Leaderboard

Popular Content

Showing content with the highest reputation on 11/26/18 in all areas

-

You have to press in the pin just next to the crown to set. This is a transition wstch between key and stem setting.4 points

-

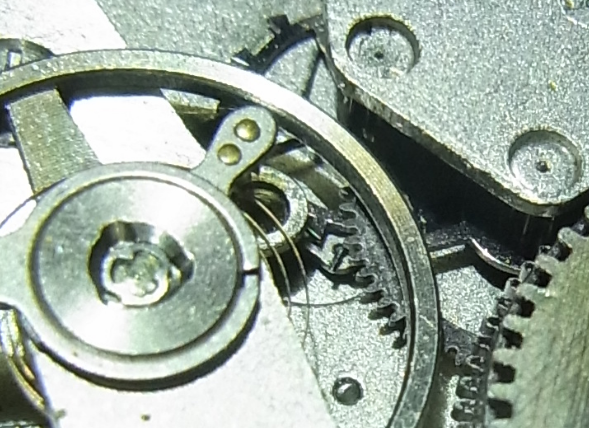

Today's watch of the day is the humble Roxedo EB 8800 pin lever I picked up a while back. Its had a new pallet fork, and balance assembly (extracted from a low mileage donor). Thi picture does no justice what so ever to the dial. I've also included a couple of images, including the "before" pic and one of the broken pallet fork and original balance. This is what I received form ebay, sold as not working. That original balance actually works fine, as I fitted it to another donor just to test. That donor has a broken mainspring holddown screw snapped off in the main bridge, so it too may end up getting parts of the first donor to make another working EB 8800. One of the broken pin can be seen quit clearly folder over in the center of this picture. It also appears that the jewel is missing, but in fact there is one there. I think it is a clear (glass? ) jewel. I like the uncluttered look of this watch, and the sunburst champagne dial. It goes reasonably well for its age, and considering it is a simple pin lever with only one jewel . This gives a slightly better impression of the dial. It shows around +20 to +40 sec per day in time-grapher, which I could probably shift to -10 to +10 sec per day with a little care, but I'm going to wear it for a couple of days to see what it actually does on my wrist. I was torn between a plain black band or this brown, with either a silver or gold clasp, but I think the brown with silver buckle looks best.2 points

-

Agree with the answers already given. Most likely a very tight snap on back . This will then require a press to re-fit. If you do not have the correct tools damage and scratches will be the most likely outcome.2 points

-

it would be worth the time to take it to watchmaker and ask "remove the back please". if you do get it off, it will be hard to get back on. on the cheaper watches (pocket watches also) it might be a factory miss match. you can enlarge I.D. with a dremel grinder. let us know what happens. good luck. vin2 points

-

nickelsilver is correct, you push the little pin in next to the button. That movement is a cylinder. You must let the power off before you remove the balance. Cylinder movements do not have pallets. If it is a gold case you can date it by the hallmarks.2 points

-

So in the end it looks like the 1198-103 works. I'll give it a go and if it doesn't work I'll have a movement for a new project. I think the 103 may be thicker than the 101.1 point

-

The figure you are interested in is "T" which is the stem height. Looks like 1.8mm for the 2824. You'd generally want to get this figure to be a fairly close match for the replacement. Thw 1198 may come in differnt versions of stem height depending on if it has a date complication, etc. Check the datasheets.1 point

-

You can check the stem heights on Ranfft. I've heard of people sub the 2836 with an 1198.1 point

-

Hi C I am not good with parts name, for reference to parts, if you will please go to OldSwissWatches.com to show the part, helpful. It dose not sound serious, I agree with HSL, most likely just a matter of tension release. By the way, anyone who likes watches is in love with landeron chrono. Regards joe1 point

-

1 point

-

Me burning the knot ends of the fishing line. Plus the leather belt is really quiet Sent from my iPhone using Tapatalk Pro1 point

-

What belt are you using? It doesn't look like the green belt. You also have a pretty large bump where you joined it together which will cause vibrations, and as Oldhippy says your lathe and motor don't look to be aligned.1 point

-

Go to the shoe store and get a thick leather boot lace. Then cut it to the right size and grip the two ends in a vice of some sort, with the tips just poking out. Then sew them together loosely with fishing line, 5 lb test...and then melt the resulting knot with a match (just the knot). Then straighten the lace out...make sure you do this with the lace inside the lathe headstock. This leather strap will last for a very very long time. I made a video on YouTube on how to do this. Search in jdrichard01 Sent from my GT-N5110 using Tapatalk1 point

-

Rubber belts are far better. You get a far better tension. What is not helping to me your lath is out of line to the motor.1 point

-

I just use rubber o rings, I find they work fine and are available in a large range of sizes. Stephen1 point

-

Have you tried penetrating oil? Alternatively, just oil and leave it for a day or so.1 point

-

I just realized how hard it is to take a decent photo of these black beauties, well never the less I have to try. This is supposed to be an 40's Silvana produced in Switzerland for the German market. Under the hood is an roaming AS1130. The 1130 was the absolute first movement I repaired so it has a special place in my brain locker.1 point

