Leaderboard

Popular Content

Showing content with the highest reputation on 08/07/14 in all areas

-

I've seen worse... Whats that stain on the balance cock.? Glue or wear? You have to understand that watches in India are basically used until they wear out... there is no parts support and the watch repair service guys have to manage the best they can. They are able to keep watches running by cannibalising others and often this is good enough to get the watches running, after a fashion. Problem is when you come to items like gaskets, crowns, crystals and auto-wind weights...once its worn they will have to make do as best as they can. I've seen one India special where the bearing was modified to run on a bush.. it was quite well done and the weight spun evenly.. basic stuff but works! You can see a lot of re-dials and this leads me to think that there is an active industry for this in India but the quality is really off. Look for Seiko chrono dials on eb@y... there is one version where it 'water-resist' was printed on the dial but the 'wa' is covered by the 9 o'clock marker making it 'ter resis'! doh! I bought a Favre-Leuba Seaking (boy size) from India and the case was quite sharp, practically new, but the movement did not match as it looked quite worn. Dial was redone but it was quite well done... only issue was the seconds hand was short but I can live with that. Things to look out for on ebay...... 1. redials.. no minute markers and the words are not sharp. No wear visible. Some really gaudy colours which even the 70s cannot match! Hands will have lume but not the dials (or vice versa). 2. Cases have been polished to death.. no sharp corners on the creases/ transition from vertical/horizontal surfaces. Caseback are usually worn smooth and have many marks where tools have slipped. 3. With the caseback off, a lot of corrosion visible in the caseback seal area in the case. India is hot/humid and this equals sweat@! 4. Movements with no brand..just seventeen jewels. 5. Possible to positively identify the last watch repair person as he left his fingerprints on the movement. 6. Missing movement spacer replaced with a bit of o-ring (large) or copper wire.. Having said that... India sellers tend to have a lot of photos on their listing so you can usually spot what to stay away from... one good thing... they are without exception.. 'recently serviced' !!! so you can be sure of getting a good deal.!!! Anil2 points

-

I picked up a nice 9ktgold Smiths Astral on Fleabay at the weekend. It is running well and just needs a bit of tidying up cosmetically. I serviced one for a friend of mine last year and was really impressed with the quality of the watch, especially the movement. Since then I had been on the lookout for one.1 point

-

All you need is one ultrasonic cleaner. Put water in the machine and have separate jars with your preferred solutions in them. All you have to do is place the jars into the water and the vibrations will penetrate the glass and clean the parts.1 point

-

I think if you're a fully professional watch repairer, doing a fair number of watches on a regular basis, then it might make sense to aspire to a dedicated watch cleaning machine. If less than that standard, then perhaps a second thought about that... If you bought a Cousins machine (for example), would that £7k get recouped in any way - or would you have a very expensive hobby! Tha analogy, for me, is with guitars. I have 4 that I use in a (nowadays) semi-professional capacity, i.e. I earn money with them on a reasonably regular basis. They cost me a total of about £3,500 - but I've paid for them all by playing gigs. Now, there's more romance and fun in a guitar than a watch cleaner, :D so I might have bought them anyway! But, on a strictly utilitarian basis, the economics have worked out for me.1 point

-

1 point

-

1 point

-

1 point

-

Thats a wrap. It looks to me perfect a touch of real class I would not fiddle any more.1 point

-

1 point

-

Excellent advise there Bob. And I totally agree that these are a lovely movement to work on, and a great confidence builder for beginners like me. The one I worked on had a broken Pallet Fork pivot , so definitely double check all the pivots. I think these watches from India are a boon for budding watchmakers to train on, cheap and lots of popular movements. I myself have grab one for a restoration I'm doing on my brother's watch; but I'll be definitely buying more for cheap spare parts and training material.1 point

-

Excellent advice from Anil, to which I'll just add that makes to beware of are those like Favré-Leuba - marques which, when the quartz era came along, were acquired by Titan Industries, the Indian industrial giant - and others whose principle market was Asia. It's not uncommon to find dials glued on to the movement, lume crudely applied to numerals and, as Anil has mentioned, case lug shapes polished away. It's also worth noting that some eBay sellers in the UK get watches as job lots from India - very cheaply - and then sell them on here for profit. I avoid Favré-Leuba on principle.1 point

