Leaderboard

Popular Content

Showing content with the highest reputation on 07/30/14 in all areas

-

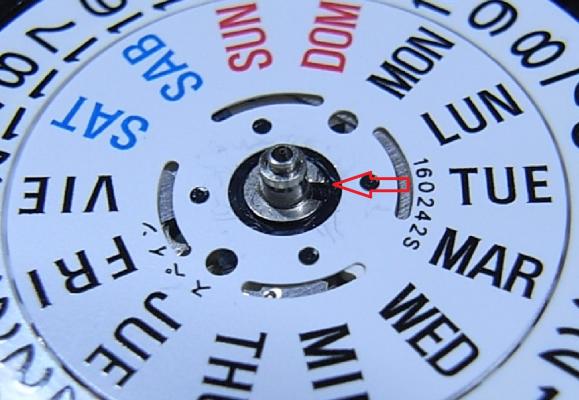

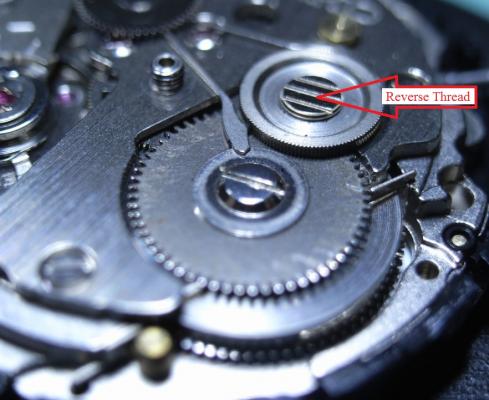

Seiko 7S26A Complete Service Background I have a good friend, a brother in Christ Jesus, who I've known for many years. He knows I've embarked on retraining myself for a new career in Watchmaking, and seen my first two restored watches. He told me that his old faithful Seiko 5, which he's worn everyday for 12 years, has recently had issues. Occasionally it will advance rapidly in time (up to an hour in a few seconds) and then just keep ticking away normally. I told him I'd be happy to take a look at it, and put it on my ACEtimer Timegrapher. The pattern on the screen looked like a B-52 drop in Nam (stupid me forgot to take a photo), and I told him that his watch definitely needed an inspection and service. So started my research on what the problem might be. After reading a "Practical Watchmaking", and the many forums that I've read, I was pretty sure it was the Pallet Fork ... either very dirty or damaged stones, or a broken/damaged fork pivot. So onward to the service... Disassembly One unusual aspect of this watch is the crown ... or lack there of, more to the point. I suppose since this is an automatic watch, they thought it didn't need to be wound. This watch also has a display back, so extra special care not to mark any of the plates, or damage screw heads! The first issue you'll face when working on a 7S26A Movement, is how to get the stem out! It isn't obvious at all, and there is a little trick. The crown needs to be pushed all the way in to expose the push plate (it is hidden in the other crown positions). I took this photo once the movement was out to best illustrate where to push. Remove the Hands, Dial and Oscillating Weight (2.0mm Screwdriver). Gently lever up one end of the circlip and carefully work your way around. You then should be able to raise the circlip up the length of the shaft without it pinging off. Remove the Day Wheel and the four screws holding the Date Dial Guard. (Use a 1.40mm Screwdriver, and this driver is good of all the screws from now on; bar one.) NOTE ORANGE ARROW: Seiko Special Tool needed for the 0.98mm Philipshead Screw (Part Number: S-921) I had to journey down to my nearest Seiko Distributor and grab one ... cost was AU$24.00 Here's a closer look at the troublesome screw. Remove Date Jumper, and note that the Date Drivewheel lips over the top of the plate. Remove all the motion work, and pull the Cannon Pinion Remove the tension from the Mainspring. Remove the Ratchet Wheel and the Second Reduction Wheel and Pinion. (remember the Reduction Wheel has a reverse thread) Unscrew the Balance Cock and remove the Balance. Also unscrew the Pellet Cock and remove the Pellet Fork. BINGO! Found the problem with my friends watch. The top pivot on the fork is broken. Easy fix with a replacement fork :) Remove the Barrel/Train Wheel Bridge Remove the Click, then the Barrel. Remove the Fourth Wheel, Third Wheel and Escapement. Unscrew the Centre Wheel Bridge and remove the Centre Wheel Now to the Keyless Work. Remove the Setting Lever Spring Remove the Yoke and the Setting Lever Pull the Stem out, and the Clutch and Intermediate Wheel will fall away. Lastly, pull the black plastic location ring off. ... and now it's bath time!!! I hope this has been of help to you guys. I'll post the Assembly steps in this thread tomorrow morning.3 points

