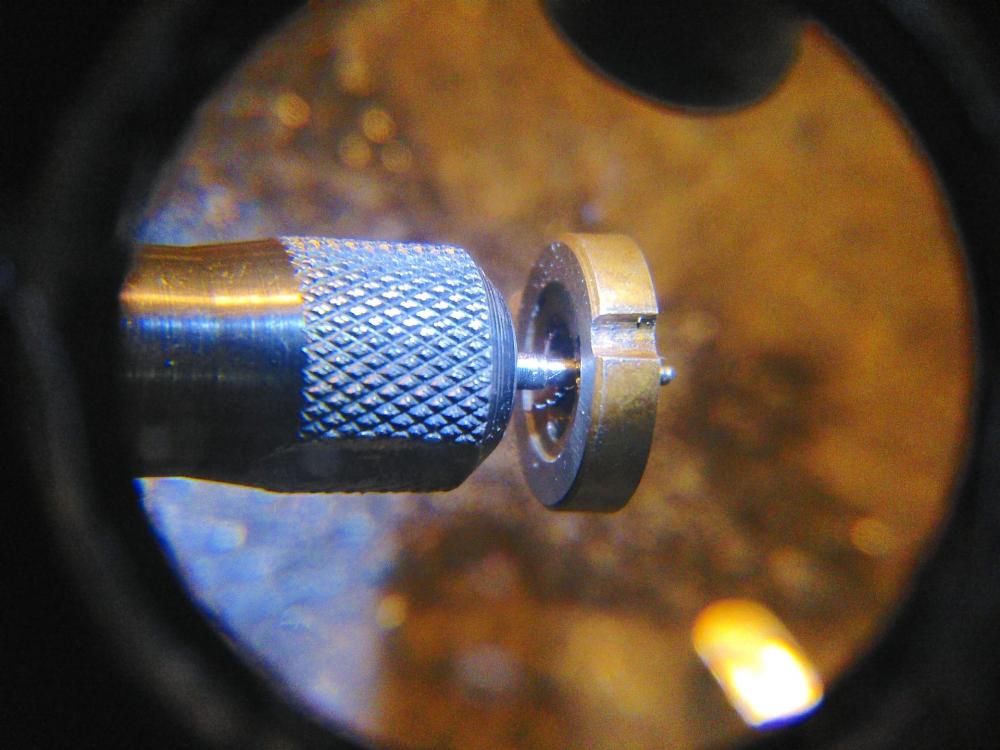

Some of You asked about my Dremel "lathe". I will post my works here with this fine tool To use the Dremel as a lathe please make sure that the bearings are in perfect condition! In addition, care must be taken no to push the tool to hard on the working piece, since the shaft is to long and thin. The tool can blunted ot the working piece can break or bend. Moreover, use only the low speed stage! The manual say it is around 15000 pm for my Dremel but I am sure its a way slower. Here, i am turning a stem for an EB1197 movement: This was my first documented try, see this video for a much better pice for HMT watch: Today i got one crown for it so continued work on the EB1197 stem. Thread was cut also on the Dremel holding (and pushing) the die with 3 fingers and turning the collet with my other hand: The Dremel is just tied with wire to a piece of iron beam. Between them are two wood pieces (one at the front and one at the end of the Dremel) with a half-circle cut to fit the two support points. Notice my adjustable T-rest! Here i had to make a longer thread and shorten the length: Just a bit more to cut down: Using a set of collets You can see in the upper left corner. They are coming from an 8 pieces set ranging from 1 to 3.2 mm as i remember. Just search for "Dremel collet" on e-bay! You have to check the Dremel shaft diameter since there are more available. Just fits in the 1.8mm collet, the thread is tap7 (120 or M1.2x0.25). It is important to note that the delicate front part has to made in one run, since the work piece wont be true after removing and putting back in the collet. But to cut down the length it does not matter. The length is perfect now, lets glue the crown and the stem together: And of course it is working flawless Ready to go: Next time i will make a replacement dial feet holding screw for my Roskopf pocket watch.2 points

-

2 points

-

2 points

-

Its a simple wave editor. Just measuring elapsed time between beats. Colored numbers were put therein Windows Paint I managed to get the loss down to 7.7 min/day.2 points

-

Maybe from CousinsUK? You will have to measure the spring to get an equivalent....2 points

-

1 point

-

1 point

-

There was no walkthrough in the thread, I moved it to the collection section. When the walkthrough is ready you can of course post it in the walkthrough section - please don't be offended, i'm just trying to keep posts in their relevant sections @toptime810, What is the point of this?? Kindly do not make pointless posts in threads.1 point