-

Lawson, for a beginner you have done remarkably well, another very interesting write-up. With the very high cost of labour it probably would not be viable taking a Seiko kinetic to a repair shop as the cost would probably outweigh the value of the watch, this is another advantage of being able to repair it yourself.1 point

-

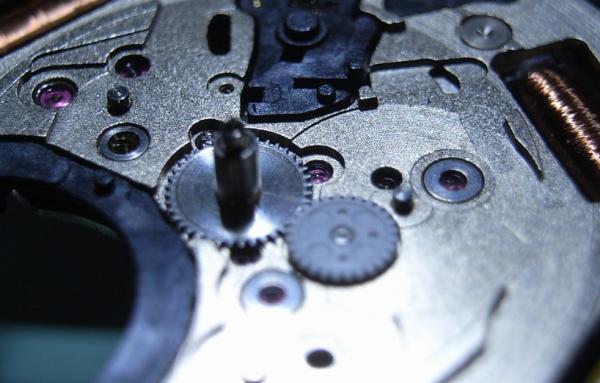

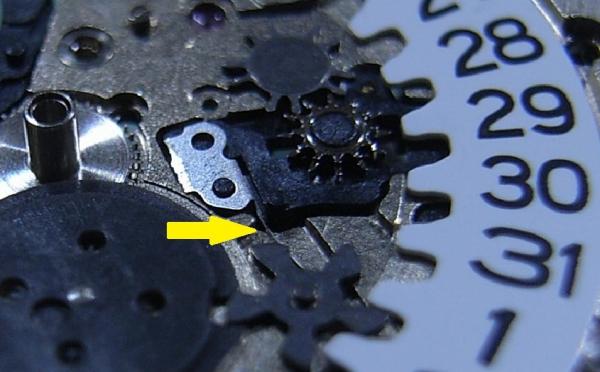

Hi rob, I think it is definitely salvageable. I was looking at cousins -- I actually ordered some parts for the same movement in your post -- they have very reasonable prices and most of the essential parts. Apparently the rotor has a bad bearing and is rubbing against the cock - if it is wear. Or maybe the stem where the rotor screws in has to be pinned in place but the picture is not telling. Lawson has a complete walk through in this site for this movement, look for it and you won't have any problems servicing it. It is an easy movement. Check for broken pivots in the pallet fork, escape wheel, balance wheel mainly... or any other wheel while you are at it. Also inspect carefully looking for rust/wear damage in the 2nd reduction wheel and pinion as well as a broken/cracked/worn pawl lever. Also check for any jewel damage just in case. I usually peg all the jewels before cleaning and even brush with a fiberglass rust brush some of the parts that may be rusting. I bet after a good cleanning the damaged part will surface right away and it will not be much. Good luck and happy watchmaking! Robert1 point

-

Dear Cassandra, Looks like you've really got a problem..! What I usually do when faced with a stuck caseback on a normal watch is use a sharp knife at the edge of the notch and use a small hammer to drive the knife deeper and start the back off. You need to support the watch well and keeps your fingers out of the way, small taps is what you need, don't try to whack it off in one go. Get someone to help as two hands really are not enough. The bracelet looks like it will be in the way so see if you can get it off.. looks like it has plain pins which press out... it will be spring loaded so getting it back on is fiddly but nothing patience can't solve. Bob is very right in saying that getting it back on will be a problem... these types of cases are usually made of pot metal and really break easily so be careful. As for gluing the bolt on the back, this is mainly for casebacks which screw on... not so much for these types. In this case I would suggest sending it to a regular watch battery shop place.... its not worth the hassle. Anil1 point