-

2 points

-

I would love one of these, but the budget and wife, won't allow it. So I bought a reasonable quality 0.001mm micrometer and formed a small piece of aluminium around the shaft, which will also slide to allow normal use of the tool. It is excellent for Jewels as they sit flat on the arc of the sleeve.2 points

-

Hi, I think of problems you are describing as puzzles to be figured out. In another post I mentioned an Omega Constellation I have. It started doing almost the same time you describe. It would run for a bit keeping good time and would stop for apparently no reason. After several times of taking it apart and putting it back together I finally realized that there was a breakdown in power transfer from mainspring to drivetrain. At first I thought there must be a bad tooth on mainspring barrel or the gear meshing with it. Took it apart one more time only to find I was wrong again. This time however I had determined that slight pressure on any of the other gears would cause watch to run smoothly but pressure on mainspring barrel and nothing would happen. When I investigated the first wheel closely I found the gear messing with the mainspring barrel to be loose on the shaft. Replaced first wheel and watch has been running for over a year now with no issues. Like I said I think of these sort of issues as puzzles to be learned from so when in doubt I walk away, grab a cup of coffee and just think about it for a bit. Another trick I find that helps is shown in Marks video where he services the rusty Breitling. He puts the drivetrain back in place and gives it a little push on the mainspring barrel before adding the pallet fork. This not only insures that all wheels are in proper place but it may allow you to feel if something is binding. None of this may help you and you may have already tried some of what I mentioned but I like to offer any help I can just as I read these forums to learn from others. Charles K2 points

-

Hi Lawson, you're quite correct about the first numbers; -9 seconds daily rate, and 230 degrees balance amplitude. The third number is the beat error. In a perfectly adjusted watch the beat error will be zero and the watch will tick evenly (or "in beat", think musically), and with the movement at rest, the balance pivot, the impulse jewel, and the pallet fork pivot will all lay in a straight line. When a movement is out of beat the ticks and tocks will be uneven. Beat error can usually be adjusted in one of two way depending on the movement. On more recent watches the hairspring stud is anchored to a lug that can be rotated around the balance pivot (like a second rate adjustment lever) so that the resting position of the impulse pin can be adjusted to bring it exactly in line with the balance and pallet fork pivots. This can be done without any disassembly and with the watch running. On older movements the hairspring stud is fixed to the balance cock so the same adjustment has to be effected by rotating the hairspring collet around the balance staff. Not so easy as the balance has to be removed from the cock for each adjustment. Yours looks to be a fixed stud so unless you are confident with working with balances and hairsprings you may want to leave this alone as 1.3ms (milliseconds) is liveable with. The last number is the lift angle of the movement. This is the angle through which the balance rotates whilst it is receiving impulse (or lift) from the escape wheel (via the pallet fork). That's my understanding anyway. It is not something that can be adjusted but is a design parameter of the movement and the timing machine needs this to be able to calculate the amplitude so you need to tell the machine what it is before you start. It's worth mentioning that these values are spot readings for the movement in that particular position and state of wind. to properly regulate the watch you should evaluate it in several positions and check it fully wound and after 24 hours of running. 230 degrees isn't too bad if you didn't install a new mainspring, although it won't be accurate unless the lift angle is correct.1 point

-

Good post Charles. What I do to check that the gear train is running freely is, remove the click spring, lever escapement and the balance wheel. Now use your puffer and gently blow air onto the periphery of the escape wheel, if all is well this should be enough to turn all the gears and pinions including the barrel. This method has helped me find a few issues in the past. It is not full proof as you are driving the train backwards, but it is a good indication of how free things are.1 point