-

Usually they provide pictures from the movement which You can identify (for example @ www.ranfft.de) and considering the bidding if the parameters match. Its really hard to find "just the case" :/ Or check here: http://www.speedtimerkollektion.com/shop/index.php?cPath=32_85 once i bought a movement for parts fore really cheap.1 point

-

You can probably use a bigger case if you have a spacer or a movement holder. Most important should be the stem height. From dial to center of stem.1 point

-

If I remember correctly, some of our members demagnetize before and after the watch is given maintenance. This means that parts go demagnetized into the ultrasound and after the watch is put together (some even say they demagnetize parts separate, maybe in a basket) it is demagnetized again. I follow the compass test. Since my demagnetizer is a cheapo one and more than once it has done the opposite, i.e. magnetize! I test always with a compass as if I were paranoid: before, after, during and at any time I remember...(err...what were we talking about?!) Cheers, Bob1 point

-

That's very good - though I think I'd prefer a bottle in a boat... Cheers, Will1 point

-

My tools don't need demagnetising in the workshop, it's a no "shop staff" allowed area. The tools I am talking about are the blunt/damaged unusable ones the shop staff use for taking out links and hitting with a hammer, I would be just wasting my time demagnetising them because the steel draws they are kept in are also used to stick magnetic name badges onto when they go home. Talk about banging your head on against a brick wall!!! I used to try and educate them but then realised I am fighting a loosing battle!!!1 point

-

1 point

-

1 point

-

Not sure on the technical side of it, considering some watch cleaning machines have built in ultrasonic I would presume they don't emit a magnetic field in general but anything that is metal that is already magnetised could transfer the magnetism to whatever you put near it. I suspect the ultrasonic tank your wife is using is already magnetised. Do some glass's have a magnet built into the frame to hold the legs closed or is this always done by a spring? I work in a watch repair workshop in a jewellers and if I ever get asked to change a battery downstairs in the shop it's a nightmare, all the tools downstairs (apart from them all being hit with a hammer at some point to take links out and are damaged to start with) are magnetised, it's a nightmare trying to put a battery connection screw back in.1 point

-

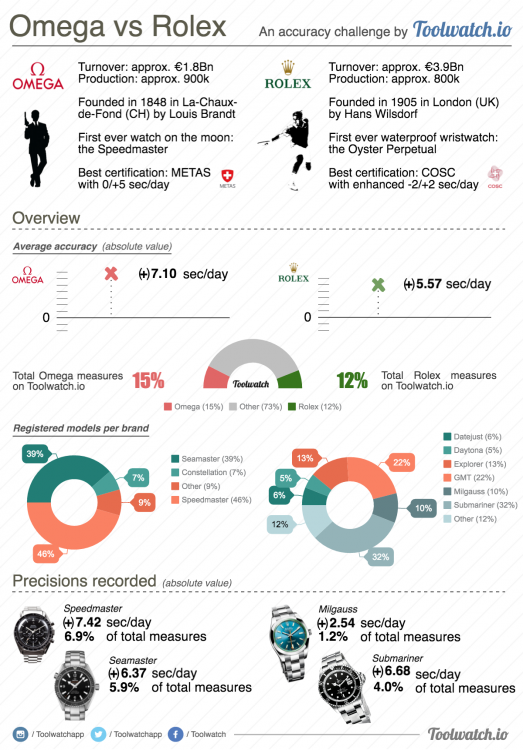

Hello everyone, I have found those really interesting stats comparing the two biggest (at least in my opinion) watch brand in the industry. Those data were collection using https://Toolwatch.io Personally, I tend to find Rolex more reliable as my Submariner is way more accurate than my Speedmaster (though this one was bought earlier). What are your thoughts on those two brands ?1 point

-

1 point

-

Putting a watch on anything metal that could be already magnetised could magnetise your watch or anything electrical like on top of a computer when you go to bed is the most common one. So I would say an ultrasonic tank could well be magnetising your wife's watch.1 point

-

OK I have been following this thread for sometime now loosely. Would I be correct in summarizing that basically, if you plan to work on more than one style, or one brand of watch, one must have approximate 50-100 different types of oils on hand that may or may not ever be needed? Or Moebius 8000 in a pinch.....1 point

-

Try some saddle soap on the watch strap or - as rogart says - some leather cleaner. Cheers, Will1 point

-

Depends on the material. No harm in trying to clean it. If it's leather clean it and put some Leather grease on it. If it's rubber it could have become brittle.Nevertheless i say go for it Show us a picture? Both of the watch and the strap Always fun to see barn finds.1 point

-

Is there any punches where one can put a very small punch or drill on? Tried to remove some old pivot from a second hand. From the other side? Would have been awesome to have a punch that was 0,17 in diameter or smaller. I did manage to remove it with a tweezers edge and cleaned it with a small nylon strip from the toothbrush. But next time?1 point