-

1 point

-

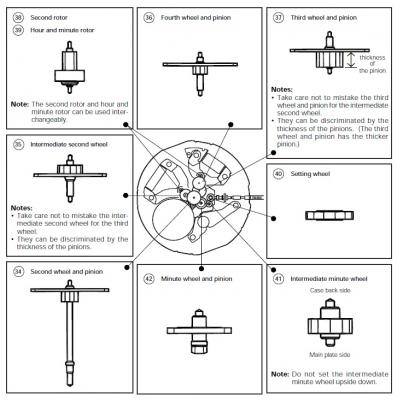

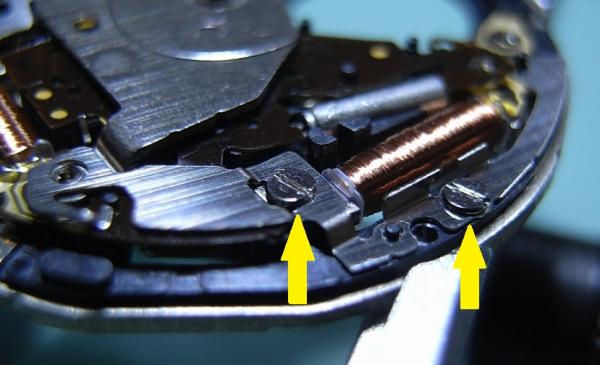

Assembly Place the Circuit Block Spacer onto the Main Plate Clean all the Stators and Rotors before you re-assembly them ... yes they are that small!! Fit the Hour and Minute Stator, and Hour and Minute Rotor Fit the Clutch Wheel and the First Intermediate Wheel for Calendar Corrector Fit the Stem Replace the Train Wheel Setting Lever, Yoke, Setting Lever, and Setting Lever Spring Fit the Generating Stator and Generating Rotor, and also the Second Stator and Second Rotor Next is the Train and Motion Work, it is by far the hardest part of the assembly. It is all housed under one plastic bridge, so to make it easier here is a location chart. First the Motion Work - Setting Wheel, Intermediate Minute Wheel, Minute Wheel and Pinion Slide the Center Wheel and Pinion in the affix the Spacer Then add the Train - Third Wheel and Pinion, Intermediate Second Wheel, Fourth Wheel and Pinion, Second Wheel and Pinion Place the Train Bridge on and locate all the gears into their jewel holes. Next steps are easy, but be careful and gentle Fit the Coil Blocks - Generating Coil Block, Second Coil Block, Hour and Minute Coil Block Then CAREFULLY fit the Circuit Block Place the Oscillating Weight Bridge; but do not screw down. Then fit the Circuit Block Cover B, and only fasten screws indicated by yellow arrows. Place Circuit Block Cover D but do not fasten Continue and fit Circuit Block Cover C, this one you can screw down ... sorry forgot to take a photo, but it's the only cover left Now place the Circuit Block Cover A Cover on and fasten down all the screws Remember to leave the Battery Screw out ... as shown in the picture below Flip the movement over and fit the Hour Wheel, then the Intermediate Hour Wheel NOTE: I pictured the Intermediate Hour Wheel upside down ... sorry about that. Fit the Intermediate date Driving Wheel Replace the Date Driving Wheel, and the Date Driving Wheel Spring (Note spring location) Replace the Day-Date Corrector Wheel (See fitting instructions on Page 9 of Tech Specs) Replace the Second Intermediate Wheel for Calendar Corrector Place the Date Dial Guard on, fit the Hour Wheel Guard Spring, and fasten Install the Battery, and then fit the Oscillating Weight Fit the Dial and Hands Case the movement back up ... and you're done!1 point

-

Hi, Just signed in to what seems to be very interesting site. Your watch is well worth restoring. The Constellation case appears to be stainless steel which should clean up nicely. I have worked on several of these Omega Constellations. There should be four screws one in each corner that holds the movement and case back in place. They screw through the case but not into the back. In theory if you took out the three non rusty screws with any luck you should be able to remove movement. Inside you will find that the movement will still be inside the case back held by a split stem. Movement will most likely be a 1001 caliber. A new crystal will run somewhere around $40.00. I just bought one about 6 months ago for mine. I don't think that Constellation movement and dial will fit into the gold case. The dial can also be redone and similar dials can be purchased on ebay. Of course taking off the dial is a bit tricky and putting it back is even more so as you have to take off the autowind mechanism so that the center sweep pinion can be supported while installing the second hand. If it would help I could take mine and take pictures of it as I take it out of the bezel to show what I mean. Good Luck Charles Kelly1 point