-

@StuartBaker104 is right on the money that this is one of the Chinese 'TY' series watches. These have the smiley sun and distinct star clustering. As well as what Stuart has advised, do a search around the TY601. If you look at http://www.watch-tools.de/movements-88/movements/automatic-watch-movement-caliber-sea-gull-ty-601.php for instance this looks like yours.1 point

-

I’d say it’s possible an old Seagull movement - similar to a TY 2869, but without a date dial. Cousins lists a range of Seagull movements here https://www.cousinsuk.com/PDF/products/8164_Sea-Gull 2015 pages 15-20.pdf, but there isn’t an exact match in the current catalogue. If you look at the dial side cover in on the TY 2869, https://www.cousinsuk.com/product/chinese-movement-list?code=TY2869M you will see the spring holes are very similar. Given the sge of your movement you may find it’s no longer made. You will note that the balance cock and shock devices are different on yours. Sadly, I don’t know of any resources for positively identifying Chinese movements, or supply of parts, except winding stems. Tech specs are pretty limited although if you can work out the movement number you might find an installation drawin* on the net. The movements are generally considered to be disposable, but plenty of people do service them, although probably not on a commercial basis.1 point

-

Let someone do it for you that has the right tools. Removing material is not a way to do it. And will just end up with lots of trouble.1 point

-

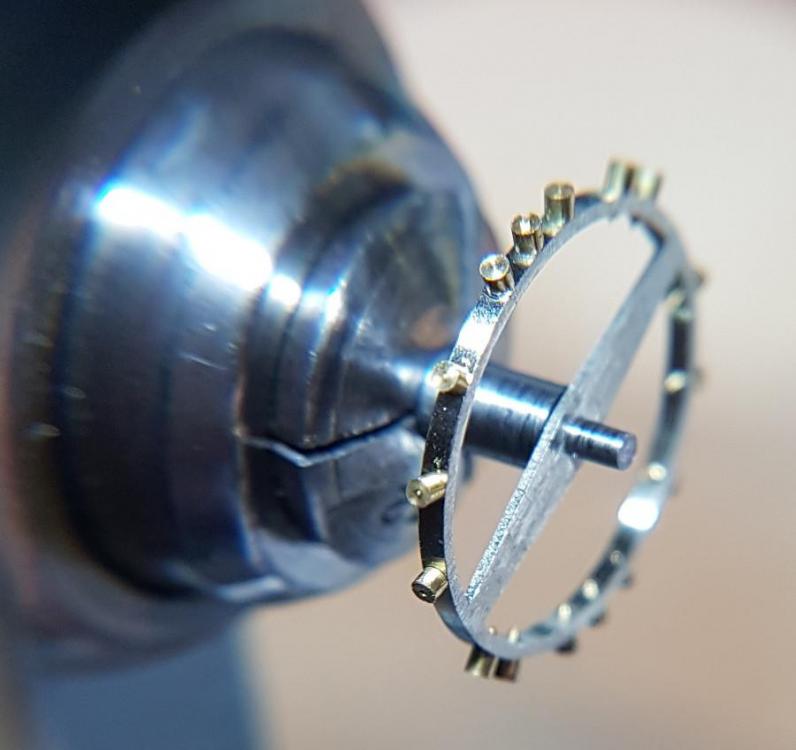

For the last few weeks I have been sorting out my BTM lathe, shaping and honing my gravers, making and fitting handles to them, replacing the motor that drives my lathe and I'm now ready to start my journey towards making a balance staff for a Unitas 235 pocket watch. I wasn't happy with the finish I had been getting with my graver so have spent the last couple of weeks just practicing parallel cuts on my lathe. Though I still have a lot of room for improvement I feel its good enough to start making a balance staff. I'm pretty sure this staff will be a failure and it will be several more attempts on before I get a workable result, so still lots of time to improve my lathe skills, and I will try and share my journey here. Just one photo tonight showing the 3.2mm blue steel rod turned down to 2.9mm and then the end turned to approx 1.25mm so the balance is a good fit onto the shaft. Tomorrow I will attempt to turn the parallel section for the hairspring, rough in the pivot on the top end and do the undercut for riveting on the balance. I will post some photos showing my lathe setup and a couple of tips I've recently be shown later.1 point

-

I have now been cutting balance staffs for over a year and have 11 lathes, four on Borel stands with countershafts and the remainder standing on traditional stump. The single biggest tip is to have five gravers. One traditional triangle for removing material fast, two that have oval tips 2 mm and 4 mm wide and two that have square ends 2 and 4 mm wide. They all need to be carbide. Then go on AliExpress and buy two 2000mm grit diamond sharpening sheets of metal. You will meet the technique. I bought the videos. You also need a seitz jeweled ruler to measure the pivot size when you do the ends. Use the gravers to about .5mm then use a stone to do the rest. Take your time. Sent from my iPhone using Tapatalk Pro1 point

-

Nucejoe ... I am looking at the Julesborel website. Is "Clutch wheel" the name of that part? I do not know the name and without the photos is difficult. Pretty useful information there BTW Sent from my Mi Note 3 using Tapatalk1 point